What is a ridge?

The ridge is the upper edge of the roof structure. This element connects the roof slopes, the planes of which converge on it in one line. Since the ridge is the top point of the roof, the height of the roof is determined by its location.

NOTE!

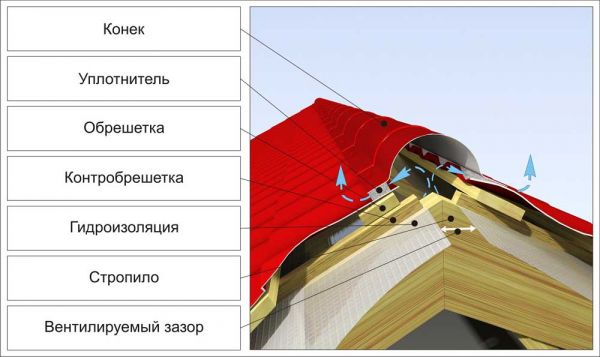

This element performs the functions of protection and ventilation.... It closes the slope joints, preventing moisture and dirt from entering the inner space of the roofing cake. At the same time, circulating air masses come out through the ridge.

Determining the height of the roof is important not only for wind and snow resistance purposes. Most roofing materials have clear ranges of possible slope angles for their installation.... When installing heavy materials, it is necessary to minimize the load per unit area of the roof base; for this, the slope angle (respectively, and the ridge height) increases.

Roof ridge

If an attic space is planned in the house, then the range of possible slope angles is limited by the requirements for the maintenance of the premises and for its fire safety. For residential attics, requirements for the convenience of moving around the room are added, depending on the height of the residents.

Parameters to be considered when installing the chimney

From the outside, all chimneys look the same, in fact, they are very different from each other. The first thing you should pay attention to is that in different houses they have different heights above the roof level.

Second, they differ in width. Indeed, the height and width of the chimney do matter. It is necessary to focus on these parameters first of all. But what is important is not only what is outside, but also what is hidden inside.

Before planning a chimney device, it is necessary to determine:

- The number of heating devices that are connected to the chimney. In a private house, there may be one outlet for combustion products for several devices. The parameters of the chimney directly depend on their number.

- Fuel used for heating. The physicochemical properties of combustion products depend on it. First of all, you need to know the chemical composition.

- Combustion temperature. It depends on the type of fuel and the way it is burned. During installation, it is necessary to take into account the temperature that will be created inside it.

The listed factors are important because they affect the parameters that must be taken into account when installing the chimney:

- Heat resistance of the material from which it is made. Chimneys are metal, more often - steel, ceramic, asbestos-cement, brick and glass. Each of these materials has its own heat resistance. The last option is the most exotic and least stable. It is used for decorative fireplaces. Another material that is unstable to very high temperatures is asbestos cement, which is used in the installation of heating boilers. The material from which it is made must be selected depending on the type of fuel and its combustion temperature.

- Chimney height above the roof. There must be sufficient draft in the chimney in order for the smoke to be removed from the premises to the street. The creation of thrust is a passive process, but for its implementation, certain air flows inside the pipe are required. If it has a lower height than required, it will not generate sufficient draft and smoke will remain inside the room.

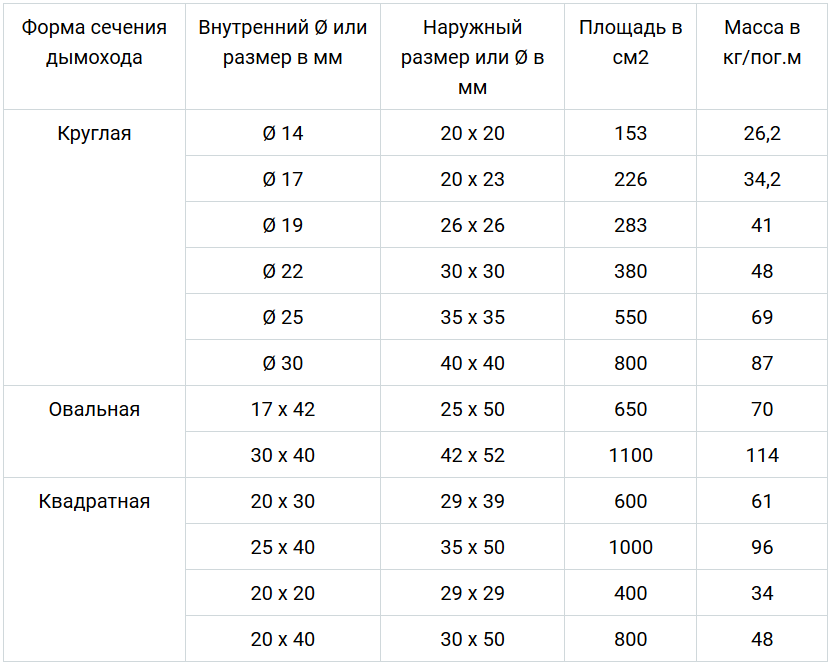

- The diameter of the inner section of the chimney.The correct inside diameter is also required to ensure sufficient traction. In addition, if the diameter is less than required, some of the gas will remain in the room, which poses a threat to both the house itself and the lives of its inhabitants.

We recommend that you familiarize yourself with: PVC well casing pipes

Correct selection of these three parameters when installing the chimney system guarantees long-term and safe operation of heating devices. In addition, external factors affecting the draft in the chimney are important. These include: the height of the roof, the slope of the roof, the height of buildings and trees around, the location of the chimney relative to the wind rose.

It is important! Incorrect calculation of the height and diameter of the chimney leads to low draft in it. In this case, carbon monoxide constantly remains in the room, which can cause a number of diseases in households and even lead to death.

Chimney height relative to the roof ridge

The correct relative position of the ridge and the chimney allows for a constant and complete exit of smoke from the chimney.

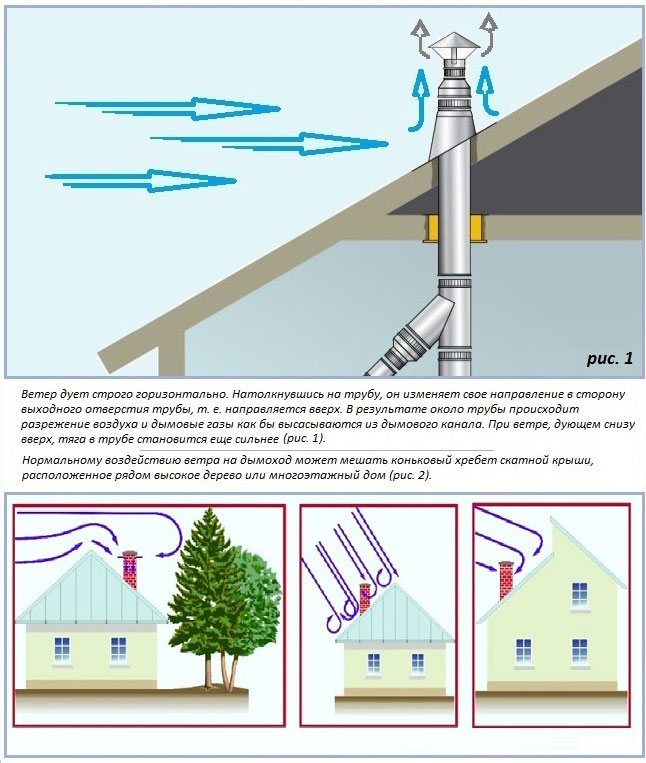

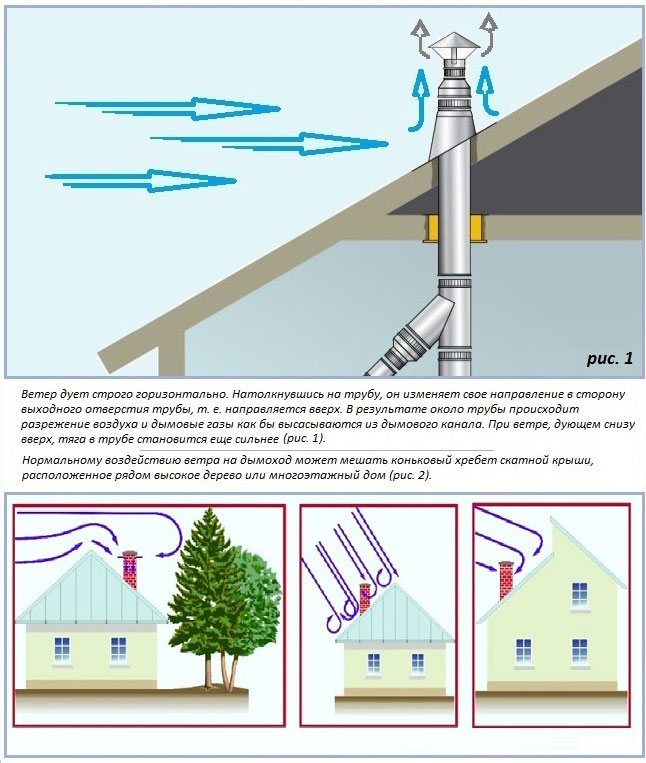

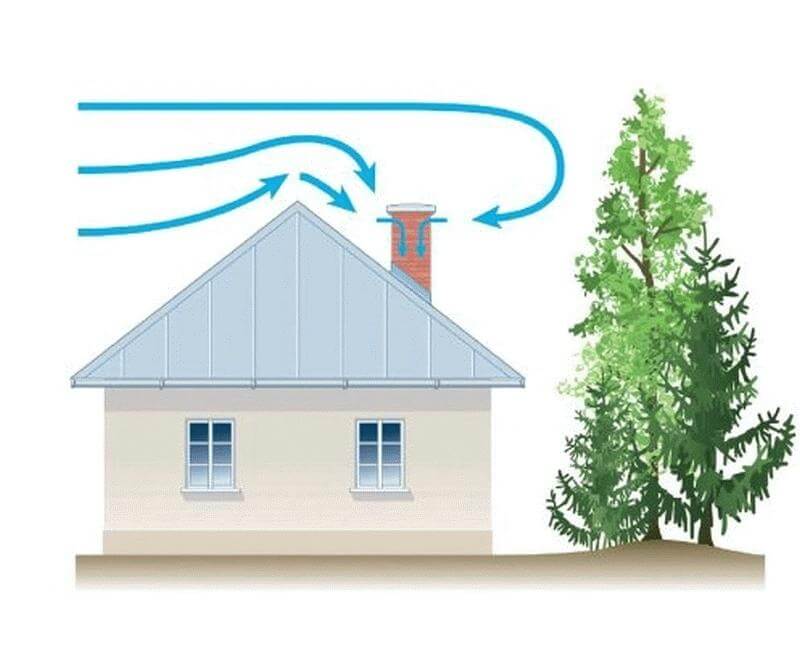

The main condition for the occurrence of traction is the wind effect on the chimney, which creates a zone of rarefied air near its walls, into which internal gas flows rush.

If there is an obstacle in the path of the wind (for example, a ridge), and the chimney is not properly blown, then the draft will be insufficient, flue gases will accumulate in the chimney and in the premises of the building.

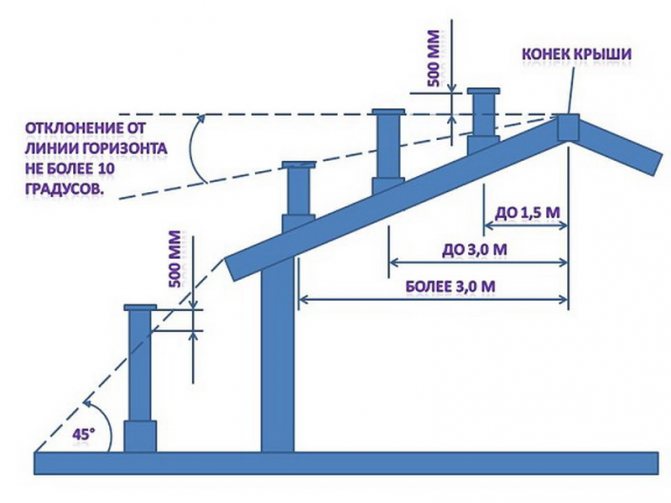

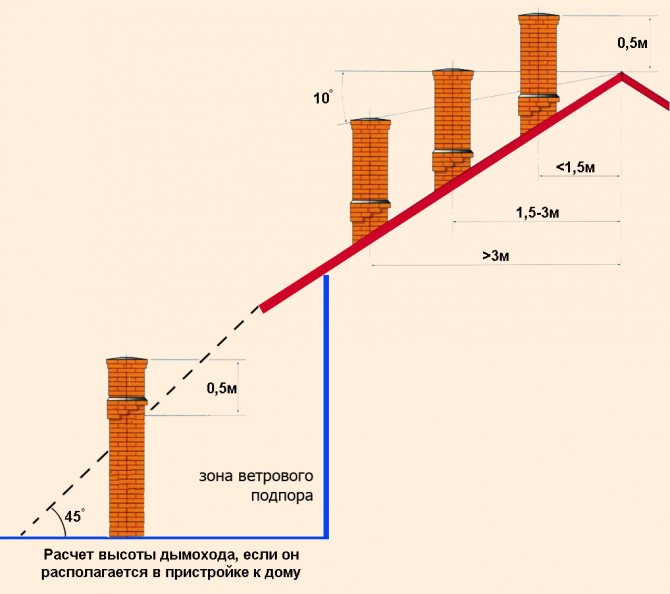

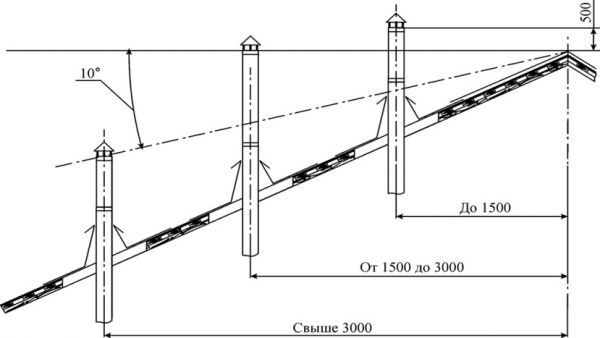

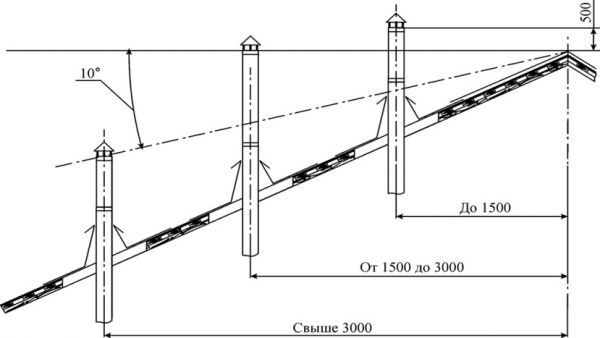

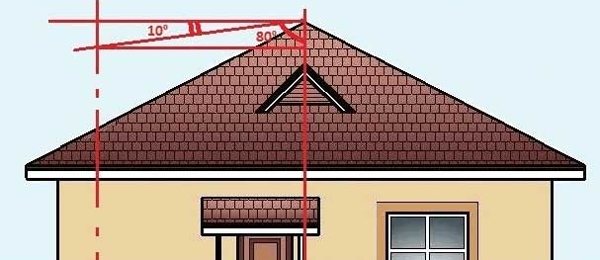

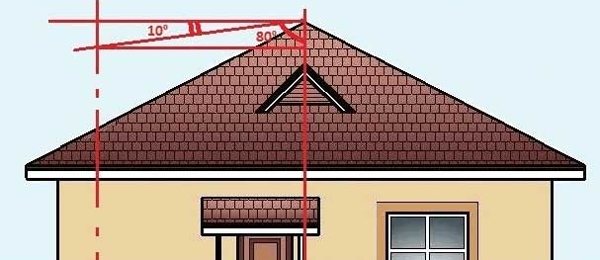

The height of the pipe in relation to the ridge of the roof determined by SNiP 41-01-2003, which regulates the issues of heating and ventilation.

Building codes have the following requirements:

- The minimum length of the elevation of the chimney above the ridge is 50 centimeters in those caseswhen the distance between these elements equal to 1.5 m or less.

- When the distance between the elements is 1.5 - 3 m the mouth of the chimney should be at the same level with the ridge or slightly higher than it.

- When the distance between the elements 3 m or more, the chimney mouth should not be below the linedrawn from the ridge down towards the horizon at an angle of 10 degrees.

When calculating, it is worth paying attention to the requirements for the minimum length of the entire smoke channel, which is 5 meters.

IMPORTANT!

It is recommended to locate chimneys as close as possible to ridge, as this minimizes the retention of wind flows by this element and allows you to locate most of the chimney inside the building.

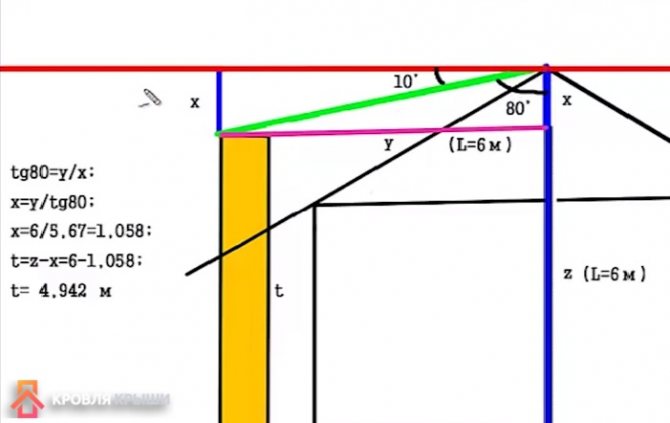

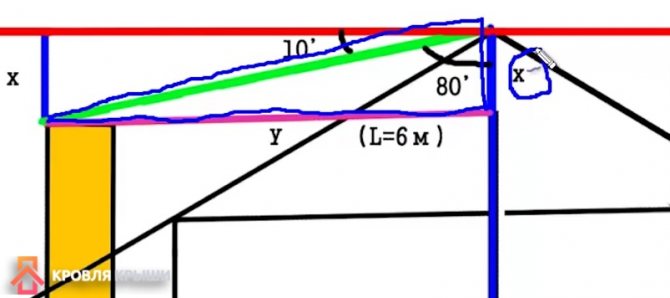

When designing a chimney more than 3 meters away from the ridge, difficulties may arise, since it is difficult to determine the ten-degree angle "by eye".

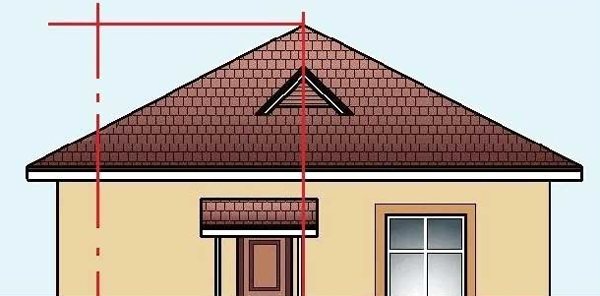

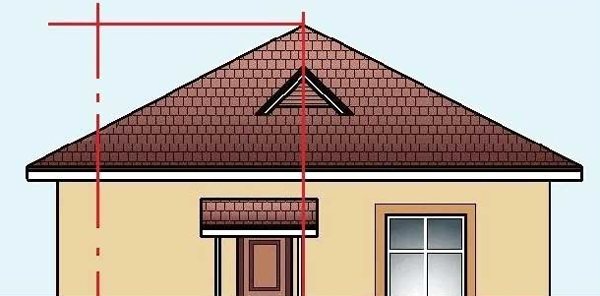

Chimney height relative to the ridge

The geometric method will help to ensure the accuracy of the calculations: in accordance with the scale, a schematic drawing of the roof is carried out with a marked axis of symmetry of the chimney (that is, the location should already be known), from the top point (ridge) a horizontal line is drawn parallel to the base of the triangle (span), at the point of intersection of the ridge and the horizontal, an angle of 10 degrees is laid.

In accordance with the angle, a straight line is drawn from the same point - the place where it intersects with the axis of symmetry of the chimney will determine its height.

Effect of chimney height on draft

Draft is the ventilation effect that any stove gives. The air that enters the house through the cracks in the lower part of the facade, heats up, passes through the ventilation holes of the stove, enters the chimney and goes outside. In its place comes dense cold air, which provides the thrust force of the furnace. The greater the temperature difference inside and outside the pipe, the stronger the draft.

The chimney not only ensures the safe exit of gases and fuel combustion products to the outside, but also affects the heat transfer of the furnace.A properly installed chimney will reduce the fuel consumption required to obtain a comfortable temperature in the house, and thereby increase the efficiency of the stove. And this, in turn, will help save money.

The higher the chimney, the longer the air stays in it on the way out and the greater the temperature difference is created at the inlet and outlet of the chimney. Therefore, the thrust force in the stove with a high chimney is greater. Back draft may occur in a low chimney: combustion products in this case go straight into the house. On the other hand, an excessively high chimney can create a vortex of fire in the furnace. Therefore, the calculation of the height of the chimney is necessary.

For more information about why the draft has deteriorated, read our article - Draft in the chimney, the reasons for its deterioration and how to strengthen it with your own hands.

If the height of the chimney is insufficient, a wind pressure zone can be created in its upper part, which will cause reverse draft.

How to calculate the height of the ridge of a gable roof

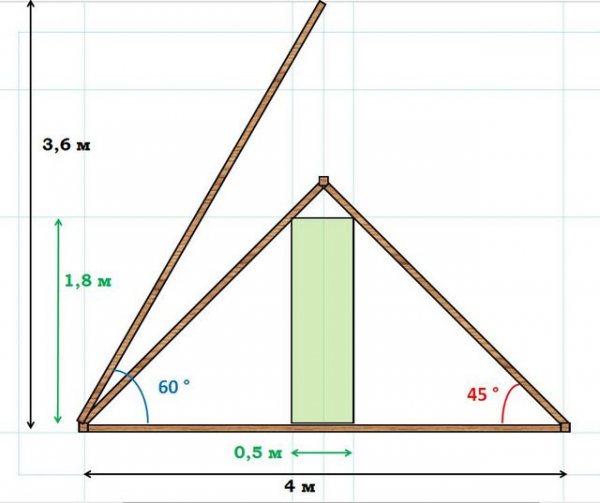

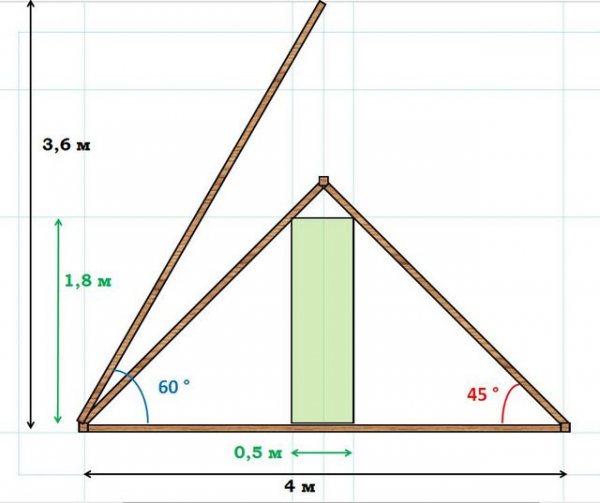

The height of the ridge of a gable roof is calculated in two ways: schematic and mathematical... The accuracy of the results obtained is approximately the same for them, since they are based on similar principles of trigonometry.

Both methods assume that the ridge height is determined from the known slope angles and the length of the roof span.

Mathematical calculation is carried out using the formula c = a × tan b, where:

- C is the length of the skate;

- a is half the length of the span;

- b is the angle of inclination of the roof.

The use of this formula is due to the fact that the construction of a gable roof is an isosceles triangle, which is divided by its height into two rectangular ones.

A schematic calculation involves the construction of a triangle with a shape similar to the shape of the roof in a strictly maintained scale. The most convenient scale for drawings is 1: 100, where 1 centimeter in graphical terms corresponds to 1 meter of real indicators.

First, you need to draw a line of the roof span, which will be the base of the triangle. Then its middle is found, the axis of symmetry is drawn from it. With the help of a protractor, the set slope angle is laid from the ends of this line. In accordance with the marked angle, you need to draw a line. The point at which it will intersect with the axis of symmetry will become the approximate location of the ridge.

NOTE!

To the obtained indicators, the thickness of the ridge board and others is added additional elements installed in the upper part of the structure.

The distance from the base to the point of intersection of the axis of symmetry with the ramp line is measured and scaled to the actual height of the ridge.

Despite the possible errors associated with the inaccuracy of the executed drawings, the graphical method allows you to get good results.

Ridge height calculation

What affects

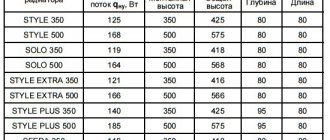

The height of the pipe and the material from which it is made have an impact on the following:

- improved traction;

- fuel combustion quality;

- the rate of heating of the channel walls.

These aspects indicate that the higher the height, the better the draft and efficiency of the heating appliances. However, not everything is so simple, since when erecting a too high chimney, the draft decreases. Smoke rises longer along a long pipe and heats its walls. The lower the smoke temperature, the greater the mass of combustion products and the worse the draft. Therefore, even with a long chimney length, there is no guarantee of a stable draft. Too high a chimney leads to the destruction of the foundation as a result of heating. The appearance of cracks affects the deterioration of traction.

Chimney types

The chimney is another functional element of a building, the location and height of which is regulated by building codes.

There are several ways to classify chimneys.

Chimneys are distinguished by location:

- wall (located inside the main walls);

- indigenous (not connected to the wall and located at a distance from it in the interior of the building);

- external (pass through the facade of the building).

The main classification method is to distinguish the types of chimneys according to the material of manufacture:

- Brick... They are distinguished by fire safety and high heat capacity, but their maintenance requires a lot of time and effort, and the draft of a brick chimney is relatively low.

- Steel single-circuit... Inexpensive and easy to maintain, but wear out quickly and require additional fire safety.

- Sandwiches... A more advanced and expensive version of single-circuit chimneys, where a layer of non-combustible material is located between the layers of steel.

- Ceramic... Fire resistant, durable, easy to install and maintain, but very expensive.

- Asbestos-cement... The cheapest variation, but its performance is at a low level: asbestos-cement chimneys quickly become clogged with soot and burn out. To avoid a house fire due to the ignition of soot, you need to constantly clean the pipes.

- Polymer... Inexpensive, but not sufficiently fireproof chimneys.

Chimney types

The nuances of choosing a chimney

When installing a chimney, keep in mind that a cylinder is the optimal shape for it. Today, metal modules are even installed in brick pipes. Modular chimneys are gradually replacing the market with all kinds of asbestos-cement and metal pipes. However, when choosing and buying them, you need to consider several points.

Often, sellers of such pipes position them as made of stainless steel. This is absolutely not a correct statement. For the manufacture of a modular chimney, corrosion-resistant steel is used. To improve its technical characteristics, alloying of materials is used. That is, an increase in certain qualities of the metal with the help of certain additives. The chimney usually needs to be heat resistant (not to be confused with heat resistance). For this, chromium is used, the only chemical element that does not oxidize when heated. This applies to solid fuel heaters.

For gas boilers, the requirements change. This is explained by the fact that when the gas burns, an acidic environment is formed, which over time will corrode any unprepared material. Chimneys for gas furnaces are produced mainly with the addition of titanium.

The main types of chimneys

Common types of chimneys:

- Brick. As a rule, an asbestos pipe is installed in a brick mine. The key disadvantage of a brick chimney is the need to install a foundation for it. In addition, this design impairs traction and also contributes to the formation of debris and condensation products. This destroys the system and makes the room damp. The advantages are high heat capacity and fire safety.

- Ceramic. The most expensive and high quality option. They are made of refractory ceramics. A layer of thermal insulation of non-combustible material is required. Pros - they do not require frequent cleaning, have smooth walls and a round cross-section (provides good traction), have high sealing and thermal insulation rates, heat-resistant, durable, easy to install. Disadvantages are the obligatory foundation and the high price.

- Modular steel. They are assembled from tees, adapters, elbows, etc. Stainless steel structures often install channels made of bricks (the aforementioned sleeve). However, you can install such a chimney separately. The stainless steel must be acid-resistant and heat-resistant so that corrosion does not appear in the chimney (wall thickness - from 0.6 to 1 mm). Galvanized steel is not suitable as zinc burns out quickly at high temperatures.Cons of steel structures - increased thermal conductivity leads to rapid cooling of gases, a large volume of condensate is formed, the service life does not exceed 15 years. Of the advantages - good traction due to the rounded shape, no separate foundation is needed, no soot accumulation occurs.

- Corrugated steel. They are a flexible pipe made of metal tape. They are used for casing curved brick structures. Easy to install, but short-lived.

- Steel sandwich structures. They are two pipes inserted into each other. The area between them is filled with a special non-combustible insulation. Cons - high cost. Pros - reduced thermal conductivity and slow cooling of gases, fast passage of smoke, minimum condensation, ease of installation.

- Asbestos-cement. Suitable if the emitted heating gases are not hotter than 300 degrees. Unsuitable for standard ovens due to poor heat resistance. Cons - fragility, lack of thermal insulation and unsatisfactory heat resistance, porosity, the need for frequent cleaning, weak rubber connection. Pros - lightness, round cross-section, low cost and easy installation.

- Polymeric. Manufactured from composite polymers. They are used for the sleeve of channels made of brick or concrete. Due to its poor heat resistance, it is not suitable for hot gases with temperatures above 250 degrees (ovens). Only for gas water heaters or boilers with increased efficiency. Cons - instability to high temperatures, fragility, lack of thermal insulation. Pros - flexibility and light weight, low cost, long service life.

We hope the material was useful to you. As you can imagine, calculating the height of the chimney is quite simple. These solutions are applied and you will always have warmth in your house.

Graphical way to determine the height

When testing this method of chimney height from the roof, you need to have basic knowledge of drawing. So, detailed instructions. To begin with, make an exact copy of your structure on a sheet of paper, with each vertex and skate drawn in full. An impromptu horizontal line should be drawn along the level of the top, 10 degrees should be “postponed” down from it with the help of a protractor. At the intersection of this axis and the chimney line, at the required angle, the exact “coordinates” of the desired point for the chimney are formed. After that, these segments must be separately determined on the dimensions of the real scale. But, nevertheless, do not forget to also focus on the norms and rules of SNiPs.

Determining the height of the chimney, the first step.

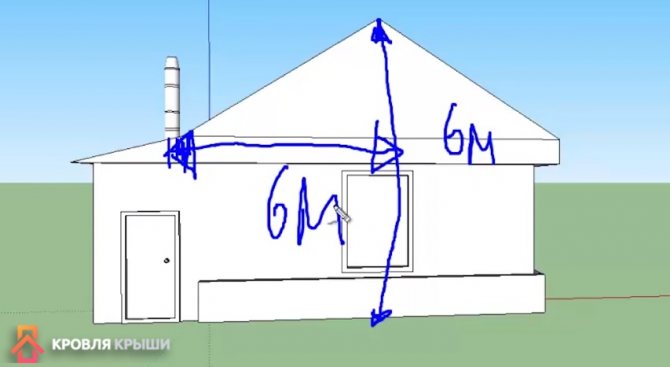

Determining the height of the chimney, step two.