Rating of the best chimney manufacturers

| Photo | Name | Rating | Price | |

| #1 |

| CRAFT | ⭐ 100 / 100 4 - voices | Find out the price |

| #2 |

| Volcano | ⭐ 99 / 100 3 - voices | Find out the price |

| #3 |

| ROSST IN | ⭐ 97 / 100 | Find out the price |

| #4 |

| Jeremias | ⭐ 97 / 100 | Find out the price |

| #5 | Thermophore | ⭐ 96 / 100 | Find out the price | |

| #6 |

| Ferrum | ⭐ 96 / 100 1 - voice | Find out the price |

| #7 |

| Elits | ⭐ 95 / 100 1 - voice | Find out the price |

| #8 |

| Inzhkomtsentr VVD | ⭐ 93 / 100 3 - voices | Find out the price |

| #9 |

| Phoenix | ⭐ 92 / 100 1 - voice | Find out the price |

| #10 |

| Baltvent | ⭐ 91 / 100 | Find out the price |

| #11 |

| Rosinox | ⭐ 90 / 100 | Find out the price |

Which chimney manufacturer would you choose or would you advise to choose?

Take a survey

Rating of the best manufacturers

It is recommended that you familiarize yourself with the best brands that offer similar products before purchasing a chimney. They have proven themselves well, and each has certain pros and cons.

Phoenix

The company offers customers reliable and durable designs. The enterprise itself is located in the Moscow region, and consumers are attracted by the high quality of chimneys and a long warranty period. To achieve this, the company uses the best equipment and makes devices using modern technologies.

All materials undergo 3D modeling, plasma cutting and TIG welding. As a result, it turns out, to make a chimney of any type and shape. The warranty period is 15 years, the company has all the necessary certificates, documents that confirm the quality.

pros:

- The use of modern technologies in the production of chimneys.

- European equipment.

- The warranty period for goods is 15 years.

- Easy installation.

Minuses:

- Poor corrosion resistance.

- The quality of the seams is not the best.

Volcano

The beginning of the production of modular chimneys from the company took place in 1996. The range of chimneys is very large, there are models for an ordinary house or industrial facilities. Employees are constantly monitoring new products on the market, exchanging experience with European specialists. The plant uses modern technology, the best raw materials, which makes it possible to create competitive goods.

The products fully comply with fire safety, the company has all the necessary certificates and licenses. The brand's clients are Toyota and Nissan. Experts note the high quality and long warranty period.

pros:

- Application of a modern technological base.

- Product warranty 50 years.

- The use of high quality raw materials.

- We have our own laboratory.

The disadvantages include only the high cost.

Ferrum

The manufacturer offers a wide range of accessories for smoke extraction. Production is located in Voronezh, the brand creates not only pipes and chimneys, but also various plugs, adapters and additional elements for arranging the system. The main raw material is stainless steel, which undergoes a series of treatments to improve appearance and durability. The quality is at a high level, which is confirmed by certificates.

pros:

- The use of quality metal.

- The presence of a large assortment.

- The ability to purchase individual components in a large range.

- Simple and convenient installation.

- Nice appearance.

Among the disadvantages, only cost is distinguished.

Elits

This company is considered a leader in the domestic market. All work efforts are aimed at the production of chimney systems with an acceptable cost. In the manufacture, they use stainless steel, which helps to increase the service life. All products are used at home (private property) and at work. The products are suitable for the most common and simple stove, as well as modern boilers that heat large areas.Experts emphasize easy installation, the evenness of the welded parts and the shine of the pipe. But customers note the wrongly chosen insulating materials, as well as the thin walls of the pipes.

pros:

- Acceptable pricing policy.

- Easy installation.

- High quality seams.

- Wide area of use.

Among the minuses are only design flaws.

CRAFT

A Russian company with a rather short experience, but with high-quality products for heating systems. All products are sold only for the domestic market, with great emphasis on the quality of materials and the best technology. Chimneys are made of metal that does not corrode and is processed on modern machines. Experts emphasize high quality, reliability of structures and their durability, which is confirmed by user reviews.

pros:

- The use of very high quality materials.

- Using the best technological base.

- Modern equipment.

- Reliability of goods.

There are no downsides.

ROSST @ IN

The company is located in Moscow, is engaged in the production of chimneys. The work experience is quite large, which allows us to make high-quality goods for boiler houses and private housing. The goods are manufactured according to new developments and technologies. In the country, this company occupies the first positions in sales. Quality and reliability are high, but you have to pay for it.

Pros:

- Durability of structures.

- Originality of goods.

- Modern technologies.

- Experienced staff.

Among the minuses, only the high cost.

Thermophore

The brand first appeared in 2003 and received its award just a year later. In the assortment you can see various products, including stoves, boilers, tanks, chimneys and all accessories for them. The specialists highlight the excellent performance of the staff and the level of the technological base. When choosing this company, you should be careful, since there are many fakes, in addition, the products are not presented in all regions of the country.

Pros:

- Application of modern technologies.

- Excellent equipment.

- Qualified staff.

- Large selection of goods.

- High quality.

Minuses:

- Lots of fakes.

- It is difficult to find chimneys in retail chains.

Rosinox

The brand has been operating since 2001, the main activity is the production of chimneys. For this, stainless steel and the best materials are used, and the factory itself is located in the city of Klin. The best German techniques are used for manufacturing, so the products are an excellent competitor to their counterparts. The manufacturer has a well-developed dealer network, so you can find products in any region, and they sell well.

The work of all employees is well-coordinated, this makes it possible to fully meet modern requirements and equipment to which the chimney is connected. In the manufacture, ecological materials are used, and the process itself and raw materials fully comply with the standards that apply throughout the world. The only drawback is the poor and not always polite support service.

Pros:

- Use for the manufacture of German technologies and solutions.

- Developed dealer network.

- The use of environmentally friendly materials.

- Excellent quality goods.

Clients highlight the incorrect attitude towards them, which can be considered a big disadvantage in the work.

Baltvent

This is a Russian company that has been on the market for many years. The plant is located in Kaliningrad, not far from Europe, which has a positive impact on the technical base. The workshops have one of the best equipment that makes it possible to make high-quality chimney systems. For example, some elements do not use overlap techniques for joining. The goods have good competitiveness and are at an average price. The specialists point out the excellent quality, but the sale is difficult due to the location of the factory. At the moment, the problem is being solved by opening a retail outlet in Moscow.

Pros:

- The use of European equipment for production.

- Application of modern technological solutions.

- The optimal cost of goods.

- Reliability and durability of chimney systems.

The disadvantages include a meager choice in almost all regions of the Russian Federation.

Inzhkomtsentr VVD

Another Russian company that has been producing and developing stoves and chimneys since 1999. The company independently develops and manufactures products. All chimneys are made of stainless steel, suitable for any heater. Customers are positive about the reliability, cost and ease of installation.

Pros:

- Acceptable cost of goods.

- Quality production.

- Easy installation.

- High degree of reliability.

Among the minuses, the darkening of the pipe is distinguished after a short period of time.

Jeremias

The brand's products are included in the premium class, the company itself is Bavarian and has been operating since 1970, but products appeared in the Russian Federation only in 2008 after the opening of a representative office. At the moment, the company is characterized by the excellent appearance of the chimneys, the evenness of the seams and the use of modern developments in the course of production. Craftsmen emphasize easy installation, and customers note high performance characteristics.

pros:

- Excellent quality materials, workmanship and seams.

- Application of modern developments and technologies.

- Nice appearance.

- Durability of chimneys.

The disadvantages include the high cost characteristic of premium class goods.

Chimney manufacturers rating: TOP-11 best

Before buying a chimney, a potential buyer should familiarize himself in advance with which brands offer the best quality products today.

Below we will tell you about the best manufacturers, as well as note their pros and cons. They have proven themselves well, which is also additionally confirmed in their reviews by the people who contacted them.

Rosinox

Rosinox

The brand, which has been operating since 2001, opens the rating of the best chimney manufacturers. Rosinox uses only high-quality stainless steel and other environmentally friendly materials, and all production is located in Klin. The best German technique is what helps a brand to have a good product.

The best German machines are used for manufacturing, so the products from Rosinox are quite competitive in relation to the products of other companies presented below.

The dealer network is well developed, which means that the products of this domestic company can be found in almost any city.

All employees work extremely well, which allows you not to worry about the good performance of the Rosinox chimney installed in your house.

The only drawback of this manufacturer is the problematic contact with the support service of this company.

pros

- Using fresh solutions and production technology from Germany.

- Dealerships can be found everywhere.

- The use of environmentally friendly material.

- High quality products.

Minuses

- It is quite difficult to contact the support team of this company.

chimney rosinox

Baltvent

Baltvent

This domestic company has existed for many years on the market of heating equipment and its components. The production is located in Kaliningrad, and this city, which is importantly located near Europe. It was the location that influenced the technical base of the enterprise from the very beginning.

The best equipment from Europe, excellent specialists, high-quality material - all this made it possible to become what we know it now - well-known and with great production.

Quite important in this company is that the pricing policy of this company is within the average value with high quality of the final product.

pros

- Modern European equipment with high production rates.

- Commitment to modern technological solutions that have improved the product itself.

- The price for the products of this company is within the normal range.

- Extremely high reliability of products from this company.

Minuses

- Few things can be found interesting in the assortment of this company.

Phoenix

Phoenix

Another domestic company with production in the Moscow region, whose products have high reliability and durability. The long warranty period will allow you not to worry about the state of the chimney, because for this "Phoenix" uses not only high-quality material, but also good equipment in combination with modern production technologies.

Before manufacturing the chimney, the company creates a 3D model on which everything is pre-checked, then plasma cutting and TIG welding. The result is obvious - a chimney from absolutely any shape and type with all the necessary certificates and documents confirming the high quality of the goods.

The clients who turned to them were generally satisfied with the quality of the service and product, noting only the average quality of the seam. Only a small number of people had a chimney corrosion problem.

pros

- The chimneys are manufactured using the latest technology.

- Quality equipment from Europe.

- Long warranty period - 15 years.

- It will be quite easy to install a chimney of this company.

Minuses

- The chimney of these products is easily corroded.

- Seam quality not very good.

Branch-sandwich 230х130

Inzhkomtsentr VVD

Inzhkomtsentr VVD

Another Russian company, formed in 1999 and known for the production and development of high-quality steel chimneys. Own production allows us to achieve high quality and low cost of products.

The versatility of the chimneys of this company allows them to be used in almost any heating system, which is extremely convenient.

It should be emphasized that people speak of this company only on the positive side, highlighting the reliability and ease of installation of their chimneys.

pros

- Anyone can buy the goods of this company due to the affordable cost.

- High quality products.

- The installation of such a chimney will take place quite quickly.

- Extremely reliable chimney.

Minuses

- After a while, the flue pipe may darken.

Elits

Elits

This company, judging by the name, makes only high quality chimneys. And this is so, because all the efforts of specialists and engineers are aimed at one thing - to create high-quality and at the same time inexpensive products.

The use of quality material in the form of stainless steel allows to achieve a long product life - more than ten years without a single complaint.

Elits chimneys can be found in many summer cottages, private homes, and even industrial warehouses. In addition, it should be noted the versatility of the products of this company.

Ease of installation, high-quality welding and appearance - all this is available in Elits chimneys. And as the name implies, the pipes are really of the best quality.

The only thing that people notice is the presence of insignificant flaws in the design that are easily fixable.

pros

- Acceptable pricing policy.

- Easy installation.

- High quality seams.

- Wide area of use.

Minuses

- Design flaws.

Ferrum

Ferrum

In sixth place is the domestic manufacturer Ferrum, the range of which is quite large. Everyone can find the chimney that suits their home better.

All chimneys are manufactured in Voronezh, where the main workshop is located. Typically, the company uses high quality raw materials that go through a series of checks before entering production and becoming a chimney. High quality material is what gives this company's products the durability that the company has long been proud of.

Clients have repeatedly noted that the quality of Ferrum products is at the highest level, although the price, in their opinion, bites a lot.

pros

- The use of quality metal.

- The presence of a large assortment.

- The ability to purchase individual components in a large range.

- Simple and convenient installation.

- Nice appearance.

Minuses

- High price.

chimney ferrum

Thermophore

Thermophore

The top five of this rating of manufacturers is a relatively fresh company, founded in 2003. The brand developed so rapidly at the beginning that a year later it already had an award.

The assortment of this company contains a variety of products, among which you can find the following products:

- tanks;

- boilers;

- ovens;

- chimneys.

It should be noted the qualifications of specialists, as well as powerful modern equipment that allows you to create a high-quality product.

However, it is important to be careful - "Termofor" has a lot of fakes, the quality of which is too far from that of the original products.

pros

- The equipment and technologies are all the most modern.

- Skilled workers, thanks to whom the products are of such high quality.

- A large assortment.

- High quality product.

Minuses

- Counterfeits are common.

- Finding products from Termofor is not always easy.

Jeremias

Jeremias

The fourth place is taken by this premium brand from Germany. The Bavarian company is the only foreign representative of this rating, so it will be quite interesting to take a look at Jeremias.

The company itself was founded quite a long time ago - in 1970, but the company appeared on the territory of the Russian Federation not so long ago - in 2008, when the company opened its own representative office.

In short, the products of this company are characterized by several characteristic features at once:

- fine chimney design;

- smooth seam;

- combination of modern developments and quality raw materials.

Judging by the reviews, the chimneys of this company are installed quite easily, which pleases. In addition, high reliability and high-quality work of specialists stands out.

pros

- Excellent quality in everything - material, workmanship and even seams.

- High-tech chimney production.

- Bright and attractive product design.

- High indicators of durability.

Minuses

- The price bites.

chimney Jeremias

ROSST IN

ROSST IN

"Bronze" in our rating is received by a company whose production is located in Moscow itself. It has long been known in the market for heating equipment and their components, and there is no doubt about the quality of the products.

The chimneys of this company are considered quite versatile, because they can be installed almost anywhere and without any problems.

Rosst In products are made according to the latest developments and using modern technologies.

High quality and reliability are what made this company one of the market leaders. A high price is a payment for the fact that the chimneys will serve for a long time and with high quality.

pros

- High indicators of the durability of the products of this company.

- From a design point of view, the chimneys of this company look pretty neat and fresh.

- Using modern technologies and only high quality materials.

Minuses

- High price.

Volcano

Volcano

The company that took the second place in this rating started the production of chimneys back in 1996. Therefore, we can say about a very rich assortment of chimneys from this brand.

Any potential buyer, whether he is a private owner or a representative of another company with his own production workshop, can find a suitable chimney model from this company.

Qualified specialists are constantly introducing new technologies. Having our own laboratory allows us to quickly test new possible options in search of the best solution.

High-quality materials and raw materials, as well as the most modern technology - what the company uses when creating its famous chimneys, which are quite capable of competing with their competitors, since such serious companies as Nissan and Toyota pay attention to them, which is extremely significant.

The products of the Vulcan company have all the necessary certificates and licenses, which confirm the high quality of the products, as well as a long warranty period, with which you can forget about the issue of replacing the chimney for a long time.

pros

- Advanced production with modern technology.

- Very long warranty period of fifty years.

- Use in the production of high quality raw materials.

- Availability of our own laboratory for testing.

Minuses

- High price.

chimney volcano

CRAFT

CRAFT

"Gold" is received by a fairly young domestic company, which has, at the same time, fairly high-quality products for the heating systems market.

It is interesting that the products of this company do not go outside the country, which means that they are sold only for the domestic market, which allows us to talk about an adequate price for most buyers.

The use of high quality materials, as well as an emphasis on modern equipment and technologies, allow us to achieve the best products that will delight you with reliability and durability.

pros

- The use of very high quality materials.

- Using the best technological base.

- Modern equipment.

- Reliability of goods.

Minuses

- Not detected.

chimney Craft

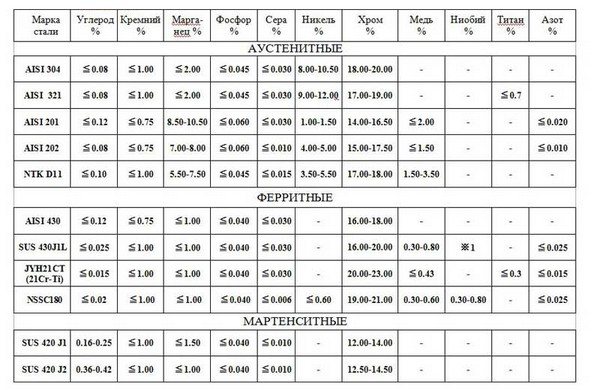

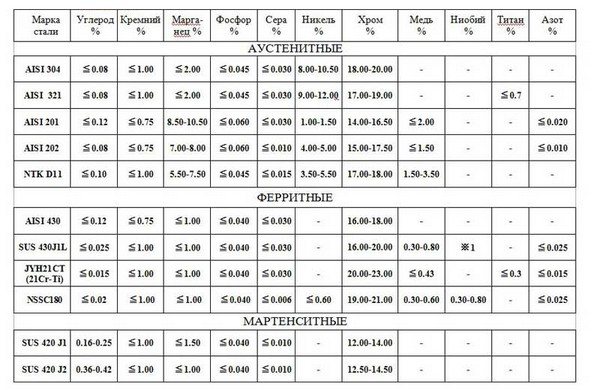

What steel grade to choose for the chimney?

11.11.2019

Stainless steel chimney - you need one maximum two times in life, but how to understand which one is right for your unit, we will figure it out below.

Stainless steel is an alloy steel (i.e. chromium, nickel, molybdenum, titanium is added to its composition) to increase its hardness, wear resistance and corrosion resistance. The cost of steel and where to use it depends on the presence of these elements.

When making chimneys and components, manufacturer Ferolife LLC, uses steel grades AISI 304, AISI 316 and AISI 430 (supplied by China, India). In Europe, in the production of chimneys, the types of steels AISI 304, AISI 316 are actively used.

AISI 304

AISI 304 - easy to weld. Additionally alloyed with 10% nickel and 18% chromium - corrosion-resistant, heat-resistant, acid-resistant steel.

It is used to make:

- inner chimney sandwich pipes

- inner tubes of heat exchangers

Type of fuel:

- diesel

- gas

Heating unit:

- gas water heaters

- gas boilers

- ovens

- fireplaces

The recommended steel thickness is 0.5 mm - 1.0 mm.

Approximate service life up to 25 years

AISI 316

AISI 316 is an improved steel AISI 304, due to the addition of 2.5% molybdenum and a higher nickel content of 14% - the steel is more resistant to corrosion, high temperatures and aggressive environments (acid-resistant). It has better creep resistance at higher temperatures than 304 AISI, which means the chimney will not collapse when heated.

Type of fuel:

- diesel

- gas

When using this type of fuel, condensate containing sulfuric acid is formed, which corrodes steel, therefore the inner pipe of the chimney sandwich must be made of AISI 316 or AISI 304. These types of steel are more expensive than AISI 430 (without expensive additives: nickel, molybdenum, titanium )

Heating unit:

- a gas boiler

- gas water heater

The recommended steel thickness is 0.5 mm - 1.0 mm. Approximate service life up to 50 years

AISI 430

AISI 430 - has a high heat resistance 850 - 1000 ° C. Alloyed with 16% chromium - which gives the steel additional heat and corrosion resistance. Low acid resistance, compared to AISI 304. Not recommended for use for gas water heaters and boilers, because acid is formed, which corrodes steel (see photo above)

It is used to make:

- chimney sandwich pipe

- chimney sandwich components

- chimneys for a sauna stove

Heating unit:

- solid fuel boiler

- wood burning fireplace

- wood-fired sauna stove

For use, we recommend a steel thickness of 1.0 mm. Approximate service life up to 10 years

Chimneys of Ferolife LLC certified. Buy a sandwich, gas, coaxial chimney, chimney for a bath or fireplace in the online store heating equipment and chimneys in Minsk thomaswerner.by, place an order on the website or call for consultation by phone +375 29 106 11 77, +375 33 315 11 77.

Stainless steel grade

Before you start making a chimney, you need to find material. In this case, it will be stainless steel. Interestingly, it can be completely different, even if its types differ from each other will not be too much.

The main differences that they will have are in their composition, which will determine their resistance to high temperatures and acid. The higher it is, the longer the material will remain in its original state.

To date, manufacturers use only one series - the three hundredth, which is an example of quality. Here we will consider it below and consider the example of several representatives of this series.

A brand can decide a lot in the production of a chimney

AISI-304

- Austenitic stainless steel. It is an admixture of steel, chromium (18-20%), nickel (8-12%) and carbon (up to 0.08%).

- Steel with high resistance to acid and high temperatures (up to 400 ℃, taking into account the average level of acidity of the environment), therefore it is recommended for gas, solid fuel boilers.

Important! It is widely used in food production.

AISI-316

- The composition is the same as that of AISI-304, but in addition molybdenum is mixed (2-3%).

- Even greater resistance to negative external effects (up to 750 ℃ without deformation).

A chimney made of such material can be used in almost any type of boiler, no matter what the heat source will be.

AISI-309, AISI-321

- Refractory stainless steel. It is an admixture of steel, chromium (19-21%), nickel (11-13%) and carbon (up to 0.2%).

- High resistance to high temperatures (up to 1050 ℃), as well as to acids.

Chimneys are made from such material, which will work in places with the most difficult conditions.

- Bath.

- Sauna.

- Solid fuel boiler.

Each brand has its own properties, suitable for a particular task

How to choose sandwich chimney pipes

Choosing the right model is a troublesome task that requires taking into account several aspects at once:

- Steel grade used.

- Insulation type.

- Dimensions such as the wall thickness of the inner raincoat and the insulation layer, the diameters of the inner and outer casings, the height (length) of the modular sections, the bending radius of the turning elements.

The quality of the chimney seams has an important effect on the trouble-free operation of the chimney. For a solid fuel boiler, priority should be given to laser welded products. A rolled (folded) seam may only be used in conjunction with a gas heat generator.

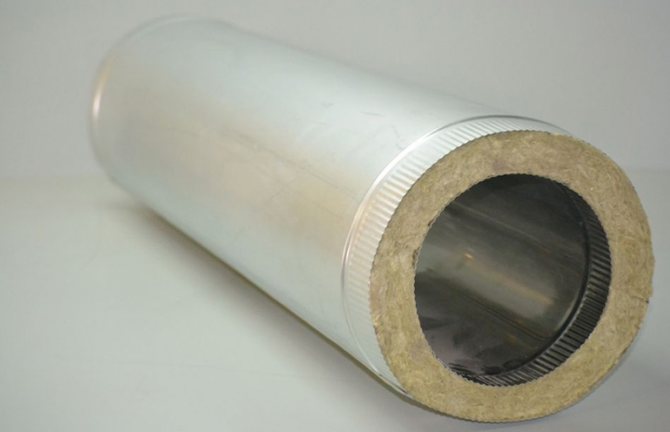

Material and wall thickness of the working inner tube of the sandwich

Only stainless steel types, including galvanized steel, are used as material. The latter is most often used as an external pipe, but if connected to a gas boiler, it can also act as an internal circuit. However, it should be borne in mind that unsafe zinc is present in the composition of galvanized metal, therefore, many experts oppose the use of galvanized channels even in baths.

Special alloyed (improved) steel grades are capable of withstanding high thermal loads, the effect of acid condensate.

When deciding on the steel grade and its thickness, the first thing you should pay attention to is the type of material, or rather, its qualitative (ingredient) composition, which determines the strength and acid-resistant characteristics of the pipe. Choosing a thicker steel that is not suitable for the operating conditions will not increase the life of your flue duct in any way.

| steel grade | Features of the composition | Acid resistance | Inner / outer loop |

| AISI 409 | Chromium (12%) | Low | -/+ |

| AISI 430 | Chrome (17%) | Low | -/+ |

| AISI 321 | Chrome (18%), Nickel (10%), Titanium (1%) | Average | +/+ |

| AISI 316 | Chromium (17%), Nickel (12%), Molybdenum (2%) | High | +/+ |

| AISI 304 | Chromium (18%), Nickel (8%) | Average | +/+ |

| AISI 309/310 | Chromium (24%), Nickel (20%) | High | +/+ |

| AISI 201 | Chromium (15%), Nickel (1%) | Low | -/+ |

| AISI 444 | Chromium (18%), titanium (1%), molybdenum (2%) | High | +/+ |

The wall thickness of the inner working circuit can vary from 0.5 to 1.5 mm, but choosing between AISI 321 steel 1 mm and AISI 316 steel 0.5 mm, it is better to give preference to the latter.

Of no less importance in determining the thickness of steel is the type of boiler for which it is selected:

- 0.5-1 mm - for gas and liquid fuel units.

- 0.8-1.2 mm - for solid fuel (coal and wood) heat generators.

- 0.8-1 mm - for sauna stoves.

- 1-1.5 mm - for gas piston, gas turbine and pyrolysis devices.

Working temperature table for chimneys made of sandwich pipes of different steel grades

The choice of steel type is determined by the temperature of the flue gases and the acidity level of the condensate. They depend on the type of fuel:

- The lowest gas temperature is produced by gas and diesel heat generators.

- The gases emitted as a result of coal combustion have the highest temperature, wood is slightly less hot.

- The most acidic is the condensate that appears during the operation of liquid fuel (diesel) units and solid fuel devices operating in the smoldering mode.

The table contains data only for those types of steel that are approved for use as an internal casing:

| Indicators | steel grade | |||||

| AISI 321 | AISI 316 | AISI 304 | AISI 309/310 | AISI 444 | ||

| Heat resistance | Above average | Average | Average | High | Average | |

| Maximum temperature condition | 600 ... 700 ° C | 450 ° C | 450 ° C | 1000 ° C | 400 ° C | |

| Fuel type | Gas | + | + | + | + | + |

| Diesel | — | + | — | — | + | |

| Coal | — | — | — | + | — | |

| Wood | + | — | — | + | — | |

Types and thickness of thermal insulation of sandwich pipes for chimneys

High flue gas temperature is one of the conditions for good natural draft and a factor contributing to the reduction of condensate volume. In this regard, it is the insulation that is entrusted with the task of maintaining optimal temperature conditions inside the smoke circuit.

However, the choice of thermal insulation material must necessarily take into account those extreme conditions in which he has to work - extremely high temperatures and temperature extremes. The latter is especially true for sections of the smoke channel taken out into the street.

Vermiculite, kaolin, basalt, fiberglass or ceramic wool are used as insulation. The thickness of the intermediate heat-insulating layer depends on the degree of heating of the flue gases and the location of the chimney (indoors or outdoors):

- For gas and liquid fuel boilers - 25-50 mm.

- For wood-fired installations - 50-75 mm.

- For coal and pyrolysis heat generators - 75-100 mm.

When taking the pipe outside, feel free to add at least another 25 mm.

On a note! For baths, basalt wool is considered the optimal material, which is neutral to conditions of high humidity. Fiberglass insulation is only used for gas installations with flue gas temperatures up to 350 ° C.

Sandwich chimney diameter

There are many methods for calculating the diameter of the chimney, which will maintain the optimal balance between the aerodynamic parameters of the draft and the cooling rate of the flue gases. These special calculations, as a rule, are very complex, therefore, in private construction, most often the diameter of the inner channel is determined based on the power of the heat generator:

| Heat generator operating power | Minimum value of the inner diameter |

| up to 3.5 kW | 115-158 mm |

| 3.5-5.2 kW | 158-189 mm |

| 5.2-7.2 kW | 180-220 mm |

| 7.2-10.5 kW | 220-226 mm |

| 10.5-14 kW | 226-263 mm |

| from 14 kW | 263-300 mm |

It is important to consider that:

- This method of calculation is most valid for straight chimneys with a height of 5-5.5 m.

- The table shows the minimum diameters, within the specified range it is better to give preference to the larger size.

- The first thing to start from is the size of the chimney of the heating installation. The diameter of the chimney pipe cannot be smaller than its diameter.

Number and type of sandwich pipe modules for chimneys

The number of sections, their type is determined by the height and configuration of the chimney. As a rule, straight modules have a length of 0.3, 0.5, 1 m.In addition to straight pipes, the following fitting elements are produced:

- Adapters from the flue pipe of the heat generator to the sandwich (start-sandwich).

- Crosses and tees with different slopes (45 °, 90 °) for parallel connection to the chimney circuit of another heat generator or condenser collector.

- Elbows (elbows) for changing the trajectory of the chimney line to horizontal, inclined and again to vertical, or to bypass some structural element of the building with angles of rotation of 45 ° or 90 °.

- Condenser collectors with watering cans.

- Sections with an inspection window or slide gate (throttle valve), plugs.

- Support or cantilever platforms.

- Ceiling and wall walk-through mono-, thermal units.

- Unloading mono- and thermal fasteners with a support platform.

- Clamps, clamps with braces, wall mountings, brackets (including support and telescopic).

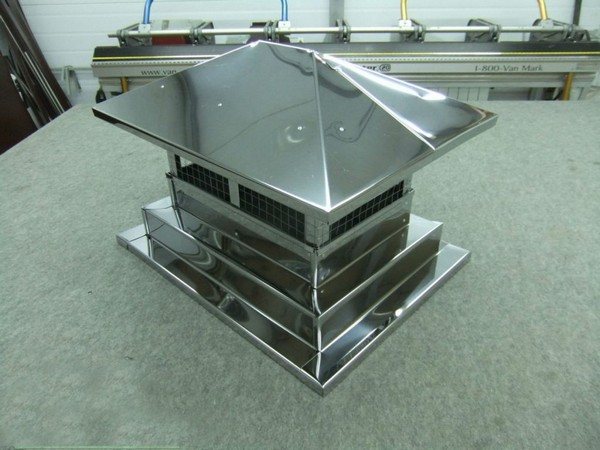

- Roofing passages - roofs (support platforms with a through-hole), aprons-fenders (rosettes), master flashes.

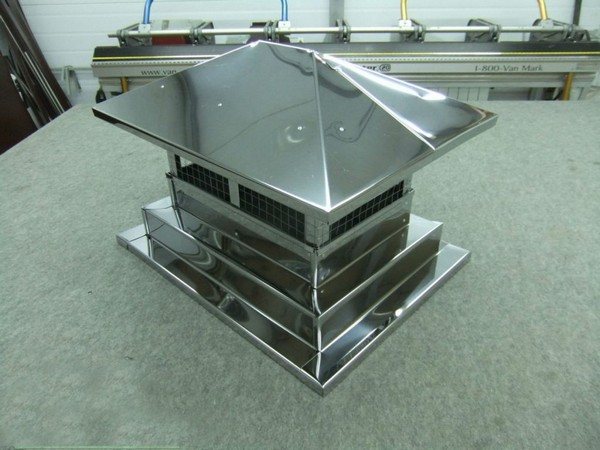

- Modules for decorating the chimney head - rain fungi, umbrellas, deflectors, spark arresters, volppers.

How much do chimney sandwich pipes cost?

Pricing factors for sandwich chimneys:

- Steel grade and thickness. The more heat and acid resistance it has, the more expensive the product is.

- Type of heat-insulating material. The most expensive construction will be with vermiculite insulation.

- Joint seam type. The cheapest is folded.

The price of a sandwich chimney reflects its strength characteristics, and confidence in the safety of your family depends on them. Therefore, in such an important matter, one should not trust unverified manufacturers with uncertified products.

Heating equipment type and chimney: what you need to know

When installing a stainless steel chimney, it is imperative to take into account not only the material itself and its brand, but also the thickness of the chimney wall. But, in addition to this, you need to consider what equipment is at home.

Below is an example of what heating equipment is available and what requirements it may have:

- stove or fireplace - AISI 321 (wall thickness - 0.5-1.0 mm);

- diesel boiler - AISI 316L (wall thickness - 0.5 mm);

- gas boiler - AISI 304 (L) and 321 (wall thickness - 0.5 mm);

- solid fuel boiler - AISI 309, 310 and 321 (wall thickness - 1.0 mm).

Conclusion number 1: solid fuel boilers need to have a chimney with a wall thickness of 1 mm. This chimney is made of heat-resistant steel, since the temperature inside the chimney can reach 500-700 ° C.

Conclusion number 2: oil and gas boilers emit acid, which means that you need to install a chimney with high resistance to temperature and acid, the wall thickness of which is 0.5 mm.

| Heating installation | Temperature inside the active installation, ° С | Stainless steel brand, AISI | Wall thickness of the inner pipe, mm | Insulation layer thickness, mm |

| Fireplace, stove | 350 — 650 | 321 | 0.5 – 1.0 | 50-100 |

| Sauna stove | 400 — 700 | 321 | 0.8 – 1.0 | 100 |

| A gas boiler | 120 — 200 | 304, 304L, 321 | 0.5 | 30-50 |

| Diesel boiler | 150 — 250 | 316L | 0.5 | 30-50 |

| Solid fuel boiler | 500 — 700 | 309, 310, 321 | 1.0 | 100 |

| Gas piston, gas turbine units | 450 — 600 | 316Ti, 321 | 1.0 – 1.5 | 100 |

| Diesel generators | 450 — 600 | 316Ti | 1.0 – 1.5 | 100 |

The choice of steel for the chimney. How not to burn out?

Most manufacturers offer dozens of different chimney designs. If you are not an expert, it will be extremely difficult to figure out their features on your own. Therefore, most often a simple choice is made between AISI 321 steel grade 0.5 mm thick and AISI 430 steel grade 1 mm thick. Sometimes AISI 439, 0.8 mm thick, is added to the selection.

Most buyers will find that AISI 430, 1mm thick, will be better than AISI 321, only 0.5mm thick. After all, we are all accustomed from childhood that the more, the more reliable and better.

In fact, everything is exactly the opposite! And the point here is not in the thickness of the steel, but in its composition and chemical properties. We offer the best chimneys.

Why do chimneys rust, because they are made of stainless steel? Most often, the reason lies not in a poor-quality chimney, but in the wrong choice of chimney steel.

The main enemy of chimney systems is acid, which is almost always present in the released condensate. It is this acid that slowly but stubbornly eats away at our chimney over time.

Acids that are formed during fuel combustion.

But that's not all! Due to the various chemical processes that occur during the combustion of fuel, we get as many as 3 different types of acids:

- Carbonic acid

... Formed as a result of the interaction of water-soluble carbon dioxide and water vapor. - Sulfuric acid

... Formed by the interaction of sulfuric anhydride SO3 contained in the exhaust gases of furnaces (especially those operating on diesel fuel) and water vapor. - Nitric acid

... Formed by the interaction of nitrogen dioxide released during combustion and the resulting water vapor.

And here is a table with the content of chemical elements in steel grades:

| AISI | GOST | FROM | Mn | Si | Cr | Ni | Mo | Ti |

| 430 | 12X17 | 0.12 | 0.8 | 0.8 | 16 | — | — | — |

| 439 | 08X17T | 0.08 | 0.08 | 0.8 | 17 | 0.6 | — | 1 |

| 304 | 08X18H10 | 0.08 | 2 | 0.8 | 17 | 9 | — | — |

| 321 | 08X18H10T | 0.08 | 2 | 0.8 | 17 | 9 | — | 1 |

| 316L | 03Х16Н15М3 | 0.03 | 0.9 | 0.6 | 17 | 14 | 2 | — |

AISI 430

- heat-resistant stainless steels for general use with very low corrosion resistance. They are mainly used in the food industry. Kitchen hoods and pans are made from this steel.

AISI 439

- as we can see from the table, this type of steel is stabilized by titanium and has nickel additives. This steel belongs to the budget, but it may well be used in heating devices with a small amount of condensate (or better with its absence).

AISI 321

- this type of steel contains a large amount of nickel. Steel is corrosion-resistant, heat-resistant, heat-resistant, stainless, with a long service life. The recommended application temperature is from 600 to 800 ° C. It is used for the manufacture of fireplaces, domestic boilers, pipes, sauna stoves and heat exchangers. It is acid resistant. And that is why, even with a thickness of 0.5 mm, a chimney from AISI321 lasts longer than a similar chimney from AISI430. For example, St. Petersburg gives a guarantee of 50 years.

AISI 316

- contains molybdenum - one of the few alloying elements capable of simultaneously increasing the strength, ductility properties of steel and corrosion resistance. It is the best option for diesel and gas boilers.

Therefore, when choosing a chimney, it is better to focus more on the steel grade, and not on its thickness.

Range

Installation of a stainless steel chimney is a rather difficult task, and therefore many people need to use a solution that is ready for installation. Many models come with various parts of the pipe, so it is quite possible to install the structure yourself.

Let's take a look at all these elements.

- Straight pipes. Their length, as a rule, is from 33 to 100 cm. Socket coupling is what firmly connects the elements of the pipes to each other.

The pipe does not need additional fasteners - Elbows at an angle of 45 °. They are best used when there is a need to deviate from the vertical.

- Elbows at an angle of 90 °. Due to them, it is possible to make transitions between the vertical and horizontal section of the place where the pipes are stretched.

Elbows 45 and 90 degrees - Condensate collector. It is placed at the lowest point of a vertically running pipe. It is used to collect water that appears when the smoke cools.

- Tee at 45 ° and 87 °. With it, you can collect pipes where condensate collection is planned. In addition, such a tee is useful when connecting two heating devices that are connected to a common chimney.

- Inspection element. The audit is installed where, most likely, soot accumulates. Its use is to check and clean the chimney.

Chimney inspection - Passages.This element provides insulation for the structure to protect against fire, seal the roof, and also guarantees an improvement in the design of the pipes.

- Additional accessories. To protect against precipitation inside the chimney structure, against back draft and against sparks, a number of accessories are installed on the roof at once, including a cap and a spark arrester.

Chimney cap

Chimney accessories

Now the assortment of these parts is very wide, it allows you to build a structure of any complexity and configuration. Installation of a stainless steel chimney is not complete without the following products:

- Elbows - 45 and 90 °. The former are used to change the direction of the system on inclined or vertical sections. The second knee is mounted at the transition from the horizontal section to the main, vertical one.

- Straight pipes. Their length is 330-1000 mm. They have a socket connection that does not require additional fasteners.

- Tees - 45, 87 °. They serve to cut off condensate. They are joined by a bell-shaped method, or "one-to-one".

- Condensate collector (drain). It is mounted at the bottom of the main vertical section.

- Revision. Its function is to provide a canal check and soot removal. It is installed at the base of the vertical channel, under the tee.

- Waterproofing skirt, spark arrester, cap are mandatory parts for the upper part of the chimney.

Special elements may be required to be used to penetrate a wall, ceiling or roof. Manufacturers do not always provide for them (for example, a ceiling-throughput unit), therefore sometimes the only way is to make them independently.

Stages of installation of the structure

To save money, you can install the chimney yourself - we'll figure out exactly how.

- At the exit point of the smoke collector, a metal pipe of a certain height is installed, since it determines what the heat transfer to the room from the heating equipment will be. It is necessary to put the structure "in smoke". After installing the pipe, you need to put it on the branch pipe and install a gate that will block the channel. All joints are carefully coated with a special heat-resistant sealant.

- After installing the main part of the structure, you need to put on a starting sandwich chimney in the form of a double pipe, which is closed on one side. All the necessary products will then be put on this sandwich. And yes, the joints are again connected with a special sealant.

- Now you can collect all the items. Everything is installed so that the condensate drains to the desired point. All joints must be sealed with a sealant.

It is important not to forget to treat all joints with a sealant. - The installation of pipes on the roof involves the use of an unloading platform, and just below you can use special clamps. They should be used where pipe parts are connected, because this can increase the strength of the entire structure. Flammable materials are insulated with a layer of basalt wool in a box.

- All lines with twists and branches must have revisions so that pipes can be cleaned without problems.

- The last stage - the apron and the conical roof are installed together with a deflector or head.

Following the stage will allow you to install the pipes so that they function correctly in the future.

Best Stainless Steel Chimneys with Roof Transit and Rear Exit

Such designs are suitable for boilers and furnaces that do not have a direct outlet of exhaust gases upward, and the exhaust duct is located on the side. To connect the chimney, you need a kit with a side inlet and the ability to mount a high vertical post (no load on the boiler).

Phoenix 120 mm, 1 mm - well suited for a bath

This is the best option for a stainless steel chimney for a bath due to a 1.0 mm wall section, which allows you to transfer high heat from a nearby boiler, where firewood is burned at a high temperature.The rear connection provides open access to the stone-setting site.

Diameter 120 mm promotes strong traction, which will melt the bath to the desired maximum level. The top has a taper and umbrella to prevent plugging the hole.

Pros:

- wide insulation board that easily adjusts to the contours of the slate or shingles to cover the opening in the roof;

- stainless support for holding the side outlet from the boiler and high mast; adjust the distance from the partition;

- internal throughput diameter 120 mm;

- stainless steel wall thickness 1.0 mm for high heat;

- strong connection of all longitudinal joints by argon welding;

- the bell system is easy to assemble with your own hands;

- eco-friendly insulating material inside;

- withstand temperatures up to 1000 degrees;

- guarantee of work with regular use up to 15 years;

- complete set of pre-furnace plates and pass-through parts for floors;

- two sealants with a temperature regime of 260 and 1200 degrees for high-quality sealing of adjacent parts;

- 8 clamps for assembly;

- tee for collecting condensate;

- the total chimney length of 6 m is suitable for output to a great height, which will provide good draft even with closely spaced houses.

Minuses:

- the cost of the kit is 29,000 rubles;

- the insulating fiber has a thickness of 30 mm, which is less than similar models.

Care and maintenance of a stainless steel chimney

For more efficient operation of the stainless steel chimney, you need to follow the recommendations below.

- Before lighting a boiler or stove for the first time, you need to check in advance if there are any foreign objects or debris in the flue duct. If there is one, then you need to take some long tool and push it through until the revision. When the debris is there, you need to open the revision channel, pull it out of the pipe, and after getting rid of the debris, the chimney and the revision channels are cleaned of soot with a brush.

- Household waste should not be thrown into an oven or boiler for incineration, as it can worsen the condition of the chimney.

- In solid fuel heat generators, as a rule, logs from conifers are not thrown. The reason is the resin content, which will quickly build up. The only exception is aspen logs, which can create a high fire and burn soot in the chimney with it.

Several rules must be followed for the chimney to work properly.

From time to time it is necessary to inspect the roof on the roof if it is made of metal. This is done to detect any rust that may have appeared on the outside of the pipe. Yes, it can even hit a "stainless steel", which is quite unusual.

What should I do if I find this problem?

- Clear space around the pipe.

- Dismantle the problem piece of pipe.

- Clean, sand and degrease the work surface.

- Holes and cracks should be carefully repaired.

- Rinse with hot water and then dry thoroughly.

- Fill all the cracks found with a special sealant.

- Take a silicone nozzle, put it on the pipe, secure with self-tapping screws for greater strength.

Mistakes made when arranging the chimney will lead to the reappearance of rust on the pipe or its transition to the roof.

The roof should not rust if done correctly

You may be interested to know which sauna stoves worth buying.

Disadvantages and advantages

The first drawback is cost. Stainless steel sandwich chimneys are used in saunas where boilers run on solid fuel. But not every owner can afford such a luxury. Another disadvantage is the service life. Brick or concrete chimneys last much longer than sandwich chimneys. However, let's talk about the service life separately.

The structure consists of several pipes. With a sharp temperature drop, the chimney can be depressurized, which means it can be damaged.

But as already indicated, the benefits are much greater. Against their background, the shortcomings are imperceptible. First of all, it should be noted that the chimney sandwich is easy to install.Anyone can install it - without the help of a professional. For the structure, you do not need to create a foundation, as it is quite light.

There are no difficulties in delivery. The chimney sandwich consists of several sections, which are quickly disassembled and also folded into a single system. There is a large selection of chimneys on the market. This means that you can create any shape of the structure. If one section of the chimney fails, then it can be replaced with a new part without any problems. The outer layer of the pipes does not get very hot due to the insulating layer. Condensation does not form and there is no fire hazard.

Inside the sandwich, the chimney has an absolutely smooth surface. Thanks to this, soot does not collect inside the chimney, and blocking zones are not created. It is easy to clean. In general, chimney maintenance takes a few minutes. It is only necessary to remove the soot and drain the condensate. The aesthetic appearance of the product allows you to install it not only outside, but also inside the house.

Stainless steel instead of ceramics: when is it better to choose steel?

Everyone knows that the chimney is an important part of the heater. And this means that his choice must be correct. And for this you need to know when and where it is better to use it. For a long time, the ceramic version was popular, and it could be found literally everywhere, but today it will be out of place, and therefore stainless steel, as an alternative, will look quite good.

Below, the experts of the Obzor-Expert.com website have identified three best cases when it is perfect.

- Boilers with a closed combustion chamber. It is better to use steel pipes for them. They are much more convenient than ceramic from the point of view of installation.

- Retrofitting a brick oven or fireplace. This is easier if stainless steel elements are added.

- Installation of an additional chimney. This is best done with double-layer sandwich pipes.

Important! It is quite difficult to choose the ideal option for heating equipment. Both options - both ceramic and stainless steel - have their own characteristics, pros and cons, and therefore you need to carefully study everything before choosing one.

Diameters

At the moment, the following types of stainless steel chimneys are being sold on the domestic market (the diameter of the chimney is used as a distinguishing factor):

- chimney 80 mm made of stainless steel - this option is suitable for a heating device that runs on solid fuel;

- chimney 115 stainless steel - the thickness of steel for such a chimney is about 1 mm. This type of flue gas vent is ideal for single wall installations;

- chimney 120 mm stainless steel - often made of steel grade AISI 409. This steel is called matte, and its thickness is about 0.5 mm;

- chimney 130 stainless steel - this type of chimney is used for heating devices powered by diesel fuel. They are often used for gas piston installations;

- chimney 160 mm stainless steel - such chimneys are used for heating equipment, which can produce a large thermal "power". For example, this type of chimney is ideal for a diesel heater;

- chimney pipe 200 mm stainless steel - a device of this type can be used both at home and in industry. These chimneys are incredibly easy to operate and maintain. Read an overview of the characteristics of the galvanized steel chimney on this page.

It should be remembered that the correct installation of the chimney will ensure a normal chimney robot.

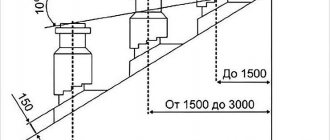

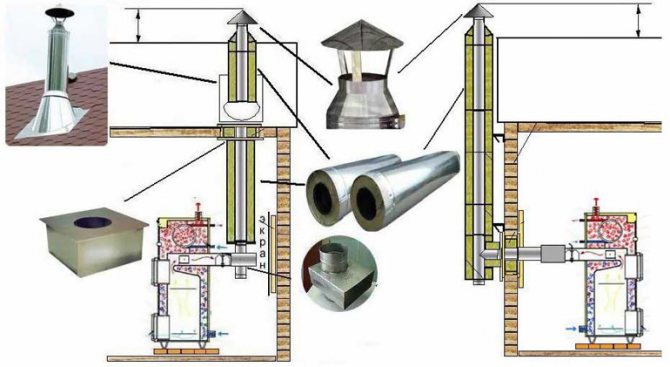

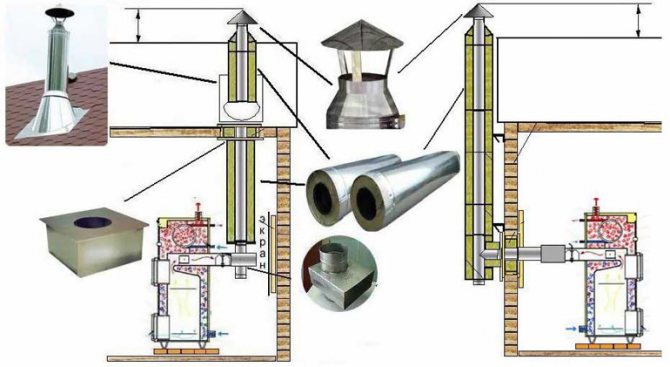

The figure shows a stainless steel chimney device.

Stainless steel pipe options

Today, you can find as many as three options for this kind of chimney.

- Single-walled (thickness - 0.6-20 millimeters).

- Corrugated.

- Three-layer sandwiches (two pipes + insulation).

Let's consider each of the options, taking into account their pros and cons in the form of a table.

| Pipe type | Advantages | disadvantages |

| Single layer | Low cost, smooth inner surface. | High heat transfer rates, condensation may form, the need to install thermal insulation. |

| Corrugated | Elasticity, some flexibility. | Low resistance to high temperatures, rapid wear, corrugated inner surface, on which condensation can accumulate, is not suitable for horizontal sections of the chimney duct, it is necessary to fix and install thermal insulation. |

| Three-layer | Low heat transfer rates, versatility, easy assembly, tight joints. | The rather high cost of this type of pipe compared to others. |

Each of the types of pipes has its own characteristics that hinder or help in choosing

Extremely important! The regulatory authorities, seeing the corrugated pipes, are likely to refuse to start the gas.

Video - About choosing and buying a stainless steel chimney

Advantages and disadvantages of chimneys made of stainless steel and other materials

The chimney serves to discharge flue gases into the atmosphere. This process is called natural cravings. Good traction is needed for proper fuel combustion. Therefore, the main task of any chimney is to provide high-quality draft. The ideal chimney should be strong, durable and easy to install.

Classic chimneys are made of brick, clay, steel. Let's briefly compare their advantages and disadvantages.

Table 1. Advantages and disadvantages of brick, ceramic and steel chimneys.

| Chimney type | Benefits | disadvantages |

| Brick |

|

|

| Ceramic (from fired clay) |

|

|

| Welded steel pipes |

|

|

A modern solution - custom made stainless steel chimneys made of high quality stainless steel. They are durable, easy to maintain, and suitable for all types of ovens. The modular design allows the installation of a stainless steel chimney of any configuration.

Advantages of stainless steel chimneys

- stainless steel is protected against corrosion and the effects of reactive condensation that forms in the pipe. This ensures a long service life of the chimneys;

- unlike brick and ceramic chimneys, stainless steel models are lightweight;

- stainless chimneys do not require a foundation. They can be installed not only inside buildings, but also outside. In this case, the chimney is attached to the wall with brackets;

- steel chimneys can be installed both during construction and in finished premises. Thanks to the modular design, the installation of a stainless steel chimney takes a minimum of time;

- the pipes have a smooth inner surface on which soot does not settle;

- chimneys are distinguished by their aesthetic appearance.

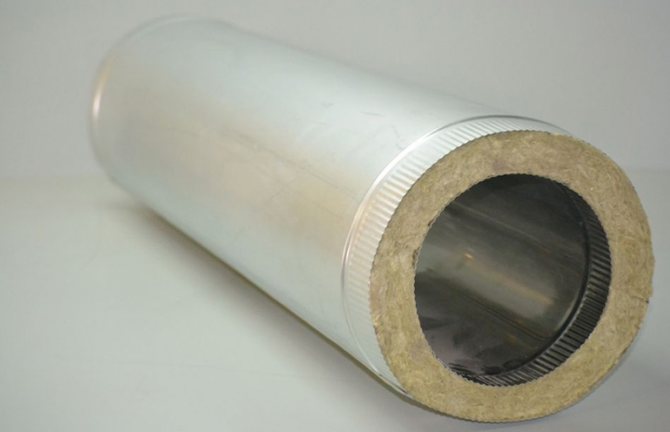

Disadvantages of stainless steel chimneys and their solution

If the chimney is located outside the building (on the roof or wall) and it is planned to operate it in winter, the chimney must be insulated. Otherwise, significant heat loss will occur and a large amount of condensation will form, which can damage the heating system. This problem can be easily solved by installing an insulated chimney. It consists of an outer and an inner pipe, between which there is a layer of insulation. This design ensures minimal condensation and prevents heat loss. The insulated chimney will last for many years even with year-round operation of the heating system.

Installation of stainless steel chimney

Corrosion-proof chimneys can be installed quickly and easily, but for their proper operation, a number of requirements must be taken into account during installation.It is necessary to select the diameter of the pipe in accordance with the capacity of the heating system, control the angle of inclination of the pipe, and ensure the tightness of the joints. Therefore, it is worth entrusting the installation of a stainless steel chimney to professionals who will install it in accordance with fire safety standards.

You can get acquainted with the requirements for the installation of chimneys in the documents, links to which are given at the bottom of the chimney catalog page.

Features of operation

A stainless steel chimney is quite popular today, but like other chimneys, it needs to be checked from time to time and generally looked after. Below we will show you how to do it correctly.

- The first thing to do when using a steel chimney is to thoroughly inspect the heater before each season. From time to time it may be necessary to clean it from soot and other dirt.

- Next, you need to check the draft when the time comes for the first ignition. If it is not there, then you need to find out what the matter is. As a rule, it is enough to simply warm up with improvised means and then check the traction with a match.

Important! The thrust is checked with the regulator damper or gate open.

- It is necessary to inspect the chimney, check if it is clogged with soot. You can get rid of it with a soft stainless steel brush and a plaque softener.

- At times, you can lay aspen wood, which can be used to remove the soot in the chimney.

- Proper use of the stove involves the use of deciduous wood that does not contain resin. It should also be noted that it is impossible to use cut plywood and chipboard for ignition.

It is necessary to take into account the presence of a number of operating features that determine the service life of the chimney

You may be interested to know which conditioners worth buying.

General installation guidelines

It is necessary to study in as much detail as possible the information on how to make the chimney pipe in the bath correctly and all the details regarding its installation, because reliability, service life, performance and, above all, your safety will depend on its quality. Any seemingly insignificant mistake can provoke irreversible consequences.

First you need to familiarize yourself with the main instructions of specialists and instructions (if any).

The sections of the passage of the smoke channel through the ceilings should be protected in advance. A step-by-step guide for this stage of installing a chimney in a bath with your own hands is as follows:

- Preparation of the pass-through pipe. It is required to fill its exterior with basalt wool.

- Next, you need to insulate the inside of the unit - decide on the mounting point on the floor and prepare a hole of the desired shape.

- At the interface with the ceiling, distribute another thermal insulation layer and then proceed with the cutting device.

- Be sure to leave a small gap between the passage unit and the flue duct.

Roof work

Start this stage by dismantling the roof:

- It is necessary to determine the dimensions from both the inner and outer areas of the roof, taking into account the roof slope (slope).

- Cut a hole inside the roof. To do this, sheathe the openings with metal sheets from both edges, the thickness of which should be 0.5 (mm). You need to make 4 holes with a size of 450 by 450 (mm), using the square section method. The scale depends a lot on the adapter.

- for the passage of the chimney through the roof, a roof cut or a master flash is used. Their main task is to seal the passage, protect it from moisture ingress.

Please note: the master flash must be inserted under the upper edge of the roof to avoid leakage. Also, pass the joint with the pipe with a sealant and fix everything with roofing screws.

Walking through the wall

We suggest that you familiarize yourself in more detail with two installation schemes with a detailed description.

Installation methods

There are two ways to locate the chimney, based on the location of the heater in the house.

- Outside the house... The simplest and therefore the most popular chimney installation technology. For the successful implementation of the venture, a double-circuit chimney with fastening in the form of clamps is used. To prevent heat loss, thermally insulated pipes are used.

- Indoors... A more complex and expensive option, which requires taking into account the design of the room, because the chimney will go through the floors and the roof to the outside, that is, to the street. The difficulty lies in the requirement to insulate the chimney, especially at the point of contact with the roof, where spark arresters are installed. However, the plus of such a system is to reduce waste on heating.

There are two different installation methods, each with its own pros

Selection principles

A sandwich pipe and accessories for it should be selected according to the following criteria:

- The type and number of modules.

- Thickness, insulation grade.

- The thickness of the pipe walls, the material from which the protective casing is made.

- The material from which the inner tube is made, wall thickness.

Smoke sandwich pipes are made from different types of alloy steels, which determines their technical characteristics.

The best is alloy steel AISI 310. This material can withstand prolonged exposure to critical temperatures without deterioration (up to 1150 degrees Celsius). The brand is indicated on the packaging or on the product itself.

Dimensions (edit)

Particular attention should be paid to the size of the chimney sandwich pipes. It should be selected depending on the power of the heating equipment. The classic tube section size is 120 mm. The optimum power is up to 3.5 kW. If more powerful furnace equipment is used, the pipe diameter must be increased. Diameter of sandwich chimneys for boilers or furnaces with a power of 5 kW - 180 mm, 7 kW - 220 mm.

Life time

The service life of a chimney sandwich depends on several factors:

- exploitation activity;

- the type of fuel burned;

- steel grade from which the inner part of the part is made.

For example, a product made of AISI 316L steel, no more than 0.5 mm thick, can withstand about 10 years of active operation. If the part is made of AISI 310 steel, which is 0.8 mm thick, the service life will be doubled.

Stacked wood for the stove

Installation Recommendations

The recommendations below will help you install the chimney correctly so that it functions without any difficulties.

- If you put a pipe with a height of five meters and more, then you can achieve good traction.

- The length of horizontal sections should be up to one meter, not more.

- Installation of a chimney on the street or in an unheated room involves the installation of thermal insulation material.

- If the chimney passes through a roof built with combustible materials, a spark arrester must be installed.

If you strictly follow the suggested recommendations, you can install the chimney without any problems

Important! Docking of uninsulated pipes in the wall is prohibited if the chimney ducts are not insulated.

Building a House

So, one important point is what steel should the chimney be made of?

It is believed that AISI-316 steel is the best option for the base of the chimney system, suitable for all types of stoves, fireplaces and boilers. Unfortunately, this is not so! The presence of a significant amount of manganese in stainless steel of this grade significantly increases the acid resistance of steel in an aggressive environment, but this fact reduces the limiting temperatures for using smoke elements made of this steel. The maximum temperature regime for this brand is 400 degrees Celsius, against 550C for steels AISI-304, AISI-321, AISI-430. In our opinion, and in the opinion of many technical specialists, the best option for all heating devices would be a chimney made of AISI-321 steel. This steel copes equally well with high temperatures, and also well withstands aggressive acidic environments.And steel grade AISI-316 is recommended for use in aggressive environments with not very high temperatures. For example, such a chimney is ideal for diesel boilers and waste oil boilers.

It is believed that AISI-430 steel cannot be used as a basis for the production of chimney systems, and it is also said that this steel is intended for the food industry.

We can safely say that this information is not true. Almost all grades of stainless steel used in the manufacture of chimney systems are certified for use in the food industry. This fact only indicates that steel, when used inside residential premises, will not emit substances harmful to humans. The chromium content of the AISI-430 steel grade is 17%, which means that the steel can be used in high temperature areas. The absence of nickel reduces the acid resistance of this brand, therefore, a chimney made of this steel is recommended for use on sauna stoves and stoves or fireplaces that do not have a secondary afterburning function. Steel is also well suited for the outer contour of any thermally insulated chimney. The use of this brand on long-burning furnaces, boilers for diesel fuel and waste oil is not recommended.

We often hear that it is possible to distinguish high-quality chromium-nickel stainless steel (AISI-304, AISI-321, AISI-316) from “low-quality” steel with the help of a simple magnet - it will be attracted to “bad” steel, but not to “good” steel. This fact does not fully correspond to reality. This method does not allow identifying steel grades AISI-200, AISI-201, famous for their low chromium content and minimum nickel content (less than 1%). It is highly discouraged to use this steel grade as a chimney system for a wide variety of reasons. But the magnet is not attracted to this steel and buyers may get a false impression that the steel belongs to the grades AISI-304, AISI-321, AISI-316. The purchase price of AISI-200 and AISI-201 steel is within the price range of AISI-430 steel, which allows unscrupulous manufacturers to speculate on the market. The magnet sticks only to 4xx series ferritic stainless steel. In fact, the magnet test misleads buyers, and unscrupulous companies can use this method for their own selfish purposes.

Unfortunately, without laboratory tests, it is not possible to check the steel grade at home, and the main factor is trust in the manufacturer, his long-term positive experience in the market, the availability of real certificates for the manufactured products, and not refusal letters, as is often the case.

Voting: the best chimney manufacturers

Which chimney manufacturer would you choose or would you advise to choose?

CRAFT

30.77 % ( 4 )

Volcano

23.08 % ( 3 )

ROSST IN

0.00 % ( 0 )

Jeremias

0.00 % ( 0 )

Thermophore

0.00 % ( 0 )

Ferrum

7.69 % ( 1 )

Elits

7.69 % ( 1 )

Inzhkomtsentr VVD

23.08 % ( 3 )

Phoenix

7.69 % ( 1 )

Baltvent

0.00 % ( 0 )

Stainless steel chimney

Chimneys made of stainless steel.

Modular stainless steel chimneys - a flue duct for the removal of combustion products, which is assembled from ready-made sections into a structure of any complexity.

Single-circuit / single-wall metal chimneys.

Design features.

A round or oval tube made of heat-resistant stainless steel with a thickness of 0.5 to 1.5 mm. Single-circuit chimneys are used for broaching in “warm” (heated) rooms or for plugging an existing channel.

The service life of the chimney depends on the grade of steel, and the thickness is important, but still of secondary importance.

Stainless steel is of different classifications and types and it will not work to determine "by eye" what you are buying. Speaking about the magnetic properties of steel, austenitic steels (see information below) usually do not magnetize due to the high content of alloying additives, but it is impossible to say for sure which steel in front of you.Usually, the manufacturer glues markings on each element with full information about steel, thickness, diameter, etc.

We will not describe in detail those. characteristics of the steel grade, however, we will go through the most popular and their capabilities in terms of the type of fuel (Aisi is the American system of the institute of steel and cast iron, it is more convenient to understand than the classification of steels under the Russian gost).

Ferritic steel class (simple types of steel):

AISI 430 - low carbon, chromium iron stainless steel. Suitable only for solid fuel (wood) heaters, small and medium power. Low price, service life 10-12 years.

AISI 439 - nickel-free stainless steel with titanium content (satisfactory corrosion resistance). Suitable for solid fuel (wood) heaters and better resists corrosion in a gas environment (improved version of AISI 430). Low price, service life 15 years.

AISI 444 - Stainless steel containing titanium and molybdenum. Suitable for gaseous media due to its high acid resistance characteristics. However, for applications in high temperature environments, it is necessary to check the temperature setting of your heater. This steel has an operating temperature of 400g, at 280-350 at the outlet of a modern stove or fireplace. Reasonable price, service life 18 years in low temperature load.

Grade austenitic steels (premium steels):

AISI 304 - austenitic chromium steel containing titanium and nickel with a low carbon content. Suitable for all fuels for use in mild corrosive environments. Low price, service life 20-25 years.

AISI 316 - compositionally similar to AISI 304 + enriched with molybdenum for use in harsh corrosive media such as gas media (excellent corrosion resistance). Suitable for all types of fuel, however, it should be noted that the heat resistance of steel is lower than that of AISI 304. Reasonable price, service life 25-30 years.

AISI 321 - austenitic high temperature stainless steel with titanium and nickel and low carbon content. It has excellent corrosion and high temperature resistance and the longest service life. Reasonable price. For example, the Vulcan company provides a 50-year warranty.

AISI 310 - chromium low carbon steel with a high nickel content. It is used in conditions of possible corrosion in high-temperature atmospheres of gases or condensates. High strength characteristics at temperatures of 1000 ° C and resistance to oxidation. Scope of application - installations for the conversion of methane, pyrolysis or furnaces on peat briquettes or coal, etc.

Cink Steel - it is used for the external contour of sandwich chimneys in order to reduce the cost, as well as painting, since heat-resistant paint on galvanized steel lasts much longer. Galvanizing is not used for single-wall chimneys, since the zinc layer burns out too quickly and at the same time releases harmful substances.

Asbestos cement pipe - maximum use temperature up to 300 ° C. When this temperature is exceeded, the material cracks and collapses (for modern equipment on wood, 260-500 ° C). The roughness and porosity of the material lead to active adhesion of soot and absorption of condensate, which means gradual destruction and the risk of furnace fire.

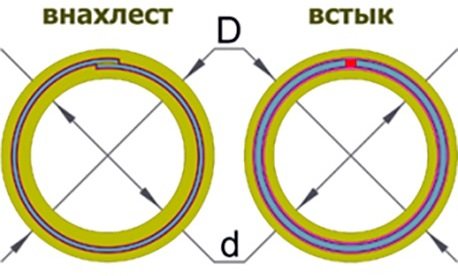

Welding quality - the weld seam provides the structure tightness and is divided into several types. It should be noted that the type of seam does not significantly affect the price, it's all about the capabilities of the manufacturer:

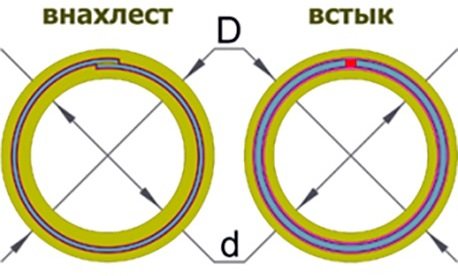

- "Overlap seam" - the metal at the junction (seam) is rolled up one on top of the other and boiled. The junction heats up much higher (the presence of a heat-conducting "bridge"). Violation of the structure of steel and loss of anti-corrosion properties of the metal at the junction.

- "In the joint" - welded by laser or plasma welding in an inert atmosphere (TIG technology).Absence of a heat-conducting "bridge" and violation of the steel structure during welding (a significant increase in the service life). Retains the anti-corrosion properties of the metal.

Sandwich chimneys or double-circuit chimneys.

Design features.

Sandwich chimneys are essentially a “pipe within a pipe” with a layer of non-combustible insulating material based on basalt rocks, which excludes strong cooling of the exhaust gases. The main purpose of a chimney sandwich is to “fight” condensation, and it also requires fire insulation in places where walls / ceilings pass and in places where people can reach (in a residential area, for example).

Main features sandwich chimney are:

- Maintaining the temperature of the flue gases - higher speed of passage in the flue duct;

- Minimal condensation

- Lower temperature on the outer circuit of the chimney;

- Possibility of installation in “cold” areas (unheated premises or street);

- Smaller (140mm versus 250mm for non-insulated pipes) opening size when passing through ceilings, walls and other structures made of combustible materials;

The insulation should have a thickness based on the climatic conditions of operation, according to SNiP "Thermal insulation", and not on the basis of the purpose of the premises.

The choice of the thickness of the sandwich chimney insulation depending on the type of heating unit.

| Heating Equipment Type | Exhaust gas temperature, ºС | Insulation thickness , mm |

| Condensing gas boilers | 60 | 40 |

| Gas boilers | 110…180 | 40 |

| Diesel boilers | 150…250 | 40 |

| Solid fuel boilers | 400…700 | 40…100 |

| Fireplaces and wood stoves | 300…600 | 40…100 |

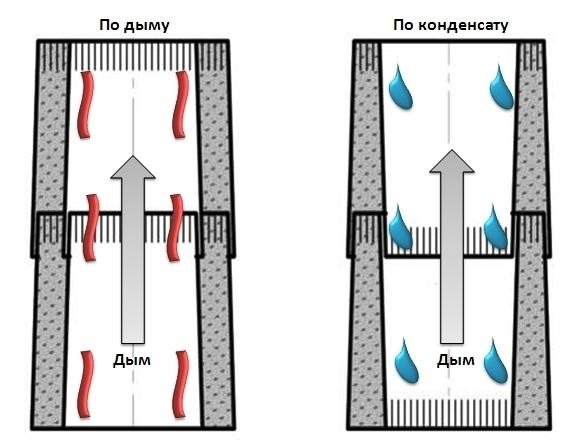

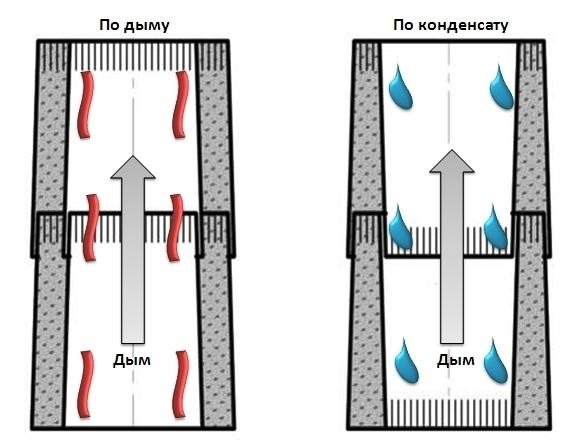

As mentioned above, the main task of a sandwich chimney is to “fight” condensation, but what is condensate?

Condensate - an aggressive solution of a mixture of oxides and moisture that precipitates during cooling (condensation) of exhaust gases on the inner surface of the flue channel. Condensation will corrode the metal or material of the flue duct.

The formation of condensation in the chimney is quite simple to describe - during the combustion of wood, natural moisture actively evaporates (the moisture level in the wood is not less than 15-20%), as well as carbon dioxide and sulfur dioxide, which mix and settle in the form of tiny drops of acids on the walls of the chimney, forming condensate ... An active process of condensation formation occurs when the chimney temperature is below the dew point * of gases, approximately 25-80 ° C. It should be noted that acid condensate (moisture droplets + soot deposits) is a problem with solid fuel equipment (firewood, coal), and when using this type of fuel such as gas (gas condensate), destructive condensate is formed mainly from water vapor and carbon dioxide, however due to the low combustion temperature, the amount of condensation is higher.

*Dew point - this is the point of the gas cooling temperature, at the crossing of which the gases begin to condense into dew).

The combustion temperature of the fuel directly depends on the amount of condensate, for example, with the combustion of dried wood and sufficient oxygen for combustion, the temperature of the gases will be much higher than in a situation with a limited supply of oxygen to maintain heat (relevant for closed types of equipment, where the combustion process is controlled from “ pioneer bonfire ”to the mode of decay). Simply put, the higher the temperature of the flue gases and the warmed up the chimney, the better the draft and the less likelihood of condensate formation and vice versa.

Supply system (supply) - external air supply directly into the heater itself (if it is dictated by the equipment itself - the presence of a special hole) or into a room * where additional oxygen is needed (more about the supply here). If you do not know, the supply system can be a big problem for the normal operation of heating equipment. Imagine a situation - you have a ready-made stove in which there is a hole for supplying combustion air, and you decide to use it by laying a short section through the fence wall.When cold air enters the furnace, the heater loses part of the efficiency for heating the air to the required temperature and, moreover, with an excess of cold air (for example, the windy side), cold air leads to cooling of the chimney, and, consequently, and more condensation... For greater efficiency of the operation of such a system, a throttle damper must be installed without fail in order to regulate or completely block the access of fresh oxygen to combustion.

* The standard house supply system usually consists of long sections, during the passage of which the air is “heated”.

It is completely impossible to get rid of condensation, but it is quite possible to reduce the formation to a minimum. The following guidelines will allow you to do this:

- Increased temperature of exhaust flue gases (dry fuel, optimal operating mode of the fireplace);

- Sufficient oxygen for combustion and traction (complete combustion of fuel);

- Chimney insulation (prevents "cooling" of the inner pipe);

- Correct size of the smoke channel without constriction;

- The steel of the chimney must correspond to the operating environment (gas and firewood are different media);