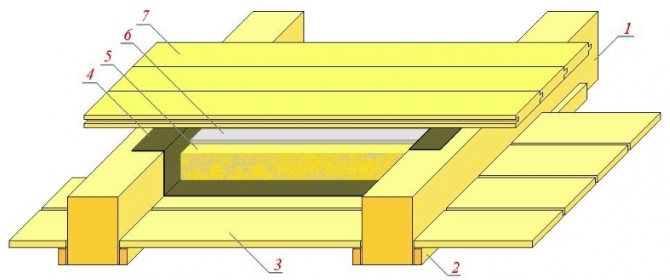

Almost all wooden floors are arranged in the same way - logs are installed between the walls, usually it is a wooden beam from 10 to 15 cm wide and 20 cm high, floorboards are laid on them. The empty space between the lags must be insulated. The main problem with this method is to fix the insulation between the timber.

First of all, wooden elements are treated with an antiseptic to protect them from the moisture of the underground space. It would be more correct to make the ventilation of the subfloor by making holes in the foundation. But all the same, it is necessary to antisept the wood. There are many protective compounds, different manufacturers and properties. But the most affordable and budgetary option, with excellent moisture-resistant qualities, is used engine oil. For ease of use, the container with oil needs to be slightly heated to make it more liquid, and apply it to wooden parts with a simple paint brush.

Most often, boards or plywood are fixed between the logs, creating shields, on which insulation is subsequently laid. If it is possible to carry out work under the floor, for example, in the presence of a basement or basement, then such shields are nailed to the beam from below. It turns out that the thickness of the insulation layer will be equal to the height of the log. If the insulation work is carried out from above, then wooden blocks 3-5 cm high and 2-4 cm wide are fixed to the lower part of the lag.

It is better to nail them in than to tighten them with self-tapping screws. Firstly, it is cheaper and faster this way, and secondly, nails are a more reliable fastening means than self-tapping screws, since the caps of self-tapping screws often break off under load. If, for any reason, the bars fall off the log, then all the insulation will fall to the ground. Therefore, it is undesirable to save neither on bars nor on fasteners.

The bars are also treated with used oil.

Next, measure the distance between the logs and from boards with a thickness of at least 2 cm or plywood cut the necessary segments and lay them on the bars. Shields are also treated with oil. You will get a flat area on which the insulation is laid. A significant disadvantage of this method of insulating wooden floors in a house is a significant reduction in the insulation layer. Consider for yourself: the height of the bars is 4 cm + the height of the board is 2 cm, plus the gaps - it turns out minus 6-7 cm.It turns out that out of the 20 cm of the height of the log, only 13 cm will have to be directly insulated.

There are three ways out of this situation. The first is to insulate to the height that remains. The second - before laying the lag, nail a wide board to the lower part, which will go beyond their edges and attach shields to it. Third, instead of wooden bars, use a metal corner, which is screwed at the base of the log along their entire length.This, of course, will greatly increase the budget for insulating a wooden floor.

But the advantages of this method of insulation should also be noted: simplicity - no need to involve a team, all work can be done by hand, insulation can be carried out at any time of the year, since no cement work is required.

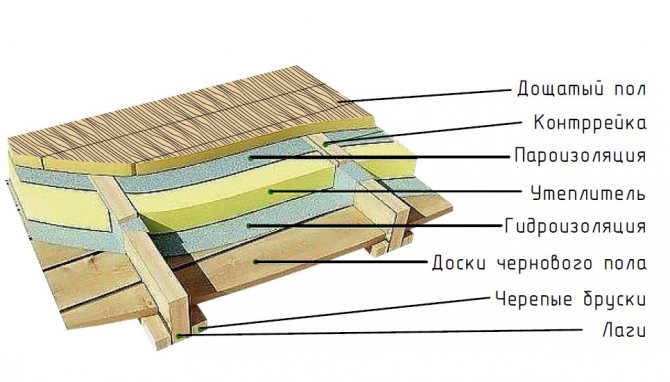

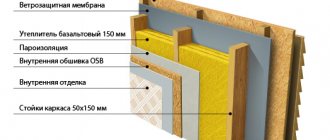

MINERAL WOOL

The next step is to install the insulation. Mineral wool is usually used for wooden floors. First, a vapor barrier is spread on the boards, attaching it to the bars with a stapler, then the insulation is laid in rows. If the insulation boards are 2 or more rows, then the seams between them should not be on top of each other. To exclude cold bridges, the second layer of insulation must be put in a checkerboard pattern to cover the seams of the first row. Mineral wool is laid flush with the lags, and again covered with a layer of vapor barrier material on top. Then the floorboards can be mounted.

It is believed that an air gap must be left between the insulation and the boards. In order not to be mistaken, insulation with mineral wool should be carried out according to the instructions on its packaging. The main disadvantage of warming with mineral wool slabs is that mice are very fond of living in it. Rodents settle there, build nests, breed. It is almost impossible to get them out of the underground space. Although the press writes that mice do not live in modern eco-samples of such a heater, since boric acid is used in the production of the material. Another disadvantage is that if the vapor barrier layer is used incorrectly, the insulation gets wet and loses its heat-shielding properties. There are many videos on the net where you can see that a lot of water flows out from under the mineral wool. Therefore, the proper use of vapor barrier requires increased attention.

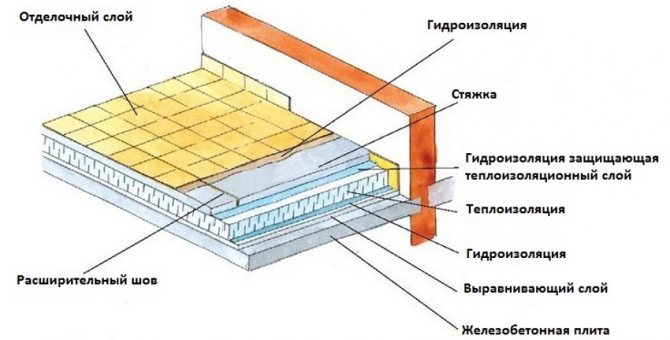

How can you insulate a basement

Warming the cellar from the inside or outside allows you to achieve good results, which will even allow you to arrange a living room below.

In this case, you need:

- Insulate the walls of the basement from the inside and outside.

- Warm the ceiling.

- Insulate the floor.

Basement insulation material from the inside

How to insulate the walls of the basement from the inside is the most important and serious question when performing such work. The finished result depends on the quality of the selected material.

The most common options for dealing with these kinds of problems are:

- Styrofoam. Its price is quite reasonable, but it is easily deformed at very high or low temperatures.

How to insulate the basement inside with foam is shown in the photo

Tip: Due to shortcomings, the material can only be used for the ceiling.

- Penoplex. This is a modern heat-insulating material, devoid of deficiencies in foam.

It is produced in the form of plates, it is mounted in almost the same way as foam.

In this case, it is necessary:

- carefully level the surface for fixing the plate;

- butt seams between them create "bridges" of cold.

Before insulating the basement from the inside with penoplex, it is necessary to determine whether it is necessary to achieve the maximum possible result of insulation.

Tip: It can be used in combination with other better options: for example, insulate the walls from the outside with polyurethane foam, then the foam is taken from the inside.

- Expanded polystyrene. This is an analogue of penoplex, which differs only in the production method. Has the same advantages and disadvantages.

- Polyurethane foam.

Thermal insulation with polyurethane

After application, the material hardens very quickly, creating a durable outer layer. The only drawback that deserves attention is only the method of its application: it requires the presence of a special installation that creates high pressure, which cannot be done with your own hands, but requires the invitation of specialized companies.

The advantages of the material include:

- complete protection against moisture, while additional protection is not required, even with constant contact with moisture;

- has a good quality result;

- creates a complete tightness of the room, which is facilitated by the absence of joints and seams;

- if moisture gets in, it will not rot and mold.

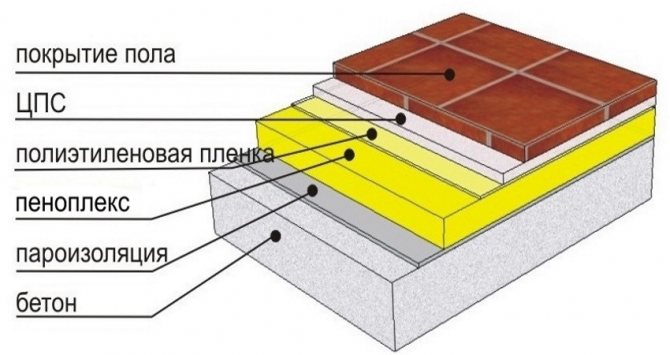

EXTRUDED POLYSTYRENE FOAM

There are other ways to insulate wooden floors. For example, when foam is used instead of mineral wool or its variety is extruded polystyrene foam. Its advantages are low coefficient of thermal conductivity, lightweight, waterproof, long service life, resistant to deformation. The main disadvantage is that it burns well and emits pungent smoke. However, this material is also readily used by homeowners for insulating floors, including wood floors. The disadvantages include the fact that it can also be gnawed by mice. Although they will not live in it, they will simply harm. To protect the expanded polystyrene from mice, laying on the boards of an ordinary roofing material, even better than used, will help. There is no information that rodents eat roofing material. They are scared off by the material itself, and the persistent smell of bitumen coming from it. Therefore, in order to protect the insulation from mice, it is imperative to put a layer of this roofing material in front of it.

The choice of insulation

Many materials are used to insulate the floors of a wooden house. The simplest and most inexpensive can be called expanded clay or sand, which is poured between the rough and final coating. They are hygroscopic and protect the boards from rotting, the spread of fungus and provide ventilation. However, free-flowing nonmetallic heaters have their own drawback - over time, their hygroscopicity decreases.

Today on the market you can find many materials for insulating a wooden house. In addition to good thermal insulation, it must meet the basic requirements:

- ecologicaly clean;

- be safe for the occupants of the house;

- long service life.

For insulation, fiberglass, mineral wool, penoplex, expanded polystyrene, etc. are used. Each of them has its own advantages and disadvantages:

o Mineral wool. It can be slag, stone and glass. The release form is also varied - plate, roll, mat. Mineral wool has a high density, does not burn, conducts heat poorly and is quite economical. The main disadvantage is considered to be low moisture resistance.

When using mineral wool, the vapor barrier and ventilation should be well thought out. The unfoil side of the board should be on the bottom.

When buying mineral wool, they carefully read the composition, since the impregnation often contains substances hazardous to the body. The richer the yellow color of the material, there it is more dangerous.

In hardware stores, the following are more in demand:

- Izovol - a product made from mineral fibers. A distinctive feature is high hydrophobic efficiency in comparison with conventional mineral wool. Additionally, it has low thermal conductivity, non-flammable, biologically and chemically resistant.

- Rockwool - basalt min-heater. Its peculiarity is that it does not cake, does not lend itself to deformation and shrinkage, like mineral wool. Rockwool resists mechanical stress well. The material is additionally used for sound insulation, since the porous structure absorbs noise of any frequency well. Like Izovol, Rockwool does not conduct heat well, does not burn and is resistant to biological and chemical influences.

- Expanded polystyrene - has a high rate of thermal insulation. It is resistant to moisture and does not absorb water, keeps its shape well during temperature changes, is durable, environmentally friendly, durable and is not subject to the destructive effects of microorganisms. Styrofoam is easy to handle and use.

- Penofol - modern heat insulator. Sold in rolls, it is insulation with a layer of foil. The thickness and weight are small.The base may be different, but in most cases it is penofol (expanded polyethylene). Thermal insulation properties are retained under high mechanical stress. Laying takes place with an overlap or butt. Seams must be glued with metallized adhesive tape. Penofol does not require an additional layer of waterproofing and vapor barrier, since the foil already performs these functions.

- Ecowool - natural cellulose heat insulator. They bind fibers with boric acid and lagnin (organic antiseptic). The uniqueness of the material is that it does not absorb water and brings it out. In the composition there are no components hazardous to health. Ecowool is fire- and bio-resistant, absorbs sound well and does not conduct heat. A special spray is used for application, but the material consumption then increases by 40%.

- Izolon - a new material in construction. With a thickness of 2-10 mm, it has good heat and sound insulation, has high moisture resistance, is not subject to decay and is durable.

Ordinary sawdust can be used for insulation. This heat insulator has been used for many centuries. Natural material is quite cheap and completely safe for the body. Sawdust often remains after the construction of a house. This is the most affordable insulation for a wooden house.

Sawdust is added to some building materials:

- sawdust concrete consists of sawdust, cement, sand and water;

- granular heat insulator - sawdust, glue and fire retardant antiseptic;

- arbolit - sawdust with cement and chemical additives;

- wood blocks - sawdust, cement and copper sulfate.

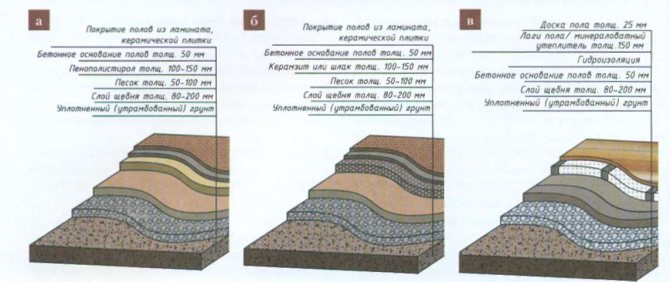

KERAMZIT

Expanded clay remains the most environmentally friendly insulation today. These are clay balls filled with air. Depending on the size of the fraction, expanded clay is also used for use in cement mortars for their insulation, and for well laying of buildings. They fall asleep both between the logs and in the attic. In this material, mice definitely do not live and cannot even spoil it. They just ignore him. The disadvantages of expanded clay are as follows: to ensure reliable protection of the floor from the cold, a sufficiently thick layer of material is required; when wet, it loses its heat-shielding properties.

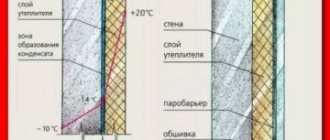

Calculation of the thickness of the insulation

The thickness of the insulation layer plays an important role. It is calculated individually for each house, taking into account the design features, climate and type of insulation. The formula is given in SNiP 23-02-2003:

- R - thermal resistance. It is determined from the tables in the SNiP appendix.

- BUT - coefficient of thermal conductivity. For each type of insulation, it has its own. The value is indicated by the manufacturer or can be found in the SNiP tables.

If you need to lay a thin layer of insulation, then it is better to use extruded polystyrene foam and other materials in mats or rolls. The mats increase strength and resilience.

WOODEN FLOOR INSULATION

Sometimes builders use a combined method of insulating wooden floors, pursuing 2 goals at once - to keep it warm and to avoid the presence of mice. This is achieved in the following way. Roofing material is first laid on the shields installed between the logs, followed by a layer of expanded clay, leaving a few centimeters for laying polystyrene foam. This material blocks the access of cold air from the ground and protects the room from the penetration of mice from below. Even if the rodents make a hole in the shields and roofing material, then they will definitely not be able to advance further than expanded clay.

From above, having leveled and tamped a layer of expanded clay, lay expanded polystyrene. Again, it is believed that it is better to leave a ventilation gap of a few millimeters between the insulation and the floorboards.

This insulation also does not allow cold air to pass through. The gaps between the lags must be filled with polyurethane foam, which, after drying, must be cut off with a knife. To prevent the expanded polystyrene from moving during foaming, it is better to press it down with some kind of load, for example, bricks. The foam will dry and fix it firmly.

Next, the floorboards are installed directly, then any floor covering. This "cake" keeps the room warm and prevents the outside air from cooling the floors.

Thermal insulation of a wooden floor in this way includes: a board from 2 cm below, then a layer of roofing material, then expanded clay, followed by expanded polystyrene from 3 cm, at the end a floorboard from 4 cm.You will also need a lot of used engine oil or an antiseptic and several cans of polyurethane foam. The thickness of these materials is sufficient to maintain a comfortable temperature in the room. The main thing is not to leave gaps when installing an insulating layer, which must either be foamed or clogged (caulked) with tow.

VIDEO

VIDEO

Important points of thermal insulation

- When purchasing insulation material, you need to control its quality. Do not hesitate to require a certificate for verification. High-quality materials recover their shape after mechanical stress.

- The main criterion for choosing a thermal insulation material for residential premises should be health safety, not cost. Floor remodeling is a labor-intensive and time-consuming process.

- Insulation waterproofing should be organized on both sides (internal and external).

- It is worth providing for an expansion gap between the insulation and the finished floor.

- A metal mesh can be placed on the rough floor to keep the floor from rodents.

- A heating system can be arranged between the subfloor and the finished floor using a special heating cable.

- The floor of a wooden house must be well ventilated.

- To increase thermal insulation, the foundation and basement are insulated.

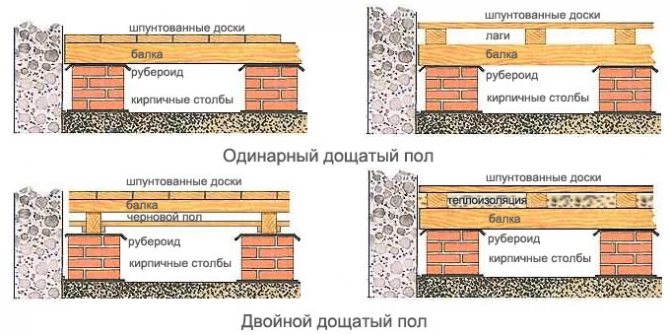

A well-equipped floor in a wooden house is a criterion for keeping warm. It is not difficult to insulate it yourself, the main thing is to choose the right material. The most popular way is the double floor system.