Installation and repair instructions for balcony slabs

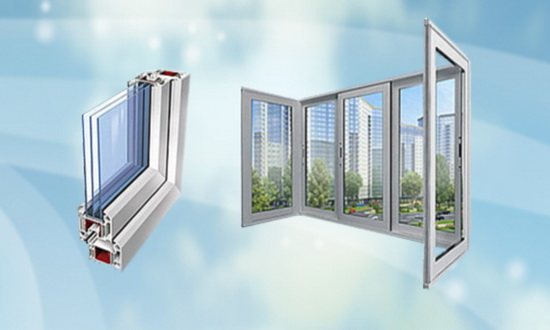

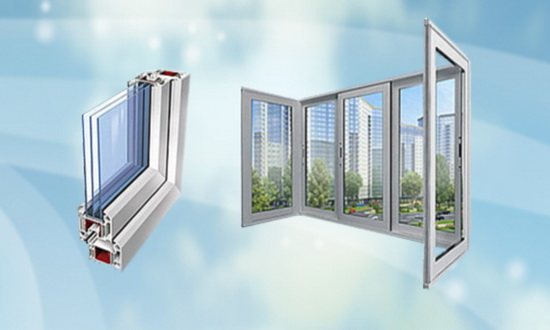

The balcony slab is the foundation of your balcony. It is from its strength characteristics and dimensions that the operational properties of the balcony structure depend. Read an overview of balcony glazing technologies with an aluminum profile.

Specifications

Types of balcony slabs, their main parameters and dimensions are regulated by GOST 25697-83.

Balcony slabs are classified into the following types:

- PB - flat solid beam;

- PBK - flat solid cantilever;

- PBR - ribbed cantilever.

Balcony slabs are manufactured in lengths from 1200 mm to 7200 mm, in widths from 1200 mm to 1800 mm. Standard sizes of balcony slabs: length - 3275 mm, width 800 mm.

The thickness of the balcony slab in brick and panel houses or in Khrushchev varies from 150 mm to 220 mm, depending on the type of slab, its dimensions and weight.

The balcony slab series consists of several groups of numbers and letters, the series is deciphered as follows: the main group of letters and numbers is the type of slab, the length and width of the slab in decimeters. In additional groups of numbers and letters, the following information can be indicated: if the balcony slab is equipped with an emergency exit, then it is indicated on which side of the slab it is located, to the left or to the right; class of prestressing reinforcement, type of concrete, if lightweight; for heavy concrete, indicates the type of finish of the upper face.

- Balcony slabs PB are reinforced concrete hollow-core slabs. Dimensions of the balcony slab pb 1: product length 3440 mm, product width 1400, product thickness 160 mm.

- In a monolithic version, the balcony slab can be integral with the floor slab.

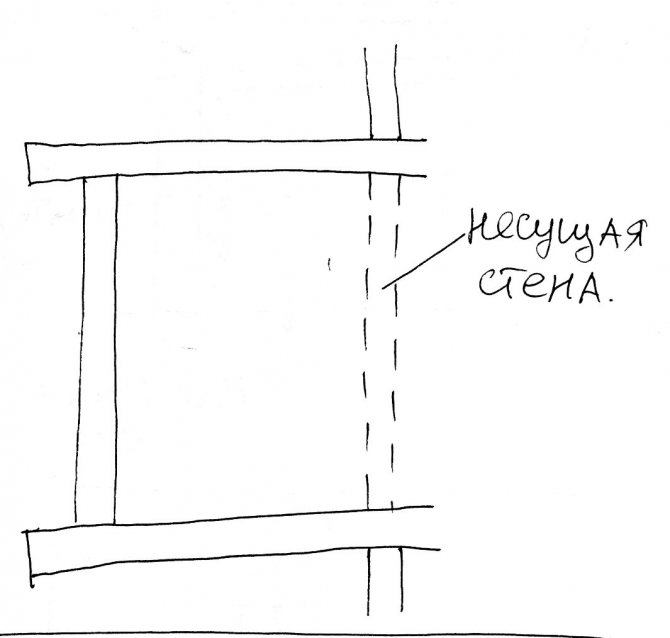

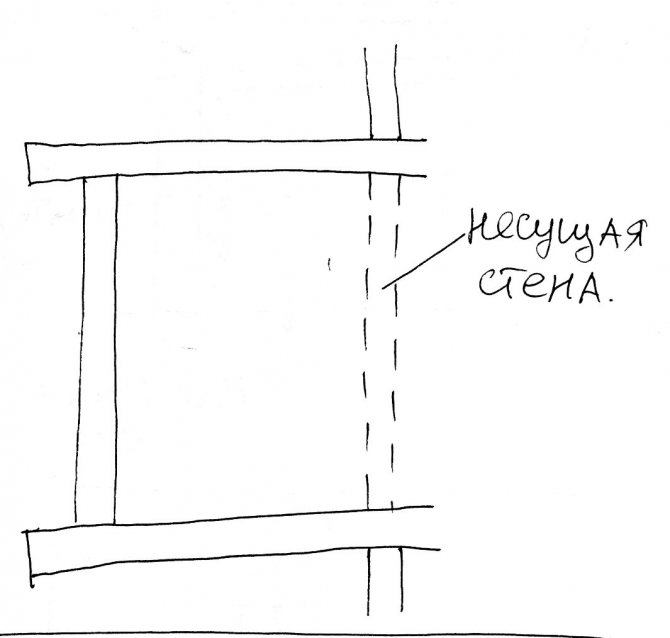

- The cantilever balcony slab is fastened by pinching it in the wall on one side, or two opposite sides. Suitable for buildings with heavy walls, such as bricks with reinforced concrete floors.

Calculation and device

The balcony slab under the brick walls has a special ledge to ensure that the slab enters a special niche in the wall formed by reinforced concrete underlays embedded in the wall. Bearing brick walls, as a rule, are made in two or more bricks, so the entry of the balcony slab into the wall is 300 mm or more.

The node for supporting the balcony slab on a brick wall is a junction of the horizontal and vertical planes. Moreover, the support unit can only be implemented on the load-bearing wall. The bearing unit is calculated to determine the permissible loads, according to GOST 956-91.

The overturning stability of a balcony slab is calculated by comparing the overturning moment with the holding moment from the weight of the structure.

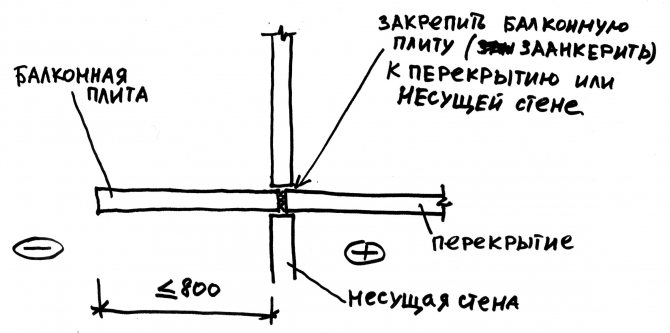

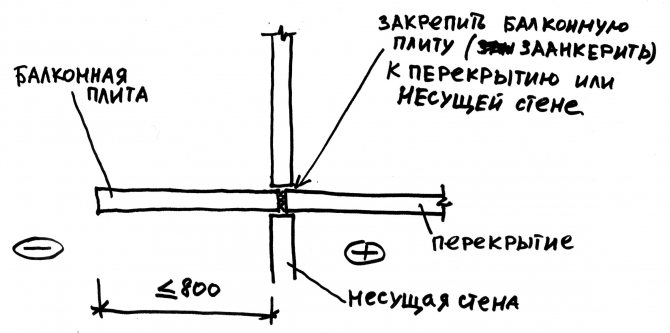

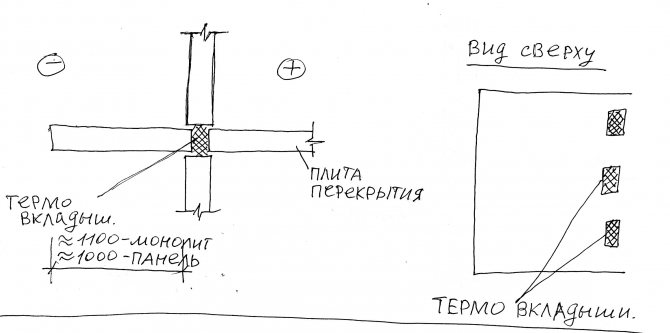

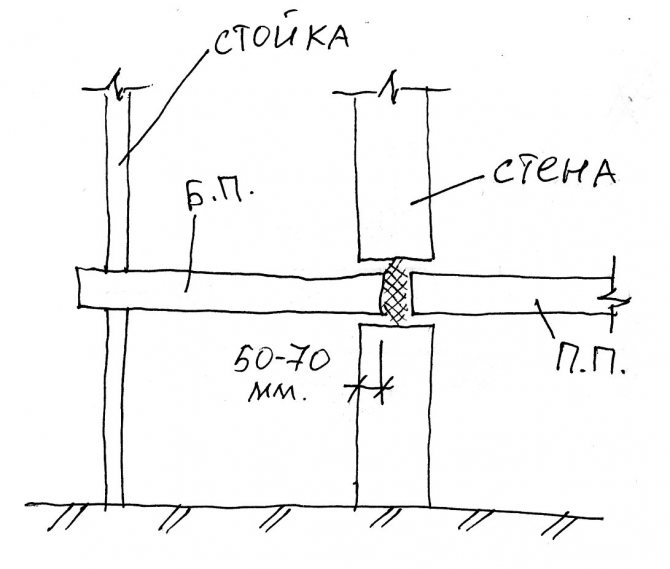

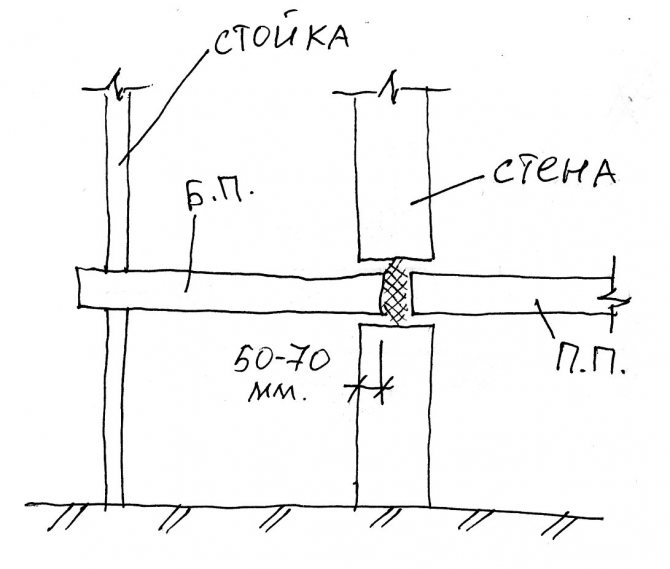

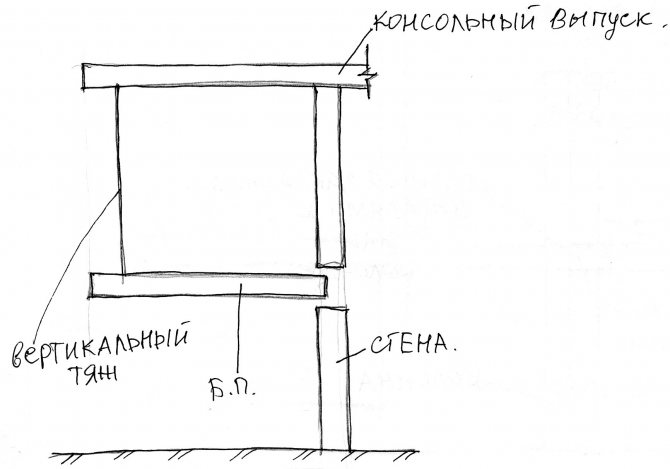

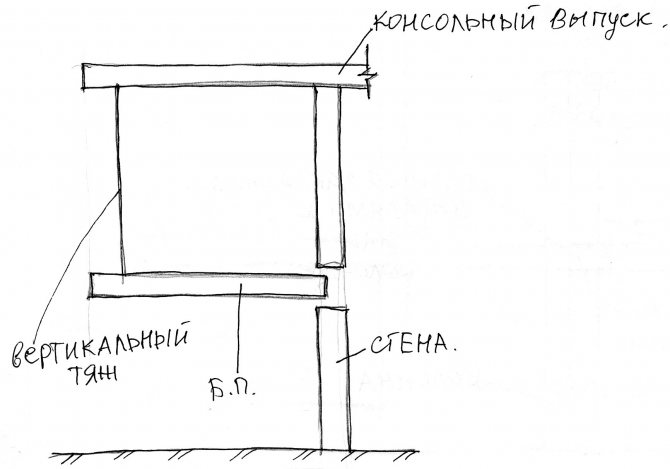

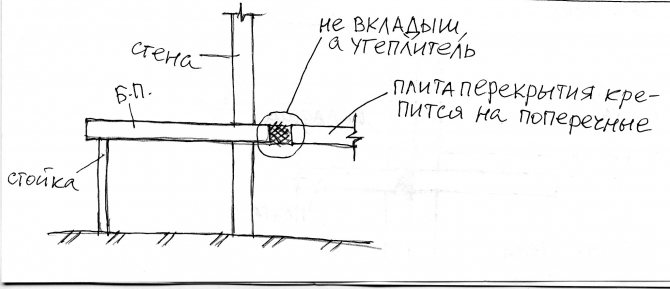

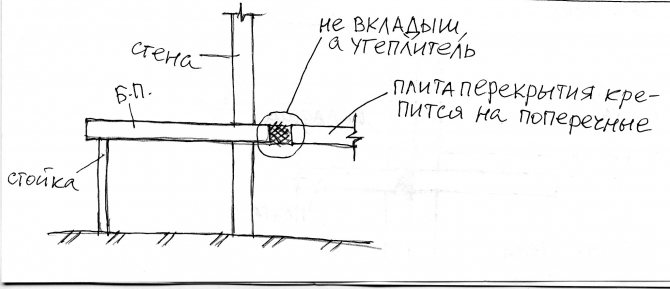

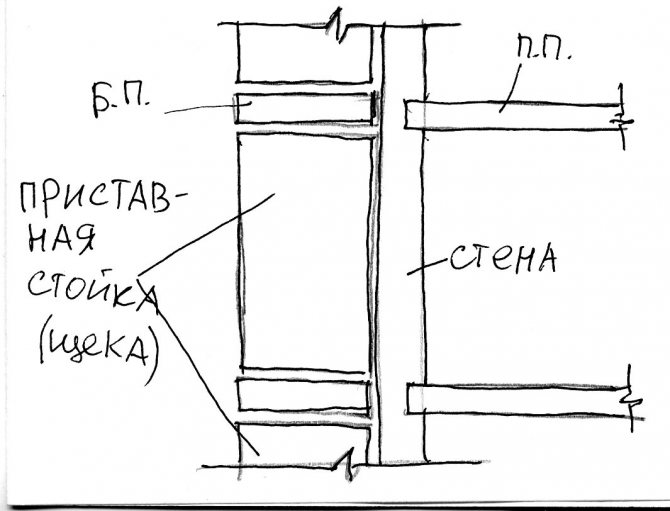

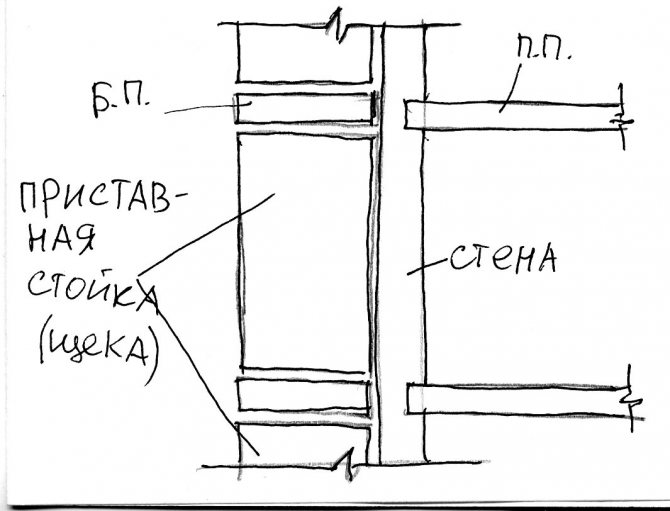

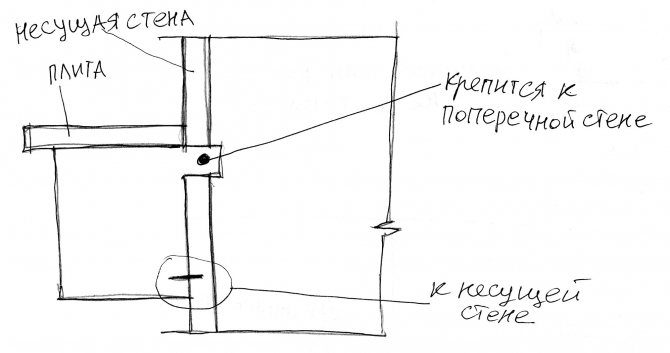

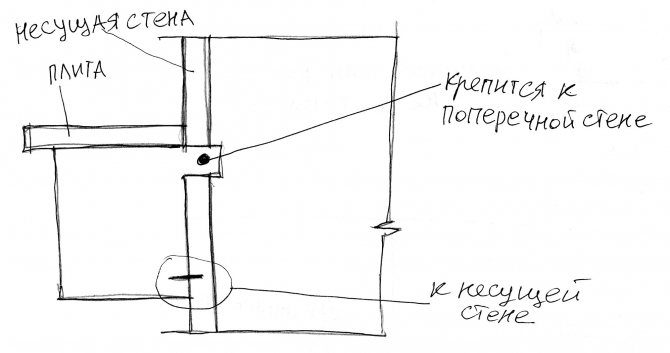

The picture shows the strengthening of the balcony slab on the upper floor.

Installation technology

The technology for fixing balcony slabs depends on the material from which the building is built.

When building a brick house, the balcony slab is fixed in the masonry of the walls.

In a large-panel building, balcony slabs are clamped between building blocks. In both versions, the balcony slabs are welded to reinforced concrete lintels and ceilings by means of anchors connected to the reinforcing cage.

Expansion of the balcony along the base of the slab

Extending the balcony at the base of the slab beyond it will provide additional usable space. But before proceeding with the work to increase the balcony at the base of the slab, calculate all the loads of the balcony structure on the slab to prevent it from collapsing.As a rule, metal brackets made from a steel angle are used to expand the balcony. Read the recommendations on which visor for the balcony to choose.

The photo shows an example of the expansion of the balcony along the base of the slab

Another example of the expansion of the balcony poita

Strengthening

To reinforce the balcony slab, a reinforcing mesh is used, mounted from a wire with a diameter of 5 mm, the rods of which are connected by welding or with a special soft wire. The mesh is laid on the slab and poured with concrete.

Balcony glazing will exert significant additional loads on the balcony slab and railing. Therefore, before glazing, it is advisable to strengthen the balcony slab (a supporting metal frame is mounted and fixed on the wall panel by means of anchors) and reinforcement of the parapet. Read an overview of balcony glazing technologies with an aluminum profile.

Reinforcement of a balcony slab in a panel house can be performed using a cement screed method.

Repair of balcony slabs

The restoration of the balcony slab is a major overhaul. This type of work is carried out if the destruction of the slab has not yet reached the base, and the reinforcement is damaged by corrosion of no more than 10%. The process of restoring a balcony slab includes: cleaning the slab, renewing the reinforcing cage, installing the formwork, carrying out the concrete screed, strengthening the parapet. Plates with more significant destruction are classified as emergency and must be replaced. If the destruction of the balcony slab is detected, it is necessary to apply to the management company with a statement to create a commission and draw up an act, on the degree of destruction of the balcony and possibly recognizing it as emergency.

Read the instructions for finishing the balcony with siding on this page.

The main insulation of the balcony slab is carried out from the inside of the balcony, and additional insulation of the balcony slab from the bottom, of course, will not be superfluous if the neighbors below will insulate their ceiling, for example, with expanded polystyrene. Guidelines for the internal insulation of the balcony here: https://balkonus-pro.ru/uteplenie/rukovodstvo-po-vnutrennemu-utepleniyu-balkona.html.

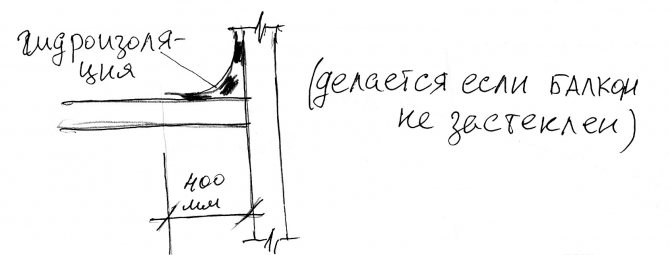

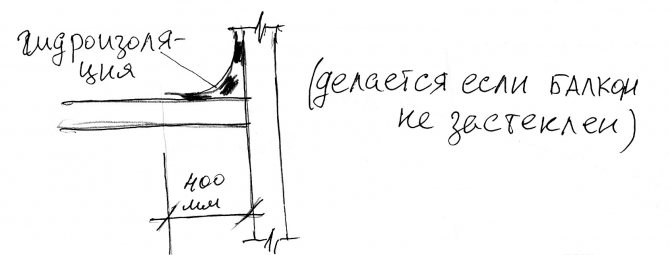

For waterproofing a balcony slab, you can use: coating waterproofing materials on a bitumen-polymer basis; penetrating compounds; roll or sheet waterproofing materials.

The cost of balcony slabs

The approximate cost of balcony slabs from 5 500 rubles / piece. up to 20,000 rubles / piece

Where to buy balcony slabs?

Where to buy in Moscow:

- LLC "MZhBK", Beregovoy proezd, 5. Tel .: +7 (499) 703-36-20;

- Group, 3rd proezd Maryina Roshcha, 40, building 1. Tel .;

- LLC Group Monolit Stroy, Chermyansky pr., 7, building 1, office. 3606. Tel ..

Where to buy in St. Petersburg:

- ,etc. Piskarevsky, 63A. Tel .: +7 (950) 025-50-60;

- , st. Domostroitelnaya, 1. Tel .: (812) 612-08-93;

- , st. Efimova, 1/4, office 37N. Tel .: +7 (812) 458-01-60.

Video

Watch the video for an example of expanding the balcony along the base of the slab:

Recently, balconies have become frequently used as living spaces. Various kinds of glazing are actively installed on them, insulation is carried out, outside the balcony is sheathed with siding, balconies are combined with living rooms, all these manipulations exert a significant load on the balcony slab, which can lead to its destruction. It is recommended to consult a specialist for finishing work on the balcony.

Do-it-yourself overhaul of the balcony in a panel house: the right recommendations

During the construction of new panel houses, the balconies in them are made according to standard templates and most often do not carry any special attractiveness. They differ in a number of design features, the absence of any decorative finishes, some of them are not even glazed. For these and other personal reasons, it is worth considering the option of reconstructing a balcony room.If the prices for the installation work by specialists are not affordable, then you can safely undertake repairs yourself.

Related article: How to decorate a window with a balcony in the kitchen

Standard balcony of a panel house

Assessment of the condition of the balcony in a panel house

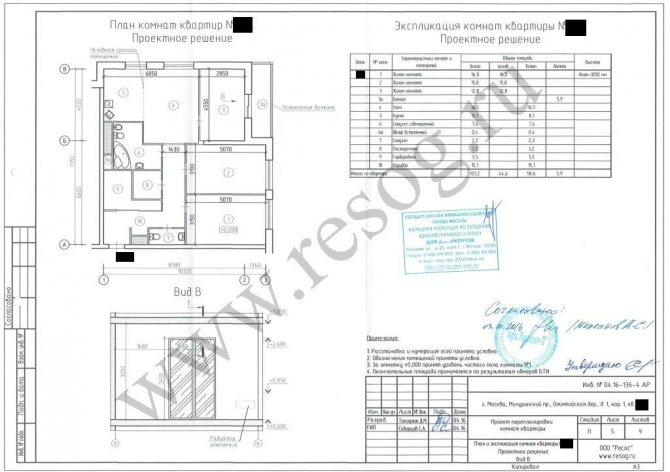

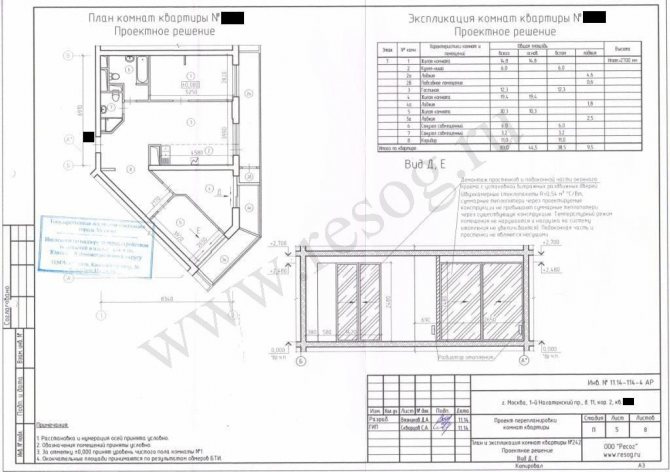

Let's consider the stages of overhaul of a loggia with our own hands using the example of panel houses of type P 44. In them, the sites differ in frame features from standard balconies, and in appearance resemble a zigzag shape. The correct approach to the reconstruction of the balcony will significantly increase the free space. Here you can easily accommodate a wardrobe, a coffee table with chairs, and, if necessary, you can organize a personal account.

The load-bearing capacity of balcony structures in panel houses are famous for their long service life. The finishing materials used in construction are rarely of high quality. In a panel house of type P 44, it is necessary to make repairs for interior and exterior decoration.

Renovated balcony - a cozy corner in the apartment

Outrigger balconies

Residents of city apartments with balconies have a unique opportunity not only to insulate and glaze this area, but also to increase the area of their housing. Now you can install a railing under the glazing with an extension. What does it mean?

When installing the frame of the fence, using a professional trick, you can take out the glazing about 30 cm behind the parapet.If you consider that this action is performed on three sides of the balcony slab, then the increase in space will be significant. This option is especially ideal for owners of very small balconies.

Advantages of overhanging balconies:

- Increase in space by expanding the area of the balcony slab.

- Getting a wide window sill.

- Strengthening the load-bearing structures of the balcony slab.

September 12, 2021 Specialization: master for interior and exterior decoration (plaster, putty, tile, drywall, wall paneling, laminate, and so on). In addition, plumbing, heating, electrical, conventional cladding and balcony extensions. That is, repairs in an apartment or house were done on a turnkey basis with all the necessary types of work.

Any balcony slab has its own margin of safety and over time it has to be strengthened around the perimeter, or it must be done to remove the balcony. If this work is not done on time, then the plate collapses at the edges. And this already poses a danger to health and life.

Perhaps what I will now tell you about strengthening the slab will be somewhat unusual for you, but these are my developments from many years of practice. So, I share my experience!

Outdoor decoration

The need for external finishing of the balcony for houses of the P 44 type is not an uncommon case. There are a number of basic rules for choosing materials for outdoor decoration:

- Only high-quality materials with strength and long service life are allowed.

- The material for outdoor decoration must tolerate well any weather conditions and precipitation.

- Affordable price.

- Ease of DIY installation.

External finishing of the balcony with corrugated board

The most suitable according to the above criteria are:

Installation of balcony cladding with vinyl siding

For DIY repair, PVC siding (vinyl) is ideal. The material is distinguished by its light weight, high strength and reliability, and a simple installation method. Such material looks good on balconies in a panel house of type P 44. Before starting work, you need to prepare:

- Vinyl siding (the number of square meters is determined from the volume of the sheathed area + 15-20% is added for additional trimming).

- Wooden beam 40x40mm for mounting the battens (length depends on the perimeter of the lower part of the balcony).

- Starting strips mounted at the bottom of the structure (the number depends on the length of the lathing timber).

- Outside corners for concealing siding corner joints.

- Fasteners (anchors with dowels, screws).

- Sill strips.

- Installation tool: grinder with discs for metal and wood, a hammer drill with a set of peaks and drills, a level, a screwdriver with nozzles, screwdrivers, hammers.

Installation of siding outside the balcony

Sheathing begins with the installation of the wooden lathing. In houses of type P 44 from 9 to 16 floors, therefore, do-it-yourself high-rise work must be performed in strict observance of all safety rules.

Important! If the siding is planned to be installed in a vertical position, then the lathing is mounted horizontally and vice versa!

To do this, at the corners of the balcony with the help of anchor bolts, racks from a wooden bar are attached. The nuts will help to better secure the batten from the inside. Then, horizontal bars are installed along the upper and lower edges of the structure. Now you can attach the vertical posts of the battens.

At the final stage of the renovation, the siding is fastened to the wooden structure. Special outer corners are screwed to the corners of the crate, and the ends of the product will be wound in them.

The balcony of the panel house is sheathed with siding

Do-it-yourself vinyl siding installation begins with a starting bar, which is attached to the lower wooden beam with self-tapping screws. Now each subsequent plank is inserted into the previous one and fixed. The uppermost span is not mounted; instead, a sill bar will be installed. When screwing in self-tapping screws, it is important to leave 0.5-1 mm as a gap, which will prevent the siding from deforming during thermal expansion.

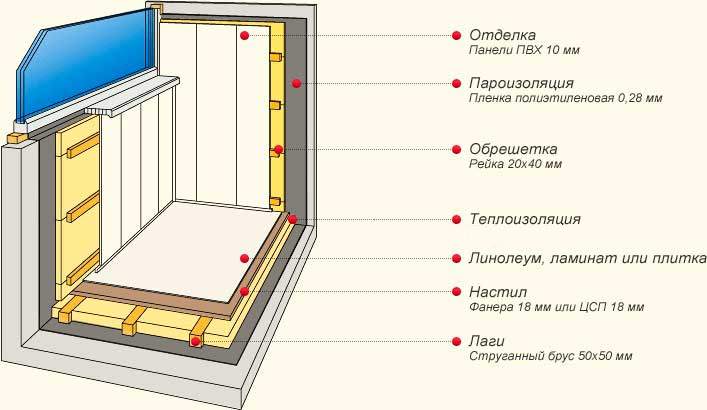

Interior decoration

After finishing the outdoor work, it is necessary to give the balcony a cosiness, warmth and an elegant appearance. To do this, use the following materials to choose from: PVC panels, plastic lining or drywall. The simplest do-it-yourself installation is PVC panels.

The walls of the balcony are sheathed with plastic panels

Wall and ceiling cladding with PVC panels

Before starting work, you must prepare the following materials:

- Wooden beam 20x20 for the installation of the battens (the number of square meters is calculated from the area of the room).

- Polyfoam or penofol for wall and ceiling insulation.

- PVC panels: U-shaped profile, H-profile, F-profile (width: 0.250, 0.3, 0.5 m; length: 5.9, 2.95 and 2.6 m). To accurately determine the number of parts for repair, we measure the perimeter of the room and divide by the selected panel width.

- Polyurethane foam.

- Self-tapping screws with a press washer and wood.

- Tool: hammer drill with victorious drills, grinder with discs for metal and wood, screwdrivers, hammers, screwdriver.

Installation of battens for covering the balcony with plastic panels

The first step is to install a wooden crate according to the principle of outdoor decoration using vinyl siding with horizontal guides. Insert foam sheets into the spaces between the frame, securing them with dowels. Then the starting corner panel is installed in the corner of the balcony where it is most difficult to work.

Each subsequent panel is inserted into the previous one using special grooves. We use the F-profile to go around the corners of the balcony. In places where the wall meets the ceiling, we install ceiling plinths. The damping profile is installed at the end of the work.

Appearance

Anything that serves as decoration: various fences, water drains, and flower boxes should be periodically updated. It is worth painting them with paints that are resistant to atmospheric phenomena. The color of the paint must be selected so that it matches the shade of the facade. The shape, as well as the location of the flower grower, must correspond to the legalized architectural design of the building.They must be installed on special pallets, maintaining a gap from the wall of approximately 0.5 m.

In some apartment buildings, loggias have an external staircase that connects the balconies in stages and is an emergency loophole.

Doors leading to these stairs must not contain any latches on the outside. Loggias through which the evacuation will take place should not be glazed.

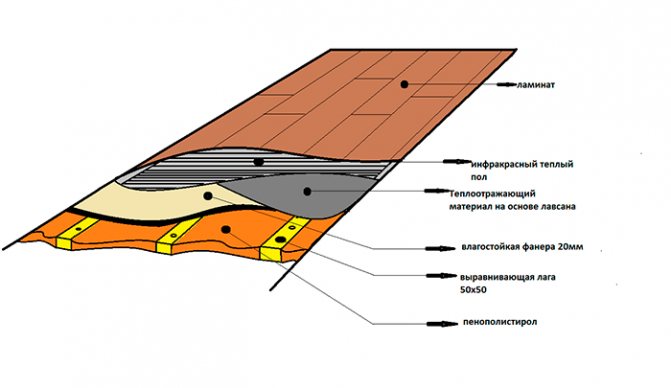

Installation of floors

To choose a flooring option, you need to proceed from the available tools and materials. The easiest way to install the floor with your own hands in houses of type P 44 is the typical lifting and insulation. To do this, you need to prepare:

- Screwdriver.

- A grinder with a disc for wood or an electric jigsaw.

- Dowels 80 mm.

- Plywood or chipboard in 20 mm.

- Wooden beams 40x40 mm.

- Self-tapping screws for wood.

- Polyfoam or penofol 30 mm thick.

- Tape measure, pencil, screwdriver, hammers, level.

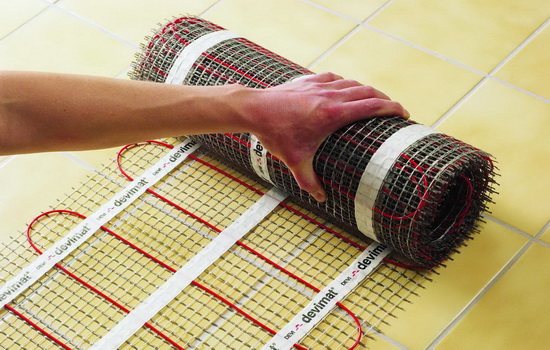

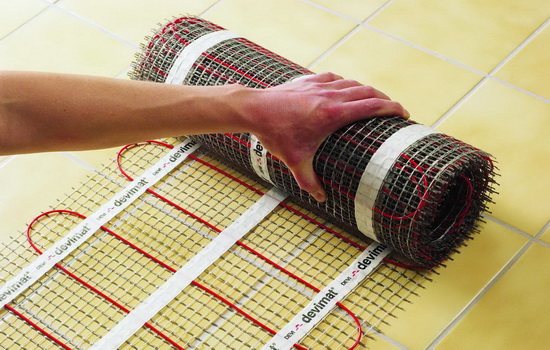

Installation of underfloor heating on the balcony

Holes are drilled with a perforator for fastening the roughing bar along the entire length of the room. We measure the width of the balcony (in houses of type P 44 it is 105 cm) and cut the beams of 40x40 mm to the corresponding size minus 1-2 cm. They are laid and mounted at a distance of 40 cm from each other. Then we drill through holes and fix with 80 mm dowels.

The foam is tightly packed into the formed cells. Make sure that no gaps are formed. Foil is laid on top. Using a level, evenly expose the layers of plywood. If necessary, add another layer of foam or foam foam. Now it remains to paint the floor in your favorite color. This completes the repair of the balcony floor.

Related article: Decorating the balcony outside with your own hands step-by-step instructions

Glazing

Balcony glazing is the final stage of DIY repair. In houses of type P 44, the most suitable option is to install double-glazed windows. You need to order windows from a trusted manufacturer. First of all, you need to take measurements. To do this, remove the old window frames up to the base of the parapet and the upper floor. Now we measure the distance between the walls and from the parapet to the ceiling. We manufacture windows according to the received technical data.

For self-installation of metal-plastic windows you will need:

- Ready-made frames with double-glazed windows.

- Drill or hammer drill with 140 mm victorious drills.

- Self-tapping screws with plastic dowels.

- Screwdriver.

- Polyurethane foam.

- Roulette, level, screwdrivers.

Installation of metal-plastic windows on the balcony

So, before installing the windows, we remove the glass unit from the frames. The frames are inserted into the window opening, where the points of future holes are marked. Insert plastic dowels into the drilled holes. Then we mount the frame using self-tapping screws, screwing them into the dowels. All cracks are sealed with foam. Then we install the double-glazed windows, fixing them with a plastic strip. We attach the swing-out sashes.

Is the balcony glazing a redevelopment or not? Is balcony glazing a redevelopment?

Once this event really related to redevelopment, but after the release of the Moscow Government Resolution No. 508, this item was excluded from the regulatory documents, and therefore coordination of balcony glazing is no longer required, as well as the installation of an air conditioner. Also, the replacement of the balcony fence or panoramic glazing device on it does not require approval. At the same time, one should not forget that a handrail must pass on the balcony at a height of 1.2 meters, a handrail must pass, capable of taking a load of 0.3 kN / m.

At the end of the article, we will give specific examples.

The main types of slabs used for the balcony and their features

A balcony is a slab that protrudes some distance from the wall of a building. For security purposes, it is fenced with railings around the entire perimeter. A balcony is a structure that includes a horizontal base plate, fixings and railings.

Today there are several types of balcony slabs that differ in design:

- Cantilever plate. It is used in brick houses with reinforced concrete floors. Fasten it by pinching it in the wall with two opposite sides or one;

- PB (balcony slab). Represents hollow-core reinforced concrete or metal floor platforms. Used in old buildings, deeper than 38 cm;

- The balcony slab in a monolithic house is a continuation of the floor slab. Features of mounting balcony slabs

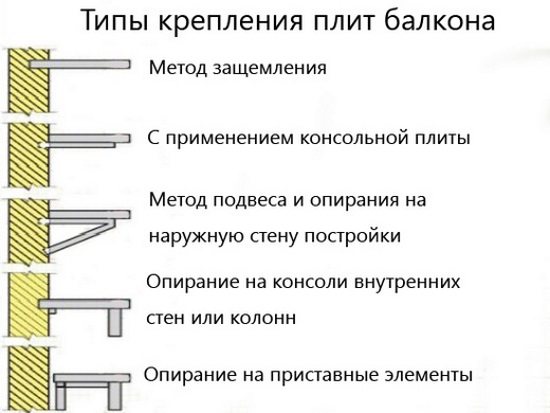

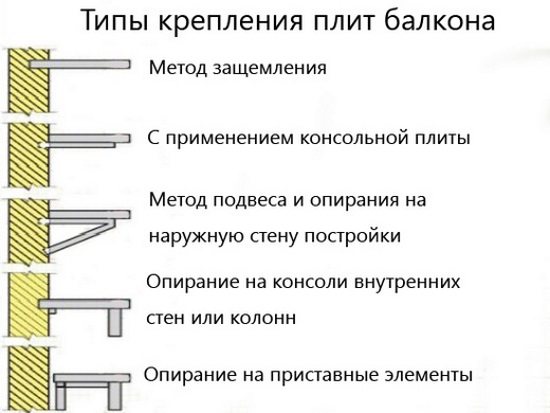

Many people think that all slabs are a continuation of the overlap, but this is not entirely true. When building a balcony, a wide variety of fastening methods are used:

- Use of additional support. It is mounted on the ground floor, as it requires an external steel, reinforced concrete or wooden support, fixed to the ground;

- Pinching in the structure of the wall of the house. A cantilever plate is used;

- Suspension to the load-bearing walls of the balcony platform;

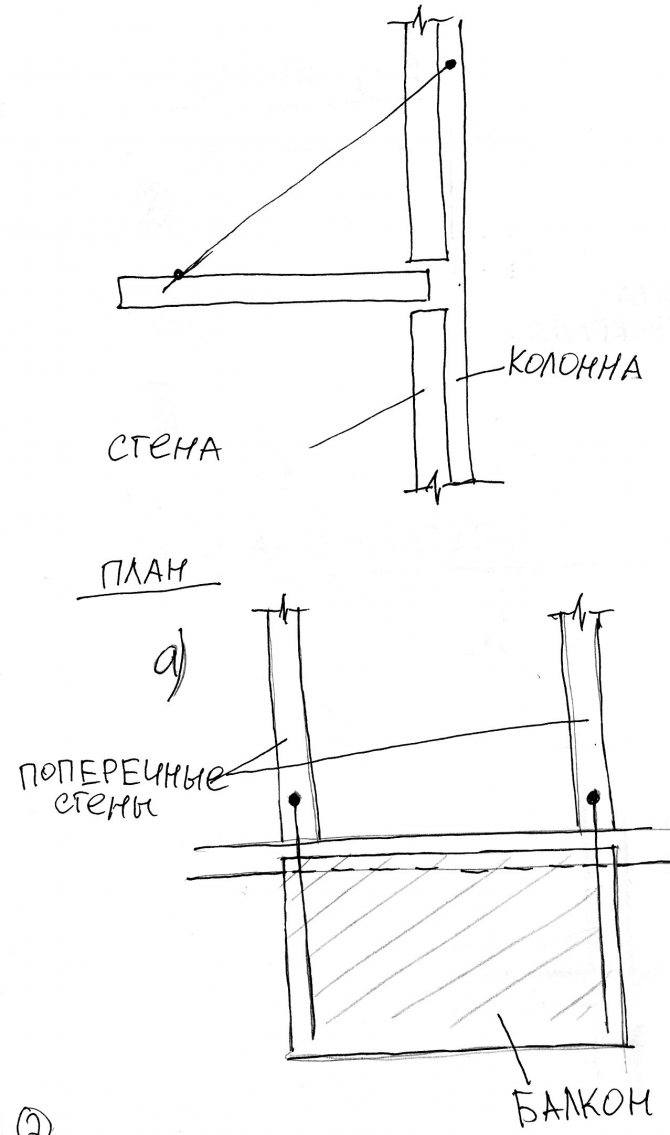

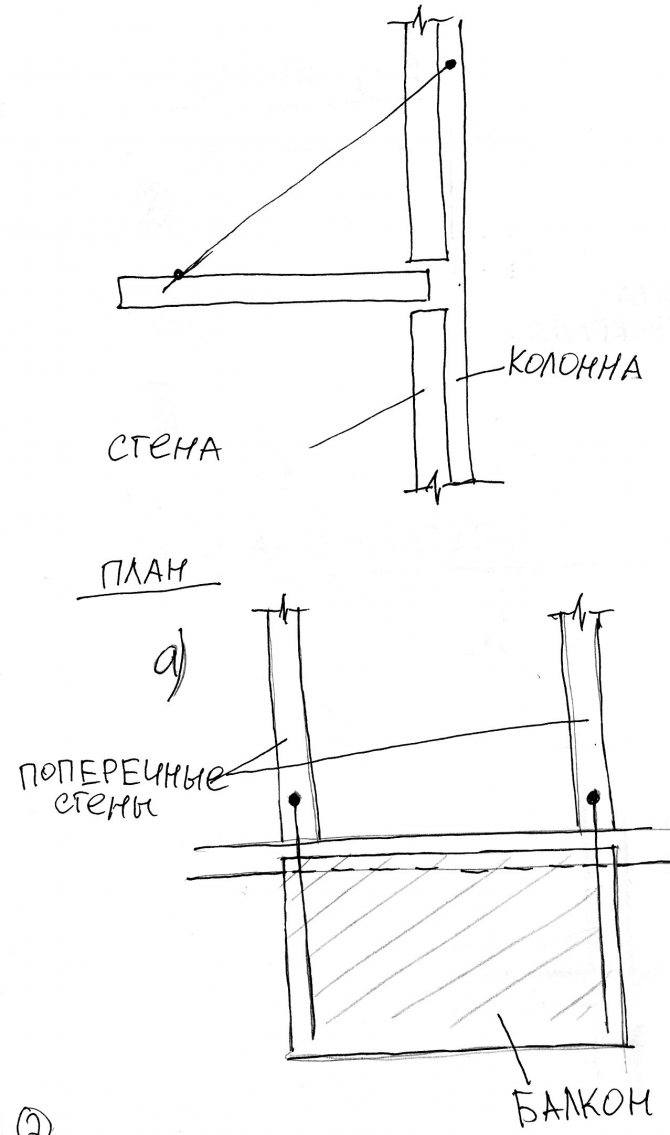

- In frame buildings, the support rests on the consoles of the interior walls or columns. In this case, there is no load on the wall.

- In panel-type houses, for example, in Khrushchev, balcony slabs are used with ceilings and with support on reinforced concrete structures.

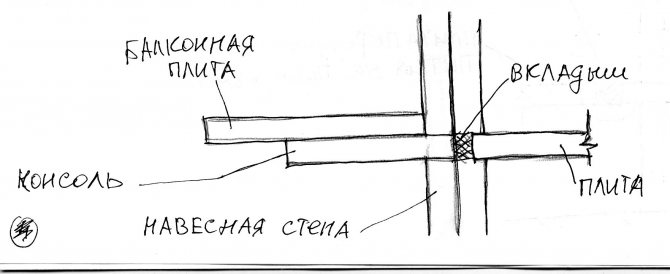

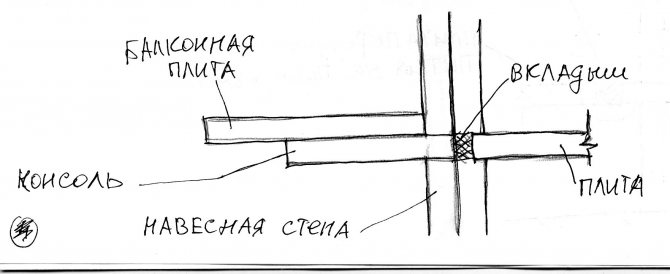

- Installation in a brick building is carried out by pinching in the facade of the house. Overhead and underlay elements made of reinforced concrete are walled up into it. They form a niche for the stove. The edge that adjoins the wall is thickened. A fairly large approach to the wall of the building is required. It must necessarily be welded with steel anchors to reinforced concrete elements.

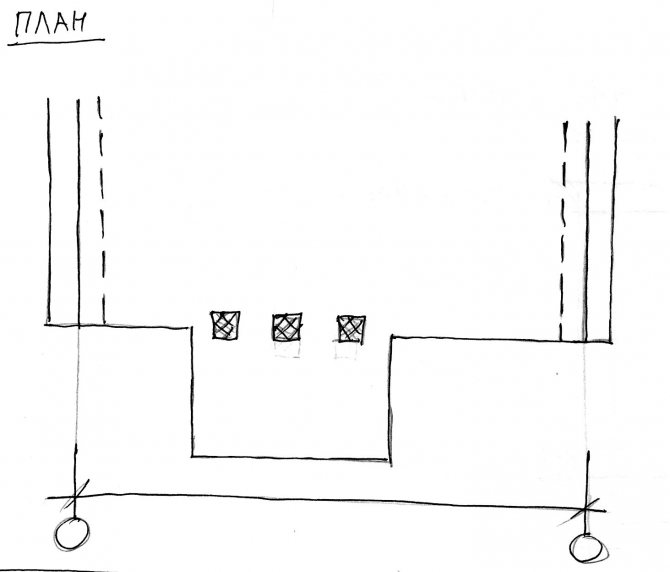

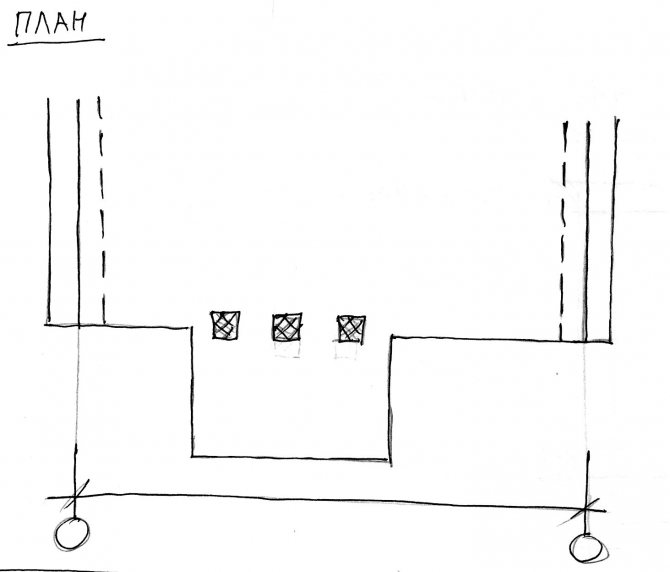

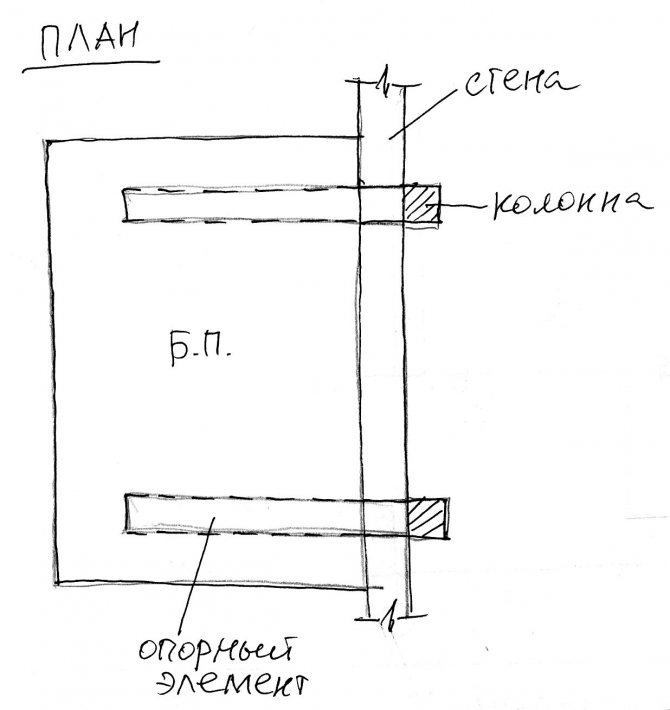

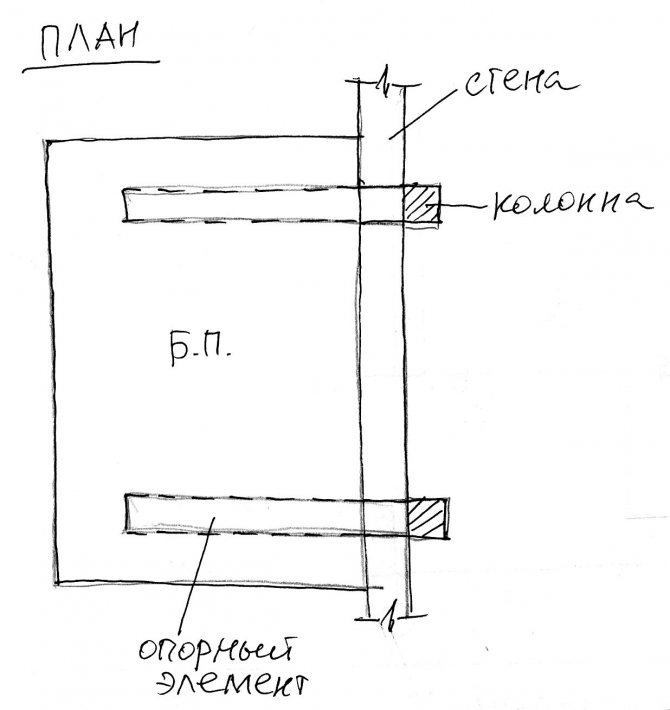

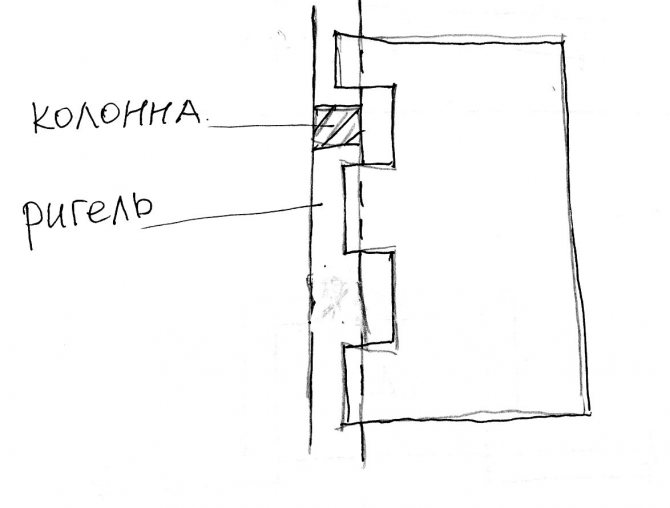

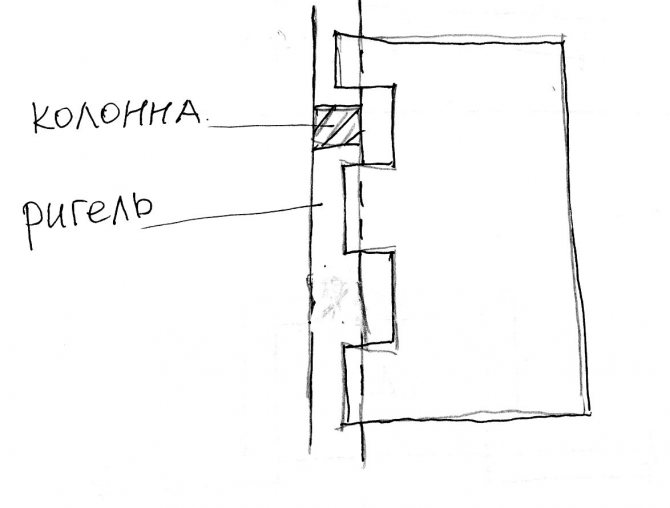

Arrangement of balconies, loggias, bay windows in buildings with various structural systems.

Balconies:

This is an open area that is fenced off to a partial height.

Arrangement of balconies.

1) For longitudinal load-bearing walls:

- Balcony console slab

-Console release of floor slab

2) For transverse load-bearing walls. Frame walls:

2.1. Self-supporting walls.

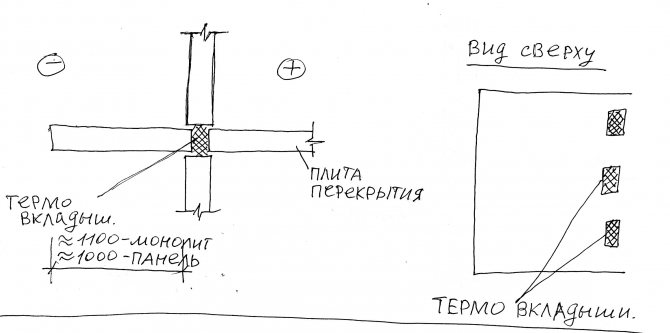

- The front edge of the balcony slab rests on the posts, and the rear edge of the balcony slab extends behind the outer wall to a minimum thickness (50-70mm.). When using racks, temperature-sedimentary deformations of racks and walls may occur (it is not recommended to do it in a building above 16 floors).

- The rear edge of the balcony slab comes to a minimum distance to the outer wall, and the front edge is suspended on straps (rigid reinforcement or cables), either to the transverse load-bearing walls, or to the overlying floor. In this case, the length of the balcony slab is equal to the constructive step, the length between the columns or walls.

- Vertical strands. Attached to the cantilever outlets of the cover plate. In this case, the slab should not be the size of the column spacing.

- Cantilever floor slab restrained by cross-bearing walls.

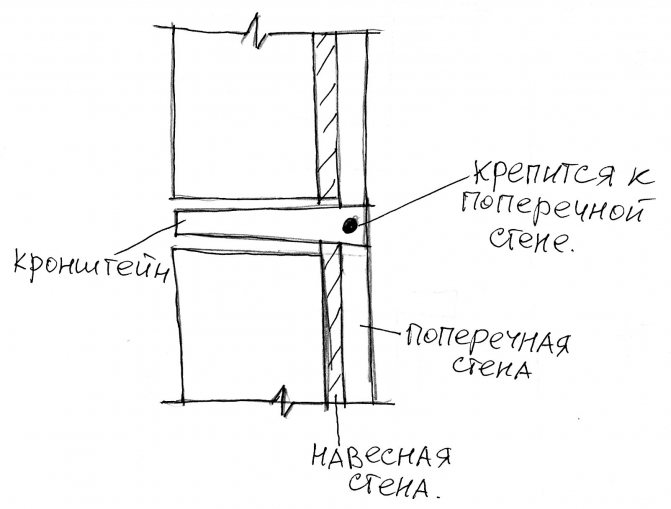

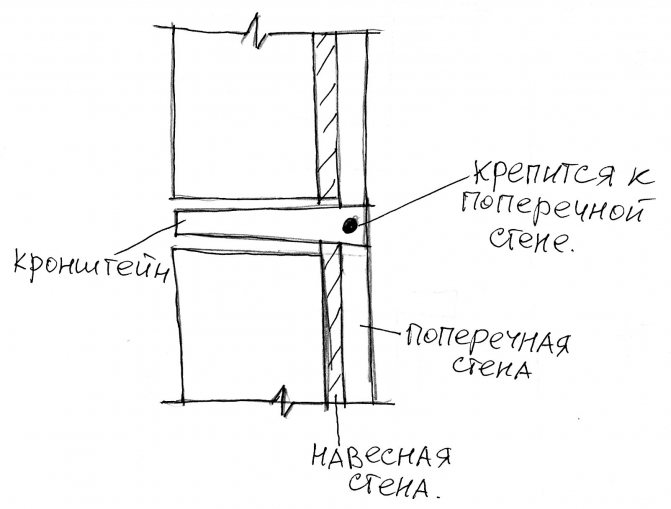

2.2. Curtain walls

- The slab rests with the rear edge on the load-bearing transverse wall, and with the front edge on the posts

- The balcony slab is supported by supporting elements that are attached to the transverse walls or columns.

- The balcony slab rests on the floor-to-floor consoles of the columns.

-700-1100 - cantilever plates

-1200-1400 - beam schemes

- with racks - for architectural reasons

Thickness of slabs:

from about 100-120 mm.

Slope from the wall 1-2%

If the balcony is not glazed -

it is necessary to do waterproofing

Balcony floor -

wood or tile

Balcony elevation -

below the room mark by 50-70 mm., and below the threshold level by 100-200 mm.

Balcony railing

Plastic, glass, fiberglass, brick

Fence height -

1.05 m. - multi-storey, 1.20 m. - high-rise

If the balcony is not glazed -

the fence does not need to be brought up to the slab

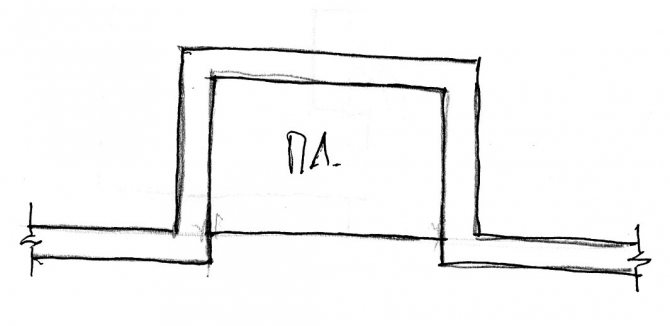

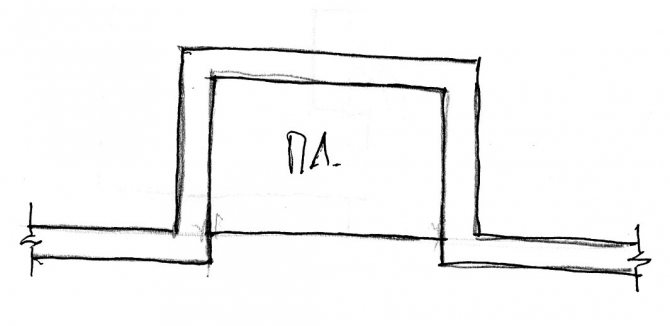

Loggias:

The presence of side walls (cheeks) is the difference between loggias and balconies.

1) Westerners (built-in).They occupy that part of the premises that could be part of the premises.

With longitudinal load-bearing walls:

3) The loggia slab rests on the side walls, which are installed on their foundations

With cross walls:

1) West loggias. Supports transverse walls.

2) Protruding walls. The loggia slab rests on the continuation of the transverse load-bearing wall, and the walls of the loggia are hinged, attached to the transverse load-bearing walls (upper edge), and the lower edge is attached to the wall using embedded parts.

For exterior curtain walls:

In this case, the walls of the loggia rest on a bracket that rests on the transverse load-bearing wall.

1) West loggias

2) Protruding loggias

- Loggia slabs are supported by side walls, which stand on their own foundation.

- Slabs and walls are supported on column consoles (floor by floor).

Elements of structures of loggias.

- loggia slabs are separate from floor slabs (to accommodate the outer wall or insulation material)

- The floor of the loggias is the same as that of the balcony, but if there is a heated room under or above the loggia, then the loggia slab is insulated (vapor barrier from the side of the room).

–

The fence is like a balcony, but the gap between the fence and the stove is not suitable (but holes are made in the corners so that the water would go out).

Bay windows:

Removal from the front of the room. Either the entire height of the building, or not the entire height (hanging).

1) Longitudinally bearing walls:

- Standing and resting on its foundation.

a) The bay window slab is the release of the roof slab

b) Console release of bay windows

2) Transverse load-bearing walls:

- Standing bay window (rests on its foundation)

- Hanging (rests on bracket consoles pinched in the transverse load-bearing walls)

3) Frame-bearing walls:

Hanging ones are supported on the cantilever outlets of the floors or on the cantilever outer row of columns

For hanging bay windows, the slab must be insulated (insulation from the outside, and vapor barrier from the side of the room). If there is a balcony above the bay window, then the ceiling of the bay window is insulated (insulation outside). If the bay window is brought under the roof, then it is made combined.

This page was last modified on 2016-08-14; Page copyright infringement

The main reasons for the destruction of the balcony

As practice shows, the main reason why balconies are destroyed is the depressurization of the joints and the violation of waterproofing. As a result, moisture enters the room, forming condensation, from which mold appears.

In addition, moisture can act on reinforced concrete, penetrating into it and causing corrosion on the reinforcement. The age of concrete directly depends on the penetrating ability of water - the older it is, the easier it is for moisture to penetrate. Corroded reinforcement loses its bearing capacity and expands, which causes a deterioration in the bearing capacity of concrete.

Also, the destruction of the balcony base is caused by high pressure on the slab, sudden temperature changes and a long absence of major and current repairs, such as in Khrushchev.

There are 2 stages of destruction of the base of the balcony:

- The first includes minor destruction when it is necessary to reinforce the slab. Such destructions are found in homes around the age of 40. You can do it yourself, as this is a minor repair. For example, in cases of crumbling corners.

- The second stage is the destructive appearance of the object. These include the collapse of a part of the balcony, the appearance of cracks at the junction with the wall, open sections of reinforcement, destruction is observed in the upper layer of the platform, or delamination in its lower part.

What determines the permissible weight for a balcony

The permissible load on reinforced concrete structures is determined by the norms of SNiP. According to the norms - for a loggia it is 400 kg / m2, and for open balconies - 200 kg / m2. But according to the current law, the permissible weight per slab should not exceed 112 kg / m2.

And this is without taking into account the decrease in the strength of concrete during operation.For example, experts estimate the load that the Khrushchev balcony can withstand at 50 kg / m2.

You can, of course, not take these numbers on faith, but there are plenty of examples of collapses. Especially in the houses of the old housing stock. Therefore, you should not start a balcony alteration without calculations and consultation with a specialist.

In order to determine how much weight a balcony can withstand, you need to take into account the following factors:

- Plate type and dimensions.

- Wall connection type.

- The degree of destruction of the slab.

- The state of the reinforcement in the slab.

- Balcony type, the presence of reinforcement.

- Age of construction.

- The quality of materials and work.

Who should repair the stove

Due to the fact that the normative acts do not specify what the balcony is (living space or part of the supporting structure), it is impossible to answer clearly the question of who to contact and who is responsible for the repair. Ideally, the balcony slab should be replaced and strengthened by the management company, but the railings and parapet are the owner of the apartment himself. However, it will not be possible to accurately answer the question at whose expense the repairs are being made. On this basis, very often disagreements arise between the tenants of the apartment and the management organization.

If the fact of destruction of the integrity of the plate was noticed, then you should write a statement to the management company. This document is signed by a specialist and recorded in the appropriate journal. A good reinforcement of your words will be an application in the form of several photos of the destroyed balcony. Neighbors who live on the floor below must leave their signatures on the corresponding application. The next step will be a decision on further actions. You can wait for the utilities, or you can make repairs with your own hands or with the help of construction teams. In the latter case, an estimate is needed in order to obtain a recalculation of the rent in the future. In the event that none of the options is suitable, you can safely go to court.

Balcony restoration stages

In order to carry out repairs with your own hands, for example, in Khrushchev, you need to know in what sequence and what to do.

- The first stage will be preparation for the repair - to clear the balcony of debris, remove all unnecessary items, remove crumbled concrete.

- The exposed parts of the fittings must be cleaned of rust. The first layer is easily removed, but the lower ones must be treated with a special tool.

- The reinforcement mesh is attached to the slab with dowels. In order for it to lie in the concrete screed without protrusions, a small gap is left between the mesh and the slab. Formwork boards are fixed around the entire perimeter of the board.

- Next, it is necessary to prepare a solution consisting of cement and sand, which will be poured onto the reinforcement. In the future, the screed is covered with cement and rubbed, that is, "ferruginate". It is important to remember that the thickness of the screed is two or more times the thickness of the mesh.

- The surface that is below should be treated with a primer and plaster a little later.

If the reinforcement cage has undergone more corrosion, the best solution is to strengthen the slab. A set of preparatory measures must be carried out here.

- The first step is to install steel beams on the sides of the platform and fix them to the wall with a console. Weld the mesh to them and start pouring concrete, the process of which was described above.

- Upon completion of the repair work, the surface should be waterproofed. For this purpose, materials of the coating or roll types are suitable.

Related article: How to make a wooden balcony floor

Installation of balcony railings

Of course, the old fence may still be strong enough. But the overhaul of the balcony slab already implies the installation of a new enclosing structure. In addition, if in the future it is planned to glaze the balcony and its insulation, then it will not hurt to think over a high-quality basis in advance.

When arranging fences, welding is indispensable.Even a beginner can work on a compact inventory welding machine that works from the network. But there are two more options:

- invite a qualified welder;

- fix the balcony railing with anchors, in this case welding is not required.

The frame of the new fence is made of a rectangular shaped tube. This fence is easy to install and will have an attractive appearance. Next, a galvanized steel ebb is attached along the entire perimeter of the balcony slab. This will protect the edge of the slab from precipitation. the screed on the balcony and what is needed for this.

Repair of the balcony of a panel house. Features of the work

From the article you will learn:

Balconies in panel houses are rather primitive. During construction, they were usually made open and remain so until now, if no subsequent alterations were carried out.

Such a balcony is usually used for storing supplies and old things, as well as for hanging washed clothes. The appearance of such a balcony always leaves much to be desired, since it does not have any design, but was created exclusively for practical purposes.

However, an ordinary balcony can be easily converted into a recreation room, a small greenhouse or a compact workplace. Less commonly, balconies can serve as dining or sleeping quarters, although these options are only suitable for the summer period.

Based on this, the possibilities of transforming a balcony are practically unlimited.

Basic recommendations before starting work

At first, it is worth carefully considering the further use of the balcony after repair, since the scope of work, and the choice of materials, and much more depends on this. Repair work of this kind is quite difficult, but after obtaining the necessary information, subject to all the recommendations and safety precautions, the repair will be easy and enjoyable.

The main difficulty in the reconstruction of a balcony is limited space... During repairs, all tools should be neatly folded in a separate place so as not to interfere with the master and not to injure him. You should also think over all your positions and movements in order to prevent emergencies.

Reconstruction of the support frame

Installation of the support frame on the balcony

Unfortunately, over time in panel houses, the frames begin to gradually deteriorate. The metal reinforcement inside the structure rusts, the concrete itself begins to crumble. That is why, before starting the repair of the entire balcony, you should reconstruct its skeleton, eliminate even the smallest defects, since we are talking about further safety during repair or operation.

It is not recommended to apply for services to various construction organizations, since they usually refuse to repair balconies in panel houses, motivating their refusal with technical, financial and other reasons. Most likely, the main reason lies in the unwillingness to take responsibility and give guarantees. Even if the company accepts the order, the price for it will be unreasonably high. Repair of the frame should be carried out either by yourself or with the help of qualified familiar builders, since this work is very painstaking and must be done conscientiously.

The frame is usually repaired using steel profiles that are used to sheathe and reinforce the concrete structure. It is advisable to create additional backup metal frame fasteners with a part of the wall. In the most difficult case, if the frame is severely damaged on the balcony of the second floor, you should additionally create metal supports from below, which can be mounted on the wall or installed on the ground. Fastening of profiles is usually carried out by welding, however, other types of fastening can be used, for example, tie bolts.

Balcony insulation and cladding works

Balcony insulated with mineral wool

First of all, it is necessary to examine the condition of the balcony railings. Usually these are thin concrete slabs and a metal fence. Experts recommend not repairing badly damaged fences, but simply replacing them, that is, creating a new metal supporting fencing structure. New concrete slabs or wooden planks should be used as the main fence.

In accordance with the further use of the balcony, you should choose the method of its insulation. For balconies that are not used during the colder months, a small amount of insulation, installed in one layer, is suitable. If the balcony will be used all year round, then several layers of insulation should be used. To use the balcony as a work space or a rest room, you should carefully carry out insulation in several layers and use high-quality insulation. Additionally, it will be necessary to carry out heating on the balcony and insulate the floor.

Electric underfloor heating is quite suitable for installation on a remote construction

After the warming process, sheathing is done. It is decorative in nature, so the materials for the external covering of the balcony can be varied. Plastics, wood, concrete and cement slabs, decorative glass and metal cladding are widely used.

The next step is to repair the window frames. If the old frame is blown out, mechanically damaged or partially rotted, then it must be replaced. If it can still be used, minor defects should be eliminated, the old paint coat removed and a new one applied. The new frame can be made of wood or plastic. It is worth noting that wooden frames will cost significantly more.

For the balcony, you can choose either warm glazing (using double-glazed windows), or cold, using sliding-type frames

After purchasing window frames, you can install them yourself, but usually this service is included in the price of the windows. By the way, balcony window sales companies also offer various types of claddings that will be in harmony with the frames. Additionally, you can replace the clothes drying hangers, if needed, and install a simple drainage system.

After all of the above steps, you can start decorating and furnishing the balcony.

Thus, repairing a balcony is a rather laborious, but uncomplicated task. Reconstruction of the balcony can be carried out in whole or in part on your own without much difficulty.