Aluminum balcony frames have become an excellent alternative to structures made from PVC. Owners of small-sized apartments more often than others use the named products in order to make or a loggia. This step allows you to increase the area of the adjacent room.

But frames on the balcony are also installed in cases where the homeowner seeks to create a place here for recreation, sports, or even organize a winter garden. The main requirement for such a design is effective and high-quality insulation of the balcony from unnecessary noise, cold and dust. Such conditions can be provided by sliding balcony frames made of aluminum.

Aluminum balcony frame

The dispute about which frame from which profile is better suited for glazing a balcony can be carried on for a long time, and each manufacturer has its own weighty arguments. Let's try to briefly figure out which material to opt for.

So, if you plan to insulate the balcony in the future, then you will definitely need warm glazing, which implies the use of a single-chamber (at least) or two-chamber double-glazed window.

A plastic frame made of a 3 or even a 5-chamber profile will cost much less than an aluminum warm profile of the EK-57 or EK-69 series. But plastic loses to aluminum in many respects (aesthetic and technical), especially when it comes to glazing a large balcony.

If the insulation of the balcony is not planned, then it is cheaper to use a sliding aluminum balcony frame made of the "cold" profile "Tatprof", "KraMZ", "Provedal", etc. They have a low price, are easy to transport and easy to install. Here is one example of how to assemble a frame with your own hands.

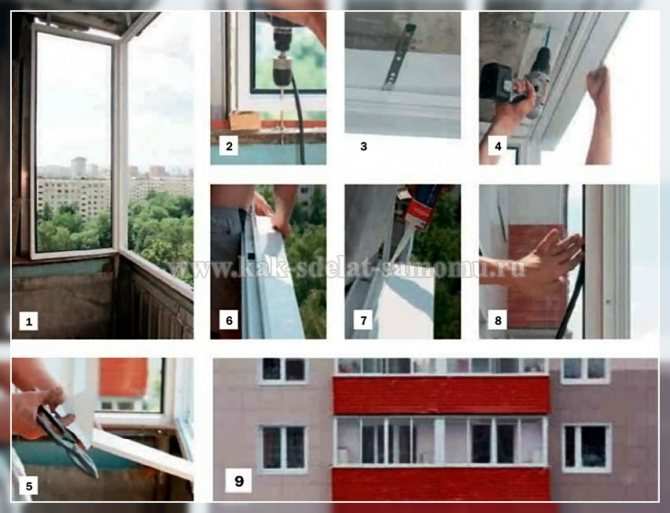

We glue the seal (included in the kit) to the ends of the upper and lower profile. Lower (photo 1)

and top (photo 2)

profiles are distinguished by the presence of side walls (do not confuse). First, we take the lower profile, attach the side to it (photo 3).

Pay attention to the location of the partitions of the side profiles. In this case (variant with four leaves) the profiles are arranged "mirrored". When changing the number of leaves, the side profiles may not be "mirrored".

We fix the profiles with self-tapping screws (photo 4).

Before installing the top profile, insert the lock striker (photo 5).

After assembly, it will be impossible to insert it. After the doors and locks are installed, fix it with a hex key at the required height (photo 6).

Install the top profile (photo 7).

The sash is first inserted into the upper one (photo 8),

then into the lower profiles (photo 9).

Adjustment of the sash level, if necessary, is done with a hex key on the removed sash (photo 10).

We insert the lock, pressing the finger on the “tongue” at the bottom (photo 11).

The frame is ready (photo 15).

You can rearrange the "tongue", as well as adjust it using the same hex key (photo 12, 13, 14).

Measurements and calculations.

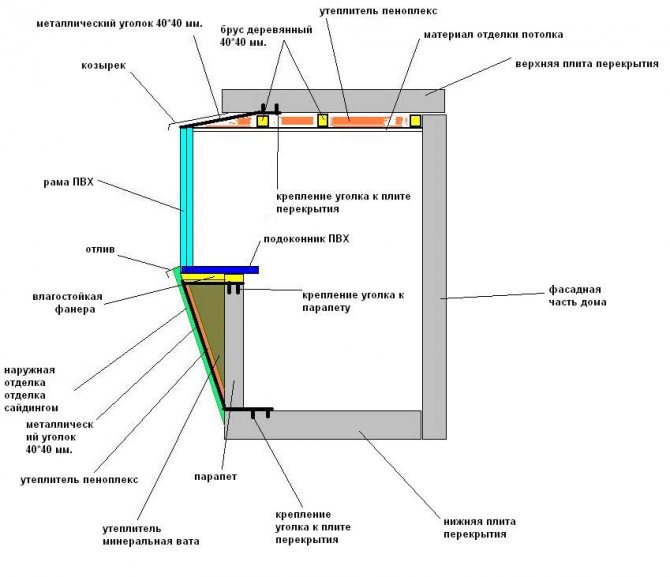

Much depends on the accuracy of the measurements and the accompanying glazing calculations, this is a fact. Due to the fact that the installation of the balcony frame is carried out on the fence of the front of the building, it is necessary to provide:

- fastening method;

- the width of the railing;

- permissible load on the fence;

- the width of the profile frame.

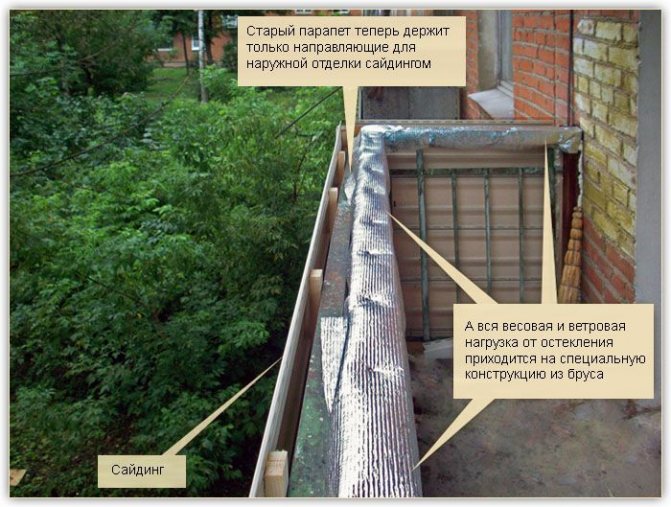

Sometimes it happens that the planned installation of the balcony frame on the railing is not possible due to the calculation of the load that the railing can withstand - the weight of the frame with the installed glass unit turns out to be more than the allowable one. To get around this moment, it is necessary to build a load-bearing structure consisting of either brick or foam concrete.

Important! Even before the construction of a new facade reinforcement, it is necessary to calculate the planned weight load, both for the reinforcement and for the balcony of the house itself. This is a prerequisite, since it is on them that the balcony frame will be installed in the future.

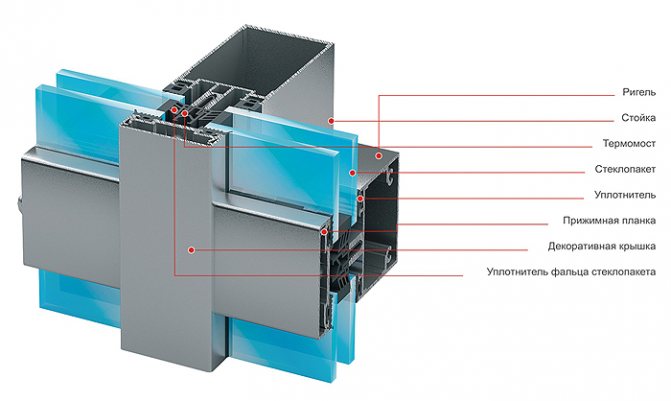

Today, the most popular are the following types of balcony glazing:

- By the type of veranda - all enclosing structures are not subject to changes;

- On the floor (the so-called ""). Such glazing is made by reconstructing not only the balcony fence, but also its other components.

Each balcony, depending on the project of the house, is capable of carrying its own weight load calculated by the designer. When carrying out work on the reconstruction of the balcony, it is necessary to carefully control that the total weight of the structures to be erected does not approach the maximum permissible value that the balcony structure can withstand.

Alternatively, you can consider the installation of the so-called "French balcony", in which the glazing will be made "to the floor". The weight load of the frames and the structure of the "French balcony" will be significantly less than the use of a solution with the installation of double-glazed windows.

In this case, it is also necessary to calculate the total mass of all components in order to compare the result obtained after dismantling the fence. The obtained lower values of the weight load will confirm the correctness of the chosen option for the reconstruction of the balcony.

When choosing a glazing method according to the type of a veranda, that is, when installing the frame on a metal balcony fence, it is necessary to perform a number of actions aimed at preparing the front part of the balcony: to close up the joints and cracks formed, to check the accuracy of fastening the cladding. Consider the use of thermal insulation materials in selected locations, if necessary.

Performing such simple actions in the future will significantly facilitate the process of balcony insulation.

If you have some experience in the field of self-repairing premises, balcony frames can be installed with your own hands, there are no special difficulties, but this cannot be done alone - you need a partner.

It must be remembered that when performing work related to the improvement of the balcony structure, it is necessary to strictly observe safety measures when working at height. The simplest solution for those who do not want to do the finishing themselves is to invite professionals who will do all the work accurately and accurately. Their coordinates can be found through the manager of the company for the sale and installation of window structures.

- Installation tool Preparing the opening

- Installing and securing the frame

- Perimeter insulation

- Adjustment of the opening mechanisms

The functionality, durability and ease of use of the entire structure depend on how technologically correct the installation of the balcony frames was.

Everyone decides which frame to install, the main thing is to strictly observe the sequence and installation technology.

First of all, you need to decide which ones you need to choose. Currently, there are three most common types for balconies (loggias): wood, PVC and aluminum. Often, many people prefer to install balcony frames made of plastic and polyvinyl chloride. This material has earned the trust of the majority of Europeans. The main advantage of plastic is the ability to make frames of the required size, to fit any opening to the structure.In addition, these have durability and strength, they are not affected by the negative effects of sunlight. Plastic is not afraid of wind and rain (even acidic). Wooden frames are considered environmentally friendly and allow decorative finishing.

Do-it-yourself installation of balcony frames is a process that requires absolute precision.

It doesn't matter what material the frame is made of, the installation processes are identical.

Installing frames on the balcony with your own hands

The point of balcony glazing is to retain heat - on the balcony and in the adjacent room. A high-quality glazed balcony often becomes a place to work (office), a bedroom (especially in the warm season) or a place for leisure. But not everyone can afford to hire professional finishers, so many decide to do the work with their own hands. And it is possible! The main questions that you have to solve are the choice of building materials and their correct use.

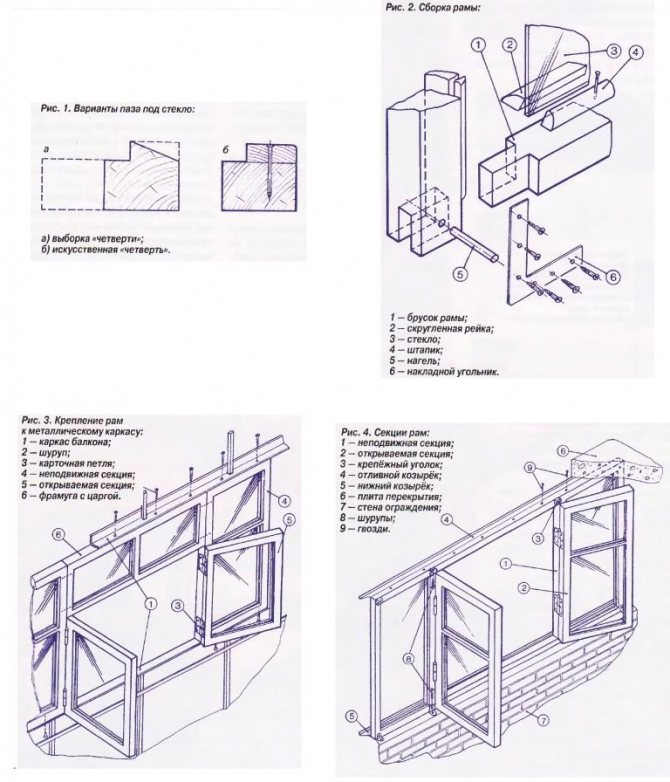

Step-by-step instructions for installing wooden windows

Since wooden windows are most often installed with your own hands from start to finish, we offer you instructions for glazing a balcony using a wooden frame.

- The mounting surface of the base beams is treated with a sealant.

- Using mounting dowels, the frame is attached to the perimeter of the balcony.

- The frames are installed without glasses to avoid breaking them.

- First of all, windows are placed on the front, then on the sides.

- Seams are sealed with sealant and polyurethane foam.

- After solidification of the frame compositions, they are glazed. The glass should be firmly pressed against the frame with glazing beads.

When glazing a balcony, you should soberly assess your capabilities and skills. Such work is often carried out at a high altitude and requires high-quality insurance, there is a risk of the glazing elements falling down. Therefore, in order not to risk yourself and the health of others and to get a high-quality result, it is better to turn to the services of professionals. You should choose trusted companies engaged in the glazing of balconies and loggias, which have long been working in the field of providing such services in your locality.

The variety of frames and their properties

There are several types of balcony frames, each with their own pros and cons:

Wood. Wooden frames are considered versatile, as they are environmentally friendly, have high sound and heat insulation properties, have an attractive appearance and a relatively low price. In addition, wood frames can be made in any configuration. For a long service life, they must be treated with special impregnations that have moisture resistance and antiseptic properties. If cold-type glazing is planned, then larch frames should be preferred. The frame must be painted or varnished every two years.

PVC. Polyvinyl chloride frames have high strength and long service life. In terms of their heat and sound insulation properties, they are not inferior to wooden frames, moreover, they do not need to be processed and painted. Thanks to double-glazed windows, the heat loss of the room is minimized.

Aluminum. Aluminum window frames are very lightweight, they are indispensable in a situation where it is undesirable to load the balcony with heavy structures. In addition, the aluminum frames are robust and provide a high level of thermal and acoustic insulation. The material is moisture resistant, does not deform over time and does not require complex maintenance.

Galvanized frames. They are used only in cases where the balcony just needs to be closed from wind, dust, rain and snow. As a rule, the glasses in such frames are single-layered, due to which this design is particularly lightweight. This is ideal for balconies, the insulation of which is categorically contraindicated.

Cold and warm glazing

Cold glazing is made with single panes in lightweight frames. Such a balcony is suitable for gatherings in summer, and under a pantry for groceries in winter. However, it is impossible to save on the supporting frame for a cold balcony: the windage of the glazing does not decrease, and the glazing frame bears mainly the wind load.

For warm glazing, the dew point must not be displaced inside the balcony. Otherwise, the falling condensation will negate all your efforts to expand the living space, and may cause the entire apartment to become damp. Also, the penetration of the dew point into the space between the glasses is unacceptable; on a balcony outside the building's outline, this is doubly difficult to achieve. To make sure the dew point is driven outward, four conditions must be met:

- Make good heat and waterproofing of the parapet and floor. Any crevice or thermal path from outside to inside will cause condensation to form.

- Use window frames with double seals and double-glazed windows. If traditional wooden frames are to be used, provide a rubber double seal for the hinged ones, and carefully seal the cracks with putty or liquid nails in the blind ones.

- It is imperative to provide for controlled natural ventilation: use metal-plastic windows with a ventilation flap, and with wooden windows in the parapet, arrange a ventilation valve outward.

- Ensure air circulation between the living room and the balcony: install an exhaust fan in the window overlooking the balcony, and make a ventilation grill at the bottom of the balcony door.

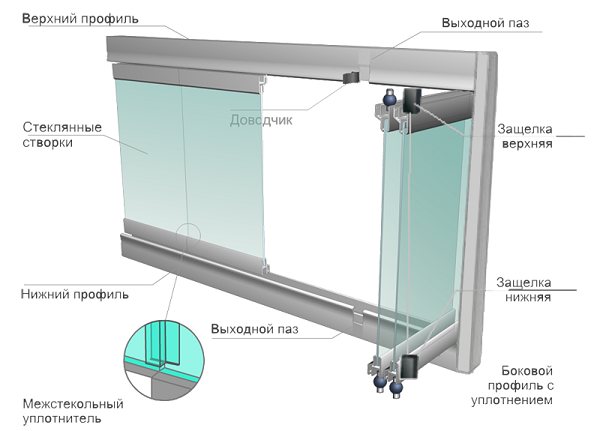

Frameless glazing

With frameless glazing, there are no vertical elements in the structure. Such frames allow the sun's rays to enter the balcony unhindered, which is important for the shady side. Features of frameless glazing:

- special tempered glasses (5-10 mm thick) are used;

- profiles are made of aluminum;

- glasses move thanks to bearings with wheels;

- there are overlays;

- it is necessary to mount the platband and ebb;

- it is necessary to install clamps;

- there must be locks on the handles;

- it is necessary to use acrylic or rubber seals;

- the sashes are fixed with tape.

Installation of a frameless structure is carried out in a strict sequence:

- firmly fix the upper ebb;

- an aluminum profile with bearings is reinforced on it;

- mount the upper silicone seal;

- glass is installed, in parallel they are connected with a seal;

- fix the lower part of the ebb;

- the gaps formed during operation (between the glass and the wall) are sealed with a sealant.

During work, materials such as nails and screws are not used. A special glue is used as a connector for glass sheets.

Loggia glazing technology with aluminum

Technologically, the installation of an aluminum profile is not much different from the installation of a PVC structure. It is necessary to carry out the following steps.

Preparation

The preparatory stage includes the following steps:

- The first step is to remove the old frame. All manipulations should be carried out carefully so as not to damage the integrity of the parapet.

- Then all residues of fasteners and other debris are removed.

- The gaps formed during the dismantling process should be carefully sealed with mortar.

After the opening has been prepared, glazing can be installed.

Installation of aluminum structures

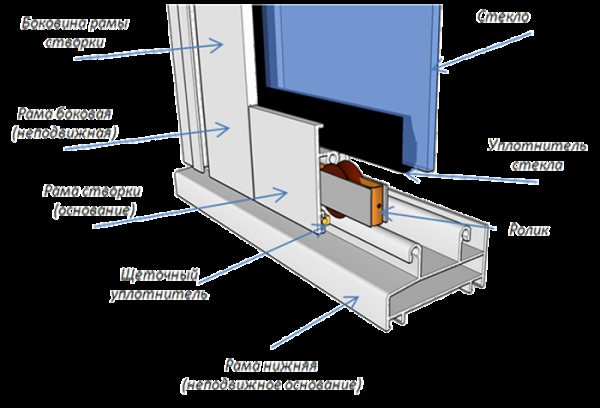

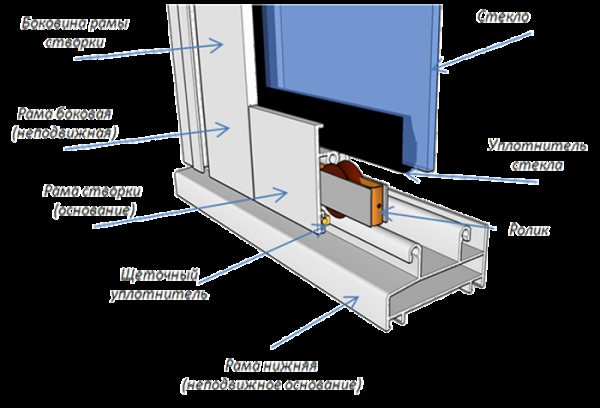

Before starting installation, some manipulations need to be made with the aluminum profile, which will make it easy to install the sliding structure:

- It is necessary to remove the sliding structural elements from the frame. This will greatly facilitate installation.

- It is necessary to remove the glazing from the fixed parts of the frame so as not to break it during installation.

- Then the mounting plates are attached to the frame in increments of no more than 70 cm.

- The frame prepared in this way is installed in the window opening and fixed with wedges.

- The frame is exposed along the planes, after which it is fastened through the mounting plates using dowels.

Advice! In the process of fastening, it is necessary to ensure that the frame does not "lead" and does not warp. In some cases, you will need to slightly loosen the mount in order to adjust the plane with the profile.

We install and adjust the glazing

Having securely fixed the frame, the previously removed glazing is installed in the fixed parts. Then the sliding part of the structure is installed, the guides make it easy to do this.

Now you need to adjust the sliding of the flaps. This is done with special screws that control the smoothness of the slide. At this stage, fittings are also installed: handles, locks and other additional equipment. After that, the sliding doors close and move on to the next stage.

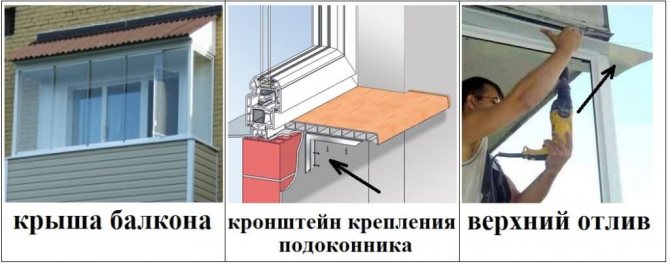

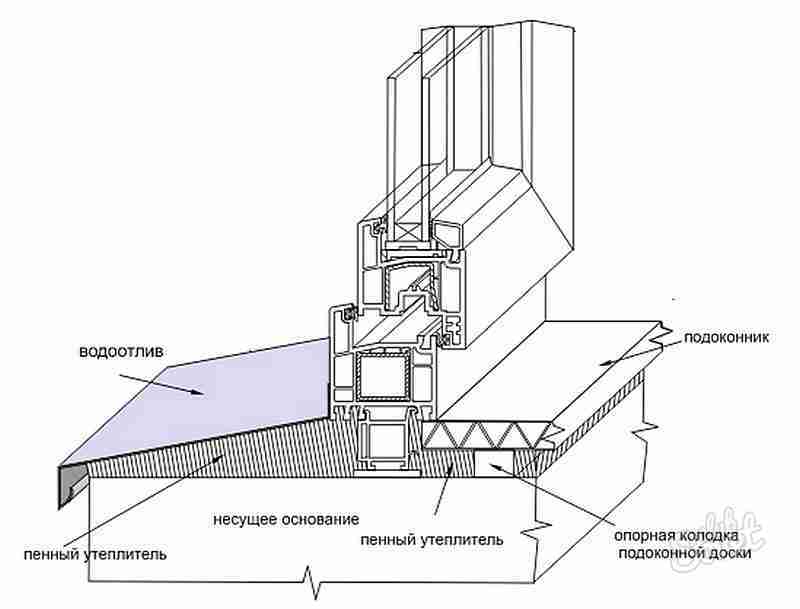

Window sill installation

The installation of this element is carried out in the following sequence:

- It is necessary to adjust the window sill so that there is no gap between it and the frame. If necessary, the trailing edge is trimmed.

- After adjusting, the window sill is removed, and mounting foam is applied to the place of its installation.

- After that, it is installed in place, verified and loaded so that there is no movement.

Sealing the structure

Having completely assembled and secured the window block, it is necessary to fill all the remaining cracks and joints with polyurethane foam. Fill the cracks with foam 3/4, leaving room for the expansion of the sealing material. Such an operation will increase the reliability of the structure, exclude blowing and moisture ingress into the balconies.

From the inside, all the gaps between the frame and the walls are closed with plastic platbands, giving the sliding structure completeness.

Advice! Having installed the aluminum frame and foamed all the cracks, it is necessary to let the structure “settle down” until the polyurethane foam completely hardens. After 24 hours, the sliding aluminum structure can be fully used.

The installation of aluminum sliding structures is quite justified for glazing in the event that it is not planned to attach a loggia or balcony to the total living area of the apartment. In this case, lightweight and cheaper aluminum profiles are the best choice. At the same time, the space of the balconies is significantly saved due to the convenient opening of the window.

Installation of aluminum and plastic frames. Instructions

The PVC frame is more massive than the aluminum frame, so the installation process will take longer. Both those and other frames are installed on wooden beams.

A hole is drilled in the concrete structure into which the anchor is screwed. Then they lay the board horizontally, checking the evenness with a building level. The bars on which the board rests can be moved until the board takes a strictly horizontal position. Then it is fixed with self-tapping screws. The next stage is the installation of galvanized ebbs, one of which is placed on the board, and the second is right below it, in the upper part of the balcony.

Ebb tides are fixed with dowels. When glazing long balconies, it may be necessary to install a multi-piece ebb. For their strong connection, self-tapping screws for metal are used.

The difficult moment of work is the installation of the frame and setting its position. First, the frame is fixed with wedges, checking the evenness of the position with a level. Then the sash is hung. They can have one- or two-chamber double-glazed windows. The work uses a hammer and a level.

The spacers can now be mounted. The windows are completely closed, with the help of the assembly, the frame is slightly raised and wedges are inserted under it. When the evenness of the structure is adjusted, they begin to drill holes for long screws, thanks to which the lower and side profiles of the window will be fixed.

Silicone sealant is used to seal the holes. The cracks and the gap between the frame and the wall are sealed with polyurethane foam.Cement is used to finish the slopes.

Installation tool

A set of tools: building level, hammer, knife, puncher, screwdriver, plumb line, grinder.

- A hammer

- Building level.

- Perforator.

- Screwdriver.

- Bulgarian.

- Dispenser gun for assembly foam.

- A drill for a hammer drill with a diameter of 6 mm, a drill for a hammer drill (for metal work) with a diameter of 3 mm.

- Dowel-nails (6x40 mm), metal screws (3.9x70 mm), self-tapping screws (3.9x25 mm) for metal work.

- Circle for metal for the grinder.

- Mounting plates (usually included with a reinforced plastic frame).

- Anchors.

- Plumb line.

Materials: wooden beams, silicone sealant, support beams, wooden wedges, galvanized sills, polyurethane foam (or other thermal insulation material), silicone putty, cement mortar (or other material for creating slopes). Self-assembly of balcony frames is carried out in several stages.

Back to the table of contents

Opening preparation

A - 6cm. - bottom. A1 - 2cm - top B and B1 - 2cm. side clearances.

There are norms according to which the construction of external walls is carried out. According to these standards, it is necessary to leave openings for windows that will be 4 cm wider than the box (2 cm on each side) and about 6-8 cm higher (6 cm below and 2 cm above). An opening above the norm will lead to a greater consumption of insulating materials.

The inside surface of the opening must be free of grooves, even and smooth. The calculation should be done so that the inner waterproofing layer is wider than the thickness of the box. We install the window at the level of this heat-insulating layer. Wooden frames are pre-painted or varnished.

Back to the table of contents

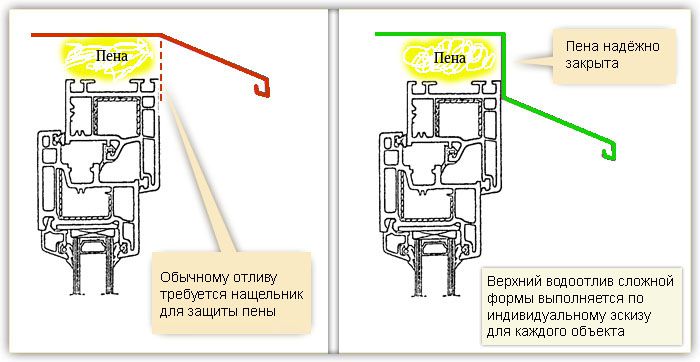

Ebb installation

The work on the installation of frames can be considered completed only after the installation of the ebbs is completed. The window must certainly have an external ebb - this will protect the balcony from moisture ingress. For its manufacture, materials such as aluminum, plastic, polyester, galvanized sheet are used. The profile part of the ebb is always equipped with a special bend fitted to the frame. When installing the ebb, they make a slight slope - this will improve the drainage of water from the window. If the work is done correctly, the balcony will be reliably protected from moisture. Also, properly installed ebb tides are highly resistant to strong winds and drown out the noise of rain. The ebb is fixed on the window with rivets, but more often with self-tapping screws. The space formed between the ebb and the frame is filled with polyurethane foam. This allows you to better keep the warmth on the balcony. Until the foam dries completely, the ebb must be fixed in a certain position.

Low tide should go not only under the bottom of the slopes, but also from above and from the sides. This will protect the walls from moisture. Aluminum is considered the best material for creating shims, because plastic loses its shape and appearance over time. Aluminum drip can be made by yourself. This requires an aluminum sheet. The markings of the future ebb tide are applied to it in accordance with the size of the window. Then the ebb is cut and folded. Before installation, it must be powder coated. The ebb can be made of galvanized steel. They only cover it with a polyester compound that lasts a long time and retains its original color. This option is cheaper than aluminum.

Glazing a balcony with your own hands is not as difficult as it might seem at first glance.

Dismantling the old structure

The procedure includes removing the old window and sill. Let's consider the procedures in more detail.

Removing an old window

Use a jigsaw to cut several parts of the frame - in the future this will help when dismantling. Then carefully pry the frame with a crowbar and pull out the window base piece by piece.

Advice! It is best to start at the bottom of the window, because it will be the easiest to pull out.

Removing the window sill

Use a hammer and, if available, a chisel to remove the sill.While dismantling, support it so that it does not suddenly fall off.

There is one universal removal method: Saw the sill down the middle with a jigsaw or saw and then break it off with a crowbar. You can also use a puncher.

Alternatively, you can simply break it off with your hands. But this will require physical training.

Now that the old window is completely dismantled, you can start installing the new one. It will start with the installation of the base of the window.

After removal, do not forget to clean the area: remove construction debris, concrete, glass shards and other items.

Aluminum windows to the balcony

Balcony glazing is one of the most important measures in the process of apartment renovation. Firstly, it is necessary to insulate housing, because a significant part of the heat comes out through the balcony. Secondly, after installing windows there, you get additional space that can be used for certain residential or business needs. But, before starting work, you need to decide from what material the glazing should be carried out. And one of the most popular options is aluminum windows to the balcony.

Aluminum windows to the balcony

Glazing of a balcony with an aluminum profile with a removal

Preparatory work

Before removing the old window, you need to acquire the necessary tools and prepare the window opening. Read how to do this below.

Preparing the old window for work

Before carrying out work, remove the curtains, remove flowers from the windowsill (if any). Cover the floor and interior in the room with plastic wrap to protect them from dirt and debris. If there is a carpet or other similar items in the room, move them to another room. Next, remove the sashes and slopes from the window.

The initial preparation is complete, it's time to start removing the old window.

Preparation of tools and necessary materials

- Chisel or jigsaw;

- Crowbar and dowel-nails;

- A hammer;

- Foam;

- Screwdriver;

- Drill and hammer drill;

- Drills for metal;

- Anchor plates;

- Plastic or wooden wedges;

- Vapor barrier membrane;

- Thermal insulating flap;

- Aluminum profile, double-glazed windows and other components of the new window.

All items have been collected, now is the time to remove the old window.

Pros and cons of aluminum windows to the balcony

The installation of aluminum windows on the balcony is gaining more and more popularity today. And for those who are just thinking about this, we will give the pros and cons of such glazing. Let's start with what are the advantages of aluminum windows to the balcony.

- Availability... Often people give their preference to aluminum windows just because of the low cost. On average, the price for them is 1.5-2 times cheaper than for a similar glazing with PVC windows.

Glazing of balconies with aluminum profiles

Aluminum sliding balcony windows

Balcony with aluminum profile windows

Photo of aluminum balcony windows

French balcony made of aluminum profile

Important! For owners of small apartments, it makes sense to consider the option of glazing the balcony with aluminum windows with a perimeter that exceeds that of the parapet. As a result, the useful area of the balcony increases and it can be used to arrange indoor plants in the warm season or as an additional refrigerator in winter.

Option of glazing the balcony with aluminum windows with a perimeter exceeding that of the parapet

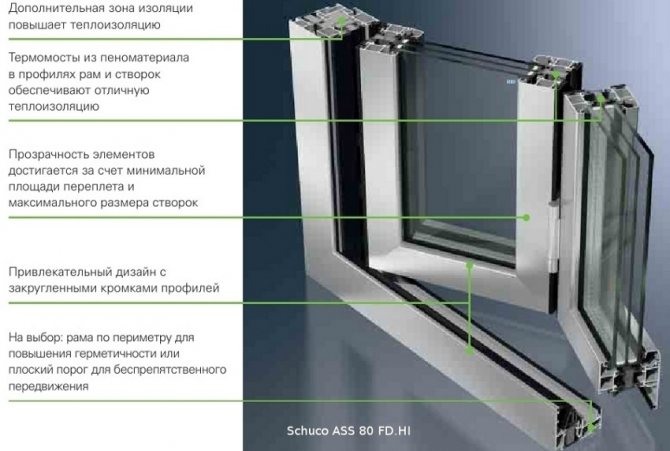

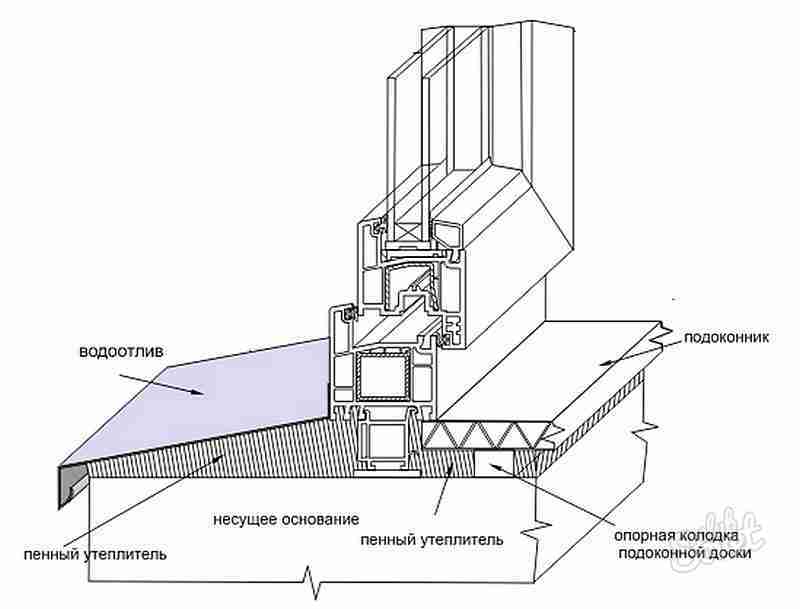

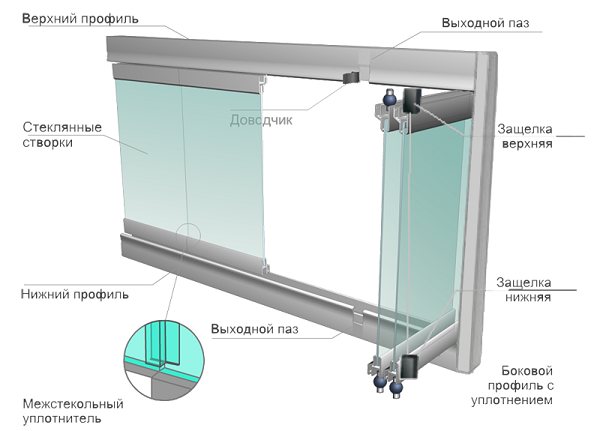

Aluminum window arrangement with sliding sash. Most often, it is these structures that are used for glazing balconies.

Section of "warm" and "cold" window aluminum profiles. The first differs from the second by the presence of two glasses with an air gap and a heat-insulating gasket between the outer and inner sides.

Also, when thinking about purchasing aluminum windows for a balcony, you should be aware of their shortcomings.The main disadvantage of such structures is the insufficient degree of thermal insulation. A balcony with aluminum windows, as a rule, will be "cold" - in winter the temperature in it will exceed that on the street by no more than 5-6 ° С.

Sliding cold aluminum frame Framex S22

Provence style balcony

The design of a balcony or loggia in the Provence style is becoming fashionable among our compatriots. They are attracted by discreet grace, French simplicity, natural finishing materials and the presence of vintage elements. For a more detailed study of the issue, we recommend reading this article.

Another disadvantage is that aluminum frames and sashes are installed only on perfectly flat and prepared surfaces. Therefore, before the installation process begins, the parapet will either have to be leveled with a cement mixture, or a wooden board should be placed under the structure and all the glazing elements will be installed on it.

Video - Installing an aluminum balcony frame

Features of the

Any design has a frame and glass (or glass unit). Structures for aluminum structures are made from a complex alloy, and other elements are added, which allow the finished product to be stronger... Usually such substances are magnesium and silicon.

Typically such frames have only one air chamber. The profile has a wall thickness of approximately 1.5 mm, for a "warm" product from 1.7 to 2.0 mm.

Sliding aluminum balconies

In their shape, sliding aluminum systems are rectangular structures on the loggia and balcony, where, with the help of rollers, the sash can move smoothly horizontally. To prevent precipitation from getting inside, the manufacturer puts a seal around the entire perimeter of the sashes.

Limiters are specially installed to protect the sash from falling out in strong winds. To block the sash, the developers installed a latch. The sash can be dismantled if necessary.

Photo:

The water that accumulates due to precipitation flows out through the drain, which is installed at the bottom of the frame. In order to better penetrate daylight, glass in double-glazed windows is used in the design. It's even possible to install sandwich panels. Also, this system can be used in conjunction with glass that reflects the sun's rays, and the rooms do not heat up so much.

Aluminum windows to the balcony

Balcony glazing is one of the most important measures in the process of apartment renovation. Firstly, it is necessary to insulate housing, because a significant part of the heat comes out through the balcony. Secondly, after installing windows there, you get additional space that can be used for certain residential or business needs. But, before starting work, you need to decide from what material the glazing should be carried out. And one of the most popular options is aluminum windows to the balcony.

Aluminum windows to the balcony

Glazing of a balcony with an aluminum profile with a removal

Testimonials

Lyudmila, 29 years old.

We installed ourselves an aluminum profile on the balcony last year. Very durable and comfortable construction.

Svetlana, 37 years old.

The aluminum glazing is really cool. Glazed 15 years ago, everything is still like new.

Valentina, 45 years old.

A couple of years ago, the godfather installed an aluminum structure on her balcony. Praises her very much.

Pros and cons of aluminum windows to the balcony

The installation of aluminum windows on the balcony is gaining more and more popularity today. And for those who are just thinking about this, we will give the pros and cons of such glazing. Let's start with what are the advantages of aluminum windows to the balcony.

- Availability... Often people give their preference to aluminum windows just because of the low cost. On average, the price for them is 1.5-2 times cheaper than for a similar glazing with PVC windows.

Glazing of balconies with aluminum profiles

Aluminum sliding balcony windows

Balcony with aluminum profile windows

Photo of aluminum balcony windows

French balcony made of aluminum profile

Important! For owners of small apartments, it makes sense to consider the option of glazing the balcony with aluminum windows with a perimeter that exceeds that of the parapet. As a result, the useful area of the balcony increases and it can be used to arrange indoor plants in the warm season or as an additional refrigerator in winter.

Option of glazing the balcony with aluminum windows with a perimeter exceeding that of the parapet

Aluminum window arrangement with sliding sash. Most often, it is these structures that are used for glazing balconies.

Section of "warm" and "cold" window aluminum profiles. The first differs from the second by the presence of two glasses with an air gap and a heat-insulating gasket between the outer and inner sides.

Also, when thinking about purchasing aluminum windows for a balcony, you should be aware of their shortcomings. The main disadvantage of such structures is the insufficient degree of thermal insulation. A balcony with aluminum windows, as a rule, will be "cold" - in winter the temperature in it will exceed that on the street by no more than 5-6 ° С.

Sliding cold aluminum frame Framex S22

Provence style balcony

The design of a balcony or loggia in the Provence style is becoming fashionable among our compatriots. They are attracted by discreet grace, French simplicity, natural finishing materials and the presence of vintage elements. For a more detailed study of the issue, we recommend reading this article.

Another disadvantage is that aluminum frames and sashes are installed only on perfectly flat and prepared surfaces. Therefore, before the installation process begins, the parapet will either have to be leveled with a cement mixture, or a wooden board should be placed under the structure and all the glazing elements will be installed on it.

Video - Installing an aluminum balcony frame

Communities ›Do It Yourself› Blog ›How to glaze from aluminum profile yourself?

Hello everyone! I want to glaze a balcony made of an aluminum profile of the type I spent 400. I found where to buy everything for this profile. Has anyone glazed an aluminum profile himself? Share your experience.

Comments 32

I already saw dumb from Moscow

and where are you from?

I can tell you everything to show, or anything complicated! from the tools you will need a screwdriver, a cutting saw, a level, and preferably a laser. what profile did you take?

I haven’t taken it yet, but I’ve seen 400 new ones like Krasnoyarsk, although they differ greatly in price

over the past 4 years, many manufacturers have either reduced the weight of the profile due to a decrease in the wall thickness or have begun to use lower quality raw materials.

I visited the thinnest somewhere 1.2 mm, the sial is twice as thick

It depends on what profile to do it. Not long ago I collected a stained-glass window for one member in the dressing room, 3 structures of 2500 * 2700 from a cold profile with windows and a door (impost for the height and width of the entire structure) from Tatprofil TP-45 (not advertising, we also use Alutech Of course, it is better to do without vertical posts in the middle of the structure, since the aluminum profile is connected on its connectors, both corner and butt-to-joint, and fastened at the top, bottom and on the extreme struts of the structure. If you want to assemble the aluminum structure, stained glass glazing (as in different trade centers), then you can do with simple trimming, everything is sawn under 90. If you need swing (folding) windows in the frames, you cannot do without crimping, but you can also assemble on dowels, but the likelihood of cracks and looseness of the structure is guaranteed, and without a two-component glue on aluminum is indispensable (you can use epoxy or poxipol, for extreme). In general, of course, you need professional equipment, even for a nail. If you need advice, write, I will tell you. from the video, the guy in the garage assembles the door, well, this is just for reference.

I boast, in the photo there is a warm entrance door with oblique imposts.

beautiful ... I see you work with Krasnoyarsk, is it thick walls?

Thank you, a kind word and warm aluminum is nice)))! Krasnoyarsk is Sial, I worked with him at my previous job, and this is Tatprof, I suppose that somewhere in Tatarstan they pour it, and paint it in the Dinskaya station. group, shtulpovaya door with side wood grouse, Tatprof too, but already a new line AlNeo. By the way, there is no shtulpa, just instead of a shtulp, the sash profile Z is used, but there are not big tricks, the main thing is not to fuck. Let's see what kind of monster. For the thickness of Siala is not I will say, I never measured.

oh sorry that you are too far away ...

If you advise me, I will tell you, I can only answer in the evening, when I get to my computer. In principle, I don’t connect the mobile Internet)).

Likewise, I also in the evening only

On the occasion of the sale of equipment for the assembly of frames of the system visited. Matrix with pneumatic press, trimming with roller conveyors, pneumatic tools. There are few accessories.

Hello. For me personally, looking at the metal structure in the photo, I do not see any reason to bother myself at all, in terms of the rather necessary equipment and finishing of the adjacent structures. It would be worth it if, instead of metal, a structure was made according to the type of facade - facade glazing - facade aluminum - maybe a ventilated facade ... to be honest, I don’t know how to name 100% correctly, in general, where aluminum itself will be load-bearing, I think my thoughts are clear. In my opinion, it is easier there, trimming is needed to cut everything smoothly + cutting angle. Then I mounted it, it is important to securely and evenly fix everything. Measure the double-glazed windows, mount them under the clamping bar, on top of the cover and you're done. Of course, there are also some nuances, but it is easier than pressing or gluing the corners of the frames + finishing and insulation of gaps between structures and metal racks. And the crown of all will be cold bridges from the racks themselves, which, in principle, will not go anywhere, unless they are insulated with something outside + from the inside also make a cake of vapor barrier and insulation. Yes, aluminum, as you intended, will give a cool appearance, but the front option still wins. The idea is interesting in terms of doing everything with your own hands, but you need someone who knows who will guide.

Balcony glazing with aluminum profile

Glazing balconies with an aluminum profile is one of the very common and fairly budgetary options for creating a cozy atmosphere in the house. Of course, such structures are called "cold glazing" because they cannot provide too high a room temperature. They are often used for technical rooms, balconies, storage rooms and more.

So if you want to use such windows to create a temperature suitable for a comfortable stay on the balcony, you should abandon the use of such technology. She will not be able to provide the required level of comfort for you. Like any windows, they have their own advantages and disadvantages. Let's break them down one by one, in more detail.

Advantages and disadvantages of double-glazed windows

There are varieties that are made using new technology and they are able to create the necessary atmosphere and maintain a comfortable temperature regime. This became available thanks to the installation of special heat-insulating inserts in the frame. But such designs are quite expensive and are not yet gaining much popularity.

A significant advantage over plastic and wooden counterparts is the ability to install double-glazed windows with a sliding frame. Thus, the sash moves sideways along the guides, which significantly saves space. With their help, you can install a window in very narrow places without spending valuable space for free movement.

Glazing with aluminum has a very low weight, which raises it in front of analogues, which can be at times heavier.Due to their low weight, they can be installed on any balcony and loggia, do not need a reinforced base and are installed very easily with your own hands, without outside help.

Manufacturers use powder paint for aluminum, which comes in any shade. It is very high quality, durable, does not fade and has a rich color. Thanks to a wide palette, it is possible to choose aluminum glazing for any design based on your preferences and needs.

What are the disadvantages

While having advantages, such frames, of course, have disadvantages, which should also be mentioned. Let's take a look at the most significant ones.

The main and decisive factor whether to buy a window or not is the very low rate of heat savings in the room. In winter, they keep the temperature by only a few degrees. In very severe frosts, sliding mechanisms and fittings can be covered with a layer of ice.

Cold and warm glazing

Then it is possible to open them only after removing the ice, which brings certain inconveniences in use. Have a critically low level of tightness. Almost all noises from the street will pass through them, in a strong wind, blowing from the cracks is possible.

It is better to glaze the balcony with an aluminum profile when the main balcony door has good sound insulation, in which case the leakage will be compensated for.

If you compensate for the disadvantages by other means, then the installation of an aluminum window will be a very good solution. So, you can save an impressive amount, and make your balcony or loggia glazed and protected from wind, rain and snow.

The better to glaze the balcony: plastic or aluminum

A thorough study of the technical characteristics of such different materials as plastic and metal will help to answer this difficult question. Plastic glazing is assumed when there is a need to make the balcony as warm as possible. Glazing with plastic frames, as well as aluminum ones, provides protection from dirt, cold and precipitation. Today, the cost of plastic frames has dropped significantly, which made it possible to create good competition for aluminum frames.

Plastic balcony frames have their advantages:

- Frames and windows made of PVC have a high level of tightness. A rubber gasket between the frame and the glass is necessary to keep the heat inside the room, and also protects the balcony from cold penetration. Depending on the number of chambers, noise insulation increases.

- Plastic frames perfectly withstand any temperature fluctuations, while maintaining an excellent appearance.

- The balcony can be glazed with a plastic profile of different colors. If you are tired of the white color, the frames can be decorated with a special colored film, which is perfectly glued to plastic.

- Installing plastic balcony frames is quite simple.

Like any other material, plastic also has its drawbacks - the accumulation of static electricity, which attracts dust. Easily subject to mechanical damage such as scratches or dents.

PVC is heavier than metal structures, therefore it excludes installation on balconies in old houses.

Glazing a balcony or loggia is quite a responsible business. It is necessary to take into account many nuances when choosing a design. For example, how much the structure weighs, the convenient location of the opening parts, the permeability of cold and dirt.

Varieties of aluminum profiles

The aluminum profile for glazing is divided into two main types, which we will tell you about.

- Cold profile - does not have a warming effect, it is designed to prevent drafts, rain and snow from entering the room. It is usually used in large industrial facilities, utility rooms and other places where a comfortable air temperature is not so important.

- Warm profile - a special type of aluminum glazing, equipped with insulating inserts. They combine inserts with thick glass, which has a very good effect on the thermal insulation performance of the structure. The profile can be equipped with three or five air chambers, which is why its quality will mainly depend. To improve the sealing, such windows are equipped with rubber bands and gaskets to reduce external noise. They are used in apartments, offices, balconies.

A common cold profile is very cheap and installation is not difficult. If you want to install a model from a warm profile, then you should be ready to pay a substantial amount of money. The price can be several times higher than that of a cold window.

Window sealing

After completing the installation, check all areas for drafts or open joints. If you find it, use polyurethane foam or sealant. After that, check the fittings and set them up (if you have not done this before).

Done, your aluminum window is installed! By the way, sliding aluminum windows are installed in the same way, except that rollers are screwed to the sash, which will help the window move to the left or right.

We carry out installation work ourselves

The glazing of the loggia with an aluminum profile can be done without the help of specialists who will require you to pay due payment for their work. There is no particular difficulty in installing, you should adhere to the basic rules and the work will be done with five points.

Let's take a look at what stages the entire installation process can be conditionally divided into:

- Preparing for installation

- DIY installation of double-glazed windows

Preparatory stage

Like any other window frame, aluminum profiles require careful preparation. The final result will depend on the quality of the prepared surface. It seems that this is not at all connected with glazing and one can treat such work obscenely, but no.

You should approach your work very seriously and take the necessary actions with due attention and perseverance.

The first step is to dismantle the old frame, but do not put too much effort on it. Otherwise, you can damage the base, which is in itself bad.

Make pressure on the plane of the window, then the risk of damage is minimal. The nails anchoring the old frame to the concrete should come out fairly easily and not destroy the base.

If parts of the old frame, chunks of chipping concrete or old fasteners remain on the railing, be sure to remove them. If the surface of the base is too damaged, it should be restored, in which case the glazing with an aluminum profile is delayed for several days, until the concrete is completely dry.

To improve the quality of the installation, a wooden beam, fifty by fifty millimeters in size, can be fixed on top of the railing. Our aluminum window frame will be mounted on it. After the preparation done, you can proceed to the next stage, the installation of double-glazed windows on your balcony or loggia.

Installation of an aluminum structure

First you need to remove all the opening parts, so you will lighten the frame, and it will be easier to install it. If there are blind areas of the window, the double-glazed windows should be removed from them so as not to damage them and further facilitate the structure.

Mounting plates or brackets are then attached to the frame. The optimal step between them is fifty to seventy centimeters, depending on the total weight of the window and the thickness of the plates. They are fixed directly into the profile, using self-tapping screws for metal.

The frame is set in place and secured with wedges. They also need to adjust the level we need by measuring it with a special device. The wedges have to sit very tightly in order to calmly hold the entire frame together with the glass units.

Finally, all cracks are sealed with polyurethane foam and left closed for a day so that the foam is completely dry. After drying, you can cut off the excess with a clerical knife and proceed to further decorate the room.

Glazing tips

Outside, the foam must be sealed without fail, since it will dry out under the influence of sunlight and will crumble. It is best to cover the seam over with any solution, and then sheathe it with the material you like.

Remember to constantly check the level of the frame during installation. Especially after the return to the place of all double-glazed windows and moving elements. Under weight, the level may shift and it will be necessary to correct it. After foaming, this procedure will be very problematic.

Window types

It may immediately seem that aluminum windows are very similar to each other, and the only thing that can serve as a difference is the shape and number of glass openings. However, the assortment is wide enough, and the main difference is the opening of the sashes. Depending on this, there are the following types of aluminum windows:

Window opening types

- Deaf. Such a metal structure is installed on those balconies, the owners of which use them as an office space.

- Folding. This type of construction is quite in demand, in particular, when it comes to vents. In this installation, the doors open from top to bottom.

- 3. Swivel. This version of windows is quite simple, it is used often and is considered a standard installation. The doors of the pivot windows open in one direction.

- Combined variety. Windows in this version can be opened both in the tilt version and in the hinged version. The population often installs such constructions.

- Sliding aluminum frame. This modification was developed not so long ago, and now it is the most suitable option for opening windows. The doors open here in those directions that are fixed along the window opening. Therefore, they do not cover a small room, unlike other mechanisms.

It is worth mentioning separately the latest balcony frames, which have gained great popularity in recent years. This is because they are easy to use and have high technical qualities. Obviously, these points will play a role in the selection process for a balcony installation. Interestingly, the price of a sliding mechanism is not higher than that of standard windows, since the percentage of aluminum profiles in them is low. This also includes seals and guide profiles.

Sliding frames

The appearance of aluminum windows is an important attribute. They go on sale already painted. During production, the aluminum profile is painted using powder technology, which is now considered the leading one. The customer can, at his discretion, choose the color of the structure, which also plays a role in competition in the modern market.

Painting with powder spraying is of sufficient quality: for a long time it does not fade in the sun, does not crack from cold temperatures, does not peel off. Humidity also does not have a detrimental effect on aluminum balconies.

In general, reviews of aluminum balconies are positive, since their appearance, installation process, convenience and cost are always justified in operation. By the way, about use: many people who have installed such glazing are satisfied that balconies are durable, and frames made of such material do not require careful maintenance.