25.08.2015

When planning the installation of a stove or fireplace in a house and connecting a chimney made of galvanized steel, you need to familiarize yourself with all possible options, as well as consider the strengths and weaknesses of each of them. For many centuries, brick or stone structures have been used for heating. We will not argue, they are still found now, but the creation of new materials allows the use of lightweight and reliable structures that meet standards and norms.

The most popular are high-quality steel products made of stainless steel or galvanized metal. But the topic of today's article is precisely a galvanized chimney pipe, its design characteristics, advantages and varieties.

Galvanized chimney pipe

- 1 About the main enemy - rust

- 2 Galvanized pipes 2.1 Video - Chimney sections

- 4.1 Option No. 1. Single-circuit products

- 6.1 Video - Installing a galvanized chimney

About the main enemy - rust

Corrosion is dangerous for all metal products. In particular, this applies to iron, because it is more susceptible to the negative effects of moisture and atmospheric phenomena. For this reason, designers are constantly developing new ways to protect against rust.

Note! Different steel alloys solve the problem only partially, but a zinc layer applied to the surface of metal products is an excellent barrier to rust.

They do it like this: steel is immersed in a molten mass, after which, by the action of special substances, iron combines with zinc and, as a result, a new protective ball is formed. The thickness of this layer is different, but not more than 60 microns. This technology both protects metal products and increases their service life.

Galvanized pipes

As many years of practice have shown, galvanized chimneys are many times superior to their stone and brick "competitors". As you know, when any fuel is burned, gases appear, which, when passing through the chimney channel, are cooled and condensed. And moisture already has a detrimental effect on both brick and metal, but the situation is aggravated by the presence of soot in it.

It contains acids that form oxide, which, in turn, leads to destruction of the walls of the chimney. From the inside, drips often appear, as well as roughness; soot and fumes "catch" on it. This causes a deterioration in draft, due to which gas enters the house through the combustion chamber and poses a serious threat to the health of people living in it.

The situation can be corrected by regular cleaning, but not for long, since the condensate cannot be completely eliminated. For this reason, experts use products in which the appearance of condensation is minimal as a chimney. These include a galvanized chimney pipe.

Coaxial chimney, what is it?

Previously, we described the main advantages, technical characteristics and features of the installation of a coaxial chimney, we recommend that you read this article in more detail Learn more here

Video - Chimney sections

Advantages of using galvanized pipes

The main advantage lies in the presence of the protective layer described above. We found out that when exposed to condensate, any metal begins to rust, and therefore the tightness of the chimney channel and the efficiency of its functioning are violated. But if the product is well protected from moisture, then it will last much longer. Because of this, galvanized chimneys have become increasingly popular lately.

Note! High-quality sheet steel is used in the manufacture. Before shaping, it is immersed in a zinc solution, where a chemical reaction occurs under the influence of reagents. The protective layer created in this way is quite sufficient for a significant extension of the service life.

And chimneys made from this material have the following advantages.

- High heating rate and, as a result, almost instant traction. This allows heating appliances to work as efficiently as possible.

- Such chimneys include several modules, which, if necessary, are easy enough to assemble.

- Installation of products can be done on any heating devices. Simply put, their versatility can be considered another advantage.

- All galvanized pipes are fire resistant, which means they are fireproof. And this is especially true for wooden houses.

- The installation requires a minimum free space.

- A wide variety of variations.

- High resistance to condensation (especially against the background of brick analogs). Only chimneys made of "stainless steel" are more effective in this regard.

- Finally, thanks to the smooth surface, soot does not collect on the walls, making cleaning faster and easier.

Note! In the light of all of the above, we come to the conclusion that galvanized products are much better than brick products, and are inferior in quality only to stainless steel pipes. Consequently, their main advantage is considered savings (both on the purchase and on installation work).

But remember that often saving on the quality of the purchased material is fraught with significant costs for maintenance and repair work.

Classification of galvanized chimneys

The products described in this article are produced in two types - one- and two-circuit (with a layer of insulation). Let's get acquainted with each of them in more detail.

How to make a chimney cap on your own

Earlier we told you about how to properly install the hood on the chimney, we advise you to read this article additionally.

Option number 1. Single-circuit products

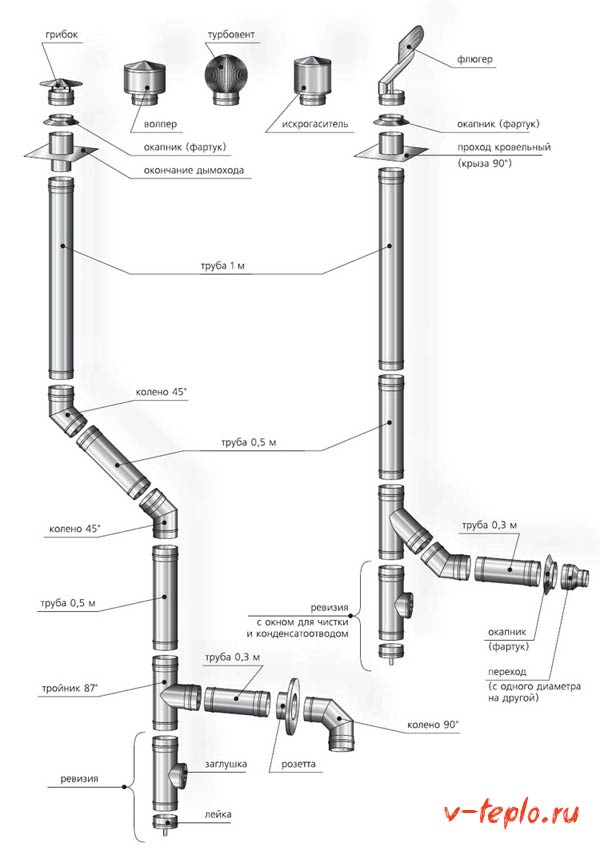

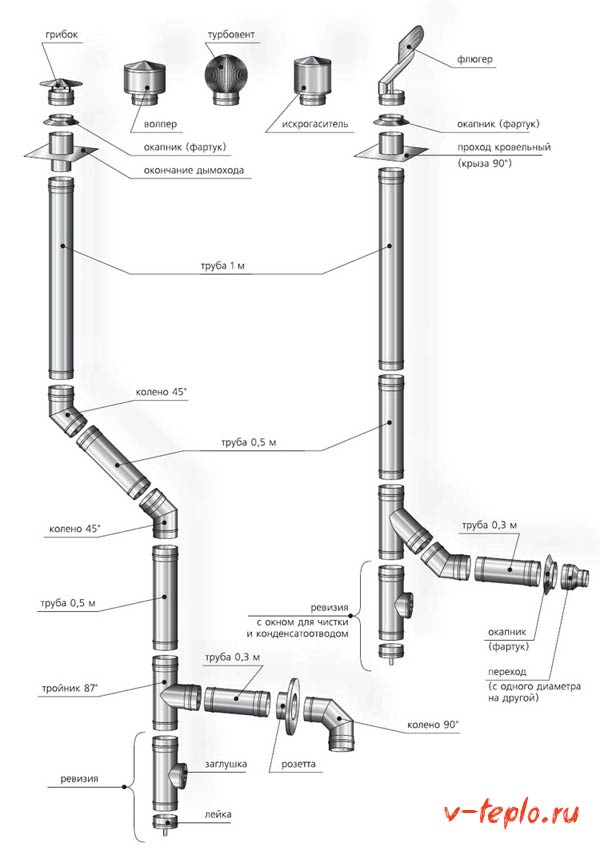

They consist of such basic components as pipes and other fittings (these include tees, adapters, various kinds of revisions, and so on). The most popular uses are as follows:

- use as an in-house chimney;

- use inside a brick chimney.

Such designs are not without drawbacks, the main of which are large volumes of condensate, especially when the heating system is connected to modern equipment with a low temperature of the exhaust gas and excellent efficiency. In order to eliminate this problem, the chimney is insulated or, as an option, the rate of condensation formation is reduced and heat loss is minimized.

As we just said, such a galvanized chimney pipe is often used for efficient and prompt repair of brick smoke channels. The purpose of this is extremely simple: instead of repairing half-destroyed masonry, a modular structure of the required size is mounted in the channel. A special mineral heat insulator is installed between the new element and the brickwork, which significantly increases the efficiency of the structure.

Note! The use of galvanized pipes from the outside is undesirable. But if there are no alternative options, then the pipe should be properly insulated.

Option number 2. Double-circuit products

For obvious reasons, such designs are also called sandwiches. Of course, predominantly stainless steel is used for their manufacture, but galvanized pipes are also quite common, often due to their lower cost. There are several sandwich chimneys made of galvanized steel, consider them.

- Only the outer contour of the structure is galvanized, while the inside is a stainless steel pipe.

- Two pipes are galvanized at once.

And due to the fact that the bulk of the loads falls on the inner pipes, the material from which they are made should be at least 0.6 millimeters thick. If we talk about the outer pipe, then 0.5 mm is quite enough for it.

Note! The outer surface of the structure is covered with special heat-resistant enamel and powder coatings, which give them a more aesthetic appearance.

The described double-circuit chimneys increase the efficiency of heating devices, and also increase the efficiency of their functioning. Of course, metal pipes are not very aesthetic, which is why they are often not combined with the overall design of the house. But this kind of disadvantage is quite easily eliminated by brick laying along the contour of the structure (although any other material can be used for this).

Construction of galvanized products

Manufacturers produce single and double-circuit modifications of these chimneys.

Single-circuit galvanized steel products are often installed inside the house or lined with brickwork.

To avoid the formation of condensation, it must be insulated. It is not recommended to use single-circuit chimneys made of galvanized steel without insulation outside.

It can be placed on its own in a barbecue or barbecue area.

The double-circuit modification (sandwich galvanized pipes) is so named because of the multilayer one. It consists of three components, two pipes inner and outer, which are insulated with mineral wool or other refractory insulation.

This design heats up quickly, which activates the operation of heating devices and minimizes the amount of moisture that accumulates on the walls.

Having given preference to a galvanized sandwich pipe, we can talk about an aesthetic appearance that fits harmoniously into the overall design of the exterior. In addition to the technology described above, structures are created from the so-called black steel.

Galvanized chimney sandwich pipes are used in houses with heating boilers, stoves or fireplaces. It is also the best option for baths and saunas.

Since the device of the bath differs from an ordinary house, in order to maintain a high temperature in the steam room, a sandwich structure is used, and the space between them is filled with mineral wool, which is thermal insulation of an environmentally friendly composition and at the same time it is not subject to fire at high temperatures.

Comparison of stainless steel and galvanized

As already noted, in some respects, galvanized structures are inferior to those of stainless steel. People who are poorly versed in this want to know which option is better and why. In order to answer the question, we will compare the most important specifications.

- The condensation resistance of stainless steel is higher than that of galvanized steel.

- In terms of fire safety, both options are not inferior to anything. They are, in other words, equal.

- In double-circuit versions of a galvanized structure, we recall that a heater is used. But sandwich chimneys made of stainless steel have not yet been manufactured.

- They have about the same warm-up time.Both designs provide good traction in record time.

- Finally, both options can be installed on any heating appliance. They are not oversized, so they take up little space. Their installation is extremely simple and quick enough. To do this, you don't even need to hire professionals, but do everything yourself!

As you can see, both options are good, but you will have to pay more for quality (read: stainless steel).

Types of galvanized iron smoke exhaust pipes

The consumer is offered single-wall and double-wall galvanized pipes. For ease of installation, manufacturers produce all the necessary components: tees, inspection channels and condensate traps. A standard range of diameters is supported. It will be quite problematic to order a pipe or adapters of non-standard sizes at the factory.

In order to select the necessary material for the smoke exhaust system, you will need to take into account the technical characteristics, the resistance of the material to burnout and the effects of an acidic environment, as well as the main possibilities of operation.

Double-circuit insulated chimney pipes made of galvanized sheet are available in two versions:

- Sandwich pipes - a structure where the inner and outer layers are made of galvanized metal. The design reduces the production of condensate, but is not able to withstand significant heat. Deformation occurs when the inner layer is heated to 500 ° C.

- Modular chimneys made of acid-resistant stainless steel with external insulation and galvanized shell. Such a device significantly reduces the cost of the structure and increases the service life almost twice.

The inner layer of the pipe should be made of metal with a thickness of 1 mm, for the outer layer, 0.5 mm is enough.

Technical data of heat-insulated outdoor chimneys in a galvanized casing are almost identical to those of analogs made entirely of stainless steel. To increase the service life, the outer contour can be painted.

The product has a simple design. The manufacturing technology of galvanized steel chimneys is as follows:

- Blanks are made from iron sheets.

- The sheets are dipped in a bath of molten zinc.

- As a result of a chemical reaction, a zinc layer up to 60 microns thick is applied to the surface.

- The sheets are rolled into pipes, the seams are welded.

Galvanized steel must be at least 1 mm. SNiP, it is allowed to install a galvanized chimney with a thickness of 0.8 mm. But as practice shows, such products quickly burn out and become unusable.

The galvanized chimney quickly burns out in the following cases:

- There is no insulation.

- Incorrectly selected pipe thickness.

- Non-compliance or disruption of the production process. Galvanizing is made from carbon steel, according to GOST 14918-80.

If all these conditions are met, a single-layer galvanized pipe can work up to 10 years.

Installation features

The diameter of a galvanized chimney pipe depends on a number of factors, including:

- heater power;

- number of devices connected to the system;

- the type of fuel used for heating.

If the purchase of a galvanized sandwich is too expensive for you, then you can make its own analogue. For this, the galvanized pipe is wrapped in a layer of refractory insulating material and all this is placed in another pipe, painted or also galvanized.

Note! If the structure consists of several modules, then with each part the diameter should decrease - this way moisture will not penetrate into the chimney from above.

It is advisable to cover all joints with a refractory sealant. In the absence of any gaps, the traction will be excellent. In addition, the joints of the elements must be secured with clamps.For this, fixing brackets are installed along the length of the pipe in increments of about 150 centimeters (although this depends on the strength of the structure).

Note! If horizontal sections are planned, then know that their length should not exceed 1 meter!

In addition, when installing a galvanized chimney, fire safety requirements must be observed. This means that it must not touch the gas line, electrical wiring or combustible materials. If the structure was placed in a brick casing, then additional fasteners should be equipped in the attic to increase the strength of the chimney. Where the pipe connects to the oven, a hole must be made for cleaning and servicing the device (it will be closed during operation).

Video - Installing a galvanized chimney

DIY chimney technology

Self-fabrication of a flat chimney with a standard diameter of 11 cm.Do-it-yourself galvanized chimney is not as difficult as it seems at first glance.

First you need to take a sheet of metal and cut it out correctly. All processes resemble the manufacture of a drainpipe, but in our case, the steel should be thicker, it is also worth taking care of the insulation in order to exclude the formation of condensation, otherwise, in addition to corrosion, icicles are also formed on the chimney in the winter.

For cutting a galvanized steel sheet with your own hands, you can use such available tools as: a disk cutter on a bed, a guillotine or saber shears.

The next stage is rolling and rolling of the surface of the future product. The process is carried out using manual rollers or with an electromechanical drive.

The main thing is that the size of the treated surface corresponds to the one you need. A do-it-yourself galvanized pipe for a furnace is made from a sheet with a length of 125 or 200 cm.The rollers must stretch a sheet about a millimeter thick.

It is advisable to choose a machine in which the shafts are located asymmetrically, in this case even the edge of the future chimney will be rolled properly without leaving flat areas. You also need to take into account the minimum diameter of the rental. The standard product has a cross-sectional size of 10 cm.

The next step is insulation to protect against moisture that occurs due to condensation. After insulation, the second pipe is put on the first pipe, which holds the mineral wool and gives the chimney improved technical characteristics. The diameter of the second is 11cm. Thus, a sandwich of galvanized pipes for the oven is created with their own hands.

Assembly features

After making the structural elements with your own hands, you can start assembling. Initially, it is advisable to create a project on which to mark the location of each of the sections, the connection and fastening points, adhering to certain standards:

- the galvanized pipe for the furnace must be at least 5 meters in length;

- the structure must exceed the highest point on the roof by 150 cm;

- when creating a project, do not forget about windows for cleaning soot.

The chimney system consists of sections of different slopes, but it must be taken into account that all of them do not exceed a meter in length.

Video

https://www.youtube.com/watch?v=jdkgVmLkHes

A do-it-yourself galvanized pipe for a furnace is mounted using adapters, tees, clamps and elbows with the desired slope. Installation starts from the heating unit and goes upwards by connecting the sections to each other.

The appearance of the galvanized chimney directly depends on where the outlet is located. If it is installed in the side, then the structure will be attached, joining the branch pipe from the side and leading out through the wall, after which the structure is brought up to the level of the roof.

It is not so difficult to make a galvanized pipe for a stove chimney with your own hands, you need to follow the step-by-step instructions exactly and show perseverance, while not forgetting about safety precautions so as not to get hurt by the sharp edges of sheet steel. Good luck with your work!