Why choose steam heating?

It must be admitted that steam heating systems cannot be classified as very popular. Such heating is rather rare. Let's take a closer look at its advantages and disadvantages.

The first, undoubtedly, include:

- Heating system efficiency. It is so high that a small number of radiators are enough to heat the premises, and in some cases you can do without them: there will be enough pipes.

- Low system inertia, due to which the heating circuit heats up very quickly. Just a few minutes after starting the boiler, warmth begins to be felt in the rooms.

- There is practically no heat loss in the system, which makes it very economical in comparison with others.

- Possibility of rare use, since due to the small amount of water in the pipes, the system does not defrost. Alternatively, it can be installed in country houses, where they come from time to time.

The main advantage of steam heating is considered to be its efficiency. The initial costs for its arrangement are quite modest; in the process of operation, it requires relatively small investments.

However, even with so many advantages, the disadvantages of the system are very significant. They are associated primarily with the fact that water vapor is used as a heat carrier, the temperature of which is very high.

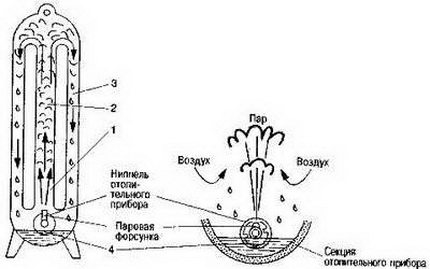

Condensation of water vapor occurs inside a steam heating radiator. During this process, a large amount of thermal energy is released, which explains the high efficiency of the system.

Thanks to this, all elements of the system are heated to 100 ° C and even higher. It is clear that any accidental contact with them will cause burns. Therefore, all radiators, pipes and other structural parts must be closed. Especially if there are children in the house.

The high temperature of radiators and pipes provokes active air circulation in the room, which is quite uncomfortable and sometimes dangerous, for example, in case of an allergic reaction to dust.

When using steam heating, the air in the rooms becomes too dry. It is overdried by hot pipes and radiators. This requires additional use of humidifiers.

Not all finishing materials used to decorate rooms heated in this way can withstand the proximity of hot radiators and pipes. Therefore, their choice is very limited.

The most acceptable option in this case is cement plaster painted with heat-resistant paint. Everything else is questionable. Steam heating has one more disadvantage that affects the comfort of those living in the house: the noise that steam passing through the pipes produces.

The more significant disadvantages include poor controllability of the system. The heat transfer of the structure is almost impossible to control, which leads to overheating of the premises.

Steam heating is a potentially hazardous system, so the choice of equipment must be treated very responsibly. The pipes for the system must be made of metal only.

There are solutions. The first is the installation of automation, which will turn on the boiler when the premises cool. In this case, those living in the house will be quite uncomfortable from the constant fluctuations in temperature.

A more "sparing", but time-consuming method is the arrangement of several parallel branches that will need to be launched as needed.

The main disadvantage of steam heating, due to which it is little used, is its increased emergency hazard. You need to understand that when a gust occurs from a pipe or radiator, hot steam will beat under pressure, which is extremely dangerous.

That is why such systems are now banned in apartment buildings and are less commonly used in production. In private houses, however, they can be arranged under the personal responsibility of the owner.

The main elements of the steam system

The steam system includes several required elements. Let's consider each of them in more detail.

The steam boiler is the heart of the system

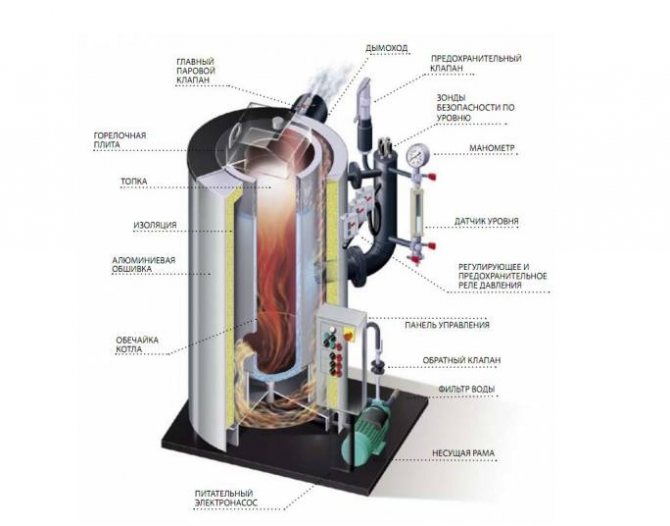

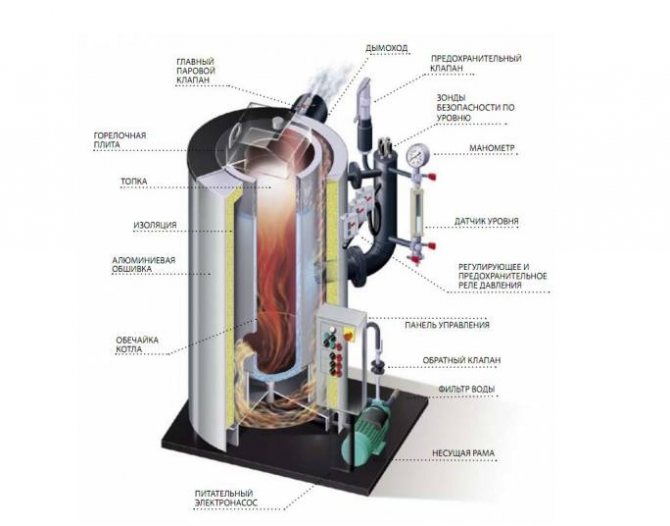

The main function of the heater is to convert water into steam, which subsequently enters the pipeline. The main structural elements of the device are manifolds, drum and pipelines.

In addition, there is a container with water, which is called a water space. A steam space is formed above it during the operation of the device. They are separated by the so-called evaporation mirror.

The figure schematically shows one of the varieties of a household steam boiler

Inside the steam space, additional equipment can be installed to separate the steam. The operation of the boiler is based on the principle of heat exchange of flue gases, water and steam.

There are two types of steam heating devices: fire-tube and water-tube. In the first case, heated gases move inside the pipeline laid inside the container with water.

They give off heat to the liquid, which reaches a boiling state. Water-tube varieties work a little differently. Here, water flows through pipes laid inside the flue gas chamber. It warms up and boils.

Water and steam inside the boiler can move either forcedly or naturally. In the first case, a pump is included in the design, in the second, the density difference between water and steam is used.

All types of steam boilers use approximately the same principle of converting water into steam:

- The prepared liquid is supplied to a reservoir located in the upper part of the boiler.

- From here, the water flows through pipes into the collector.

- The liquid from the collector rises into the upper drum, while passing through the heating zone.

- Steam is generated inside the water pipe as a result of heating, which rises upward.

- The steam, if necessary, is passed through a separator, where it is separated from the water. After which it enters the steam line.

A steam boiler can use a wide variety of fuels. Depending on this, certain changes are made to its design. They touch the combustion chamber. For solid fuel, a grate is set up, on which coal, firewood, etc. are placed.

For liquid and gaseous fuels, special burners are used. There are also practical combined options.

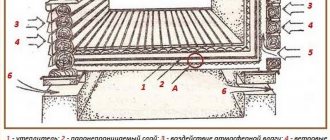

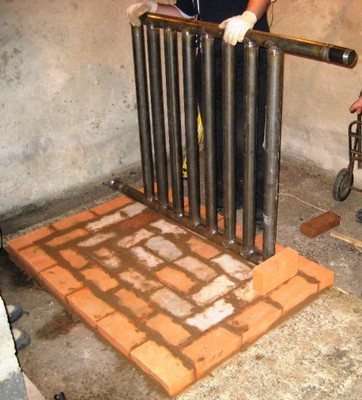

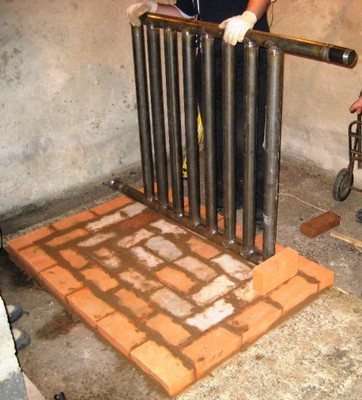

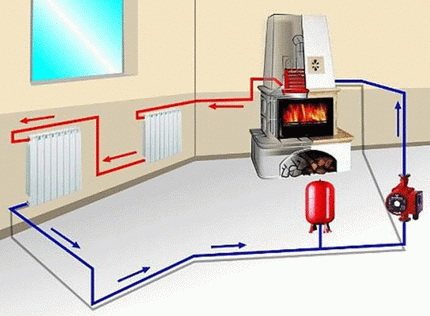

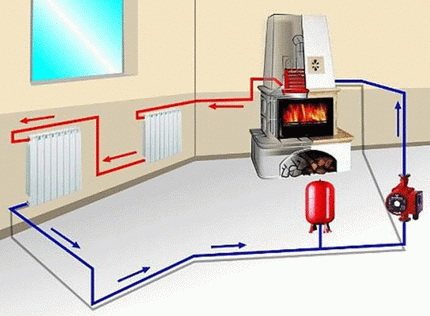

Among home craftsmen, the arrangement of steam heating using a stove is especially popular. The photo shows one of the possible options for reworking the furnace.

The power of the boiler is selected depending on the area to be heated.

This can be done based on the average values:

- 25 kW for buildings up to 200 sq. m;

- 30 kW for houses ranging from 200 to 300 sq. m;

- 35-60 kW for buildings from 300 to 600 sq. m.

If more accurate data is needed, they use the standard calculation method, where for every 10 sq. meters account for 1 kW of equipment power. Remember that the formula is used for houses with a ceiling height of 2.7 m or less.

For higher buildings, you need to take more power. When choosing a boiler, special attention should be paid to its certification. Any steam heating system is potentially dangerous, therefore equipment testing is imperative.

Heating pipes and radiators

The coolant temperature in steam systems ranges from 100 to 130 ° C, which is much higher than in liquid systems, where it ranges from 70 to 90 ° C. Therefore, it is strongly discouraged to use similar equipment for arranging systems.

First of all, this applies to metal-plastic and polypropylene pipes. The maximum operating temperatures for these materials vary between 90-100 ° C, so their use is strictly prohibited.

Ideal for arranging a steam heating system copper pipes. They do not corrode, withstand high temperatures, but are very expensive

For main pipelines of steam systems, three types of pipes are usually used. The most inexpensive option is steel. They can easily withstand temperatures of 130 ° C, which is more than enough, and are quite durable.

However, the condensate formed inside the parts quickly destroys the pipes, since the steel is susceptible to corrosion, and the aggressive medium formed by the steam only enhances this disadvantage.

Another disadvantage of steel elements is the need to connect by welding, which takes a lot of time and effort. Galvanized steel pipes are much more resistant to corrosion. They also withstand high temperatures well.

To connect them, a threaded method is usually used, which greatly simplifies the process. The main disadvantage of galvanized pipes is their high cost.

Copper pipes are considered ideal. The material can withstand high temperatures, is sufficiently plastic and at the same time durable, does not corrode. Soldering is used to connect copper parts.

Copper piping is very durable and strong, but the cost is very high. Thus, the most acceptable option in terms of quality and price ratio is steel pipes with an anti-corrosion coating or galvanized.

The best choice for steam heating is cast iron radiators. They will be able to withstand the severe stress caused by the presence of hot steam inside the batteries.

Radiators for steam systems are selected on the basis of durability. It is important that they can withstand high temperatures and are resistant to corrosion. Based on this, massive cast iron batteries can be considered the best option, steel panel batteries are the worst.

Given the high efficiency of the system, in some cases, the use of ribbed steel pipes is quite acceptable.

Control and measuring equipment block

The steam heating system is characterized by increased emergency danger, therefore, the presence of control devices is mandatory. The pressure in the system is monitored, if necessary, it is normalized. For these purposes, a gearbox is usually used.

The device is equipped with a valve through which excess steam is removed from the system. For powerful installations, you may need not one, but several such valves.

Do-it-yourself steam heating from the stove

In order not to install a heating boiler for the installation of a steam heating system and spend money on this, you can use the stove available in the house. It will act as a heat source with inexpensive solid fuel, moreover, it does not depend on the central gas and electricity supply. A heat exchanger acts as a steam generator, which can be made to order or independently. The disadvantages of a steam boiler are the same as in a conventional stove or fireplace: the lack of the possibility of precise regulation of the heating temperature, the lack of complete fire safety, as well as the possibility of smoke in the room due to improper kindling. Thus, the boiler-furnace has the same disadvantages as a conventional one, and the advantages are much greater.

Before making steam heating from the stove, it is necessary to check the heat exchanger for leaks.This can be done as follows: kerosene is poured into the device, while the seams are surrounded by chalk. Places where the chalk has darkened means a leak, which means that this device cannot be used for a steam heating system.

To divert steam heating from the stove, you will need the following components:

- Heating batteries. Their number should be equal to the number of windows in the room.

- Heat exchanger

- Copper or galvanized pipes for condensate drainage and steam lines.

- Shut-off valves (air bleed valves, valves)

- Connecting fittings: elbows, pipe clamps, fittings.

- Brackets for radiators

- Hydraulic shutter

- Reduction and cooling unit, with the help of which the steam is converted into a liquid state.

- Reducer for reducing the pressure inside the system.

- Pump for forced circulation of liquid.

- Inverter welding machine

Before starting work, a connection diagram and installation of pipes are preliminarily developed. The drawing determines the location of the boiler-furnace, from which the wiring diagram with all the necessary connection elements is then laid. For heating the area is not more than 80 sq.m. a one-pipe connection diagram for radiators is suitable. With this method of connection, the convectors heat up sequentially, the first of them is stronger than the others. The two-pipe system is suitable for heating rooms over 80 m2. and two-story houses. The pipes are connected in parallel to the convectors. If you plan to install the system according to the principle of natural circulation, the heat exchanger should be located below all convectors and pipes at an angle of inclination. This requires the installation of a pump for uninterrupted circulation of the heating system.

After the scheme has been developed and all the structural elements necessary for assembling the heating system have been taken into account, you can draw up an estimate for the purchase of materials and start working.

Work technology

It should be borne in mind that the installation of a steam heating system without dismantling the old stove is impossible. In order to build in the heat exchanger, it is necessary to mount it inside the furnace at the stage of laying the furnace.

Radiators are arranged under each window, to which the supply and discharge pipes are connected at a slight slope of 3mm. Each radiator is equipped with an air release valve.

To secure the system, shut-off valves are installed in front of each convector and in front of the entire system as a whole. At the beginning of the system, a cooling reducer and a pressure reducing valve are also installed. At the end of the system, a condensate collection tank is installed with the same slight slope as the pipes. From there, water flows into the heat exchanger. A pump is installed in front of the stove in a forced circulation system.

The chimney of a stove with an installed steam generator must be cleaned of soot more often. In order to ensure free flow of condensate to the lowest point, it is better to install the stove in a basement. Installing valves will help prevent accidents and should not be ignored.

When installing a heating system in a wooden house, it is necessary to ensure fire safety measures by protecting the wooden surfaces from overheating. For this, the adjacent wall with the stove and the floor surface must be covered with a fireproof material. The shutter door of the firebox and the blower at the stove must be installed. It is better to plan the location of the boiler-stove not near the load-bearing wall for the convenience of installing the chimney system.

The chimney height should not be less than 4 meters, otherwise the accumulated condensate will get into the furnace chamber. If the stove is located in an adjacent building (for example, a detached boiler room), it is not necessary to dismantle and move it inside the house. In this case, it is necessary to insulate well the pipeline that connects this building with the stove and the house.

In order to prevent overheating of the coolant above 100 degrees, you can adjust the temperature if you completely close the blower and open the furnace firebox.

Stove heating of a private house is still one of the most popular in all Russian regions. Previously, several stoves were used to heat a large house, which were installed in different rooms, but this is not the most economical option, since it requires a large amount of solid fuel.

Today, thanks to the developed modern schemes, as well as the fact that many different modern types of stoves have appeared on sale, it has become much easier to organize heating. It comes in different types and uses different fuels. To choose the most acceptable option for your home, which will be suitable in all respects, you need to take a closer look at some types and find out how they work.

Heating system selection

- For small, well-insulated houses, consisting of one or two rooms and a kitchen, one heating and cooking stove made of bricks will be enough.

- For larger buildings, it is necessary to think over the heating system so that the whole house can be heated from one stove. For this, heating using a water or steam circuit is used.

- For a one-story building, such a circuit can be connected to a brick oven or made of cast iron. When arranging the system in a two- or three-story house, a cast-iron boiler-stove is more suitable.

The next thing to decide on is the type of fuel. The system can be heated with wood, coal, peat, gas, diesel, electricity or several of them. This choice will determine which heating stove to purchase.

Brick oven

So, as mentioned above, for a small building, it is enough to build one stove, which will be heated with wood or coal.

The model of the stove must be chosen in such a way that it can not only heat the premises, but also be an assistant in cooking.

So that this heating structure does not bring any inconvenience and is as efficient as possible, you need to choose a suitable place for it. A well-placed stove can easily warm two rooms and a kitchen.

For example, this model shown in the figure would be a good option for heating three rooms. You need to know that the heat transfer from the furnace depends on the surface area of the structure, i.e. if one side of the stove enters the room, it will be fully heated. In addition, the massive structure cools down much longer. Having heated the building in the evening, you can be sure that it will give off heat to the room until morning.

The stove must be laid during the construction of the house, but its foundation must be separated from the general foundation of the building. It is possible to install a brick oven in an already built house, but this will be more difficult, since you will have to lift part of the floor and make a hole in the ceiling and roof for the chimney.

This diagram clearly shows the structure of the building, the foundation arrangement, the chimney channels and the passage of the pipe through the ceilings with all the necessary parameters that must be adhered to.

Brick structure with water circuit

A brick stove can also be adapted for heating large areas, if, during its construction, a heat exchange element is placed near the firebox, through which the coolant will pass, heating and then circulating in the heating system diluted around the house. In this case, it may be necessary to connect a water pump, which will accelerate the movement of the coolant in the system.

Heat exchange elements can be of different shapes, one of them is shown in the photo.It is embedded in the structure of the furnace near the combustion chamber, so that, passing through it, the water quickly heats up and enters the pipes and batteries.

The pipes for the inlet and outlet of the heat exchanger are led out from the furnace structure, and the heating circuit is connected to them. Further, the system is filled with water, which will act as a heat carrier.

In this case, metal-plastic pipes were used for wiring and connecting to the circuit.

In this diagram, the heat exchanger is located above the firebox and is shown as a red grid. The blue line marks the cooled coolant, which passes through the circulation pump and enters the heat exchanger - this part of the circuit is called the return. The red line marks the heated water entering the radiators.

Also, a membrane tank is installed in the heating circuit, which can be located anywhere in the circuit, but it is advisable to install it on the return pipe.

It is also called a closed-type expansion tank. On its upper part there is a nipple, through which air is pumped into the upper chamber. When the water in the system heats up, it expands, and its excess rises into the tank, stretching the membrane. When it cools down and the pressure drops accordingly, water is squeezed back into the system. Thus, possible pressure surges in pipes are smoothed out, the risk of destruction of the integrity of the system from overheating is minimized.

Video sketch: an interesting option for a fireplace stove with a heating circuit

Cast iron stove

Cast iron stoves, although they are small, are capable of heating a fairly large room with a volume of up to 80-90 cubic meters. meters. This option will be ideal for a country house, since the appliance has a hob function. Thanks to their elegant design, today they are also happily installed in expensive mansions, as they are an interior decoration.

The best option of all cast iron models is a long burning stove. It is able to give off heat to the room for a long time, despite the fact that the laying of firewood in it is done once during the entire heating time. This effect is achieved due to the internal design of the furnace, which allows the active flame to be reduced to a slow glow.

A long-burning boiler-furnace can also have a water circuit.

Cast iron stoves with a water circuit

Cast iron stoves with a water circuit are produced in different capacities and are designed for heating of various areas. Some of them are capable of heating a two- and three-story house. The heating circuit is arranged according to the same system as for brick ovens.

Furnaces are made of cast iron and combined type, i.e. having electric heating, which turns on automatically when the temperature of the smoldering wood drops. This combination of oven functions will always help keep the heating system at the desired temperature.

Cast iron boiler-furnaces can also be provided for a two-circuit heating system, i.e. plus to the heat in the house, the owners will also have heated water.

What should be considered when choosing and arranging a stove?

Choosing which heating stove will be installed in the house, you need to correctly formulate the requirements for it, and, relying on them, purchase or build a heating device.

- The heating of the entire structure of a brick oven is very important. Therefore, if it is decided to install such a furnace, you need to choose the right project and ensure the perfect construction of the structure.

- The efficiency of the heating system will also depend on the design and layout of the water circuit, as well as the choice of radiators for the heating system. There are furnace schemes that can operate in summer and winter modes - this factor also contributes to the economical operation of the device.

- Part of the savings can be attributed to the long cooling of the furnace, which will use less fuel.

- An important point is ease of operation and maintenance.

- The design must comply with all fire safety rules for its location and installation.

- A properly executed structure will have the required thrust, which will protect the house from carbon monoxide entering the premises.

- The oven must be designed for a long period of operation.

- Of course, it would be nice if the stove became a real decoration of the house, and not only was functional only from a practical point of view.

Positive and negative aspects of stove heating

In most cases, stove heating is arranged if necessary, in the absence of main natural gas. But heating with a stove has its advantages and disadvantages, which it would also be nice to know about.

What are the disadvantages?

The negative aspects include:

- A sufficiently long heating of the oven, and therefore of the premises. This is due to prolonged heating of the walls and the coolant in the system.

- Not very high efficiency of a brick structure. To increase it, you have to arrange a higher chimney, make it a labyrinth type, so that the heat stays inside the structure longer.

- A brick oven occupies a fairly large area, but only at this scale is it capable of heating several rooms at the same time.

- Unlike heating with natural gas, the stove must be supervised throughout its entire firebox, since brick options require constant fuel addition. Long-burning cast-iron stoves are an exception, since firewood is laid once per heating session.

Positive points

Stove heating has many positive qualities, which are often decisive in choosing it for a device in a private house.

- Autonomy, which means reliability. The house will always be warm, even if the electricity and water are cut off.

- Affordable construction and operation of the structure.

- Economy in the purchase of fuel and no bills for the main supply of gas or hot water.

- Ease of operation - the oven does not require programming, and if problems arise, they can be completely eliminated independently, without the involvement of specialists

- Since the oven for its operation does not require communications, it can be installed or erected in a house located in any region and village.

Video - how to independently build a stove with a heating circuit

Due to the fact that today gas pipelines are not everywhere, stove heating remains relevant and irreplaceable. Stocking up on fuel in advance and keeping the fire on the stove is all that is required of the owner of a stove-heated house. Therefore, in some houses, even with gas heating, they are in no hurry to get rid of reliable brick buildings, and they also install cast-iron fireplace stoves to create not only a warm, but also a cozy atmosphere in the house.

Wood fired boiler for heating

In an age of unprecedented success in science, it is already difficult to imagine that someone else is heating a room with firewood. Nevertheless, they have not yet been forgotten, and even today they are not at all uncommon. True, today these are no longer old Russian stoves, and not even their elegant tiled counterparts.

Most modern ones combine two components - a traditional, time-tested source of energy - simple firewood and a steam heating system that came into use relatively recently - just some 100-150 years ago.

To a city dweller, of course, this may seem like a relic of the ancient past. But in many villages and dachas, boilers are still used to heat a house with wood. And given the growing demand for everything natural, solid fuel boilers can be found more and more often in cottage settlements.And it's not about the high efficiency and high heat transfer of this heating method. It's just that in the minds of many there is a strong association of an open flame of a wood-burning stove with a feeling of calmness, comfort and security.

And in those places of our boundless Motherland, where the gas pipeline has not yet reached, wood-burning boilers, in fact, are the only way to organize steam heating.

Varieties of the heating system

In practice, you can find a fairly large number of variations in steam heating. By the number of pipes, one and two-pipe types of steam systems are distinguished. In the first case, steam moves continuously through the pipe.

In the first part of its journey, it gives off heat to the batteries and gradually turns into a liquid state. Then it moves like condensation. To avoid obstacles in the path of the coolant, the pipe diameter must be large enough.

It happens that steam does not partially condense and breaks through into the condensate pipeline. In order to exclude its penetration into the branch intended for the drainage of condensate, it is recommended to install condensate drains after each radiator or group of heating devices.

A significant disadvantage of the one-pipe system is the difference in the heating of the radiators. Those located closer to the boiler heat up more. Those further down are smaller. But this difference will be noticeable only in buildings that are large in area. In two-pipe systems, steam moves through one pipe, condensate leaves through the other. Thus, it is possible to make the temperature equal in all radiators.

But at the same time, the consumption of pipes increases significantly. Like water, steam heating can be single or double-circuit. In the first case, the system is used only for space heating, in the second - also for heating water for domestic needs. Heating wiring also differs.

Three options are practiced:

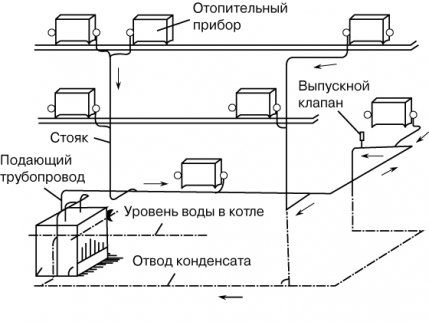

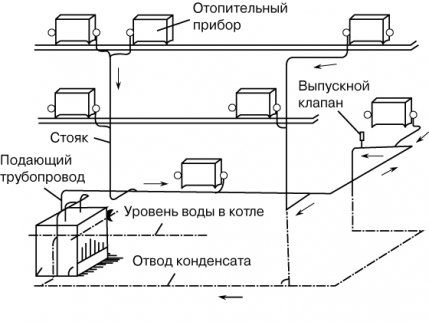

- With top wiring. The main steam line is laid above the heating devices, pipes are lowered from it to the radiators. Even lower, at the very floor, a condensate line is laid. The system is the most stable and easiest to implement.

- With bottom wiring. The line is located below the steam heating devices. As a result, steam moves along the same pipe, which should be slightly larger than the usual diameter, and condensate moves in the opposite direction. This provokes water hammer and depressurization of the structure.

- Mixed wiring. The steam pipe is mounted slightly above the level of the radiators. Everything else is the same as in a top-wired system, so all its advantages are preserved. The main disadvantage is the high risk of injury due to easy access to the hot pipes.

When arranging a circuit with natural compulsion, it must be remembered that the steam line is mounted with a slight slope in the direction of steam movement, and the condensate line is for condensate.

The slope should be 0.01 - 0.005, i.e. for each linear meter of the horizontal branch, there should be 1.0 - 0.5 cm of the slope. The inclined position of the steam and condensate lines will eliminate the noise of steam passing through the pipes and ensure free drainage of condensate.

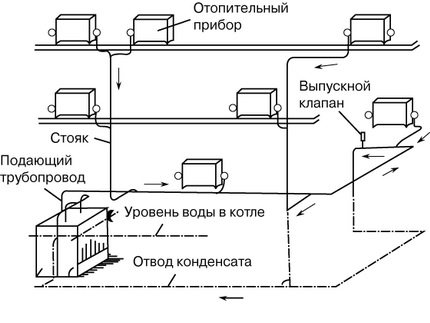

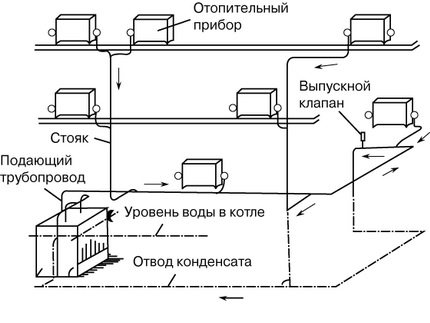

Steam heating systems are built according to a one-pipe and two-pipe scheme. Among the one-pipe, options with horizontal connection to heating devices prevail. In the case of constructing a circuit with vertical connection of devices, it is better to choose a two-pipe version

According to the level of internal pressure of the system, two main types are distinguished:

- Vacuum. It is assumed that the system is completely sealed, inside which a special pump is installed to create a vacuum. As a result, steam condenses at lower temperatures, making the system relatively safe.

- Atmospheric. The pressure inside the circuit is several times higher than atmospheric pressure. In the event of an accident, this is extremely dangerous. In addition, radiators operating in such a system heat up to very high temperatures.

There are many options for arranging steam heating, so everyone can choose the best option for their home, taking into account all the features of the building.

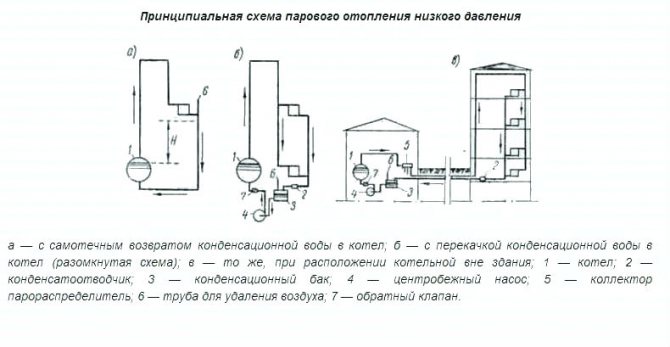

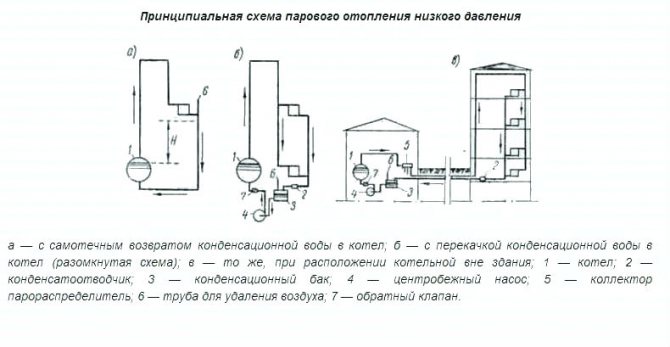

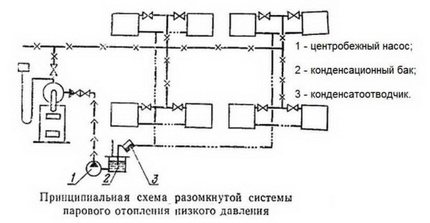

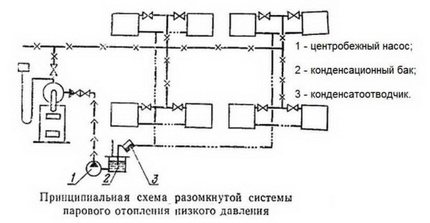

The figure shows a diagram of an open-loop steam heating system

How to make steam heating in a private house, diagram

Living in a country house in winter is unlikely to be comfortable without good heating. Harsh and prolonged winters in our country force the owners of private houses to provide the premises with an effective heating system. At the same time, everyone wants to establish a system that will not ruin the family by spring. According to the reviews of many owners of mansions, steam heating in a private house from a wood-burning stove is an optimal and fairly economical option.

Steam heating has been used for many years to heat large and compact houses. Such a system has a number of advantages, including the following:

- High efficiency.

- Reliability and durability.

- Easy to install and use.

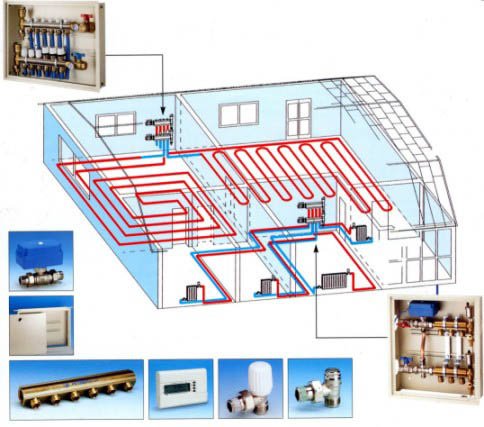

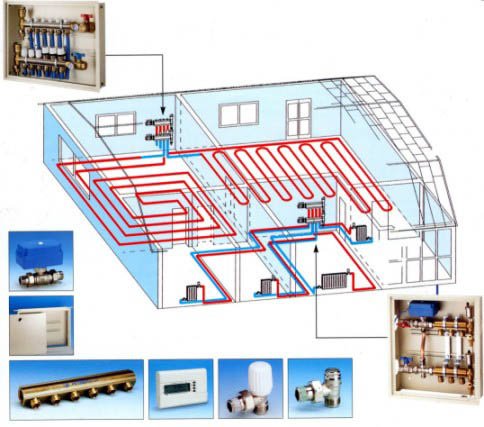

In modern houses, you can use steam heating, implemented according to different schemes, namely:

- single-circuit - used for heating premises in a private house;

- double-circuit - allows you to heat a house of any size and at the same time provide the premises with hot water.

The advantage of steam heating is that the distribution of the heating system main can be done in the upper or lower way, and the pipelines are used vertical or horizontal, as shown in the diagram.

An important feature of heating from a wood-burning stove is the circulation of the coolant, which can be carried out forcibly using a pump, as well as in a natural or gravitational way. To save money, many install a system with a natural way of circulation, in which heavy cold water sinks into the lower part of the system, and hot and lighter water rushes up.

Many people install a system with a natural way of circulation to save money.

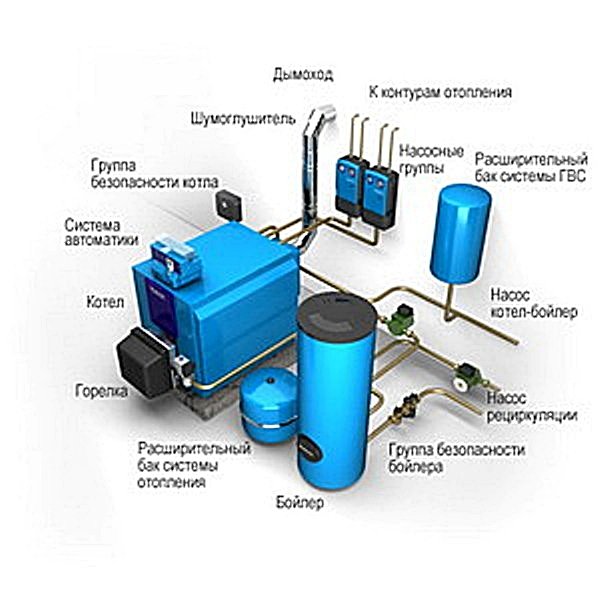

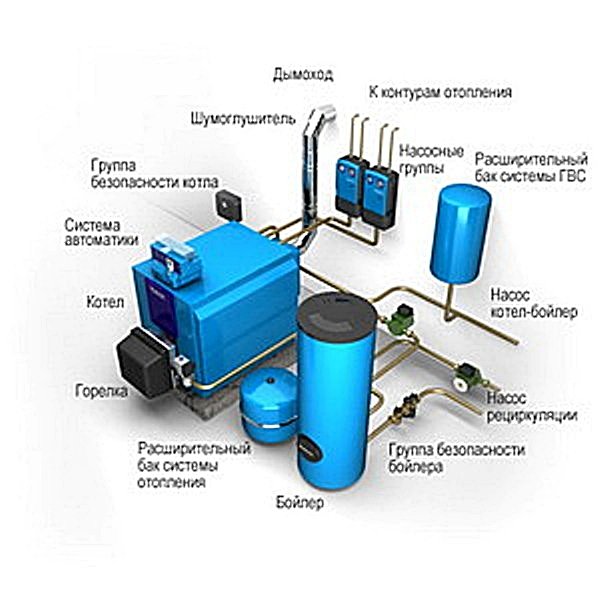

How to equip a boiler room?

A steam boiler operating on any fuel must only be installed in a specially equipped room.

The standards developed for standard steam appliances with pressures up to 0.07 MPa, generating steam with a temperature of 120-130 ° C, provide for a number of requirements for such boiler rooms:

- the distance from the walls to the heater cannot be less than 100 cm;

- the height of the room must be at least 220 cm;

- the minimum level of fire resistance of doors - 30 minutes, walls - 75 minutes;

- the presence of high-quality ventilation;

- the presence of doors and windows facing the street.

It is best to equip the boiler room in a separate room, but partitioning of a suitable room is also allowed. Inside, it must be finished with non-combustible materials. Ceramic tiles are best suited for these purposes.

The walls in the boiler room should be finished with non-combustible materials, for example, ceramic tiles.

Development of a design solution

Before installing the boiler and laying the pipelines, it is necessary to develop a project or a diagram of the device for a future steam heating system.

When developing a project, it is necessary to take into account not only the route of pipelines with all possible branches, turns and other trifles, but also the material of the pipelines, the arrangement of instrumentation, safety and stop valves.

Selection of a steam heating scheme. Click to enlarge.

It is imperative to decide on the total length of the pipelines, the number of tees and adapters. To ensure reliability and safety, use only compulsory certified equipment.

Ideally (with the appropriate qualifications), the project can contain the calculated temperature graph of the steam heating network and the calculation of heat losses.

Requirements for the room when installing a steam heating system

There are some requirements for the room in which the boiler will be located:

- Ceiling height not less than 2.2 meters.

- The distance from the boiler to the wall is at least 1 meter.

- The fire resistance of the walls must be at least 75 minutes, and the fire resistance of the door must be at least 30 minutes.

- Wall material - brick, facing material - ceramics or mineral plaster.

- A working ventilation system, and the presence of window openings and an exit leading to the street.

These requirements correspond to a standard steam boiler with a steam pressure not exceeding 0.07 MPa and a steam temperature of 120 ° C to 130 ° C.

The sequence of actions for self-installation

Do-it-yourself steam heating involves the sequential implementation of the following main stages and operations:

- Development of a project or a schematic plan.

- Preparatory construction works in the boiler room.

- Installation of a boiler (below the level of radiators and pipelines) and heating radiators and pipelines.

- Installation of instrumentation, safety and non-return valves, drain fittings and other equipment.

- Testing the system performance and checking the serviceability of automatic protections.

The laying of pipelines must necessarily precede their connection to the radiators of the heating system. After that, the circulation pump is connected to the pipelines, in front of which a direct filter must be installed.

Steam heating installation. Click to enlarge.

The installation of the expansion tank and the connection of the boiler complete the installation process.

When installing individual elements of a steam heating system, one should take into account not only the general requirements and safety standards, but also the recommendations of the manufacturers, contained in the passports and operating instructions.

Some rules for self-installation

How to make your own steam heating reliable and durable? To do this, you must follow some basic installation rules: use factory-made pipelines.

When installing flange connections, use paronite gaskets (3-5 mm thick) pre-soaked in hot water.

Use good quality condensate siphons. Be sure to equip each boiler with safety valves. Be sure to perform a test run after completing the installation work.

Preparing to install the steam system

To properly make steam heating, you need to start with the preparation of the project. Its development is a complex task, which is best solved by specialists. In the finished project, many points must be taken into account.

First of all, the calculation of thermal loads on each of the premises and on the building as a whole is carried out. The source of steam is selected, as well as the mechanism and degree of automation of the system is determined.

In addition, the steam consumption is necessarily determined, based on this, the equipment and the scheme of its use are selected. After the project is ready, you can start drawing up an installation plan.

To complete it, you will need a building plan, on which the locations of the equipment are applied. They usually start with a boiler. Its location is determined. If the system has natural circulation, the boiler must be below the level of the batteries.

In this case, it is usually lowered into the basement or into the basement, so the condensate can drain independently to the device. Then the layout of the entire heating system is applied to the plan of the house. Moreover, all the necessary equipment is noted.

Experts advise to perform this operation directly "on site", being in the room where the equipment will be located.This is the only way to notice and take into account all the protrusions and obstacles that will have to be skirted.

Before starting the installation, a plan diagram of the future system must be carried out, on which all equipment and radiator attachment points are marked

All transitions and corners must be marked on the diagram. After it is completed, you can proceed to calculating the amount of material required for its implementation. Once again, it is worth paying attention to the importance of choosing the right equipment.

The steam system is potentially hazardous, so you shouldn't skimp on materials and appliances. Everything must be of high quality and certified, otherwise serious problems cannot be avoided.

Steam heating installation technology

Work begins with the installation of a heating boiler. It is mounted in a pre-prepared room on a concrete base. In some cases, a separate small foundation is prepared for the equipment.

The device is installed on the base strictly horizontally, the correctness is checked by the building level. Any errors noticed are eliminated immediately.

The boiler placed on the base is connected to the flue gas system. The connection must be solid and completely sealed.

The next step is to hang the radiators. To do this, in the places indicated on the installation diagram, special hooks are driven into the wall, onto which the batteries are attached. If the use of finned tubes is supposed, then they are fixed.

Finned pipes can be used in steam heating systems instead of radiators. The high heat transfer parameters of the system will be significantly enhanced due to the increased area of the heat-conducting surface

The strength of the fixing of the heat emitters is checked. Next, you can start arranging the expansion tank. It is fixed at the highest point at a short distance from the heating boiler, it is best to keep this distance as small as possible.

You can now set up a group of control devices. They are installed at the outlet of the boiler. At a minimum, a pressure gauge and a relief valve should be located here.

All installed equipment is connected by pipes. The connection method depends on the material from which they are made. In any case, the correctness and reliability of the connections should be carefully checked.

For open systems, a condensate collection tank is installed at the end of the line and a pump is installed. The branch pipe that goes from it to the heating device must have a smaller diameter than the rest of the pipes.

The steam boiler is connected to the heating circuit. In this case, all the necessary shut-off valves and filters must be installed, which will retain large particles of dirt that may be contained in the water.

If the equipment runs on gas, the fuel line is connected. In this case, it is forbidden to use flexible hoses - only rigid liners.

All connections are made exactly according to the standards in order to avoid an emergency situation later

Then you can carry out a test run. To do this, water is poured into the circuit, after which the equipment is put into operation. At first at the minimum operating temperature, then it is gradually increased, while monitoring the correct operation and integrity of the system.

When the slightest shortcomings are revealed, the equipment is stopped and all malfunctions in its operation are eliminated.

Composition and options for a steam heating device

Steam heating system composition. Click to enlarge.

A typical steam heating system consists of the following elements:

- Steam boiler.

- Trunk pipelines.

- Branches with heating devices.

- Risers.

The above elements are typical for an autonomous (independent) heating system.The boiler used in such a system as a heat generator can operate on gaseous, liquid, solid or combined fuel.

When installing a centralized system, an individual heating point acts as a heat generator.

In a private house, steam heating can be single-circuit or double-circuit. In the first case, only the building is heated, in the second, the heating function is supplemented by hot water supply.

The piping system, which includes vertical and horizontal pipes, can have a top or bottom routing. Installation of one or another type of piping is carried out depending on the individual characteristics of the room.

Advantages and Disadvantages of a Steam Heating System

Before carrying out steam heating at home, it is necessary to carefully weigh all the advantages and disadvantages of this system.

Main advantages:

- Compact size and relatively inexpensive installation.

- High heating rate, as well as the ability to heat large rooms and areas.

- High heat dissipation and overall efficiency

- No heat loss in heat exchangers.

- Less danger of freezing of the system (freezing of water in pipelines).

Some disadvantages:

- Stronger heating of the surface of heating devices, solved by installing a decorative screen.

- The inability to carry out smooth regulation of the temperature inside the premises.

- Corrosive effect of steam on pipelines.

Thus, steam heating has many more advantages than disadvantages. Self-installation of a steam heating system complements the list of numerous competitive advantages.