Properties of mineral wool in slabs as insulation

The thickness of the insulation depends on the base

Mineral wool is a stone-based insulation that allows you to create thermal insulation for a building. Lava rocks for the manufacture of material are heated and melted. Binders are added to shape and tighten the fibers. The final product retains the properties of basalt:

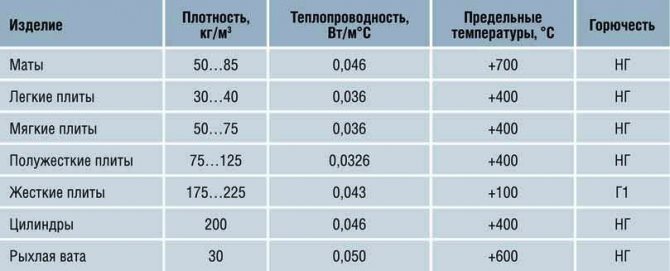

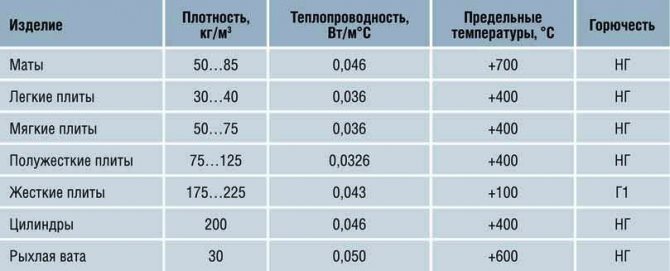

- Thermal conductivity from 0.03 to 0.04 W / m - the ability of insulation to maintain temperature. With an indicator of a mineral material with a thickness of 10 cm, 25 cm of timber, 200 cm of sand-lime brick and 117 cm of ceramic are comparable.

- Density - the indicator ensures the use of plate isolate and on average equals 60-80 kg / m3. For arranging a pitched roof, you will need light slabs of 30-50 kg / m3, for a flat one - from 100 kg / m3. For industrial purposes, models from 160 kg / m3 are used that do not deform under the influence of an external load.

- Resistance to fire class NG. Basalt fibers are non-flammable, do not spread fire, and can heat up to +750 degrees. Non-flammable modifications are heated up to 1000 degrees for 2 hours.

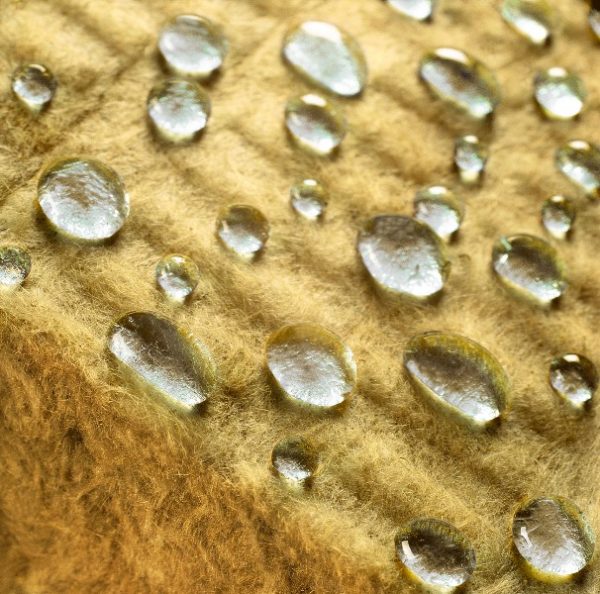

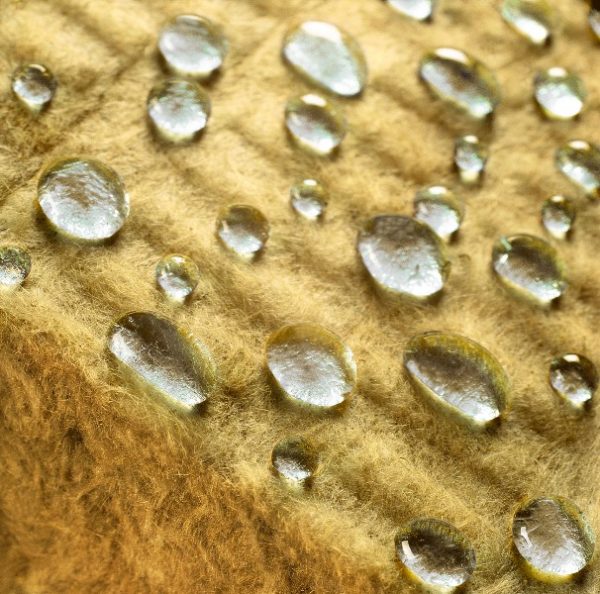

- Moisture absorption. Min plates have an indicator of 1-2%, i.e. do not absorb condensation and precipitation.

The thermal conductivity index depends on the direction of the fibers. The best option is a chaotic location.

How the purpose of mineral wool affects its size

Insulation is necessary for any building in order to:

- reduce heat loss in winter;

- protect from overheating in summer;

- preserve the elements of the supporting structure of the building from the effects of negative environmental factors;

- increase the service life of the structure.

These tasks are quite within the power of inorganic insulation. From a solid list of materials of this kind, mineral wool is in special demand. Mineral wool has long been successfully used in construction.

Related article: The thickness of the load-bearing wall of expanded clay concrete blocks

By giving preference to this type of insulation, the consumer receives the following advantages:

- thermal conductivity index 0.035 W / mk, one of the best;

- quality dielectric properties;

- high rates of vapor permeability;

- the best parameters of fire resistance;

- low hygroscopicity;

- high resistance to aggressive environments.

This material can be used for wall insulation, both inside and outside. It is used for roofs, attics and basements, and interior partitions. Its dimensions are of the same standards as the distance between the guides where the mineral wool is laid. If there are violations of standards in construction, it becomes necessary to adjust the size of the insulation.

Advantages and disadvantages

Benefits of basalt wool

Products are delivered rolled up and then cut out. Mineral wool is suitable for all types of insulation work due to the advantages:

- sound insulation - can be installed in houses next to the roadway and production halls;

- lack of cold bridges - sheets do not shrink at joints;

- special structure - the fibers are located in a chaotic direction or intertwined, which prevents the removal of warm air from the room;

- ease of installation - slabs can be easily cut with a knife or hacksaw in place;

- durability - the insulation retains its properties for 20-70 years;

- environmental friendliness - made on the basis of natural basalt rocks.

The disadvantages of miniplates include the complexity of installation due to their high vapor permeability.

general information

Mineral wool is produced according to the technology that has already become a classic. This is the use of raw materials from rocks such as basalt, which are processed under high temperature.

After remelting, the result is combined with special chemicals and stone wool fibers are obtained. Cotton wool is already created from the fibers themselves, as a full-fledged building material.

As you can imagine, this initial structure affects the properties of mineral wool. So, its thickness should be quite impressive so that the fibers can stick to each other. Also, cotton wool has a high density, does not react to many external influences, etc.

Moreover, the density of mineral wool is really high. Especially if plate heaters are taken into account. Here, the density of the board can be equal to the density of the foam. And at the same time, the thickness of the material will have little effect on its density, as well as the size. But this factor still needs to be taken into account.

This insulation is almost ideal for decorating walls and insulating walls of an apartment from the inside, since its installation is carried out using the simplest technology. If desired, it can be combined with other materials. For example, lay drywall, siding, etc. over mineral wool.

Dimensions and shape of mineral wool

Mineral wool insulation is produced in two main types or forms. Vata is found in:

- Rolls;

- Plates.

Cotton wool in rolls are long strips of mineral insulation that are rolled into a small roll. Its length in unfolded form can reach 7-10 meters, but its width rarely exceeds 1.2 m.

Mineral wool slabs

The roll thickness is 50 millimeters maximum. This size of the workpiece allows you to safely transport rolls of insulation, without spending too much space on its placement.

Cotton wool in rolls is most often used cheaper. It absorbs moisture faster, it can settle over time, and its installation on the walls is not carried out using the easiest technology. The density of the cotton wool in rolls is also, as a rule, lower than the density of the insulation in the slabs.

To fix the roll and insulation to protect the walls of the house with high quality, you will have to tinker seriously. After all, first it must be spread (and it is not so easy to do this on a vertical wall), and then also fixed. It is not possible to cope with such work alone.

And the size of the roll, or rather its length, must also be taken into account. If it has a length of more than 6 meters, then using material in this form for wall decoration will be simply unproductive (it will have to be cut additionally).

But the mineral wool in the slabs was specially created for wall decoration and other vertical structures.

The slab size is on average 1000 × 1200 mm. Its width can vary, but a length of 1200 mm is considered almost the standard.

The thickness of the slab can vary depending on its purpose. So, the thickness of the slab for floor insulation can be only 30-40 mm. But the thickness of the facade slab or insulation for thermal insulation of a flat roof can be up to 80-100 mm or even higher.

The size of the slabs of liquid thermal insulation allows them to be conveniently laid anywhere. Their installation is carried out even independently, and from the available tools you will need only a few tools.

The density of the insulation in the slabs also changes significantly. Heaters for roof slopes have an extremely low density. For this type of slab, such a parameter is a real necessity.

Slabs for walls or flat roofs, on the contrary, have an increased density. It is already possible to walk on them with the load, without fear that the mineral wool will bend or deform.

Mineral wool properties

Let's turn directly to the properties of mineral wool, for which it is so appreciated in the construction industry. And by the way, she has just a huge amount of positive properties.

How to choose the right insulation?

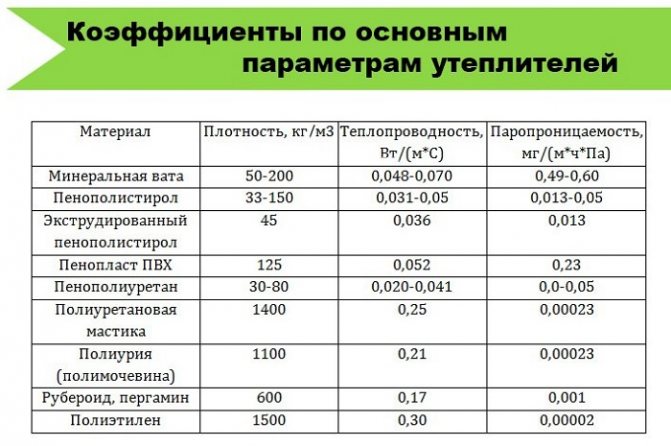

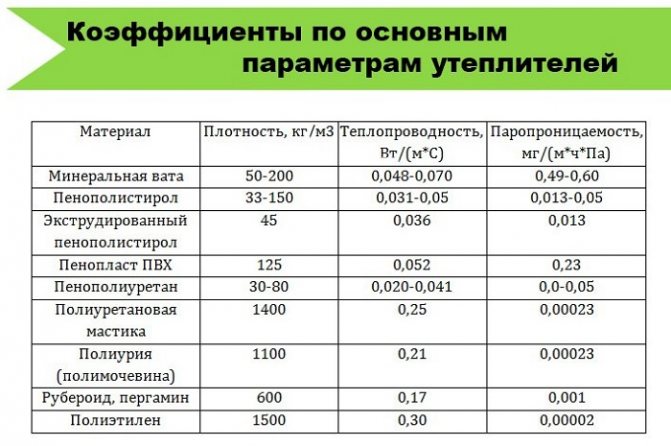

When choosing a heater, you need to pay attention to: affordability, scope, expert opinion and technical characteristics, which are the most important criterion.

Basic requirements for thermal insulation materials:

- Thermal conductivity.

Thermal conductivity refers to the ability of a material to transfer heat. This property is characterized by the coefficient of thermal conductivity, on the basis of which the required thickness of the insulation is taken. Thermal insulation material with low thermal conductivity is the best choice.

Also, thermal conductivity is closely related to the concepts of density and thickness of the insulation, therefore, when choosing, it is necessary to pay attention to these factors. The thermal conductivity of the same material can vary with density.

Under density understand the mass of one cubic meter of thermal insulation material. By density, materials are divided into: especially light, light, medium, dense (hard). Lightweight materials include porous materials suitable for insulating walls, partitions, and ceilings. Dense insulation is better suited for outside insulation.

The lower the density of the insulation, the less weight, and the higher the thermal conductivity. This is an indicator of the quality of the insulation. And the low weight contributes to the ease of installation and laying. In the course of experimental research, it was found that a heater with a density from 8 to 35 kg / m³ it retains heat best and is suitable for insulating vertical structures indoors.

How does thermal conductivity depend? from thickness? There is a misconception that thick insulation will better retain heat indoors. This leads to unnecessary costs. Too large a thickness of the insulation can lead to a violation of natural ventilation and the room will be too stuffy.

Why are mineral wool sizes needed?

Mineral insulation has a lot of advantages, which makes it possible to choose it as the main material for the installation of a heat-insulating system. To accurately calculate the required amount of material, you should know the dimensions of the mineral wool slabs that you decided to use in your work. If, when buying a heat-insulating material, it is necessary to take into account the cubic capacity, then in a number of works it is necessary to take into account the dimensions of the mineral wool.

In what cases are the dimensions of mineral wool taken into account?

When installing a heat-insulating system with the creation of a frame, pre-specified dimensions of mineral wool slabs, which are optimal for thermal protection in a given region, allow preparatory work to be carried out in advance, which makes it possible to reduce the time for creating thermal protection. These can be works:

- for floor insulation, since the insulation plates should be tightly laid between the logs;

- when insulating the attic, since the size of the mineral wool affects the size of the cells or the step of the lags, between which the insulation is tightly packed.

For outdoor work, a frame can also be pre-created, into which plates of heat-insulating material are then carefully inserted between the profiles or wooden slats.

Needless to say, the high performance characteristics of mineral slabs, their elasticity and appropriate density, allow, if necessary, to cut off a piece in order to neatly put it in the right place. But do not do this during the entire installation process. Yes, and unnecessary joints - no one needs.

What sizes are mineral wool slabs?

It is generally accepted that the standard sizes of mineral wool, which are the most popular with buyers, are 1000 mm x 500 mm.Since the choice of the thickness of the insulation depends on the insulated structural element and the region of residence - it is determined in each specific case. The thickness of the insulating material can, however, affect its dimensions, since plates with a thickness of 150-200 mm are also available in larger widths - up to 600 mm.

In principle, each manufacturer produces its own products, the sizes of which may differ from the usual ones. For example, Isover suggests:

- the size of the Isover P-32 frame is 1170 by 610 mm (the thickness varies from 40 to 150 mm);

- Isover frame P-34, the thickness of which varies from 40 to 200 mm, has dimensions of 1170 by 610 or 565 mm;

- the slab used for the "floating floor" system, with a thorn-groove edge, with a thickness of 20 to 50 mm, has already other dimensions - 1380 by 1190 mm;

- Isover rigid slab for a flat roof, 30 mm thick, has dimensions 1550 by 1180 mm.

Pros and cons

Now we can create a complete list of pros and cons to structure the knowledge presented.

Exterior decoration of the facade of the house with mineral wool slabs

Main advantages:

- High density;

- The ability to mount in a short time;

- Non-flammability;

- Hydrophobicity;

- Environmental friendliness as when insulating a hangar using polyurethane foam;

- It is not gnawed by rodents, insects, etc .;

- Water vapor permeability.

We have already noted the main disadvantages - this is a high price. You will also have to pay more for the installation of mineral wool. The installation process, although simple, is quite laborious in terms of mechanical work.

Differences between mineral wool

As we have already said, there are three types of mineral wool insulation. Each of them is made from different raw materials and has its own properties.

Glass wool

A material consisting of molten glass broken, dolomite, sand, soda, or limestone.

Benefits:

- Air permeability.

- Fire resistance.

- Elasticity, vibration resistance.

- Withstands low temperatures.

- Lower cost than other mineral wool.

Minuses:

- Short shelf life - 5-10 years.

- Shrinkage 80%.

- Strongly absorbs moisture.

- Causes itching or even an allergic reaction on contact with the skin.

As for the scope of application, usually it is mineral wool for insulating walls inside the house.

Slag

Produced from metallurgical waste. It is inferior in characteristics to other types of insulation.

- Does not provide adequate sound insulation.

- Cannot withstand strong heat. Does not burn, but cakes and loses its thermal insulation qualities.

- Does not tolerate temperature extremes.

- Protective clothing and a respirator are also required for mounting.

- Do not insulate damp rooms with metal fasteners, since under the influence of humid air, slags will contribute to corrosion.

- High hygroscopicity.

Related article: The warmest insulation for walls

Plus - such a layer in the wall does not attract rodents and insects. Most often used on dry surfaces of temporary buildings or non-residential buildings.

Stone

Most expensive material. It is he who is usually chosen for outdoor work in private, including frame wooden houses. The production uses rocks. Thanks to this, the final product has a lot of advantages:

- High density, and hence strength.

- Fire resistance. Does not ignite at any temperature.

- Minimum shrinkage (5%).

- Long service life (up to 50 years).

- Provides excellent sound insulation.

- Almost does not break in the process of work, which happens with other types of products.

- Water vapor permeability. The fibers repel moisture.

The downside is the high cost. Despite all the advantages, it is not always rational to insulate with these particular plates.

Types depending on the material of manufacture

The 3 options for thermal insulation plates made of mineral wool are related to - glass wool, stone and slag wool.

These varieties have a specific width of mineral wool, fiber length and technological parameters that establish their popularity in a particular area.

Slag

Slag wool is produced from electrode blast furnace slag, has a fiber size from 4 to 12 microns and a length of 16 mm. Thermal conductivity is 0.48 W / mK with increased hygroscopicity. Mineral wool dimensions - 500 × 1000X50 mm. This modification is hydrophobic and more than others has a predisposition to moisture, which does not make it possible to use it on external roofing insulation, and its low level of fire safety excludes its use in attic rooms.

Another disadvantage is that the fibers are rather brittle, and it is possible to work with such material only with gloves. Despite all this, given the good flexibility and uniform thickness, it is quite convenient to work with such a material. In addition, the slag is not heavy, even a decent amount of mats does not form a load on the roofing system. It has a very light structural structure, thermal conductivity 0.048 W / mK.

Due to its own texture, it has a high vapor permeability and hygroscopicity, and therefore, with this type, it is necessary to use waterproofing.

Glass wool

Glass wool - refers to budget building materials for thermal insulation. At the same time, it has a very good density and elasticity, with a thermal conductivity coefficient of 0.050 W / mK. It is made from the same consumable material as ordinary glass - sand, soda, dolomite and limestone. Fiber size up to 15 microns. The dimensions of the mineral wool insulation in the slabs are 1250X600X50 mm.

The permissible temperature regime is + 450C. The main advantage is the relatively low price. The disadvantages are low performance and a high risk for the respiratory organs of humans and the skin, which makes it necessary to quickly perform insulation work, with dense protection of the laid layer with surface material, while the employee must use special clothing, respirators and goggles when working.

Main categories

Insulation for walls is divided into 2 groups:

- For internal insulation.

- For external insulation.

These categories differ from each other only in the ability to pass steam or retain it. Mineral wool, packaged in slabs, mats, rolls, is easy to use, easy to cut and fills in the most inaccessible corners, leaving virtually no waste after cutting.

TechnoNIKOL

- Technofas. It is produced in the form of a slab with a size of 600 * 1200 * 50/100 with a density of 145 kg per 1 m3.

- Technoven Standard. Plate. Dimensions 600 * 1200 * 50/100, density 80.

Knauf

- Insulation FKD. Slab (600 * 1200 * 20-160, density 140-150.

- Insulation FKL, plate. 200 * 1000 * 20-200, density 85.

- Insulation FKD-S, slab 600 * 1200 * 60-180, density 140-160.

- Insulation HTB, plate 1000 * 500 * 20-180, density 35-150.

Rockwool

- Fasrock, roll 1000 * 600 * 100, density 135.

- Wentirock max, roll 1000 * 600 * 50, density 50-90.

- Panelrock, plate 1000 * 600 * 50-100, density 65.

ATTENTION! The fine-fiber structure of mineral wool contains formaldehyde, therefore it belongs to carcinogenic building materials. For safe installation, it is necessary to have special protection for the worker performing the insulation or insulation. To prevent scattering of fibers throughout the room, the pressed plates should be protected with membranes. And only after that start finishing work.

Recommendations for the thickness and density of mineral wool

Taking into account the climatic characteristics of the region is of decisive importance when choosing the size of the insulation. For the outer walls of houses located in areas of a temperate continental climate (Moscow, Leningrad, Volgograd and other regions), it is recommended to choose slabs with a thickness of 80-100 mm. With the remoteness of the region from this area (continental, sharply continental, monsoon, maritime climate; subarctic, arctic belts), the thickness increases by about 10%. For example, for the Murmansk region, it is advisable to take mineral wool with a thickness of 150 mm on the outer walls, and for Tobolsk the correct range will be from 90 to 110 mm.

Insulation with a density of up to 40 kg / cu.m is used only in unloaded horizontal surfaces, so it is better to ignore them. Such cotton wool is produced in rolls, rolled out on sheathed interfloor partitions, floors, etc. For insulation of external walls of non-residential or industrial premises, the indicator varies from 50 to 75 kg / cu. m. If the user makes a ventilated facade, the slabs should be even denser - up to 110 kg / cu. m. Otherwise, the indicator can reach 130-140 kg / cu. m, but on condition that later the walls will be plastered. The first option implies the subsequent finishing with siding or a similar method of finishing work in order to extend the service life.

Structures insulated with basalt slabs

The use of basalt wool is quite wide. Manufacturers produce basalt wool for insulating various surfaces. Consider the brands, sizes and density of basalt wool from leading manufacturers for insulating facades, walls, partitions, floors and roofs.

Thermal insulation of facades with basalt wool

Stone mineral wool is used to insulate facades. This can be a layer of thermal insulation for "wet" and ventilated facades. Thermal insulation of facades with cotton wool is the most popular among the options for insulating modern buildings for any purpose. This option of thermal insulation serves for a very long time - more than 40 years.

Manufacturer Brand Type Dimensions, mm Density, kg / m3

| TechnoNicol | TECHNOFAS | plate | 600×1200, 50 (100) | 145 |

| TECHNOVENT STANDARD | 600×1200, 50 (100) | 80 | ||

| Knauf | Insulation FKD | plate | 600×1200, 20-160 | 140-150 |

| Insulation FKD-S | plate | 600×1200, 60-180 | 140-160 | |

| Insulation FKL | plate | 200×1000, 20-200 | 85 | |

| Insulation HTB | plate | 1000×500, 20-180 | 35-150 | |

| Rockwool | Fasrock | roll | 1000 × 600X100 | 135 |

| Panelrock | plate | 1000x600x50-100 | 65 | |

| Wentirock max | roll | 1000x600x50 | 50-90 |

Popular materials of the TechnoNikol company: TECHNOFAS and TECHNOVENT STANDARD; Rockwool companies: Fasrock, Wentirock max and Panelrock; and Knauf companies: Insulation FKD, Insulation HTB and others.

Basalt wool for insulating partitions and walls

Manufacturer Brand Type Dimensions, mm Density, kg / m3

| TechnoNicol | Mat TechnoNICOL ordinary | roll | 1000x4000, 50 (100) | up to 30 |

| ROCKLIGHT | plate | 600×1200, 50 (100) | 30 | |

| TECHNOLIGHT EXTRA | plate | 600×1200, 50 (100) | 30 | |

| TECHNOLIGHT OPTIMA | plate | 600×1200, 50 (100) | 35 | |

| TECHNOBLOCK STANDARD | plate | 600×1200, 50 (100) | 45 | |

| Knauf | Insulation LMF Alur | roll | 1000×2500, 20-100 | 35-90 |

| Rockwool | Domrock | roll | 4750×1000, 200 | 20 |

| Superrock | roll | 1000x600x50 | 35 |

Basalt wool slabs are used for internal and external wall insulation. The material provides good thermal protection of the room from the inside, in addition, it provides excellent sound insulation. Mineral wool slabs are suitable for noise insulation of interior partitions in offices and living quarters. But given the fact that low density basalt wool is used for these purposes, it is more rational to use the material in rolls. This simplifies installation work. For example, the manufacturer Knauf produces Insulation LMF Alur mats for insulating partitions, while Rockwool produces Domrock and Superrock rolls.

Thermal insulation of floors with basalt wool

Manufacturer Brand Type Dimensions, mm Density, kg / m3

| TechnoNicol | ROCKLIGHT | plate | 600×1200, 50 (100) | 30 |

| Teploroll | roll | 4000Х1000, 50 (100) | 30 | |

| Knauf | Insulation LMF Alur | roll | 1000×2500, 20-100 | 35-90 |

| Insulation PVT | plate | 600×1000, 20-120 | 175 | |

| Rockwool | Rockmin plus | plate | 1000x600x50 | 31 |

| Rockton | plate | 1000x600x50-120 | 50 | |

| Superrock | roll | 1000x600x50 | 35 |

Basalt wool is an irreplaceable material for thermal insulation of floors. Basalt insulation slabs are used for flooring. They are distinguished by high rigidity, perform the functions of sound and heat insulation. The material is placed under slabs, joists and under the screed. In addition, basalt wool slabs are used in such a popular system as "floating floor".

Thermal insulation of flat and pitched roofs with basalt wool

Stone wool in the form of slabs is widely used for roof insulation. On the modern construction market there are special boards used exclusively for thermal insulation of roofs.

Manufacturer Brand Type Dimensions, mm Density, kg / m3

| TechnoNicol | ROCKLIGHT | plate | 600×1200, 50 (100) | 30 |

| TECHNOLIGHT EXTRA | plate | 600×1200, 50 (100) | 30 | |

| TECHNOLIGHT OPTIMA | plate | 600×1200, 50 (100) | 35 | |

| TECHNOBLOCK STANDARD | plate | 600×1200, 50 (100) | 45 | |

| Knauf | Insulation DDP | plate | 600×1200, 20-180 | 150-200 |

| Insulation DDP-K | plate | 600×1200, 40-160 | 105-110 | |

| Rockwool | Dachrock max | plate | 2000×1200, 40-200 | 130-210 |

| Domrock | roll | 4750×1000, 200 | 20 | |

| Megarock | roll | 3000 (6000) x1000x200 (100) | 28 | |

| Monrock | plate | 2000x1200x50-200 | 115-200 | |

| Rockmin plus | plate | 1000x600x50 | 31 | |

| Rockton | plate | 1000x600x50-120 | 50 | |

| Superrock | roll | 1000x600x50 | 35 |

Features of mineral wool for insulation

Modern construction cannot be imagined without the use of mineral wool as an insulating material.It has a wide range of uses, which makes it particularly popular with builders. The most common use of mineral wool is to insulate building structures.

Manufacturers produce products of different types and purposes: plates, mats, rolls, cylinders

Usually, roofs, floors, walls and ceilings are insulated with mineral wool: the size of the materials depends on the area of the room and the type of insulation.

Mineral wool is often used to lay the middle layer. At the same time, loads on the insulation of various types of surfaces in any buildings, houses and structures are avoided. Vertical laying of mineral wool is used to insulate facades and walls. The inclined and horizontal laying method is chosen for insulation of the ceiling, roof and roof.

What is mineral wool used for:

- For equipping ventilated façade systems and for installation in curtain walls.

- Mineral wool is used to insulate building sandwiches of panels and blocks, which are used to build multi-layer walls with different types of cladding. They can be metal, concrete, particle board, fiberboard and OSB.

- To insulate various industrial structures, equipment and pipelines.

Related article: Insulation for the walls of the house outside for siding

Modern manufacturers offer consumers different types of general construction insulation. Cotton wool can be presented as a lightweight heat and sound insulating material that does not have a coating. Another option is cotton wool with one-way caching using aluminum foil. Cotton wool can be equipped with special sound-absorbing material.

Other important markings

In order to understand in what form the insulation will be presented, you should consider additional markings on the packaging. Namely:

- P-75. The number means density, the less dense the mineral wool, the more convenient it is to roll it up. This is exactly the case. Such types are used for walls that will not take on the bearing load.

- P-125. These are already slabs, they are used for the ceiling, floor. She has increased sound insulation properties.

- PPZh-175. In addition to the fact that the density of this stone wool is 175 kg / m³, it also has increased rigidity, as evidenced by the marking "Zh".

- PPZh-200. The densest mineral wool, which is also fire resistant.

Mats are comfortable to use on the floor

Tips from experts

Finding out the dimensions of stone wool is often necessary in order to calculate how much material is required for insulation. Do not think that it is too easy, often buy too much or, worse, too little material. In order not to make mistakes in calculating the quantity, you need to take into account the following points:

- Almost every package indicates how much area one "portion" of mineral wool can cover. It is this information that will help determine how many packages are needed.

- Do not forget that stone and any other mineral wool has such properties as shrinkage - it is better to buy it with surplus. Therefore, about 15% should be added to the results obtained. This will help prevent gaps from forming.

- In order for the consumption of insulation and waste from it to be minimal, it is necessary to calculate the optimal distance at the stage of construction or installation of the lathing, often it is 50-60 cm.

- It is imperative to double-check the size of the roll or sheet of insulation, since they may differ even from one manufacturer. As well as the area of the roll.

In general, to calculate the required amount of stone wool you need:

- Determine the area to be insulated. To do this, multiply the length by the width. If the area is not a standard shape, then it must be divided into component parts.

- Determination of the perimeter of the house if everything is insulated - walls, ceilings, floors. Multiply the perimeter by the height and by the number of floors, if there are several.

- If you also need to insulate the roof, then calculate its area.

- It remains to add up the dimensions obtained and do not forget to add about 15% to trim the seal.

Important! Manufacturers do not take the dimensions of rolls and mats from the ceiling, they are due to building codes that help standardize the process of building insulation of houses.

Mineral wool can be of different thickness from the same manufacturer

Insulation classification by density level

Usually everyone remembers the physics of the school and associates the density of the insulation with weight, mass.

The heavier - the better, but this does not always follow, based on what factors and what operating conditions.

The choice of insulation directly depends on the budget, no matter how paradoxical it sounds, and of course the load on the structure as a whole or on a certain element.

According to the density of the material, the following classification is distinguished:

Extra light

These include polystyrene (expanded polystyrene), which has a porous structure.

Designed for insulation in the cavity of walls, partitions, for unloaded elements of the house.

Lungs

These are mineral wool based heaters. They have a low coefficient of thermal conductivity. It is widely used in the construction of private houses and cottages.

Average

These types usually include foam glass. It is in the form of blocks and slabs, with high heat-insulating and noise-insulating properties. It is not widely used in Russia.

Thick or hard

They also include rock wool, densely pressed under high pressure. This type of insulation is used for outdoor work, it is resistant to moisture and mechanical stress.

What kind of wool is better to choose for thermal insulation of the roof, floor and walls

The most important thing in the selection of building materials is the thickness of the slabs. It depends on the following conditions:

- Dew point position;

- atmospheric climatic region of the location;

- roofing system design;

- the ability to withstand the load;

- thermal conductivity of a variety of insulating material;

- the form in which it is manufactured.

Additional Information! The width of the roofing slabs is available in a variety of modifications. In order to get away from difficult types of calculations, it is better to choose the insulation parameters that are recommended for different climatic regions. So, for example, in the southern regions, mineral wool sizes vary in the range from 120 to 180 mm, then in the central regions - 180-240 mm, and in the northern regions up to 360 mm with an average heat resistance of a heat insulator - 0.04 W / mK.

Mounting errors of mineral wool boards

- Lack of surface preparation. It should be flat, clean and treated with an antiseptic (if it is a tree).

- Carrying out work during precipitation or leaving finished work without rain protection.

- Insufficient adhesive application. Correct when it is distributed over the entire surface, including the perimeter. The most suitable adhesive is polyurethane foam or dry mix. The first products are easier and faster to work with, but slightly more expensive. Both products are resistant to external influences and guarantee good adhesion.

- Unfilled seams between insulation parts. They can only be closed with inserts of the same material. The maximum clearance is 2 mm.

- Intersection of slabs in window and door corners. There should be no joint in these places.

- Lack of mechanical fasteners. Anchors and dowels are used as additional connections for heavy sheets. The optimal amount is 3-4 pieces per piece (two at the corners, 1 or 2 in the center).

- Smooth mounting, joint to joint. Masters advise to install the elements in a checkerboard pattern - this way it is easier to avoid cracks in the structure.

These are the main mistakes people make when doing thermal insulation at home on their own.

The use of cotton wool of different densities for insulation

The choice of insulation according to the indicator in question depends on the place of its use.You don't always need to overpay in order to get the desired result. Most often, the facade, walls, roof and floor are insulated. These are the options that are worth considering.

Regardless of the density, the material must be protected from moisture

Facade

When choosing insulation for the facade, you need to pay attention to the mass and density of mineral wool. For most buildings, weighting is very undesirable. It is also worth paying attention to the possibility of subsequent finishing, because the indicator in question also affects this. So:

- If the facade is equipped with a ventilated one, then the sufficient density is 45-100 kg m³. Here, cotton wool is laid in the crate and will practically not experience any load. The main tasks for this type are to maintain shape and not sag under their own weight, and the specified indicator is sufficient for this.

- If the facade will be plastered over the insulation, then the compaction should be above 100 kg m³, optimally from 145 to 165. This will allow the use of any types of plaster mixes, including bark beetle, barenko and even mosaics. Since this mineral wool will have to withstand heavy loads during installation, it must be securely fastened for this, a system with dowels is used in combination with an adhesive fastening.

Wall insulation

In this case, the selection is carried out for ease of installation, that is, the density should be at least 30-45 kg m ³. In this case, you need to insulate from the inside, MDF or drywall plates should be screwed onto the material from above. In order to mount such a mineral wool, a crate is needed, rolls or sheets are laid in it.

Roof

Since the roof insulation works are carried out at a height, the main criteria for the selection of mineral wool are light weight and ease of use. These qualities can please the material with a density of 30-35 kg m³. Its sound and thermal insulation properties will be excellent, and at the same time it is light in weight. Installation can be carried out in two ways:

- With a construction stapler.

- In a crate with a vapor barrier closure.