Among heating systems, a flueless boiler using natural or liquefied gas occupies a special place. Having appeared on the market relatively recently, these devices have become a real breakthrough in the application of new technologies in heating systems. Consumers also appreciated it - recognizing the convenience and reliability of these boilers. However, when choosing a device for an individual heating system, you should carefully study all the qualities in order to be sure of the right choice.

What are smokeless boilers

In the design of heating boilers, a large place is occupied by the problem of removing combustion products. In gas boilers, in comparison with other types of heat-generating devices, there are much fewer such products than in solid fuel ones, but despite this, their design is a very responsible matter.

The classical scheme for installing a gas boiler, like a solid fuel unit, requires that a chimney be provided in the building structure itself. And this is a rather complex structure erected during the construction of the entire structure of the house. A smokeless gas boiler is another matter; its installation does not require a high chimney and smoke ducts in the walls of buildings. And the place of installation of this device is not so rigidly tied to the structure of the building and the communications laid in its premises.

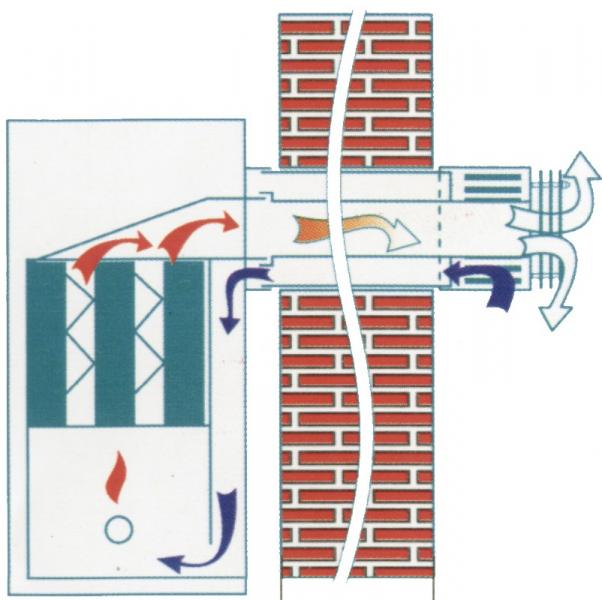

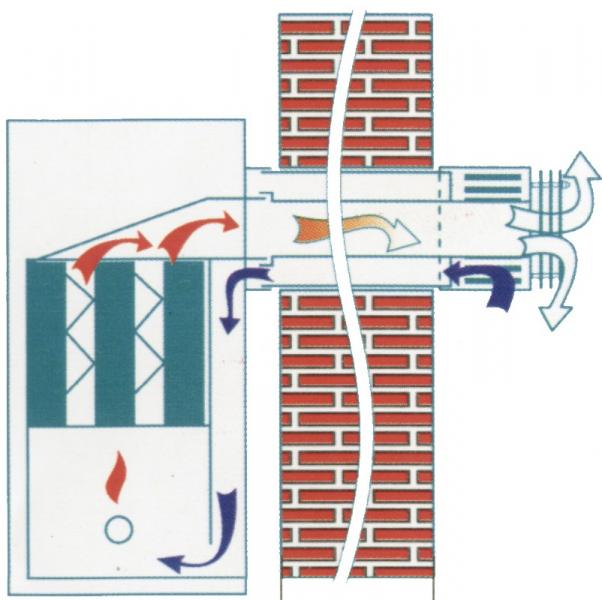

In the technology of smokeless heating boilers, a scheme is implemented in which air is supplied for fuel combustion and combustion products are removed through a coaxial channel. This is the fundamental difference between conventional chimney boilers with an open gas burner and a closed combustion chamber. As for the design of the coaxial channel, it is nothing more than two pipes inserted into one another, in which a thin inner one is designed to remove combustion products, and the second, of a larger diameter, is intended for the flow of atmospheric air.

Such a coaxial chimney can be installed in any outer wall of the building, which allows for the most convenient location of heating equipment inside the building.

Equipment device

Chimneyless boilers are designed to perform the same function as conventional boilers. They are able to heat the room and prepare hot water, but their combustion chamber is arranged somewhat differently and there are differences in the principle of operation. If a conventional gas apparatus operates at the expense of a chimney and draft, then this model carries out air intake and exhaust gases through a coaxial pipe. Equipment of this type can be connected to the system from one or two sides. In this case, gases are removed through the inner part of the coaxial pipe, and air is taken into the boiler through the outer system.

The design of smokeless gas boilers is very convenient to use, and besides, it is fireproof. The high temperature of the combustion products is extinguished by the cold air coming from the street. Another plus is that the boiler is undemanding to the presence of draft and air flow - all these operations are performed forcibly due to the fan built into the equipment.

The principle of operation of chimney boilers

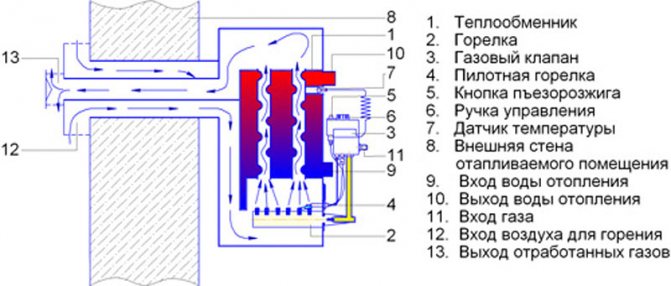

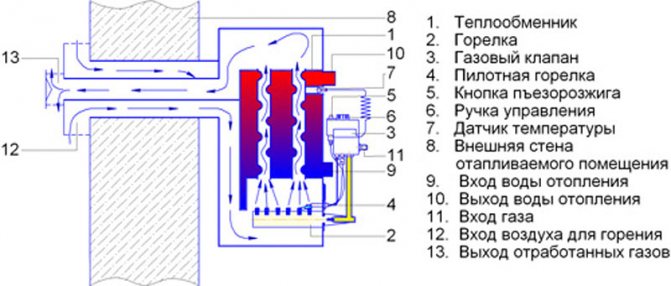

In principle, this group of heating devices is no different from conventional boilers with an open burner. In the heat exchanger above the gas burner, the heating medium for the heating system and water for hot water supply are heated.The movement of the coolant through the system is carried out under pressure created by a circulation pump. Burner ignition is controlled by a control system that reacts to data changes with a temperature and water flow sensor. The difference lies in how atmospheric air is supplied to the combustion chamber and how the exhaust gases are discharged.

The gas burner is located in a closed circuit; when a signal is sent from the control board, an electric turbine starts to work before igniting the piezoelectric element. Its design has two independent chambers with impellers located. One impeller wheel draws air into the combustion chamber circuit from the channel between the pipes of the coaxial chimney. The second impeller creates flow through an internal duct that draws air to the outside. 2-4 seconds after the start of the turbine, gas is supplied to the burner and the flame is ignited.

During operation, combustion products are removed through an internal pipeline. At the same time, given that the temperature of the exhaust gases is high, the air supplied to the combustion chamber is heated, which has a positive effect on the operation of the boiler.

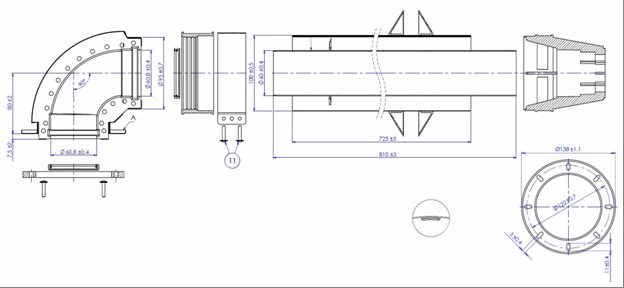

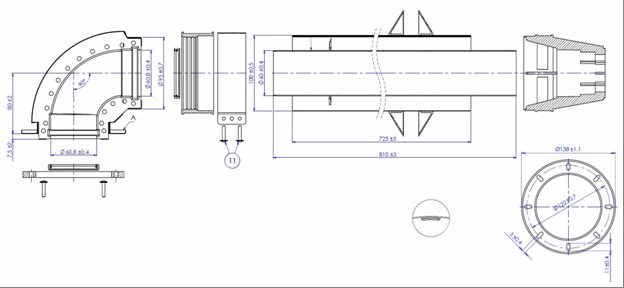

The design of the coaxial channel is as follows, outside the building, the pipe extends 30-50 cm, depending on the design of the chimney. The outer contour is located at a distance of 15-25 cm from the plane of the wall, and the pipe through which the gases are discharged is extended beyond the outer contour by 10-15 cm. So during operation, both flows do not mix.

Floor standing boilers:

Consider floor standing boilers from the manufacturer Baxi. Their boilers are equipped with the latest electronic technology - an automatic diagnostic system detects up to 10 possible malfunctions in the heating system, which makes the use easier and more comfortable. Made of stainless steel, they have a permanent modulation of the flame, which helps to save on gas consumption.

Floor standing boilers Baxi

The model range of the Baxi brand includes single-circuit and double-circuit boilers. Double-circuit boilers are represented by the Baxi Slim model range - 2.230 i, 2.300 i, 2.300 Fi (TURBO). When purchasing this type of boiler, you will also have hot water supply, in addition to heating.

The lineup

All these models have the following advantages:

- Automatic timer

- Stainless burner

- Continuous flame modulation

- Cast iron heat exchanger

- Fault diagnosis system

- Protection against overheating of water, against freezing of the heating circuit

- Automation that determines the outside air temperature

What requirements should be considered for the installation of smokeless boilers

As with other gas equipment, flue-free boilers must comply with stringent government regulations regarding safe installation and operation. True, it is worth noting that the installation of such equipment is much safer than conventional chimney models with an open combustion chamber. Otherwise, the requirements for these devices are standard - they cannot be installed above the plates, the set distance must be maintained, the room must have a working alarm.

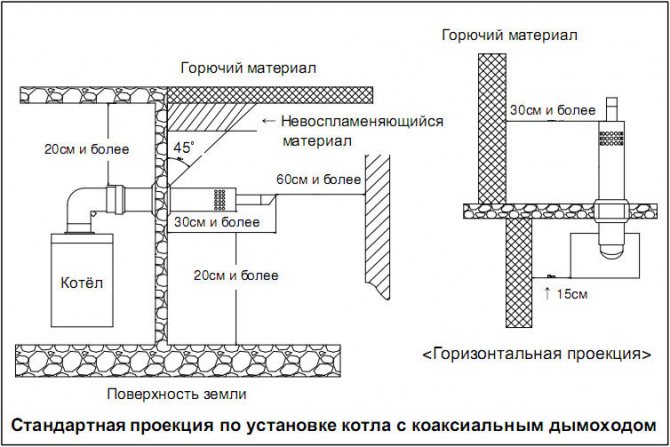

Devices are selected in terms of power, depending on the area of the heated room and the requirements for the volume and temperature of heated water. As for the coaxial chimney, it can be installed horizontally or vertically. When installed horizontally, it is done at a slope of 2-3 degrees towards the wall, so that the condensate formed between the circuits does not enter the combustion chamber.

A vertical chimney is installed when it is not possible to install a horizontal chimney, for example, when the distance between adjacent buildings is less than 1.5 meters or the chimney is located near a window. Under such circumstances, the horizontal gas discharge scheme is unsafe and the vertical chimney scheme is used.

The height of the vertical coaxial chimney must be such that the total length of the chimney does not exceed 5 meters. Another condition for installing a vertical chimney is that there should be no more than 2 bends in the structure.

Theoretically, a coaxial chimney can be made independently, there is nothing complicated about it. But on the other hand, professionals advise using branded components for the boiler and chimney. The fact is that manufacturers are developing universal chimney systems for different brands of boilers, but of their own production. At the same time, for other brands, these components may not be suitable both in size and in the method of fastening.

In branded accessories for the internal pipeline, stainless steel is used, and for the external one, either high-quality plastic or stainless steel.

Design features

Floor-standing chimney gas boilers are primarily divided into:

- Single-circuit (perform only a heating function);

- Double-circuit (capable of simultaneously heating the premises of the house and connecting to the water heating systems of the house itself). This also makes it possible to always have hot water available for domestic purposes.

Interesting to know: additional efficiency and high efficiency of such devices is achieved due to the presence of only closed combustion chambers (burners). This prevents gas and combustion products from entering the premises. They are immediately discharged through the chimney. The heated air masses pass through a specially provided block of the system and enter the combustion compartment. Due to the heated air masses, the boiler equipment circuit begins to heat up. At the last stage, the air is removed from the heater, through the hood to the street.

Most devices come in neutral white

Miniature model included with coaxial chimney

Floor-standing design with small dial

The floor-standing gas flueless boiler works by means of a coaxial chimney connected to it, which in turn consists of two pipes (coaxial), which have different diameters and cross-sections, which allows one of them to be inserted into the other. Such a structure allows the air flows to cool slightly after warming up (due to the cold air coming back from the street). The advantages of such systems include efficiency, high efficiency and environmental friendliness. The outer pipe is necessary so that air from the street is supplied and supplied to the furnace device, the inner element, on the contrary, serves as a means of removing combustion products and gases to the street.

Advice: if you decide to buy a boiler with a high power, you should play it safe and equip the hood with such an element as a deflector. Thus, the speed of the air flows will increase many times, and the thrust will operate at full capacity. And so that the thrust does not deteriorate due to sudden gusts of wind, the structure is additionally equipped with a windproof element.

Installation Basics

The floor-standing chimneyless gas boiler belongs to the category of universal devices and can be installed with equal success both in a small private house and in an apartment or production room.

Basic rules for installation and installation:

| Primary requirements | Detailed description |

| Installation rules

| If it is quite possible to assemble the boiler equipment itself with your own hands, only the master working in the gas service is engaged in the connection. The equipment is installed on a special pedestal, and the floor surface is insulated with refractory materials. If the equipment has electronic boards, it must be additionally connected to the mains. |

| Requirements for horizontal sections | Any instruction drawn up by a professional indicates that the coaxial chimney should be output through the wall ceiling exclusively in a horizontal position. However, this horizontal section should not be more than one meter in length. In exceptional cases, such a horizontal section can be replaced with a vertical one. However, its total length should not be more than three meters. |

| Distances and safety

| The distance from the ground to the hood should not be less than two meters. Try to install the chimney as far away from windows and doors as possible. The minimum distance in this case is 500 centimeters. The outlet must not under any circumstances be located near window openings and doors, as in this case gas and other hazardous to health and life products of combustion can enter the room! You can also learn more about this stage and rules by watching the video in this article. |

| Choice of slope and diameter | In order to prevent a large amount of condensate from accumulating on the inner surface of the chimney during the operation of the heating equipment, place the pipes at a slight slope equal to 2-6 degrees. The diameter of the branch pipe must match the section of the pipe itself, and all places where the system passes through partitions and ceilings are insulated with non-combustible materials. |

You can also view illustrative photos of each stage described in the table in our gallery.

The chimney consists of two pipes with different diameters

The main components of the device, with the display of the circulation of air flows

What features do you need to be prepared for when the boiler is operating

What you need to pay attention to

First of all, turbo boilers are dependent on electricity. In the event of a power outage, it automatically turns off. On the one hand, this is fraught with cooling of the premises and the lack of hot water supply. But on the other hand, this means that the gas valve shuts off the gas supply, and the blocking system does not allow the burner to be ignited. So in places where the power supply is unstable and where there are frequent power outages, you will have to consider the issue of emergency power supply.

The second feature is the need for regular maintenance by service center specialists. This is especially true for regions where natural gas has a large amount of impurities. Cleaning in the device requires not only the burner with a combustion chamber, but also the turbine.

The third point is that quite often chimney-free gas boilers that are too short, or vice versa, long chimneys can be blown out by gusts of wind. In most cases, this problem is solved by installing a deflector instead of a decorative grill.

Malfunctions of a smokeless gas boiler

As for characteristic faults, gas boilers without a chimney have the same typical faults as conventional chimney ones:

- Control board malfunctions - most often the cause of the malfunction is a factory defect, voltage drops or water leakage from the heat exchanger (for many wall-mounted models, the control board is located in the lower part, under the main equipment);

- Malfunctions of electrical equipment - sensors for temperature, pressure, water flow, centrifugal pump and turbine usually fail after a long period of operation;

- Heat exchanger leakage is especially common in double-circuit gas boilers without a chimney after 7-10 years of operation. In the places where copper plates or pipes are soldered, holes are usually formed through which water or coolant seeps;

- A coaxial chimney often simply needs to be cleaned of dust and carbon deposits.But if this is not done regularly, during boiler maintenance, the likelihood of debris getting into the combustion chamber and clogging the burner nozzles increases significantly.

But, despite this, smokeless gas heating boilers are currently one of the most reliable and safe heating devices. In a closed combustion chamber, when the turbine is stopped during blowing by the wind, the gas supply is instantly stopped. The burner will reignite only when the automatics diagnose all equipment and allow gas to start again.

Boiler application:

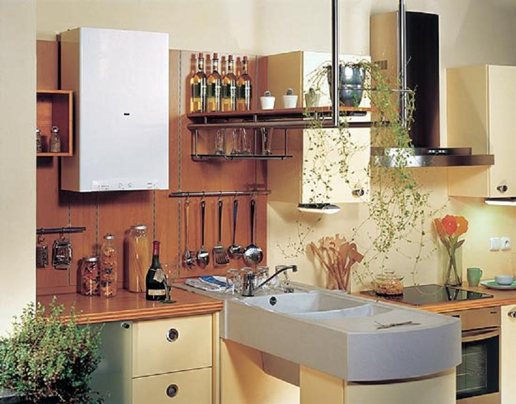

Gas boilers are often used to heat an apartment. This option is currently the most profitable and has a number of advantages over a centralized system. It is easy to install, does not require additional costs for chimney equipment, has a compact size and modern design, and also allows you to turn on heating during the off-season. These advantages and the presence of a coaxial pipe made the smokeless boiler very popular and in demand in the Russian climate.

Gas boiler in the apartment

How to choose the right chimney boiler for living quarters

First of all, when choosing, it is necessary to decide on the place of installation of a gas flueless boiler in the room itself. Among the models of many manufacturers, there are both parapet and wall models. To install the parapet model, it is necessary to take into account the location of the windows - the chimney should not be at the same level or below the level of the windows.

It is recommended to install a wall-mounted gas flue gas boiler on the outer wall of the room. As an exception, installation on internal walls is allowed, but the length of the coaxial chimney should not be more than 5 meters.

Boiler power is selected depending on the area of the heated room. As for a specific brand, here professionals advise you to pay attention to how much this brand is represented on the market, and whether this brand has a network of service centers. This is an important point, since the maintenance of this equipment requires not only trained specialists, but also the availability of branded spare parts. So, most domestic brands, like global brands of manufacturers of climatic equipment, advise to carry out diagnostics and maintenance of smokeless boilers at least once a year, before the start of the heating season.

A chimney-free gas boiler allows you to solve the problems of the device of individual heating in almost any houses and apartments, providing warmth and comfort in the most severe frosts.

Features of the installation of gas boilers with a coaxial chimney.

Floor standing flueless boilers for autonomous heating systems are installed in small buildings and in many apartment buildings or industrial premises.

Chimneyless gas boilers are installed on a special stand. If the boiler is controlled by an electronic board, then it is connected to electricity according to the rules for the installation of electric and gas equipment by specialists.

They are included in the heating system and gas mains in the same way as chimney gas boilers. The difference is the installation of a coaxial chimney.

Installation diagram of a horizontal coaxial chimney

Requirements for installing a coaxial pipe as a chimney:

- The chimney outlet to the street passes through the wall horizontally. The length of this pipe segment is no more than 1 meter.

- The chimney is horizontal, but if a horizontal outlet is impossible, a vertical chimney is used. The length of the vertical part of such a chimney is about 3 meters.

- The outer part of the pipe is located at least 2 meters from the ground.

- The distance from the pipe to window or door openings is at least half a meter.

- Do not place a pipe outlet under a window.

- To prevent the accumulation of condensation liquid, it is installed at an angle of 3-5 degrees.

- Observe the diameters of the pipes of the coaxial chimney and their ratio for fire safety.

- The hole drilled in the wall for the pipe is lined with insulation made of non-flammable material.

Compliance with these requirements will make the boiler operation safe and efficient.