Basalt wool is considered one of the highest quality and widely used heat insulators today.

Made from natural materials, it is safe for residential use. It can be found when decorating a house, in the process of building buildings for various purposes. No less widely, this building material is used in the construction of private houses, as well as in the thermal insulation of air ducts.

The use of basalt wool is in demand to provide thermal insulation of industrial equipment (boilers, boilers, furnaces), process pipelines and pipelines of heating networks. Basalt slabs can be used as unloaded sound and heat insulation in a horizontal enclosing structure of any type of building and structure. In addition, basalt insulation is used for thermal insulation, which is subjected to loads in horizontal, inclined and vertical building envelopes and other types of structures.

Thermal insulation of the roof with basalt wool

Insulation of roofs with basalt wool is a very common use of the material.

Today, special basalt slabs are on sale for roof insulation. The main advantages of such insulation are the incombustibility of the insulation, high soundproofing, good thermal insulation performance and ease of installation. Such material is produced in the form of plates, cylinders, mats, there is also foil insulation.

Thermal insulation of facades

Basalt insulation is an optimal material for insulation with a set of characteristics that can solve many problems of thermal insulation in any type of structure: from an ordinary residential building to a large enterprise. This building material is resistant to fire, moisture, low temperatures.

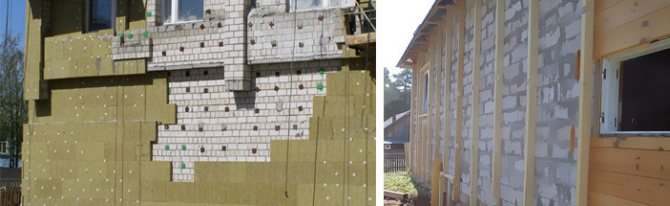

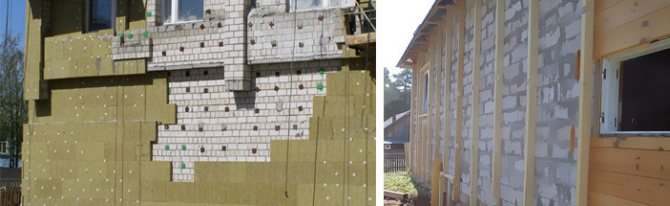

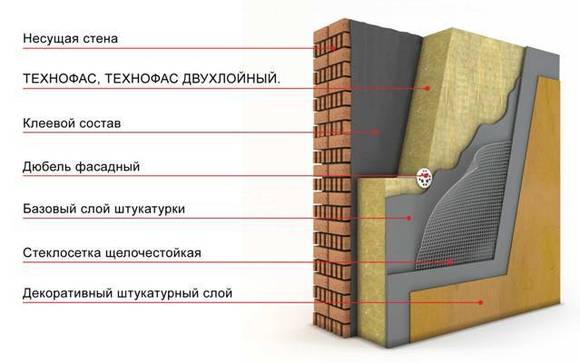

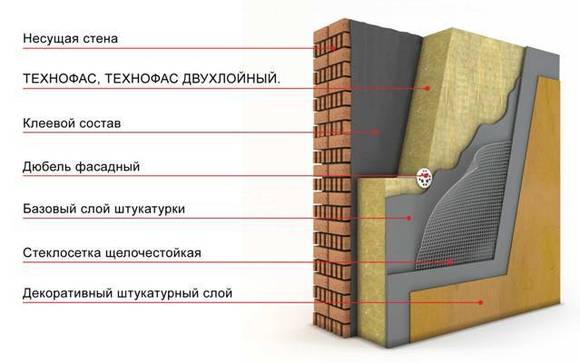

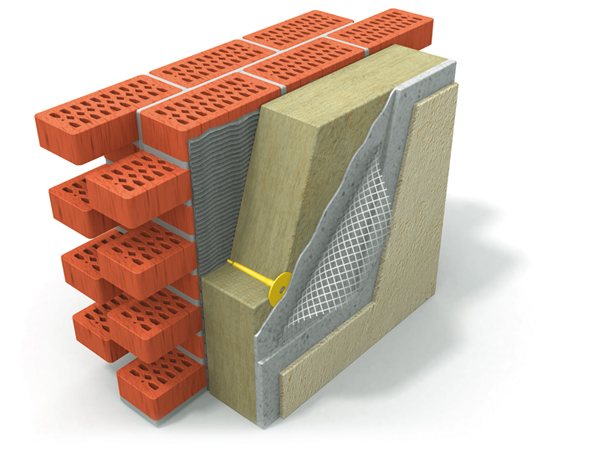

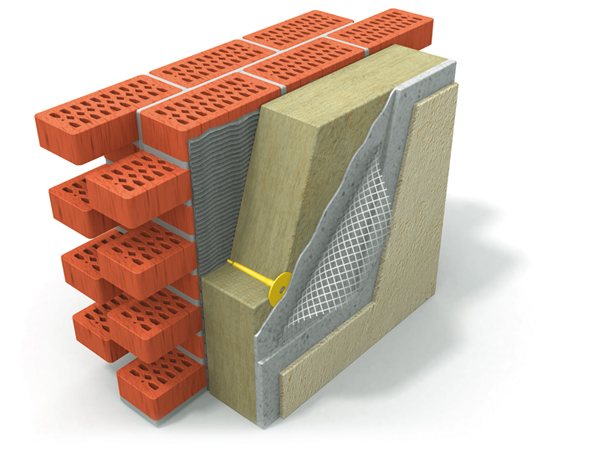

Since basalt slabs are characterized by high strength and resistance to weathering, they are the best option for external insulation systems, the so-called thermal insulation of facades. Very often this type of insulation is used with the "wet" facade technology, where the building material does an excellent job with its main function - thermal insulation.

When insulating with basalt slabs, quartz soil, paint on a silicate or silicone base, decorative plaster are used. Silicone based paints allow facades to breathe.

For insulation, it is recommended to use a high density insulation of 90-135 kg per cubic meter. m. The use of building materials with a lower density is not recommended, as this can lead to slipping of the basalt insulation.

Unlike polystyrene, when installing basalt wool, a fastening such as an umbrella with a metal nail is used. This is due to the large weight of the material, which requires reliable fastening. Thermal insulation of facades with basalt wool is a laborious process and requires responsibility.

What are the features of stone wool?

According to the type of raw material, thermal insulation materials are divided into two large groups: inorganic (based on basalt stones, fiberglass, asbestos, etc.) and organic (fiber boards, foam and foam plastics, peat plates, etc.).We will talk about stone wool heaters, which are made from natural materials and are used without restrictions in the construction of a wide variety of structures - from high-rise buildings to small private houses.

The process of producing stone wool begins with the melting of volcanic rocks (basalt, porphyrite, diabase) at a temperature of 1500 ° C. Then the plastic mass, practically "lava", is fed into the centrifuge.

EVERYTHING YOU NEED FOR THIS ARTICLE IS HERE >>>

where, under the influence of a powerful air flow, thin fibers are formed from it. A small amount of a binder (2-4% of the total mass) is added to them to maintain the shape of the plates, a water repellant to repel moisture. Then they set a chaotic direction to the fibers, create a structure of the required density and send them to the polymerization chamber. Here, at a temperature of about 200 ° C, the binder is cured and finally plates or mats are formed, which are subsequently cut into products of a certain size and packed in polyethylene.

Stone wool insulation is manufactured by many companies, including the most popular on the domestic market: TechnoNIKOL, Izoroc, Izover, Izovol. Paroc. Rockwool.

Reference by topic: Insulation of a private house from the outside - from the foundation to the roof

Insulation of internal walls

Wall insulation with basalt wool can also be performed from the inside of the building, where the building material demonstrates excellent thermal insulation properties. In addition, the insulation also performs the function of sound insulation.

Very often, mineral slabs can be found in the internal partitions of offices and apartments, where they are used to provide sound insulation. Vata absorbs sound very well. However, to isolate airborne noise, it is better to use looser slabs with a low density, and for shock noise it is advisable to use rigid and semi-rigid slabs and mats.

Important properties of stone wool

The main characteristic of thermal insulation is the value of the thermal conductivity coefficient. For stone wool materials, this parameter ranges from 0.035 to 0.045 W / (m • K), which makes them very effective.

The key to the durability of stone wool is the natural properties of natural stone and components that ensure the strength of the bonding of the fibers, the homogeneity of the structure. And the finest fibers forming the material, located chaotically, in horizontal and vertical directions, at different angles and tightly woven with each other, give the necessary rigidity and stable shape. Therefore, cotton wool does not deform and does not shrink for a long time.

Due to the open porous structure (the fibers are intertwined with each other in different directions and form a multitude of communicating smallest cavities), stone wool insulation absorbs air and impact noise well, reduces vibrations. Therefore, it is used in acoustic ceiling systems, when arranging interior partitions, ceilings and floors.

Stone wool does not burn, because, you see, it is impossible to set fire to a stone. Fibers from this natural material can withstand temperatures up to 1000 ° C, protecting building structures from fire and preventing their destruction. In case of fire, the insulation does not emit heat and smoke, and does not turn into burning droplets. In addition, it prevents the spread of fire, so in the event of a fire in the room, there is more time to save people and property.

Products of well-known manufacturers comply with sanitary and epidemiological standards and do not harm human health and the environment. Quality materials have all the necessary certificates confirming their safety.

When choosing stone wool insulation, one should take into account its properties, scope, type of insulated structure and operating conditions.Any material will be effective only if used correctly, and then the house will be warm in winter and cool in summer. In addition to creating a comfortable indoor climate, insulation will reduce heating costs, reduce operating costs, and increase the service life of load-bearing structures; also thanks to it it will be possible to purchase boilers and air conditioners of lower power. Stone wool insulation is used in all types of buildings; on pitched and flat roofs; when insulating attic, interfloor and basement ceilings; walls of residential buildings, baths and saunas, both outside and inside; when erecting frame structures and interior partitions; arrangement of floors with screed, floor slabs or logs.

Insulation of a frame house

Warming a frame house with basalt wool is one of the most popular ways to keep warm. After all, the most important requirement of wooden housing construction is fire safety. In addition to the fact that basalt fiber insulation belongs to the class of non-combustible building materials, it is an excellent means of protecting against fire.

When erecting frame buildings, great attention is paid to the use of thermal insulation as thermal protection of the structure. Most often, thermal insulation is used from the outside.

However, such insulation is also applied from the inside. The method of insulation from the inside is considered less advantageous from a constructive point of view. This opinion is due to the fact that with this method, conditions are created inside the building for the formation of condensate in the inner part of the structure, the presence of which over time leads to a reduction in the operational life of the erected building.

When building frame houses, special attention should be paid to the steam and waterproofing of the walls.

The penetration of moisture into the framework is unacceptable. It is necessary to reliably protect the insulation from external adverse environmental influences, such as: the formation of condensation due to an insufficient level of vapor barrier, as well as the penetration of warm air from the heated room, increased humidification as a result of moisture penetration through the outer skin of the building. Capillary suction of ground water brings no less harm.

Rigid mats and slabs are used for protection. Due to the fact that there is no ventilation gap in the structures, there is no need to use foil mats and plates.

Basalt wool is a time-tested thermal insulation, but it is very important that when insulating frame houses, the width of the slabs used should exceed the distance between the inside of the frame by 2 cm. This will reliably fix the used material.

The main advantage of basalt wool, in comparison with fiberglass, is its high density, which allows the building material to withstand heavy loads.

Basalt insulation is very popular in the construction of industrial, commercial and private buildings. Such popularity of this material among specialists and ordinary people is explained by the fact that this material is characterized by a number of unique properties, among which the following attracts attention:

Fire safety. The material is non-flammable and able to resist the spread of fire.

Even under the influence of high temperatures, it does not release substances harmful to the human body; Moisture resistance. The material is not hygroscopic. Even without additional waterproofing, it prevents the accumulation of moisture; Frost resistance.

The listed characteristics make it possible to widely use this material for facade insulation. This article will consider the options for using basalt wool and basalt slabs. In particular:

How to choose for insulation: rules

Buying insulation, everyone hopes that the material will serve for a long time and fulfill its functions of keeping warm.

But this is not always the case.

Therefore, it is important to understand that it is not always necessary to blame the builders for the negative final result.

The reason may be incorrectly selected mineral wool in terms of size or technical performance.

So that the installation of insulation does not become a waste of time and money, you should familiarize yourself with the recommendations of specialists regarding the material.

Thickness and density

Mineral wool has a different density level from 30 - 220 kg / m3. The higher the density, the more likely the material will be able to withstand deformation under its own weight.

The density is determined by the mass per 1 m3 of wool. When purchasing rolls, it is important to take into account the characteristics of the room where the material will be used.

Material density:

- P - 75, used for insulation of all types of buildings;

- P - 125, used for frame-type buildings, lightweight low-rise buildings;

- P - 175, suitable for metal surfaces;

- PPZh - 200, material of increased rigidity, with a high level of density, fire retardant, used for profiled flooring.

For outdoor work, a suitable option would be cotton wool with a density of 125 kg / m3. For interior partitions, an indicator of 75 kg / m3 is sufficient.

Dimensions (edit)

Sheet wool is made in rolls, then cut into separate sheets according to certain sizes.

They are indicated on the packaging, but depending on the manufacturer, they can be different. There are also different numbers of plates. The designation is performed in the following form: 1000x500x50mm.

Common sizes are:

- length from 1 to 2 m;

- width from 0.5 to 1 m;

- thickness from 5 cm to 1m.

Rolled cotton wool is slightly cheaper than sheet wool at a cost and is produced, depending on the manufacturer, in the following dimensions:

- width - 1 m 20 cm;

- thickness: 5 cm;

- length from 7 m to 12.5 m.

If it is necessary to carry out insulation with a thickness of more than 5 cm, then double installation should be performed.

Refractory properties

Refractory wool is made from similar components as other types, but compounds obtained from rocks (clay, dolomite) are used as a binder. Withstands material up to 1000 ° C without losing its original shape.

The content of formaldehyde resin in the composition is minimized, since it ignites quickly when the flame is open. Therefore, this type of wool does not burn when exposed to high temperatures, but melts. This is also due to the constituent components of clay and sand. Inside the room, fireproof wool prevents the spread of fire further.

Other selection options

Since each type of mineral wool has its own characteristics, buyers need to pay attention when choosing some important points:

- regardless of the manufacturer, the material must comply with GOST;

- make sure the purpose of the selected type of insulation;

- foil wool will help to avoid heat loss;

- so that it copes with the basic functions;

- mineral wool with randomly located fibers is able to withstand heavy loads;

- wet cotton wool will lose its properties even when it dries;

- packaging must be intact and original;

- the date of manufacture is not worth paying attention to, it does not matter.

Facade insulation technology with basalt wool

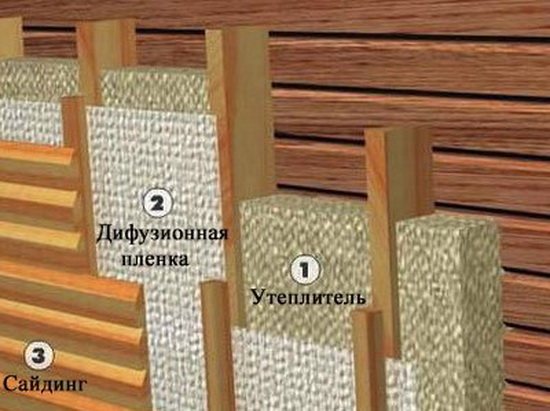

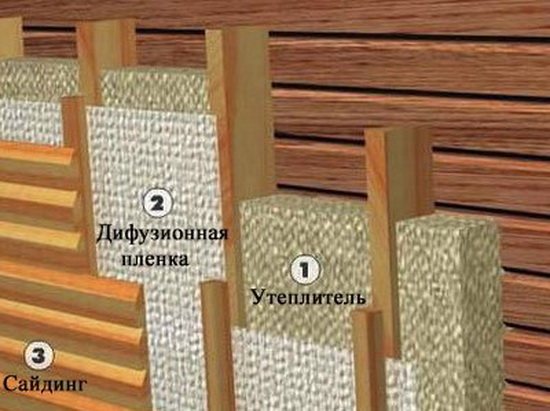

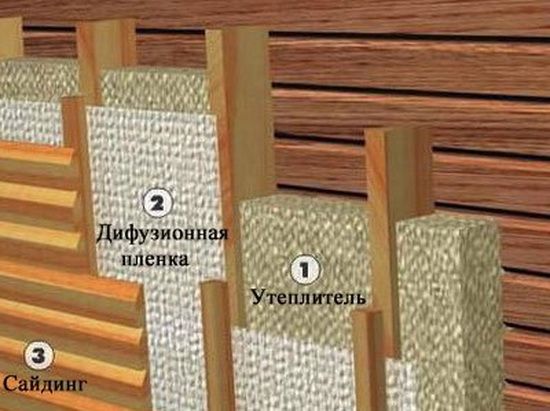

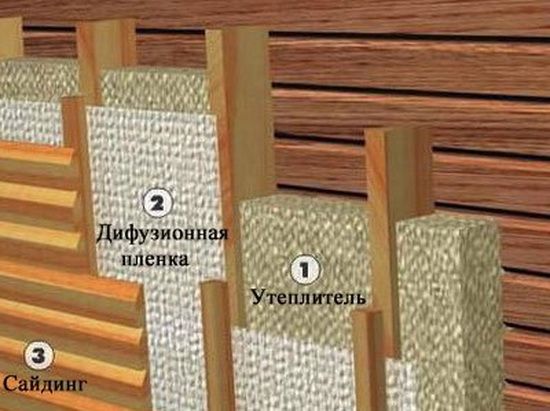

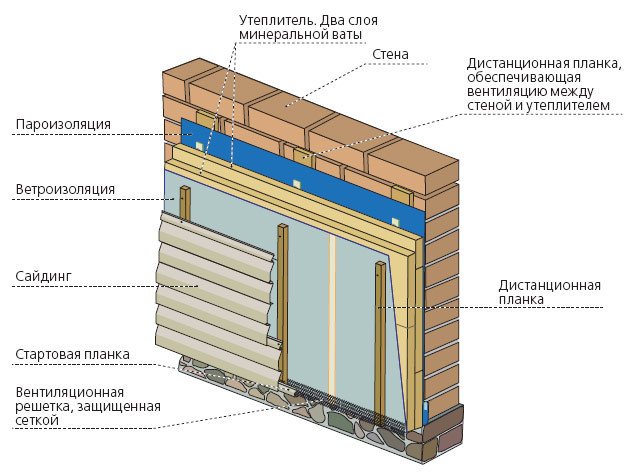

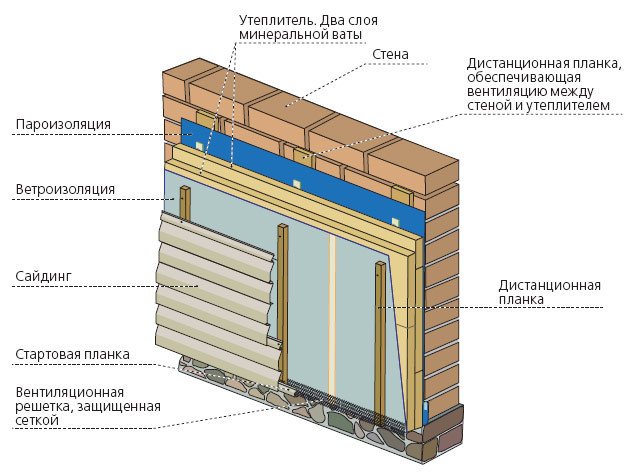

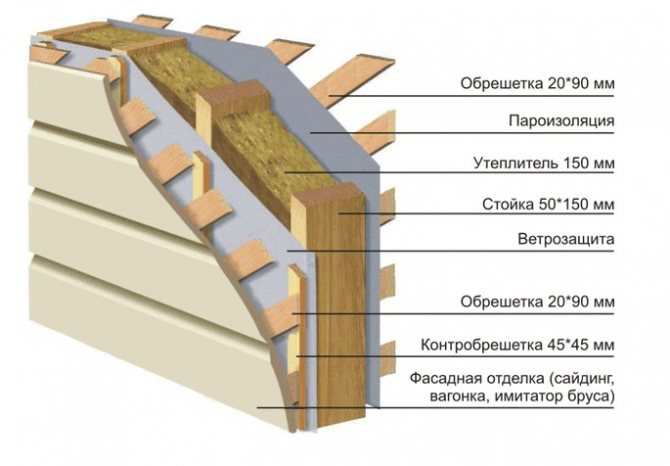

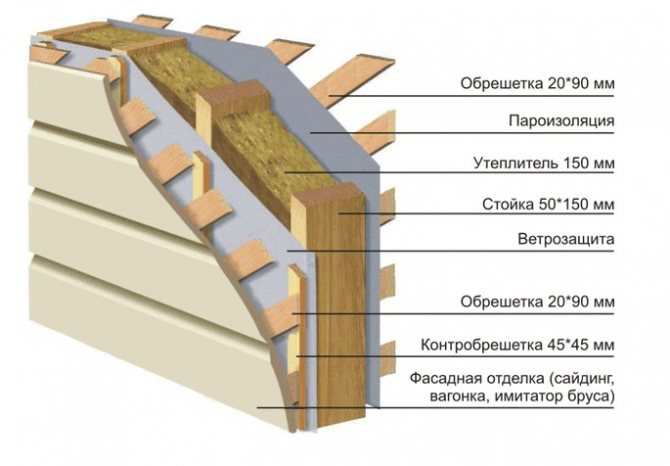

Basalt wool is used to insulate facades, which will be additionally sheathed with finishing material. This material is most widely used for insulating facades covered with siding.

The density of basalt wool should be at least 90–135 kg per cubic meter. m. It is not recommended to use a material of lower density due to the fact that, in this case, there is a possibility of the insulation slipping.

In addition, the thermal insulation characteristics of a less dense material are significantly lower.In any case, the installation of a basalt wool insulation layer requires the manufacture of a reliable frame. It is better if the frame is double, this will eliminate the “cold bridges” in the insulating layer.

Modern industry produces basalt wool in rolls, sheets and cylinders. The most convenient for insulating the walls of a private house are sheets. As a rule, in hardware stores you will be offered the following sizes of basalt wool: 1000 × 500 × 500 millimeters.

The thickness of the basalt wool is a multiple of 50 millimeters. The thermal conductivity of this material ranges from 0.032 to 0.048 W / mK and is identical to the thermal conductivity of foam, foam rubber and cork. Basalt wool is characterized by high vapor permeability, which ensures good moisture exchange with the environment.

The technology of installing an insulating layer based on basalt wool is quite simple and does not require the use of special equipment. With free time and desire, you can do the insulation of the facade with basalt wool with your own hands. The installation algorithm when working with selected materials includes two stages:

- Installation of the frame (lathing); Laying the insulation material.

The frame (lathing) of the insulation structure is made of a metal profile or wooden beams.

Its thickness directly depends on the thickness of the insulation, the width of the cells on the size of the sheet of basalt wool. There are a number of factors to consider when choosing the material that is best suited for the fabrication of the frame. In particular: wall material, climatic conditions (rainfall, wind load, etc.).

In most cases, in private construction, a wooden beam or a galvanized profile is used. All other things being equal, preference should be given to the profile. If the choice when searching for a material is made in favor of a wooden frame, then before installation it is necessary to carefully treat all the wooden parts of the frame with antiseptics and fire retardants.

The insulation should be placed between the frame beams as tightly as possible. If the insulation material requires additional waterproofing, then a polyethylene film is used for these purposes.

Insulation of the attic with stone wool

The transformation of a cold attic into a residential attic is impossible without well-chosen and carefully installed thermal insulation. Such reconstruction allows you to increase the living space with minimal costs, and the thermal insulation material becomes

a buffer that neutralizes temperature drops and maintains a comfortable thermal regime. After all, the roof of the house, especially metal, heats up to 70 ° C in summer, and cools down to -DO ° C in winter. Among the products recommended for roof insulation are Light Butts and Light Butts Scandic (Rockwool). Rocklight (TechnoNICOL), eXtra (Paroc), Isover Opti-mal (Saint-Gobain).

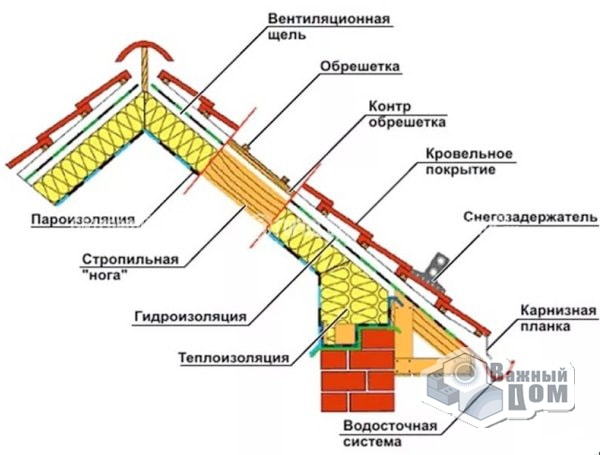

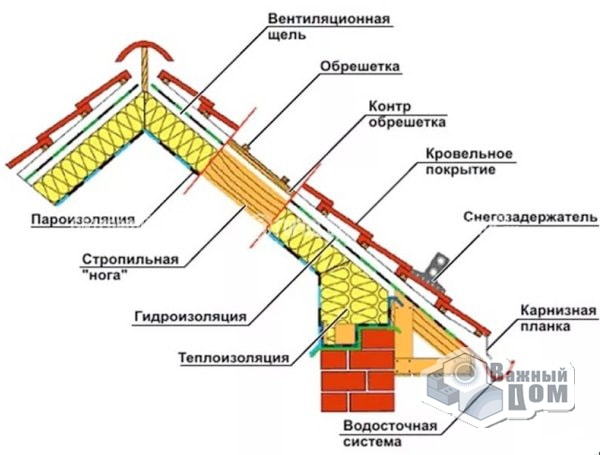

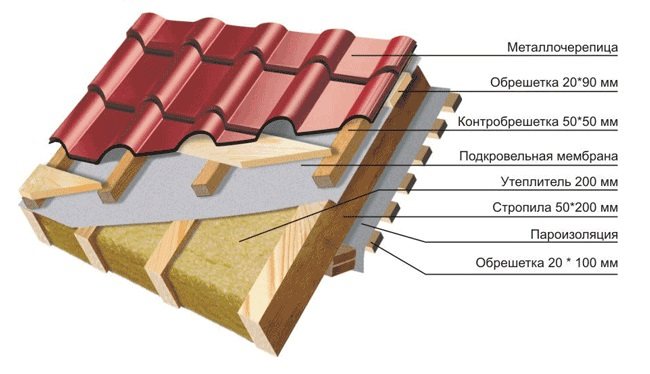

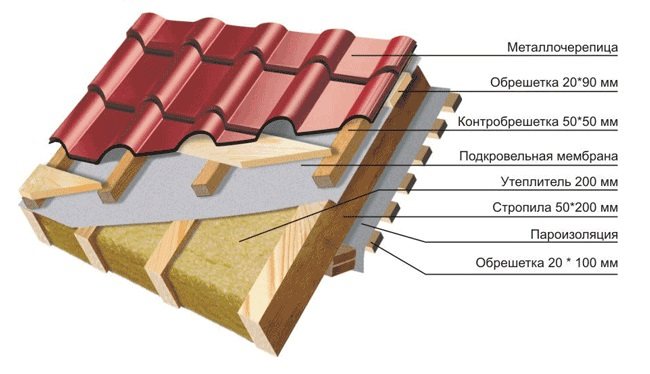

The main load-bearing element of the roof is the rafters. Most often, insulation is placed in the space between them. First, the rafters are covered with sheets of moisture-proof membrane with high vapor permeability. They prevent moisture from entering the thickness of the insulation, which penetrates into the under-roof space through the cracks and joints of the elements of the roof covering or falls out in the form of condensation on its inner side. It is no secret that wet insulation loses its insulating properties and provokes rotting of wooden parts of the roof structure and corrosion of metal ones.

On top of the membrane, lathing bars are installed along the rafters, and, if necessary (depending on the type of film), counter battens and lathing. Then the roofing is mounted. Heat-insulating material is placed under the waterproofing, placing it between the rafters along the entire length of the slope to the walls.A vapor barrier is attached to the bottom or ends of the rafters, which protects the stone wool from humid air coming from the living quarters. After that, the bars are attached, which serve as the basis for the finishing cladding. By the way, in dry weather, the roofing cake can be laid in the reverse order (vapor barrier, insulation, waterproofing, roofing), which greatly facilitates and speeds up the work.

Reference by topic: What is the best insulation?

Facade insulation technology with basalt slabs

Basalt slabs, due to their high strength and resistance to weathering, are the best options for insulation material for external thermal insulation systems in private houses. Their use makes it possible to significantly expand the scope for technical and design solutions related to facade decoration.

This building material is used (as insulation) in the "wet facade" technology.

The surface of basalt slabs can be treated with quartz soil, decorative plaster, silicate and silicone paints. When choosing paint, it is better to give preference to silicone-based solutions. Such paints do not impede the flow of air into the surface of the facade, in other words, they allow the facade to "breathe".

Basalt fiber slabs are characterized by all the physical, chemical and operational characteristics of mineral wool. They do not contain any additives in their structure.

A distinctive feature of basalt slabs is the high manufacturability of this building material. It is easy to transport, store and install.

Warming the facade with basalt slabs with your own hands is within the power of a person who does not have special skills and knowledge. In addition, like mineral wool, the installation process does not require special equipment. Despite the rather high density of the slabs, they can be cut with an ordinary kitchen knife.

The thermal conductivity coefficient of basalt fiber slabs is in the range of 0.035–0.043 W / m * K, which almost corresponds to the indicators of basalt wool. The vapor permeability indicators of these materials are also identical. Due to their denser structure, basalt slabs have good sound insulation properties.

When installing an insulating layer "under plaster", two types of basalt slabs are used - with a random arrangement of fibers and slabs with an arrangement of fibers perpendicular to the wall plane, and the dimensions of the slabs are mainly 120 × 20 cm.

The process of installing basalt slabs "under plaster" has some peculiarities at the stage of laying the insulation. Plates are glued to the walls using special glue and additionally fixed with umbrella dowels. After installing the entire surface of the insulation, the plates are covered with an adhesive solution and reinforced with a special mesh.

Plates, to a lesser extent than wool, are demanding on the accuracy of the geometric parameters of the frame, but this should not be abused - a tight fit of the insulation to the lathing machines is necessary to ensure a reliable heat-insulating layer.

- Date: 17-09-2015Rating: 33

Basalt insulation has natural materials in its structure.

It is based on the material of volcanic rocks and is produced in the form of heat-insulating plates, which help to insulate walls and facades. Basalt slabs are insulation in the form of panels that have a fairly rigid fibrous structure. This structure contains basalt fibrous threads, which are linked by various additives and synthetic elements.

Basalt insulation is made from volcanic rocks by high-temperature melting and subsequent blowing.

One of the important components of any private house is its insulation. Thermal insulation of the house allows you to keep it cozy and comfortable.

The use of basalt will fully help to achieve this task.The experience of using it has shown that such wall insulation is not only reliable and safe, but also fireproof. Those. it can be used for almost any room.

Various forms of basalt insulation make it possible to insulate various structures.

The raw material for such a material is a thin fiber from rocks of magmatic origin. These include basalt, andesite, diabase, etc. In the process of high-temperature melting of these materials (1400-1600 degrees) and their subsequent blowing with the help of a high-speed gas jet, the molten mass is gradually converted into staple fibers.

Next, the resulting fibers are placed in a drum. There, the threads are intertwined in a chaotic state and reach the required density. After cooling to 200 degrees, the resulting mass hardens, and it is given the desired shape.

Its form can be of several types:

- Material in the form of slabs (has a formed structure of various thicknesses and areas). Bulk material (made by granules that have different densities and sizes). Basalt wool (made in the form of soft rectangular tiles). Shapes in the form of mats (they consist of quilted fibers, to eliminate the loss of their shape) .Lamellar forms (can be square and rectangular). Basalt fabric (in rolls).

All these materials will provide sufficient protection for the house from freezing, but basalt slabs, due to their ready-made shapes and sufficient thickness, are the most convenient.

Back to the table of contents

Scheme of roof insulation made of metal tiles.

The procedure for laying the material for thermal protection of the house must be developed at the stage of its design.

It is necessary to immediately determine the possible places of heat leakage. In each house, they will be their own because of its architectural features and location. The most challenging areas will be the attic, roof, slabs and façade.

When laying basalt slabs that provide thermal protection to the roof, it is necessary to use a film to create a vapor barrier. It should fit on horizontal bars between the rafters.

The resulting joints must be sealed with a special tape. The thickness of the layer to be laid should be 180-200 mm. Next, you need to lay a layer of wind protection and make a crate with beams (to ensure ventilation).

In the process of insulating the attic, the insulation must be laid between the logs that are on the floor of the attic. The equal distance between them will ensure the ease of laying basalt slabs. And the resulting gaps need to be covered with cellulose insulation.

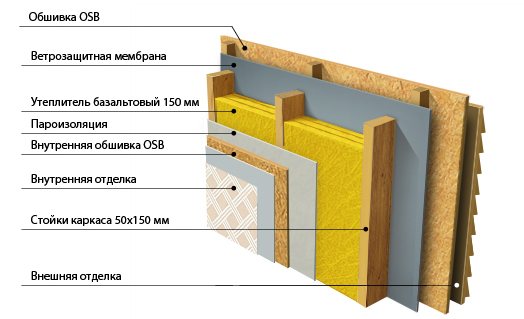

Scheme of warming the walls of a frame house.

Insulation of the floor and ceiling will provide not only their thermal, but also sound insulation. During the work, slabs of material are laid on the floors. The vapor barrier membrane must first be decomposed on them.

The sub-floor is laid on this structure. It should be made of moisture resistant plywood (OSB plywood, etc.). After that, you need to lay the substrate, and on it - the desired floor covering.

In the course of insulating the walls of the building, the facades are insulated at the same time. Basalt slabs can be used to insulate both the inner side of the wall and the outer one. The order of their insulation is slightly different.

For internal work, it is necessary to initially make a crate of the surface. The step of the lathing should be 60 cm. This width was not chosen by chance, because

because the slabs are of exactly this size. An impervious film is laid on top of the insulation, and the interior decoration is made with it.

When insulating the walls from the outside, you need to do their preliminary crate. The basalt slab is laid with a slight gap from the final cladding to provide ventilation. It is attached to the base of the wall with self-tapping screws.

Then the windproof film is laid.The work is completed by finishing with siding or any other external coating material (lining, porcelain stoneware, etc.).

Back to the table of contents

Insulation scheme for the external facade of the building.

The peculiarity and advantage of such a material for keeping warm in the house is its versatility. Basalt can be used for both exterior and interior decoration. Moreover, it is completely harmless and environmentally friendly.

It contains no phenolic compounds, the fumes of which are very harmful. They can lead to various diseases. The use of this material leads to a decrease in the total cost of heating the house by an average of 60-65%.

Plates made of this material retain heat very well, since they have a rather low thermal conductivity. At the same time, they protect the room from excessive moisture penetration into it. Therefore, the combination of these factors together allows you to ensure good air circulation and create a comfortable environment in the house.

The construction of basalt slabs is such that their installation will not cause much trouble. They have a fairly reliable and durable structure.

Therefore, they can withstand fairly strong loads without deforming and retaining their appearance. With a competent approach to work on insulation and skillful handling of the assembly tool, you can quickly complete the fastening of this coating.

Various materials are used to insulate the facade of a house from a bar.

Nowadays, basalt thermal insulation boards are considered the best materials for insulating the walls of the house from the outside. Mineral wool and foam are also often used, but the first material is not so environmentally friendly, and the second does not breathe. Insulation of the facade with basalt slabs: video and photo materials about insulation in one article.

Stone wool insulation materials

PLUSES OF STONE WOOL AS A HEATER

+ Fireproof, non-combustible (the melting temperature of the fibers is above 1000 ° C).

+ They have a low coefficient of thermal conductivity (0.035-0.065 W / (m * K). + Perfectly insulate shock and airborne noise in the middle frequency range. + Vapor permeable and hydrophobic. They freely pass water vapor, but do not absorb moisture from the air due to the minimum sorption capacity.

+ They have good physical and mechanical characteristics. + Convenient and safe to lay. + Chemically and biologically stable, unaffected by bacteria and microorganisms, not of interest to rodents. + Durable (last at least 50 years). + Safe for humans.

MINUSES OF INSULATION WITH WAO STONE

- Slight (maximum 30%) shrinkage of the material in the package, therefore it requires more space during transport.

- Quite high cost.

Basalt insulation pros and cons

Basalt slabs are made of mineral fibers pressed into slabs.

The fibers are interconnected with an adhesive based on various resins. It is made from natural raw materials. Basalt slabs can be used to decorate any living space, as well as food and childcare facilities.

Quite often, this heat insulator is used when decorating private houses and cottages from timber, air ducts and other structural elements. The use of basalt wool is often necessary to provide thermal insulation for industrial equipment (boilers, furnaces, boilers). Basalt slabs can be used as light sound and thermal insulation in a horizontal fencing structure of any type of buildings and structures.

The main advantages of insulation include:

- Lightweight. Does not burn. High heat and sound insulating properties. Suitable for most types of finishes. Elastic material, therefore does not break and is not afraid of mechanical stress. Does not collapse from moisture like glass wool. Eco-friendly. Does not block the flow of oxygen into the house.that does not violate the microclimate of a wooden house. Easily mounted on any surface. There is no need to level the insulated surface.

Cons of basalt mineral slab insulation:

- The price for the material is higher than for mineral wool or foam. Not every glue can be attached to a wooden facade.

Stone wool: a note

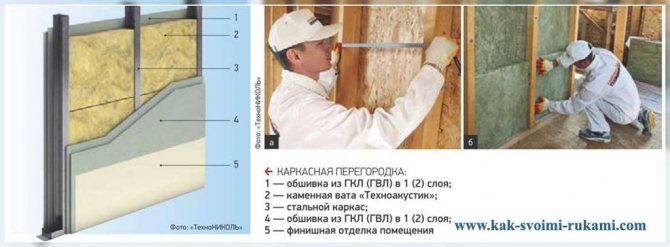

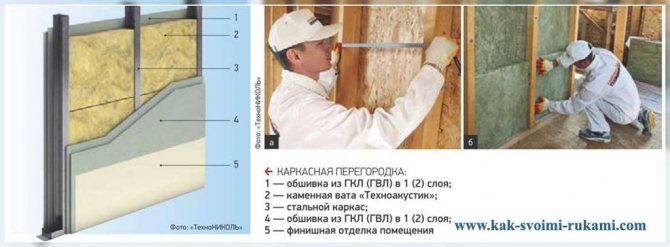

The physical and mechanical properties of acoustic stone wool ensure reliable operation of the material in vertical structures for a long time (at least 50 years).

Plates "Techno-Acoustic" ("Techno NIKOL") are used in frame partitions, suspended ceilings, floor slabs without load on the material.

Frame partitions are fireproof, easy and quick to install, have a low weight, and most importantly - excellent sound insulation of air and impact noise.

External insulation of the house helps to increase the usable area of the building without changing its size, to reduce the consumption of building materials and to lighten the structure.

The optimal size of the air gap between the foil layer and the cladding (for example, from the lining) is 1 cm. The gap will create the effect of heat protection, reflect infrared rays.

"Sauna Butts" (Rockwool) are insulating boards lined with aluminum foil on one side.

The vapor barrier foil layer is sealed, for which the joints of the plates are glued with adhesive tape that can withstand an elevated temperature.

Reference by topic: Heaters for walls, floors and roofs - how and which one to choose?

Facade preparation

Before starting work on warming the facade of a wooden house with basalt slabs, it is imperative to inspect the outer walls of the house, its basement and roof. To do this, you need to pay attention to the following actions:

- Look for visible cracks and damage at the junction of the foundation and the first crown, in window and door openings, walls. Look for strong bulges and curvatures, if necessary, cut, put guide bars 2 m long, 40x40 mm section on top. and finish the basement of the house with waterproofing materials, for example, roofing material or coating compounds: liquid glass, bitumen mastic. Clean the surface of the walls of the house from contamination, if there is an old sheathing, dismantle.

Thermal insulation with stone wool: schemes

ROOF ROOF ROOF. LOCATED ABOVE THE MANSARD: 1 - roof covering; 2 - crate; 3 - thermal insulation between wooden rafters; A - waterproofing membrane; 5 - vapor barrier film; 6 - interior finishing coating

INSULATION OF STONE WOOLED FLOOR ON LAGS; 1 - rough lathing for covering the floor from OSB or gypsum plasterboard sheets; 2 - superdiffusion membrane; 3 - slabs of stone wool between wooden logs; th - vapor barrier film; 5 - rough floor; 6 - substrate and topcoat

INSULATED STONE WOOL FRAME PARTITION: 1 - plating made of gypsum plasterboard (GVL) in 1 (2) layer; 2 - stone wool "Technoacoustic"; 3 - steel frame; 4 - plating made of gypsum plasterboard (GVL) in 1 (2) layer; 5 - finishing the premises

If the inner distance between the supports is less than the width of the mat by 10-20 mm (a), a piece of the required length is cut off and the spatula is placed (b). If the dimensions do not match, the slab is cut to a size equal to the step of the supports plus 10-20 mm.

SCHEME OF INSULATION OF THE FACADE WITH STONE WOOL 1 - inner lining made of gypsum plasterboard; 2 - counter rail; 3 - vapor barrier; k - wooden frame of the building; 5 - two layers of stone wool; 6 - hydro-windproof film; 7 - counter rail; 8 - block house

Installation of slabs on the facade of the house

Basalt slabs are installed wet and dry.

For a wooden house from a bar, it is better to choose a dry one, when the material is attached to the facade using a dowel of nails with a wide head. If the wet method is chosen, then a silicone-based adhesive and quartz sand is used. The fact is that it is more difficult to glue plates to wood than, for example, to cement or brick.

Basalt slabs for the facade of your house are taken with a density of at least 90-135 kg per cubic meter. m.The use of building material with a lower density is not worth it, since it is soft and can slide off a vertical wall over time.

Fastening the material along the entire facade is laborious, so not everyone can do it with their own hands. Basalt slabs will not only protect a wooden house from the cold, but also give it sound insulation no worse than a foam finish.

The only thing you should pay attention to is the weight of the plates. It is higher than that of polystyrene, therefore, even with the wet method, it is recommended to additionally secure the material with mushroom nails. More details on how the facade is insulated with basalt wool, in the video:

Installation of mats is carried out in accordance with the selected facing material. The following technologies are used for painting and plastering:

Horizontal strips are mounted on the plinth, they are needed so that the insulation does not slide down and lie flat.

It is necessary to fasten the planks strictly according to the level.Fix the material starting from the corners of the house around the entire perimeter, below the plank. (the method resembles a strapping). Since the standard height of the insulation is 50-60 cm, and the thickness is 20-100 mm, a belt of these dimensions will be obtained. The next stage is to attach the second row of plates, while it is necessary that it is located with the first in a checkerboard pattern. On top of the plate, cover with a hydro-vapor barrier and a reinforced mesh Then the structure is plastered and painted.

Installation under panels (siding, block house, lining, imitation of a bar):

A crate is attached to the walls (vertically) from a bar or metal profiles with a step of 60 cm. To fasten the crate, you must start from the corners of the house, fixing on each side of a bar. Tip: To avoid measuring 60 cm each time, make a stencil from a small piece of plywood or Boards. From the bottom between the crate, guide bars 60 cm long are attached, they will support the heat insulator. Between the crate, a basalt slab is mounted.

It is fastened with dowels with a wide head. A hydro-vapor barrier is laid on top. It is mounted with a construction stapler directly to the lathing. The counter lathing is attached to the lathing. It is necessary in order to create an air gap in the structure. Facing material is attached to the counter-batten.

Alternative to mineral insulation

In addition to mineral wool, there are several other types of materials for insulating housing outside. For example, foam or felt.

Expanded polystyrene

Polyfoam or, as it is correctly called polystyrene foam, is a light-colored insulation of a cellular structure, which consists of small hollow structures with air. It is made by thermal foaming of polystyrene materials under the influence of a blowing agent.

The structures contain air in a stationary state, cells in the form of figures with a large number of faces have a wall thickness of 0.001 mm and dimensions of 0.2-0.5 mm.

Because of this, 97% of the foam contains air, thanks to which it has unique thermal insulation properties.

The main technical characteristics for GOST-155588-86 15 are the following indicators:

- Density - 11-15 kg / m3;

- Compressive stability at 10% linear deformation 0.07 MPa;

- Thermal conductivity - 0.038 W / (m * K);

- Humidity - 1%;

- Self-burning time - 4 sec;

- Water absorption within 24 hours - 2%.

Expanded polystyrene is a material with extremely low thermal conductivity, which makes this type of insulation an excellent insulator and is used at various stages of construction. The temperature regime varies from -50 to +75, which makes this material practically indispensable in our latitudes.

Sound-absorbing and sound-insulating characteristics at the highest level, all thanks to the cellular and porous device. The greater the thickness, the stronger these qualities. But still, this insulation cannot be used as a sound insulator, the sound absorption effect of this material is not large enough and is equal to 4 dB.

Such qualities as vapor permeability, moisture absorption and humidity are absent in this material, since even completely immersed in a liquid, this material practically does not absorb water. For this reason, it is excellent for insulating foundations and basements.

Excellent resistance to temperature fluctuations, as well as fire resistance, classifies this material as 3-4 flammability class. The degree of heat at which spontaneous combustion can occur is +492 ° C, which is 1.8 times higher than that of wood (+260 ° C); paper has a spontaneous combustion temperature of +230 ° C, which is 2.1 times lower than that of foam.

It is also noted for its excellent resistance to bacterial and chemical influences. Well tolerates the effects of various salts, soap solutions and weak acids.

Felt

This material is made from wool, made in the form of rolls or mats. Has a protective coating. Refers to unique materials for warming areas in the spaces between the rafters. Felt binds with aldehydes, which is an undeniable advantage.

The main disadvantage is that this type of insulation is susceptible to damage from rodents and other parasites.

Insulation of the frame structure

Basalt insulation near

Basalt slabs are considered the best heat insulator for a timber frame house.

It is necessary to mount the insulation outside the structure, since during the interior decoration the frame remains unprotected and condensation will accumulate between the heat insulator and the timber. It gets into the capillaries of wood and will cause rapid decay and mold. When insulating frame houses, special attention should be paid to the vapor and waterproofing of the structure.

The penetration of moisture inside the house is unacceptable In this case, the design of the facade finishing must be ventilated.

Since the temperature difference between the inside and outside of the building will be significant in winter, condensation may form. For better insulation, you can use basalt slabs foiled on one side. The price for them is higher, but the house will be protected from moisture.

At the same time, it is necessary to qualitatively waterproof the foundation of the house, since the tree will absorb moisture from the foundation and it will be difficult for it to erode from the structure with slabs. A basalt slab with a thickness of more than 2 cm is chosen for insulating a wooden frame house, or it is necessary to make a double structure.

Insulation of partitions with stone wool

The premises in the house are separated by partitions, which should prevent the transmission of noise from a working TV, radio, as well as loud conversations from one room to another. Sound insulating ability of structures

characterizes the airborne sound insulation index Rw. The higher the value, the more effectively the baffle prevents the penetration of sounds. Most manufacturers of stone wool offer special slabs with enhanced sound-insulating properties, for example, Technoacoustic (TechnoNICOL). Acoustic Butts (Rockwool). Isover ZeukoProtection (Saint-Gobain). Frame structures filled with these materials often have an Rw sound insulation index that exceeds the requirements of SP 51.13330.2011 "Noise Protection", according to which the Rw of partitions between apartment rooms should be 52 dB.