Siding principles

Siding is widely used for exterior cladding in construction. To transform the facades of houses, basement siding material is used. The shape and color of the panels changes in accordance with fashion trends.

The composition of the upholstery is also varied. It can be made from wood, PVC, vinyl, metal. Some types are cement based.

Do-it-yourself installation of basement siding involves studying some information.

Fastening siding

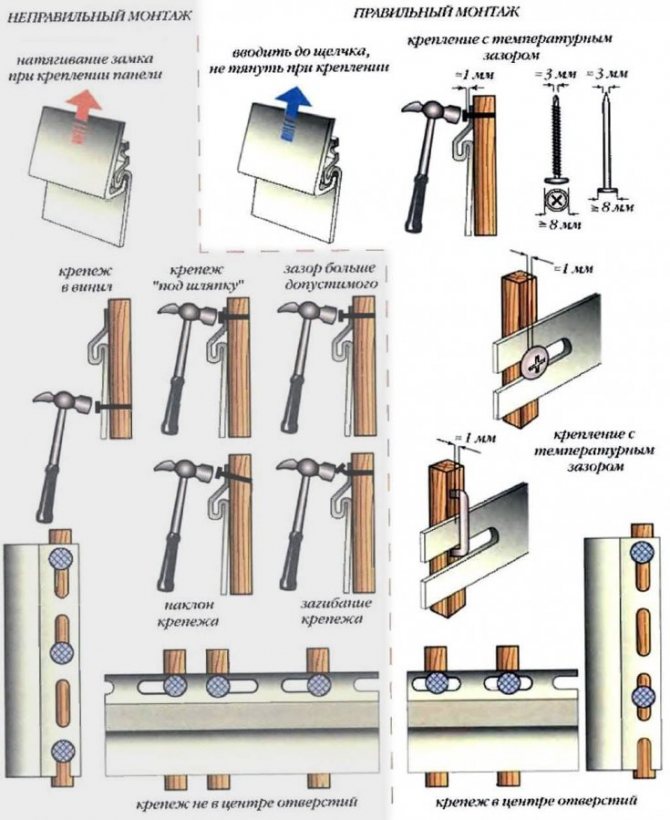

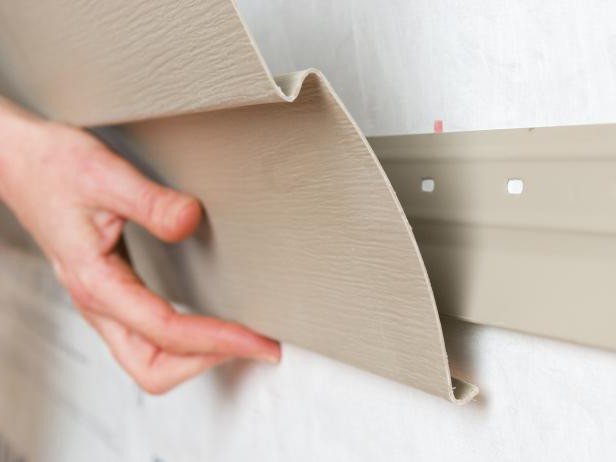

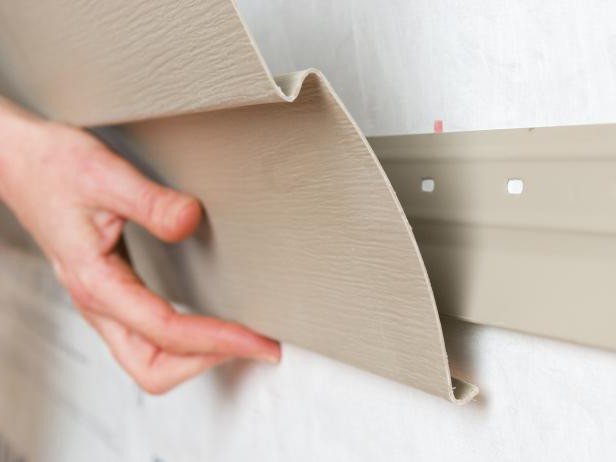

After carrying out all the above work, you can proceed to the direct sheathing of the house with panels. It should be borne in mind that vinyl siding should only be fixed in the special holes it has. It is not recommended to punch the panel with nails and screws. Otherwise, the service life of the product will be significantly reduced.

Attach the siding to a wooden crate. Its first row must be attached to the starter bar. From the bottom, you need to wait for the lock to click, and from above, attach the panel with self-tapping screws. All other rows are installed according to the same principle. After installing the last panel, a finishing strip must be attached to the crate.

Some owners, in order to give their home a more attractive look, decide to install basement siding on its facade.

How do you mount these panels? Such works are similar to those described above for building facades. The fasteners for siding are the same - nails or screws.

Siding is dependent on temperature changes

At high degrees, the pores of the upholstery expand. Low values contribute to its compression. This point is important to consider. When carrying out construction work, the material should not be tightly applied to each other.

At room temperature, it is correct to leave a 2 mm distance between the panels. If installation is carried out in winter, the gap is increased to a centimeter. In the heat, nine millimeters is enough.

Siding panels are mounted in the middle. Round self-tapping screws or roofing nails are used as fastening elements.

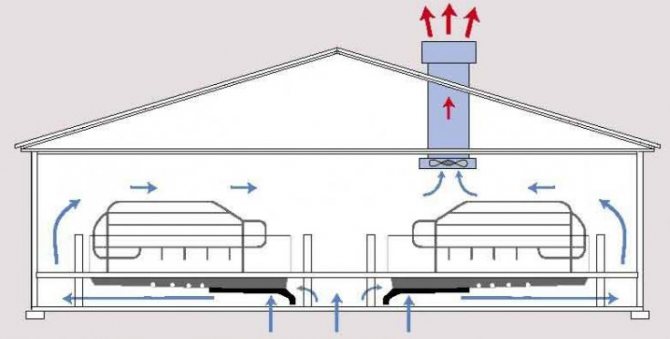

The unevenness of the walls can be easily hidden by lathing made of metal or treated wood. The method is also suitable for a flat surface. This air cushion will insulate the structure.

Step by step guide

Siding assembly instructions are a key document that a good manufacturing company must supply their products with. This documentation contains the necessary recommendations and procedures for the installation of materials.

Note! You must strictly adhere to the instructions in the instructions, otherwise you may lose your product warranty.

General rules

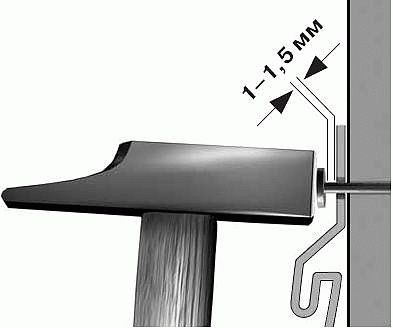

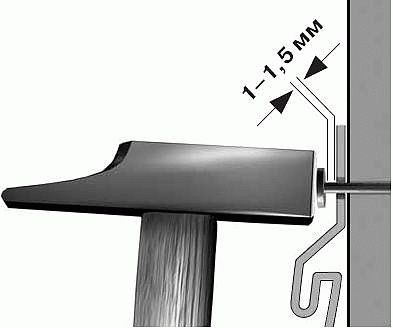

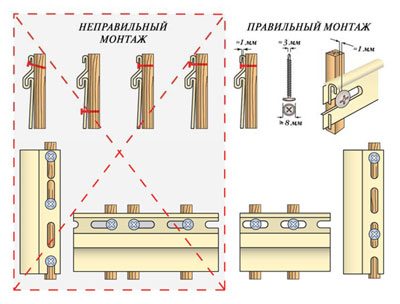

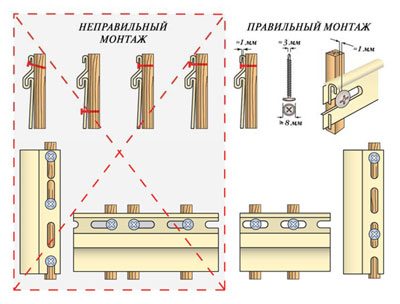

- You cannot hammer in nails to the end. Always leave a gap of 1 to 1.5 mm between their caps and the cladding material.

The main rule of hammering nails

Note! Once secured, the siding panels should move freely horizontally.

- Drive the nail exactly in the center of the mounting hole.

- The siding assembly technology provides for an expansion gap between the siding and accessories (5-6 mm). If installing in cold weather, leave a gap of about 9-10 mm.

- Once the siding panel has latched onto the bottom member, do not use force to further pull it in.

Instruments

- Circular saw and hacksaw for metal.

- Metal ruler, hammer and tape measure.

- Pliers.

- Screwdriver and awl.

- Knife and scissors for metal.

- Building level.

Surface preparation

- Secure old lagging wall boards securely, replacing them with new ones if necessary.

- If necessary, remove any remaining plaster around window openings and doors.

- Remove downpipes, window sills, and various fixings from your home.

- Remove any plants that are in contact with the wall.

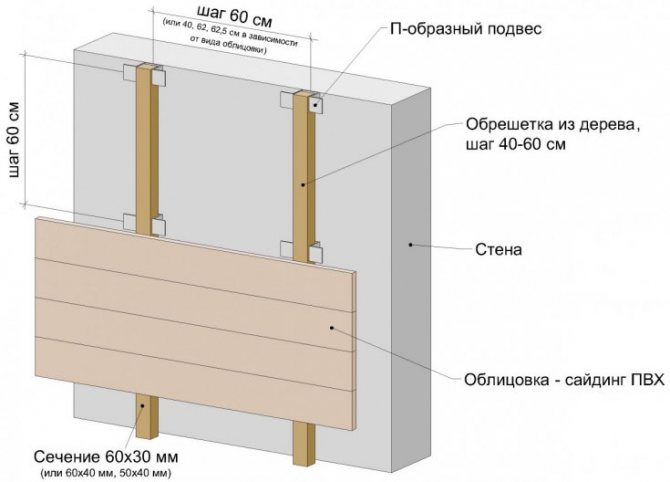

Installation of lathing

Most often, the crate is made of boards or wooden slats - the price of such materials is low compared to metal profiles. For the installation of horizontal siding, the lathing elements must be installed vertically with a step between them 0.3-0.4 m.

- Do-it-yourself basement siding installation: step-by-step instructions

- Siding installation technology

- Vertical siding: photos of houses and buildings

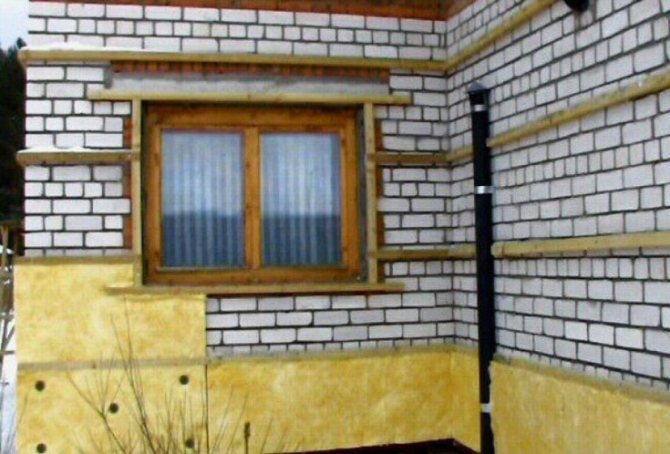

The lathing is ready, the basement siding is secured

Note! For vertical installation of panels, the rules for installing the lathing are the same, but they are installed horizontally.

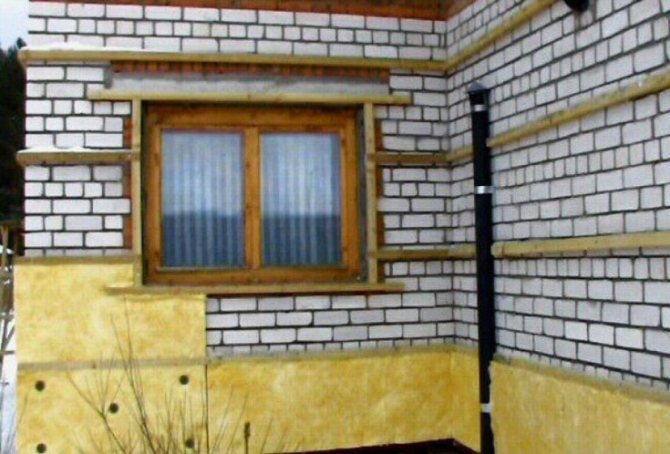

Before you know how the siding is going, you need to pay attention to the fact that the lathing allows you to accurately and evenly install the insulation plates. This will not only increase the efficiency of the house, but will also prevent the manifestation of the so-called "Ripple" effect.

And what will you fix on the crate?

Advice! When using insulation in slabs or rolls, please note that loose material cannot be used - it can deform.

Siding installation

- Using a spirit level, string, and chalk around the entire perimeter of the house, draw a horizontal line on the wall. Use the first nail to be driven 4.0 cm above the lowest point of the house as the reference point.

- Secure the starter strip with nails by placing the top edge on the chalk line. Do not fix it too tightly.

- When adding sections of the starting strip, leave a distance of about 6 mm between adjacent elements, which compensates for possible expansion.

- At the junction of the walls, set internal corners, taking into account the distances to the eaves and the starting strip. Attach this accessory with nails in the center of the holes - it should hang freely from them, and not be nailed down!

Installation rules

- The siding assembly scheme provides for the observance of a similar technology for the installation of an external corner, which is mounted, leaving a distance of 6 mm to the eaves.

- The J-rail is fastened around the various openings, not nailing it too tightly to them.

- To install the first element, insert the bottom edge of the panel into the starter strip and nail in its upper edge. Start assembling the siding from the back of the building, gradually moving towards the facade.

- Next, let's look at how to assemble the siding after completing the installation of the first row. To continue the installation, each time you need to install a new row, starting from the back of the house, again moving towards the pediment. Siding panels must be positioned so that the joint of their upper row is not over the joint of the lower row.

The preparatory work is over - now the process will go faster

- To install the panels under the window - cut the required size of the elements. Measurements will be required. Place the siding under the window and, while holding the panel, mark the width of the opening on it, in addition to which add 6 mm on each side.

Some of the nuances of siding assembly

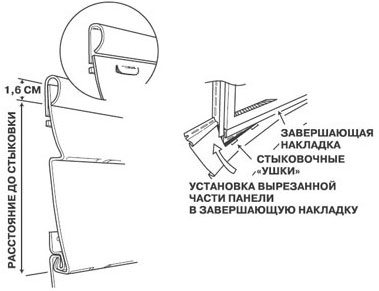

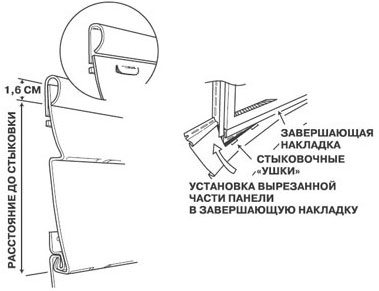

- To install the last siding panel under the eaves, nail one or more finishing battens to the wall of the house, flush with it. Docking the parts exactly as shown in the photo.

Docking the finishing rail under the eaves

Surface preparation

Before carrying out the main work, you need to foam or cement all cracks, remove protruding elements.

Check it out here!

DIY illuminated ceiling: 85 photos of the best options! Types of illumination: spots and peculiarities of their connection, LED illumination, diode illumination, "starry sky"

Do-it-yourself shower cabin assembly: pallet assembly, preparation and installation of walls, installation of a portal. All stages of assembly with a photo

How to make ventilation with your own hands - we provide freshness in the house, we create comfort on our own (photo + video)

The walls are thoroughly cleaned of dirt. When facing with siding, the surface of a wooden house is treated with an antiseptic, and foam blocks are carefully primed.

Fastening the lathing

The lathing is based on wooden slats or a metal frame. Concrete and brick surfaces are galvanized with a profile.

First, the walls are marked out in a straight line using a level, then they begin to fasten the vertical elements.

The distance between the two slats is about 40 centimeters. Places of corners and window blocks require additional guides.

Preparatory work

Any construction process should always start with the selection and purchase of the necessary materials, tools and the preparation of drawings. In order to carry out the installation of the siding with your own hands and make the crate, you will need the following tools:

- a hammer;

- building level;

- drill and screwdriver;

- tape measure with a large footage;

- hacksaw or fine-toothed saw;

- plumb line;

- scissors for metal or a knife for cutting vinyl siding.

In addition to this list of tools, goggles are a very important piece of equipment. If the work will be carried out at a height, then, of course, a ladder or scaffolding will be needed. In addition, if, along with the installation of siding, you will also need to carry out insulation:

- a special knife for cutting insulation (a serrated bread knife is perfect for this;

- special stapler with staples, required for fixing the vapor barrier membrane.

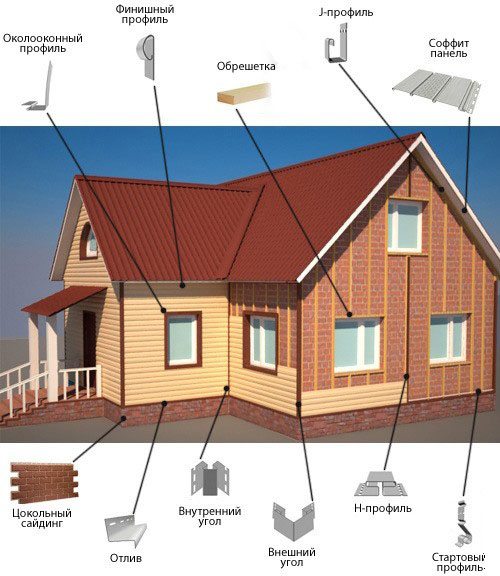

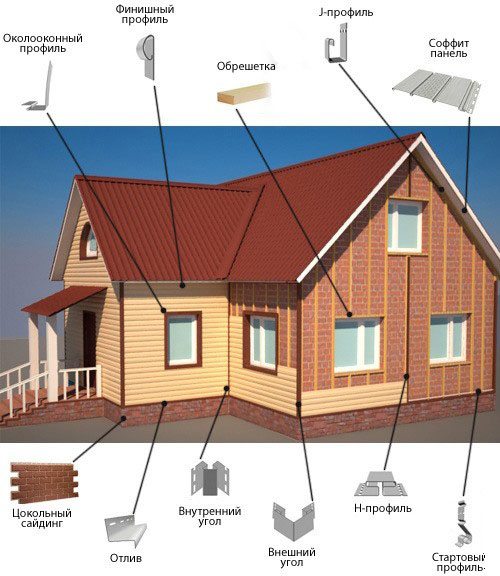

In addition to tools, the following materials will be needed for high-quality siding installation:

- siding (metal or vinyl);

- special J-profiles designed for attaching siding;

- external and internal corners;

- start profiles;

- any insulation (mineral wool, basalt or fiberglass insulation in slabs);

- self-tapping screws and special nails for installing panels and lathing;

- dowel-nails for the installation of insulation (with wide heads);

- edged board or slats required for the lathing;

- for insulation of insulation, a diffusion membrane.

Protection against temperature extremes

Upholstery work involves preliminary insulation and protection of walls from moisture penetration. The need for thermal insulation is considered individually, while waterproofing is a prerequisite for installation.

Check it out here!

How to make a drywall arch: we make an interior arch according to the photo instructions. 120 photos of arches in the interior

How to make a balcony with your own hands - tips on how to make a beautiful balcony in an apartment. Step-by-step guide to the use of modern building materials + 70 photos of the best design options

Do-it-yourself coupe door installation - step-by-step instructions for installing sliding doors and advice on choosing accessories (110 photos + video)

Fastening the guide parts

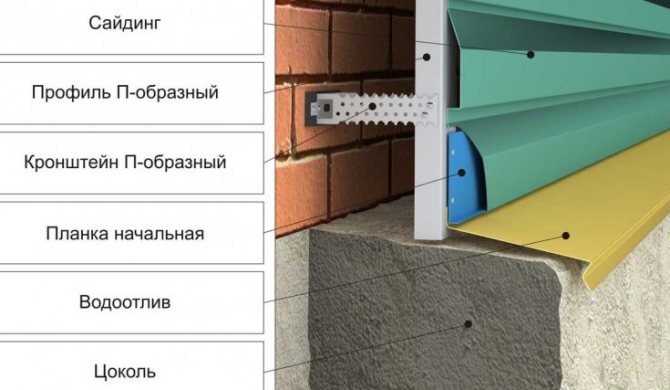

Installation of elements begins with the drainage area. The profiles are fixed at the corners with self-tapping screws, after which the main guide element is attached.

In the area of the window opening, the slats and profile are fixed in such a way that the lower edge on the outside is slightly lower than the inside. The door is framed around the perimeter with a profile marked J.

Siding panels are fixed so that there is a small gap at the bottom, half a centimeter is enough. Above, all the shortcomings will be hidden by the closing bar.

Installation technology for siding and its structural elements

Siding cladding technology determines the device of additional decorative and functional elements. Installation is carried out from bottom to top. The plinth finish can be plaster, tile or special siding.

Low tide Is a decorative element that performs the function drainage of atmospheric precipitation from the facade... The ebb is installed according to the level, observing the horizontal, and is attached to special nail holes to the frame using self-tapping screws. If the nail holes do not hit the guide post, you can make a hole in the right place using a punch. The ebb is mounted in such a way that it can easily move within the limits of the nail hole, this will prevent deformation of the mounted siding. Low tide installed along the perimeter of the building above the basement... After installing one element, the next one is mounted with an overlap of 2.5 cm.

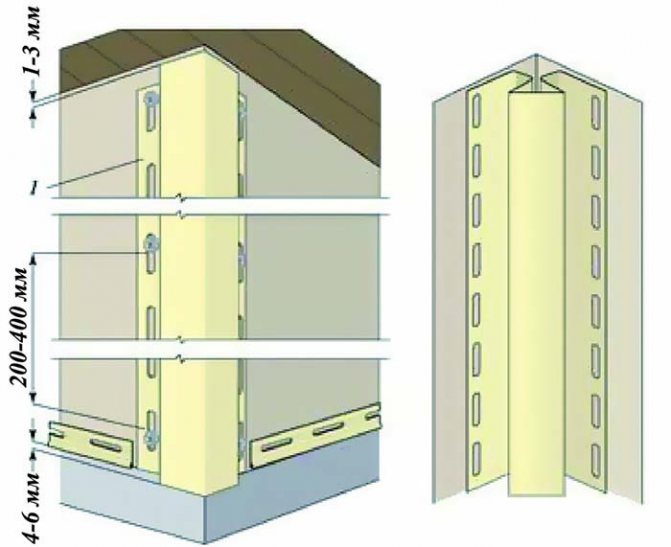

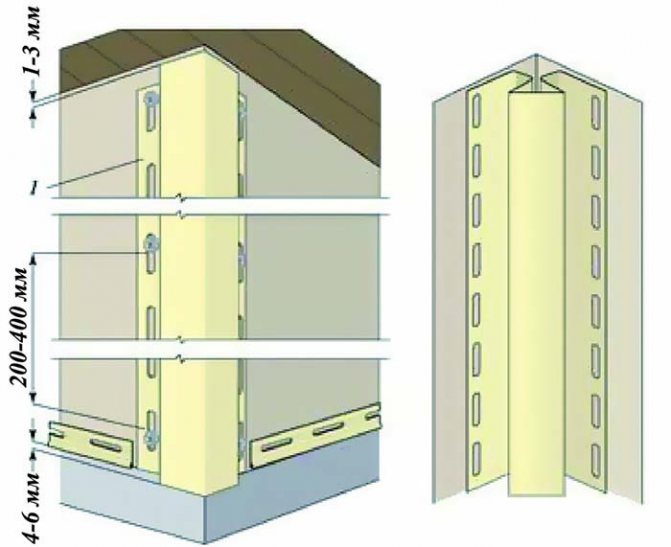

Outside and inside corners installed with one element to the entire height of the building. The element of the outer or inner corner is measured by size and cut off with a grinder. Then it is installed in the appropriate corner and fastened with one self-tapping screw. In this position, it is necessary to correct so that the corner element is located strictly perpendicular to the foundation. When the level is set, the corner is attached to the frame with self-tapping screws in increments of 200 mm. The attachment is carried out in the same way as the attachment of the ebb. The correctness of the installation is checked by moving the element along the axis.

Start profile installed slightly above the ebb and fixed with self-tapping screws to the frame in the same way as other elements. The correctness of the fastening is checked by horizontal movement of the profile. If it does not move, then it is necessary to release some of the fasteners a little.

The platband is cut to fit the size of the window opening... Each element must be trimmed at a 45 degree angle. Thus, the size of each casing is taken with a margin of 150 mm. In the upper platband, special tongues 20 mm long are arranged to protect against atmospheric precipitation. First, the lower element is attached, then the vertical, side ones. The upper casing is attached last, the tongues are inserted into the vertical elements. Fastening is carried out in the center of the nail holes, and all elements must be capable of axial movement.

Siding installation starts from the bottom panel... The lower part is inserted into the starting profile, and the upper part is screwed to the guides with self-tapping screws. Attaching siding to a wooden house starts from the yard. Work starts from areas with increased traffic: doors or gates. If the length of the wall is longer than the length of the siding, a connecting element is installed, it is used as it n-profile, the ends of the profile are inserted into it. After attaching the first panel the second is installed, in the same way... The installation of the last panel is carried out only after the installation of the finishing profile. If the last panel does not fit, it can be cut with a knife. The cutting line is marked and several times is drawn along it with a knife, and then the excess part of the panel is broken off with pendulum movements. Window and door openings are cut in the same way.

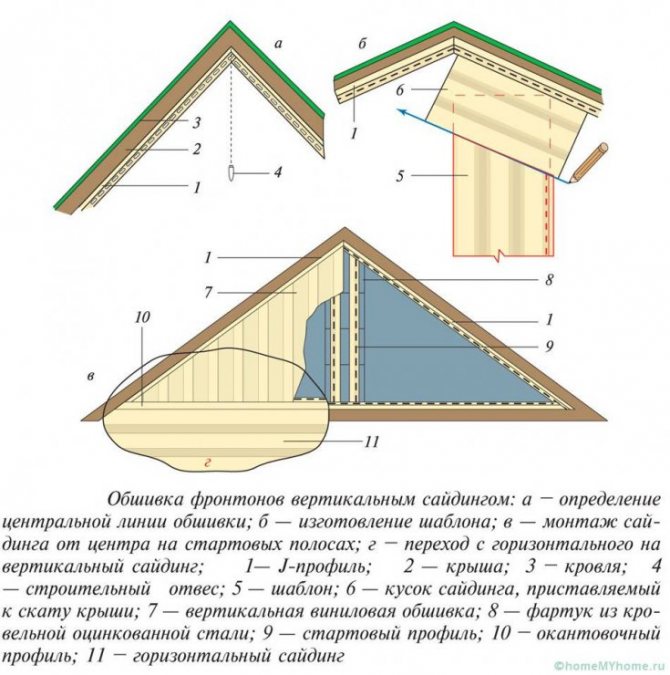

Soffit for finishing open gables of roofs gives the building a finished look. J-profiles are used to install them. One is mounted against the wall, and the second is parallel to it at the plumb line of the roof. The distance between the profiles is measured and the soffit is cut along it, but it should be 6 mm less for possible thermal expansion. The soffit is mounted between the profiles.

Back to content

Installation of panels

After installing the guiding elements, you can start attaching the siding. The basic installation is started by fixing it to the main starting plate. The rest of the panels are fixed in the same way.

The distance between the elements must be respected, they must not overlap. If the panels are long and require trimming, use a color-matched H-rail alignment.

Check it out here!

Do-it-yourself countertop installation: selection, installation and fastening of the countertop. 155 photos of the best ideas and tips for their application- Do-it-yourself canopy - beautiful ideas, best projects and tips on how to build a canopy with your own hands (90 photos and videos)

Do-it-yourself pool - 115 photos of the best ideas for building a vacation spot and an overview of current projects

Do-it-yourself installation of metal siding is carried out from the bottom up. The same principle of fastening and vinyl material.

Armed with theoretical knowledge and having watched several videos of do-it-yourself siding installation on the Internet, you can try.

Installation of corner profiles

How to install vinyl siding? After completing the lathing and installing the weir above the plinth, it is the turn of the corner profiles. They are rigidly fixed along a strictly vertical line. If you follow the instructions for installing the siding, then the upper edge of the corner profile will need to be located 5-6 mm from the eaves. The lower one, on the contrary, should be lowered by 7-8 mm from the installed starting bar. Installation of siding corners, if one lanka is not enough, overlap.

The fasteners should be made in such a way that the upper part flows over the lower one. The corner profile is fixed with nails or self-tapping screws at intervals of 20-40 centimeters.

Photo of the process of installing siding with your own hands

Read here - Do-it-yourself wiring installation - correct construction of circuits, recommendations and installation tips from the masters

Installation of panels: step by step instructions

After completing all the above steps, you can go directly to finishing the house with siding. According to the instructions, in order to correctly install the panels with your own hands, you must adhere to the following scheme:

- We take a guide profile and fix it to the wall along the perimeter;

- Next, panels are inserted into the profile, after which we proceed to the assembly of the siding, adhering to the vertical installation scheme.

Thus, it becomes clear that the last stage is the least difficult. However, here too there are some nuancesto be aware of. When screwing in the self-tapping screws, you need to make sure that they do not enter completely. Then, when it gets especially hot with the onset of summer, the material will have free space for expansion. If this recommendation is disregarded, it can lead to subsequent cracking of the panel.