What you need to consider when deciding to install a meter

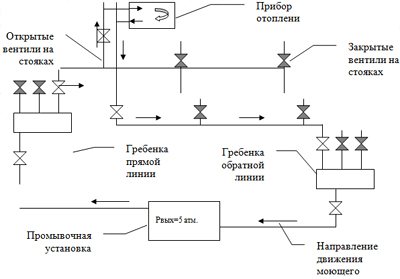

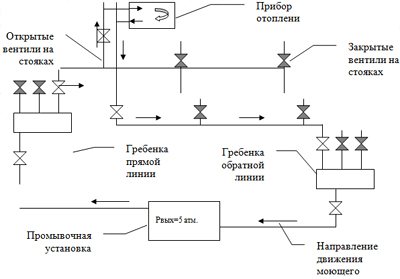

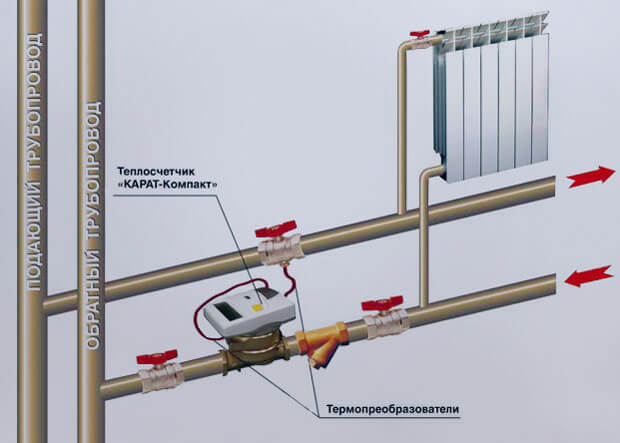

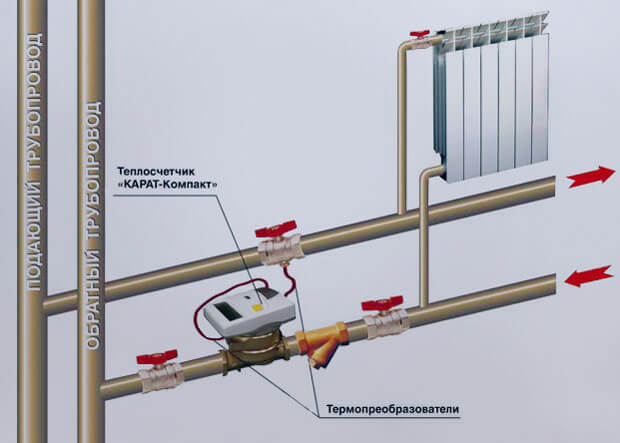

Some difficulties may arise depending on your heating system wiring diagram. So with a horizontal wiring diagram, it will be enough for you to put one meter at the entrance of heating pipes to the apartment, but what if you have a vertical layout. I have a vertical scheme in my apartment and 4 risers of heating pipes, and it turns out that when installing a heat meter, I will have to install one meter for each heating device. Naturally, this option is not profitable, but not all that bad. Manufacturers of heat meters produce distributors that measure the flow rate of the coolant based on the difference between the surface temperature of the heating device and the temperature of the internal air. The cost of this equipment together with the installation will be approximately from 3 to 7 thousand rubles, it all depends on the equipment configuration.

Installation

Before thinking about installing a heat meter, you should find out if it can be installed in your apartment. There are some conventions regarding this:

- If you use a vertical pipe routing, namely for each radiator a separate pipe riser going from the bottom up, then installing a heat meter is irrational. Otherwise, you will need to install several computing devices at once on each heating riser. Plus, you will create additional hydraulic resistance in the system. This will significantly affect the heating mode of the entire building.

- If the routing of pipes in an apartment or in a private house is horizontal, that is, when two supply / return pipes are installed and all radiators are connected through them, then the installation of a heat meter is even recommended.

The second installation case completely eliminates the disadvantages of the first option.

As for the installation stages, there are several sequential steps here:

- Installation of an automated heating unit.

- Balancing the heating system along the risers.

- Equipping radiators with thermostats.

According to the calculations for the transition to apartment heat metering, the reconstruction of the heating system will pay off within 2-4 years.

When flushing the heating system is required

The frequency of flushing is always regulated by individual technical standards, but we can also talk about emergency situations, which include:

- Increasing the hydraulic resistance of the heating system to critical values. This hazard can only be diagnosed using special equipment.

- Inefficient system operation. This is reflected in an increase in heating costs, uneven heating of devices, as well as significant fuel consumption. When deposits form inside batteries and pipes, their effectiveness drops significantly.

- Replacement of a separate section of pipes or several batteries.

- Preventive flushing of the heating system at home. Ideally, it should be carried out upon completion or at the beginning of the heating season, once every 3 years.

Installation of an individual heat meter

Step one

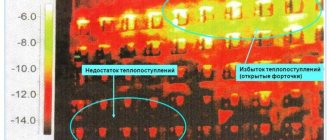

... It is necessary to eliminate the existing sources of heat loss, including cracks in the windows, insufficiently insulated entrance doors, freezing corners. Only after this installation of the heat meter will result in significant savings in money.

Step two

... The management company (ZhEK, HOA) must provide the owner of the apartment with technical specifications (TU) - they attribute the requirements that must be met in order to connect. Typically, the text of the conditions occupies an A4 sheet. It certainly indicates information about the temperature and pressure of the coolant entering the pipeline of a particular house.

Step three

... Knowing these parameters, you can start buying a heat meter necessarily in a company operating legally. When purchasing a device, you must require a sales receipt and a cashier's receipt, a certificate confirming the quality, rules and instructions for use.

Step four

Step five

... The installation of a measuring thermal device is carried out by employees of a licensed organization specializing in this type of service.

When choosing a company, it is advisable to pay attention to a number of nuances:

- for the availability of information about the organization in the Unified State Register of Legal Entities;

- for the presence of a package of necessary documentation, including certificates, certificates, SRO approvals;

- for the availability of qualified specialists;

- for the presence of special equipment;

- to perform a complete list of installation works;

- for the availability of a free visit of a specialist to the client's apartment in order to inspect communications;

- for the availability of warranty obligations for the work carried out.

Step six

Types of devices

If you plan to install equipment in an apartment, then before starting to search for a suitable company that will carry out the installation, you will need to make sure that there is horizontal heating distribution in the house, when a separate pipe leaves from the central riser to each floor.

With one of the two types of vertical wiring, it is irrational to install an apartment meter, because there are several risers in the house, and you will need to install a separate apparatus for each of them, in this case, general house equipment is mounted, which records the readings of the heat meter of the entire building, and payment is made in accordance with the heated ones. square meters of housing.

You can go to the choice of the type of device. There is no ideal and you will need to compare the pros and cons of each of them in order to determine the option that is acceptable for yourself out of four possible:

- Mechanical.

- Ultrasonic.

- Vortex.

- Electromagnetic.

Taking readings from a heat meter of any of these types does not have fundamental differences and can differ only in terms of designations and the number of recorded values.

Varieties of devices

Before installing such a meter in an apartment, you should familiarize yourself with its varieties. They are divided according to the principle of work. They are:

- Electromagnetic.

- Mechanical.

- Ultrasonic.

- Vortex.

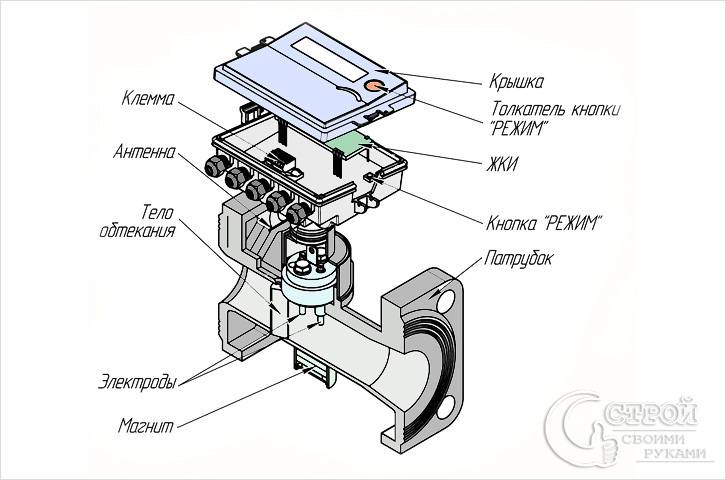

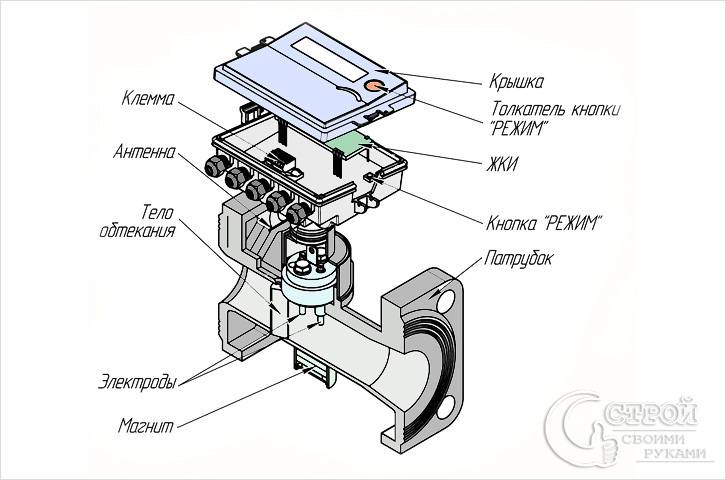

Electromagnetic

At the heart of electromagnetic meters is the phenomenon in which a magnetic field acts on the coolant fluid and excites an electric current. To put it simply, electromagnetic induction appears, which links the average velocity and volumetric flow rate of the coolant with the field voltage and potential difference. It appears on the electrodes with a reverse charge. It turns out that the amount of heat is determined by measuring small quantities of current. Therefore, such counters must be installed correctly.

Note!

They need special operating conditions. The error will increase if additional resistance appears at the connection points, poor wire connection. Also, impurities and iron compounds in the water will affect the result. But, as tests show, such devices are good enough.

Mechanical

If you want a simple meter, then buy a mechanical one. The principle of operation is quite simple: the measuring element rotates under the movement of the coolant flow. Thus, the amount of heat energy is measured.Such a model consists of a mechanical vane or rotary water meter and a heat calculator. Their advantage is their low price. The only time to increase the life of the device is to install special filters.

Note!

It is not recommended to use a mechanical meter in a private house or apartment where the water, which is the heat carrier, is hard. Rust or scale will get stuck in the parts of the appliance or in the filter, which will damage the meter. Another disadvantage is that the water pressure in the system decreases.

Ultrasonic

The most expensive are ultrasonic meters. Heat consumption is measured by the time interval during which the ultrasound travels the distance from the signal source to the receiver. It all depends on the rate of flow of the coolant in the heating system. When installing such a counter, it is important that the signal source (emitter) is opposite to each other with the signal receiver. The ultrasonic signal from the transmitter reaches the receiver through the water column. The liquid flow rate is determined by the time it takes for the signal to pass, since it is related to the flow rate of the coolant.

Note!

The error is allowed if the liquid has impurities, scale or sand. A feature of such meters is the adjustment of the fluid supply through two different channels.

Vortex heat meter device

The latter, vortex counters, take into account the vortices that form behind an obstacle in the path of the flow. The composition of the device: a permanent magnet, which is installed outside the pipe, a triangular prism installed vertically in the pipe, and an electrode located a little further than the prism, which measures the data. The fluid flows around the prism and the flow pressure changes. This allows the device to calculate the volume of the heating medium. The stronger the movement of the flow inside, the more often vortices are formed. The advantage of this model is that the readings are not affected by pipe deposits, impurities and placement.

Having decided which heat meter to buy, you can start working on its installation.

What information does the meter give

A heat energy meter is a complex mechanism that records signals from sensors for the volumetric flow rate of the coolant, temperature. The calculating unit of the heat meter makes the appropriate calculations and gives results for the following parameters:

- the amount of heat energy used for a certain period (in giga calories);

- the amount of cooling energy (in giga calories);

- thermal power (heat energy consumption per hour);

- volumetric flow rate of the heat carrier (both in the supply pipe and in the return pipe. Measured in cubic meters per hour);

- the volume of the heat carrier in each pipeline (in cubic meters);

- temperature of the coolant in the supply pipeline (in degrees Celsius);

- temperature of the heat carrier in the return line (in degrees Celsius);

- temperature difference (in degrees Celsius);

- date Time.

Positive and negative aspects of meters

Let's consider how to take readings from a heating meter in an apartment using the example of a mechanical type from SensoStar, Gross and Supercal. Such a device is equipped with an impeller, which rotates when the coolant flow passes. The part is connected to a sensor that reads revolutions and determines the volume of fluid. To set the current consumption, the device is equipped with a liquid crystal monitor, which shows the amount of thermal energy in Gcal, the volume of flowing hot water taken into account, the temperature of the carrier on the inlet and return pipes.

Ultrasonic equipment measures the speed and wavelength that travels along the flow of the coolant and back. In accordance with the received data, the calculation takes place.This type of device is ideal for metering the consumption of thermal energy in closed and open water supply systems. It is advisable to take readings of the heat energy meter from equipment from the German Sharky or the Ukrainian Sempal.

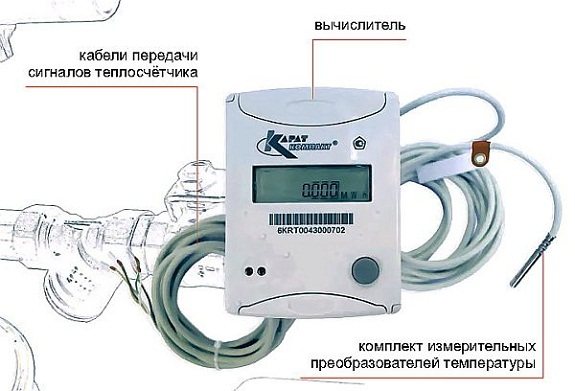

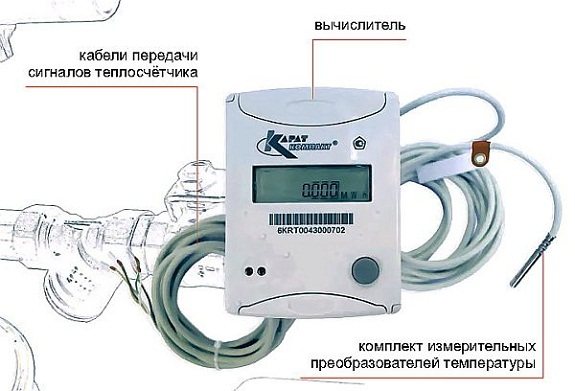

Vortex devices analyze the vortices formed when the coolant flow passes through the obstacle. It is not difficult to take readings from a heat meter of this type, but you will need the help of a qualified specialist who understands all the capabilities of the equipment and knows how to manage it. Recommended for installation are Ultraheat, Karat and TSK products.

The readings of an electromagnetic heating meter are more accurate because the analyzer makes calculations based on measurements of the current generated by the passage of hot water through a magnetic field. Data retrieval is carried out directly, through a monitor with a control system, by connecting external drives, where archived data are copied, or through a remote connection. Among manufacturers, users also note Pramer.

General house meter readings

Heat metering devices are divided into industrial and apartment. Industrial models are used as general household.

The costs of purchasing common equipment are shared among the residents of the building.

In accordance with the provisions of the Decree of the Government of the Russian Federation of 05/06/2011 No. 354, the presence of a common house meter will avoid the cost of paying for heat, which did not even enter the building.

Having figured out how to take readings from the heating meter, each resident of an apartment building can check the correctness of the charges.

The volume of consumed heat is measured in different units:

- megawatts,

- giga calories

- kilojoules.

Since the supply companies calculate the amount of heat in giga calories, it is worth choosing an appropriate meter. If the meter measures heat in a different quantity, the consumer should know that 1 Gcal is equal to 4.18 GJ or 1161.1 kW / h.

According to clause 31 of the aforementioned Resolution, every month from 23 to 25, a representative of a resource supplying organization or a management company takes data and enters them into the register of readings of general house meters.

The presence of consumers is not required. But each apartment owner has the right to contact the appropriate organization and get acquainted with the information recorded by the meter.

Types of heat meters

All heating meters available for purchase are divided into the following types:

Tachometric or mechanical

It measures the amount of coolant that has passed through the cross-section of the pipe using a rotating part. The active part of the apparatus can be screw, turbine, or in the form of an impeller.The devices are affordable and easy to use.

The weak side of such devices is their sensitivity to dirt and dirt, rust, and water hammer sedimentation inside the mechanism. For this, a special magnetic mesh filter is provided in the design. Also, the devices are not able to store the data collected during the day.

Ultrasonic

It is more often used as a general meter in an apartment building. Has varieties:

- frequency,

- temporal,

- Doppler,

- correlation. Works on the principle of generating ultrasound passing through water.

The signal is generated by the transmitter and picked up by the receiver after passing through the water column. It guarantees high measurement accuracy only if the coolant is sufficiently clean.

Electromagnetic

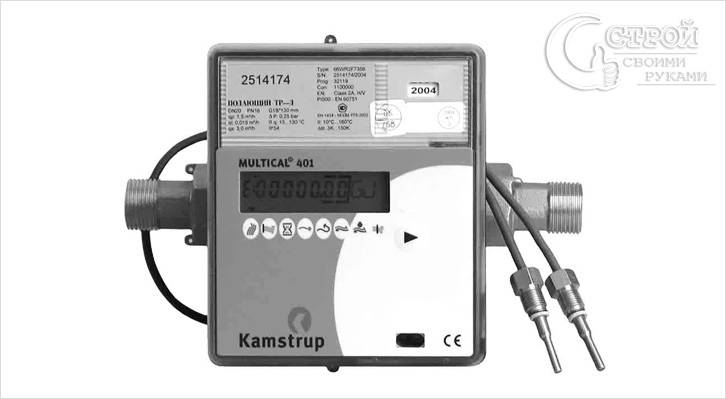

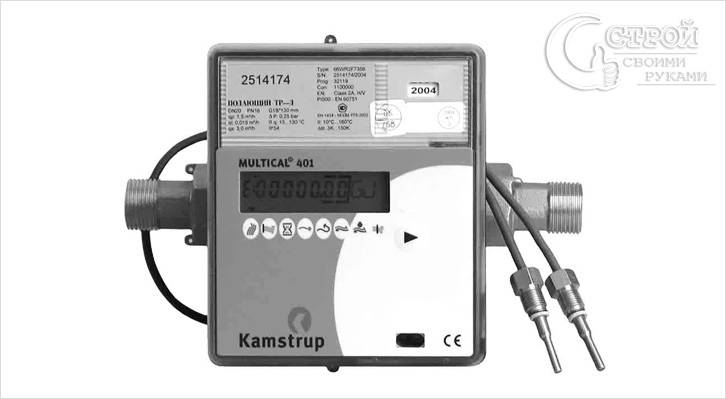

Differs in high accuracy of readings and cost. The operation of the device is based on the principle of passing a magnetic field through the flow of the coolant, which reacts to its state. The device needs periodic maintenance and cleaning.Consists of a primary converter, electronic unit and temperature sensors.

Vortex

It works on the principle of measuring the number and speed of vortices. Not sensitive to blockages, but reacts to the appearance of air in the system. The device is installed horizontally between two pipes.

What are the elements of TEM heat meters?

From a constructive point of view, such devices consist of a computing and measuring unit, directly to which transducers of such types are connected as:

- a heat carrier flow transducer, that is, a primary transducer;

- temperature mode converter;

- gauge pressure transducer.

The measuring unit of the TEM heat meters itself consists of a microprocessor system that collects and processes the data obtained from the results. Also, this system displays the finished results on the display. In addition, the computing and measuring unit is provided with a liquid crystal indicator and an indicator of the heat meter operation.

The connection of the measuring transducers is provided by the terminals located on the board of the analog signal processing unit, the terminals of the consumable transducers are located on the digital signal processing board.

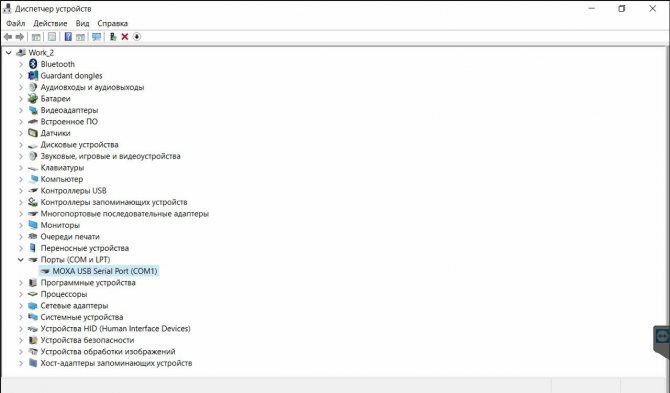

In addition, the digital processing board is equipped with serial capabilities, which are provided by RS232C and RS485 interfaces, and also has built-in DC output current signal pins.

Is it possible to be present when taking readings of heat meters

It is possible and even necessary. It is necessary to be present when taking readings from heat meters first of all for the peace of mind of the residents of the house, for the correctness of taking readings there is no need for this.

Why exactly for the peace of mind of the tenants?

Unfortunately, the times of Leonid Ilyich Brezhnev taught many to steal. I remember when the newspaper Argumenty i Fakty first appeared, it was something like Leninskaya Iskra, a piece of paper folded in half from the cheapest gray and yellow paper, it was 1980. We read the newspaper to the holes, passing it from hand to hand. I read there a conversation between Leonid Ilyich and someone from his entourage

Unfortunately, I don't remember with whom, but it doesn't matter

Leonid Ilyich was informed that the people live in poverty, the wages are miserable - although of course now one could argue with this. Leonid Ilyich replied - "so they can steal, no matter how lazy they are, I myself worked as a student unloading cars - I know."

These were the words of our leader, and it was a bitter truth; unfortunately, they cannot get rid of the very notion that one can live without stealing our older generation. In addition, the years of perestroika have even more convinced us in this. Therefore, the presence of representatives of the house at the first stages is simply necessary for the peace of mind of the tenants.

what it is necessary to have for taking readings from the heat meter

... Start a notebook or a small notebook, put it in a shield or box with an installed heat meter, and record the readings of the heat meter simultaneously with the reading by the service organization.

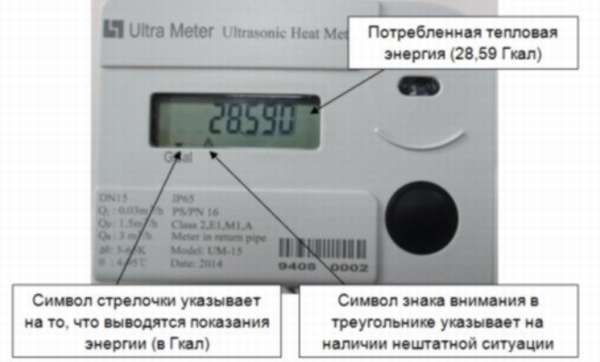

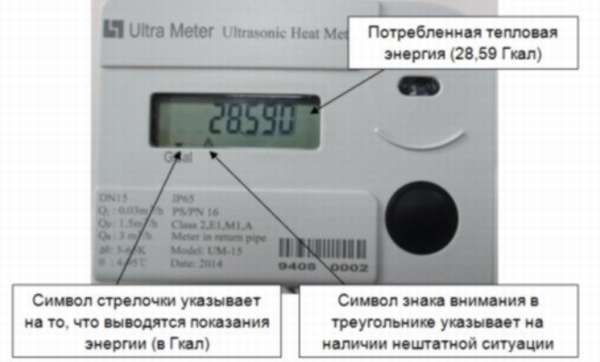

Apartment heat energy meter how to correctly remove and transmit readings

Readings from apartment heat meters should be taken by analogy with water meters. The only difference is that heat meters display several indicators on the indicator and in order to choose the one you need, you should carefully read the operating instructions and strictly follow the manufacturer's recommendations. After receiving the necessary information, the difference in readings for the previous and reporting periods should be entered into the receipt for payment for heat energy, multiplied by the tariff set in the region, and the amount received should be paid.

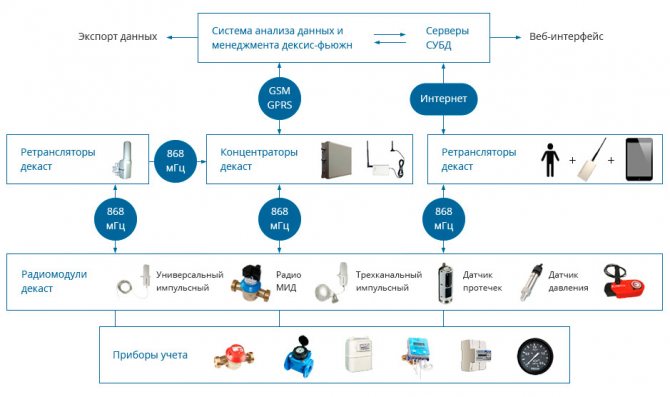

At present, modern heat metering devices are equipped with a built-in interface that allows you to read data in automatic mode.For example, the domestically produced "Kombik-T" counter has a built-in radio antenna, which allows taking readings from the device even without entering the apartment. It should be noted that a water meter (water meter) with a pulse output can be connected to such a device, which will allow taking readings of water consumption (hot and cold) also without visual contact.

The installation of such metering devices will be a good solution for people who often go on business trips or trips and cannot personally meet the controller who comes to take readings. Please note that an individual heat meter can only be installed in apartments with horizontal piping and separate heat carrier inputs. In houses where heating systems with vertical wiring are equipped, individual meters are not installed

From the information provided in this article, we can conclude that the procedure for taking and transferring readings from heat meters should be treated with a sufficient measure of responsibility.

Currently, in almost all Russian regions, charges for utilities occur according to the same scenario: the tenant transmits readings from his metering devices to the management company, and the Criminal Code takes readings from general household meters and calculates the difference in readings between them and individual metering devices.

If this difference is not more than the standards for common areas (staircases, corridors, basements, etc.), it is proportionally divided among all tenants. Otherwise, the management company pays the difference from its income. If the tenant has not submitted the readings from his metering devices to the Criminal Code in a timely manner, or his devices have expired the calibration interval, then the first two months the management company charges payment for the resources consumed, taking into account the average consumption for the previous period. In the future, the CM charges the payment based on the standards for a particular region.

Typically, the standards are significantly higher than the actual need for resources. For example, in central Russia in modern energy-efficient houses, the real heat consumption in 2-2.5 times less than the standard

... Accordingly, the timely transfer of testimony is primarily in the interests of the tenant himself.

The process of taking readings from a heat meter is described in. In this article, we will tell you a little more about how to take readings from the SANEXT heating meter.

Taking readings of an individual heat meter

Before taking readings from the meter, you should carefully read the technical documentation, which contains information on the functional features and rules for servicing the equipment.

As a rule, meters provide the ability to visually read data using the LCD display.

The resulting power consumption values and temperature data are not used for billing with the service provider, but for monitoring consumption.

Different models provide several user levels, the transition between which is done by pressing a button. Several data are displayed on the meter display at once, so you should be careful not to make a mistake in which readings of the heat meter to supply.

There are also more modern heat metering devices combined with an automation tool. With their help, you can automatically or remotely read the necessary information.

Storing readings in the archive

According to clause 37 of the Decree of the Government of the Russian Federation of November 18, 2013 No. 1034 "On commercial metering of heat energy, coolant", the heat metering unit is equipped with varieties of metering devices that are included in the Federal Information Fund for Ensuring the Uniformity of Measurements, have an indelible archive of the main technical characteristics and adjustment coefficients.

Information can be displayed on the counter or on a computer.

In accordance with this normative act (clause 34), all metering devices are equipped with standard protocols, interfaces for remote data collection, and can be equipped with an hourly, daily, monthly and annual module for archiving readings:

- heat consumption and total operating time;

- uptime and downtime;

- temperature in the heat pipe.

Remote transmission of readings

Heat meter readings in the apartment can be transmitted via the Internet. This possibility is fixed by the provisions of the aforementioned Resolution No. 1034. For this, metering devices must have the function of using telemetry systems and the corresponding software.

If there is reason to doubt the reliability of the readings and the correct operation of the heat meter, the consumer or the heat supply organization has the right to organize an inspection. If disagreements arise, it is quite possible to initiate an extraordinary verification of the meter.

Stage 6. Re-commissioning of UUTE into commercial operation.

Before each heating period and after the next verification or repair of the UUTE, the readiness of the UUTE for operation is checked - the re-entry of the UUTE into commercial operation. Based on the results of this inspection, an act of periodic inspection of the UUTE is drawn up.

The re-commissioning of the UUTE is carried out by a commission created by the owner of the UUTE. The composition of the commission is similar to the composition of the commission created during the initial commissioning of the UUTE.

A call from a representative of Branch No. 11 "Gorenergosbyt" of PJSC MOEK to draw up an act of periodic inspection of UUTE is carried out at the written request of the client (owner of UUTE) addressed to the Director (or deputy director - head of the sales department) of Branch No. 11 "Gorenergosbyt" of PJSC "MOEK", provided in:

The application is submitted by the client at least 10 working days prior to the day of the proposed check of the UUTE. When re-putting the UTE into operation, the commission checks:

- Compliance of the installation of UUTE components with the design documentation agreed with PJSC MOEK;

- Availability of passports, certificates of verification of measuring instruments, factory seals and stamps;

- Compliance of the characteristics of measuring instruments with the characteristics specified in the UUTE passport data;

- Correspondence of the measurement ranges of parameters allowed by the temperature schedule and the hydraulic mode of operation of heating networks, the values of these parameters, determined by the contract and the conditions for connecting to the heat supply system.

In the absence of comments, the commission signs an act of periodic inspection of the UUTE installed by the client. When the act is signed, the UUTE is sealed in accordance with the design documentation for the UUTE, while the number of seals and their placement should exclude unauthorized interference with the operation of the UUTE.

If the members of the commission have comments on the UUTE and identify shortcomings that impede the normal functioning of the UUTE, this UUTE is considered unsuitable for commercial metering of heat energy, coolant. In this case, the commission draws up an act on the identified deficiencies, which provides a complete list of the identified deficiencies and the time frame for their elimination. This act is drawn up and signed by all members of the commission within 3 (three) working days. Re-acceptance of UUTE is carried out after the complete elimination of the detected deficiencies.

Application for periodic verification of ODU

Apartment heat energy meter how to correctly remove and transmit readings

Readings from apartment heat meters should be taken by analogy with water meters. The only difference is that heat meters display several indicators on the indicator and in order to choose the one you need, you should carefully read the operating instructions and strictly follow the manufacturer's recommendations.After receiving the necessary information, the difference in readings for the previous and reporting periods should be entered into the receipt for payment for heat energy, multiplied by the tariff set in the region, and the amount received should be paid.

At present, modern heat metering devices are equipped with a built-in interface that allows you to read data in automatic mode. For example, the domestically produced "Kombik-T" counter has a built-in radio antenna, which allows taking readings from the device even without entering the apartment. It should be noted that a water meter (water meter) with a pulse output can be connected to such a device, which will allow taking readings of water consumption (hot and cold) also without visual contact. The installation of such metering devices will be a good solution for people who often go on business trips or trips and cannot personally meet the controller who comes to take readings.

From the information provided in this article, we can conclude that the procedure for taking and transferring readings from heat meters should be treated with a sufficient measure of responsibility.

Today I will tell you about how to convert Gcal to kWh and vice versa. The length, width, thickness of the object can be measured with a tape measure. The weight of an item can be determined by weighing it. But the amount of heat energy cannot be measured either with a tape measure, or with the help of scales or some other simple measuring instruments. Heat energy can only be calculated mathematically. Like any quantity, thermal energy has its own units of measurement.

Meters, centimeters, millimeters, decimeters, kilometers, nanometers and so on are units of measure for length. As you may have guessed, kilograms, grams, tons and so on are units of weight.

But Gcal, kW * h, J are units of measurement of thermal energy. Moreover, just as meters can be turned into millimeters, and kilograms into grams, so Gigacalories can be easily recalculated by turning them into kW * h and J. When you install your heat meter, you will have to learn how to recalculate Gcal in kW * h and back.

You need to be able to do this in order to transfer the readings of this meter to your UK (managing company). The fact is that some meters give readings only in Gcal, and some only in kW * h. Management companies accept meter readings only in some one unit. So we have to recount every month. Recalculation is not tricky.

Let's say you want to convert 1 Gcal (one giga calorie) into kWh, then you need to remember that one kWh is equal to 0.000860 Gcal

... We make up the simplest proportion:

1kW * h = 0.000860 Gcal

We remember mathematics at school, and we calculate what is equal to X to W * h in this proportion: X = 1 kW * h x 1 Gcal / 0.000860 Gcal = 1162.8 kW * h

Or vice versa, you need to convert 1 kW * h (one kilowatt hour) to Gcal. Again we make up the proportion, remembering that one kWh is equal to 0.000860 Gcal

.

1kW * h = 0.000860 Gcal

Again, we do calculations based on the usual proportion: X = 1kW * h x 0.000860 Gcal / 1kW * h = 0.000860 Gcal

Here, in fact, we figured out the translation of Gcal in kW * h. Everything is easy and very simple. Especially when you make these simple calculations every month, after taking readings from a heat meter. We'll explain how to shoot them in the next chapter.

By the way, I deliberately did not give any coefficients for converting Gcal to J and kWh to J. Simply because usually such a unit as J (joules) is now practically not used. It's like decimeters in length. Decimeters seem to be as it is, you can and should know about them, and nothing more. The same epic with the Joules.

Another subtlety that you need to know about is the Kilo, Mega and Giga prefixes.

For example, kWh (kilowatt per hour), or MWh (megawatt per hour). Kilo means the number 1000, Mega - 1,000,000, but Giga - 1,000,000,000.

1 kW * h = 1000 W * h.

1 MW * h = 1,000,000 W * h = 1,000 kW * h.

1 Gcal = 1,000,000,000 Cal = 1,000 Mcal = 1,000,000 kcal.

Household heat meter: how to take readings?

Heat meters can measure this very heat in different units (for example, megawatts, giga calories or kilojoules).Most often, heat is measured in gigacalories, since it is in these units of measurement that the price for heating is calculated and set by the heat supplying organization.

A good solution would be to create a separate log where the readings of the heat meter will be regularly recorded (see example below). It is optimal to record information on the last day of each month, when it is already known exactly how much heat was consumed per month. Keeping such a log will help control and verify the data of the management company, on the basis of which consumers are billed for heat.

At the moment, according to the new rules for accounting for commercial heat, the keeping of the accounting log was canceled. This is due to the fact that modern metering devices can read information from the meter directly, or through a computer or flash drive.

Among the new type of heat meters, there are quite compact models made of special grade steel. The functioning of such devices is ensured by accumulators, the service life of which is 10 years. At the top of the meter there is a screen on which data is displayed regarding energy consumption, as well as the main parameters of a specific heat supply system, such as: flow rates (current and instantaneous), information about temperatures, information about the state of the heat meter (taking into account error codes), and See also archive information for several previous months.

It is important to keep in mind that if an old metering device is installed in an apartment building, then at the next calibration it will necessarily need to be replaced with a new one, but for now, you should continue to keep a record log. To fill it out correctly, you need to familiarize yourself with the meter operation manual (maintenance section), which must be attached to each heat energy meter.

Heat meter readings: reading and transmission

Specific readings are displayed on the indicator by pressing the button / buttons on the front panel of the device. For the correct presentation of information, you will need to remove the following information:

- Heat energy Q (Gcal, GСal, GJ, MWh);

- Mass of the coolant in the supply pipeline M1 (t);

- Mass of the coolant in the return pipeline M2 (t);

- Temperature in the supply pipeline T1 (° С);

- Return line temperature Т2 (° С);

- Timer (h).

An example of filling out the log of readings of a heat meter

| date | Heat quantity, Q, Gcal | Heating agent temperature on the supply pipe-line Т1, ° С | Heat carrier temperature on the return pipe-line Т2, ° С | Heat carrier mass along the supply pipe-wire М1, t | Heat carrier mass along the return pipe-wire M2, t | Timer, h |

| 1 | 3 | 4 | 5 | 6 | 7 | 8 |

| 01.02.17 | 7423.41 | 85,5 | 44,4 | 2521 | 2435 | 1785 |

| 02.02.17 | 7445.87 | 84,1 | 43,2 | 2631 | 2545 | 1809 |

| 03.02.17 | 7456.85 | 80,6 | 42,3 | 2738 | 2659 | 1833 |

| … | … | … | … | … | … | … |

As a rule, meters can also display information on the volume of the coolant (V, cubic meters), both in the supply and return pipelines, however, during the filling of the log, one should indicate that parameter (mass or volume of the coolant), which is determined by the act acceptance into operation of a specific metering device. Heat meter readings are taken every day (exceptions - weekends and holidays), at a certain time, and with entry into the corresponding columns of the heat consumption log. Based on this information, a protocol / statement is drawn up for subsequent transfer to the heat supply company within a specified time. This should be done until a specific date that each heat supplier sets for consumers on their own.

Tips for operating a heat meter

Quite often, there are cases when persons authorized by consumers to control and take readings from the meter for heating make mistakes. In order to ensure the uninterrupted operation of the heat meter and correctly take readings from it, the following rules should be observed:

- It is impossible to entrust the taking of readings from the heat meter to unprepared persons;

- The data collection must be carried out in a timely manner, and then the readings of the heat meter must be transmitted in due time;

- If any malfunctions are noticed in the operation of the heat meter, then this should be immediately reported to the appropriate authorities (heat supply and service organizations).

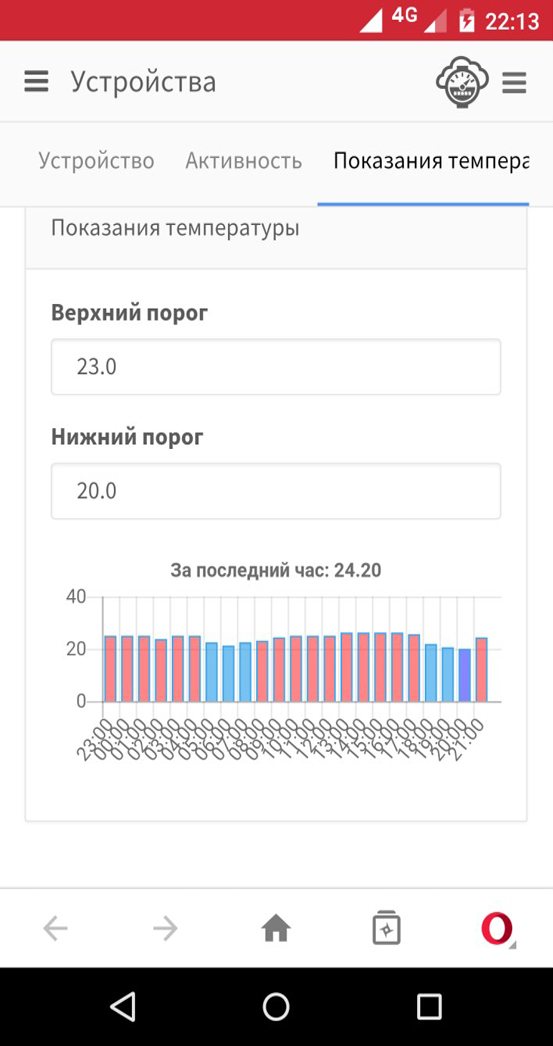

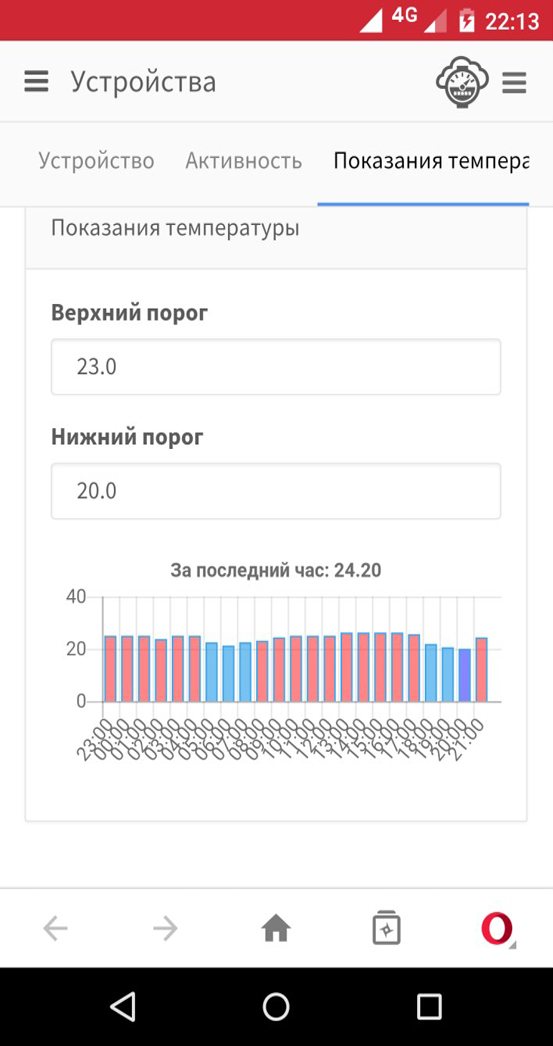

If you need more temperature, humidity, voltage, current and more

Starting with resource accounting, we went further - we organized an opportunity through the KUB-Infra service to monitor temperature and humidity, voltage and current, as well as remotely control something at objects, for example, by one click to de-energize all sockets.

It is especially pleasant that all these functions can be organized using the same KUB-Infra controller. The device provides all the corresponding sensor I / O. Therefore, if, in addition to accounting for resources, you need to organize something else, it is enough to purchase an appropriate sensor (temperature, humidity, current sensor, voltage control unit, etc.), and connect it to KUB-Infra. You will keep track of the parameters in the same place - in your personal account on the KUB-Infra service. At the same time, if the parameter goes beyond the normal range, the system will notify you about it by e-mail or via a messenger.

When using apartment heat meters, heating costs can be significantly reduced. All this happens not only due to more accurate accounting of the consumed heat, but also due to the fact that the consumer is interested in more economical consumption of thermal energy. He begins to regulate the flow rate of the coolant through his heater in the apartment, as well as to insulate walls, windows, etc.

Sometimes the benefits are obvious and the heat meter pays for itself in a matter of months, but the opposite often happens, when the consumed amount of energy comes out of the meter more than according to standard indicators. We will talk about how to choose the right counter and the need to install it in this article.

What should you pay attention to and whether it is worth installing a counter. What must be taken into account when deciding to install a meter Registration of a heat meter How to take readings correctly? You decided to install a meter, what should you be guided by when choosing an installation organization

Data reading methods

If you have a visual reading device installed, you can only take readings directly from the information board. The consumer can record the data himself, and then transfer it to the management company or service provider organization. In addition, employees of the management company or the heat supply service can take readings. The consumer is obliged to provide them with access to the heat meter located in the apartment.

Remote reading of data is also possible. To do this, the device must be equipped with one of the following modules:

- pulse output. It is equipped with a sealed contact, the closure of which leads to the formation of an electrical impulse. This impulse is recorded by a reading device, which transmits information to an automated control center;

- radio output - information is transmitted over a radio channel, independent of cellular communications;

- digital output. The RS-485 interface is used. Data is transmitted over a wired communication line.

Remote reading is relevant if access to the heat meter is difficult or if a common house metering system is organized in an apartment building. Equipping the devices with these modules allows not only to remotely read information, but also to store it in a non-volatile archive for further viewing, output to paper media, and entry into reporting documentation.

Restrictions on installing a heat meter in an apartment

In such a situation, there is only one solution - to put meters on heating batteries, but such a solution is difficult to implement for the following reasons:

- the installation of several heating devices in one apartment will cost its owners a tidy sum, since each meter for a heating battery costs a lot of money;

- taking readings from each device is hampered by the fact that utility workers are not able to monthly walk all the rooms around the apartments of the house in order to record the data. When doing this work yourself, you can get confused in numbers and make mistakes in calculations;

- maintenance problems - several instruments are much more difficult to monitor and verify that they are functioning correctly;

- the counter for the heating radiator has poor accuracy, since the difference at its inlet and outlet is so small that the device is often unable to fix it.

A heat meter - a device for accounting for the consumed heat carrier, is currently very profitable, since it allows you to save money by paying only for the consumed heat, excluding overpayment.

An important point is the correct choice of the type of device, depending on the installation location and design features of the heating network, as well as the conclusion of an agreement with a service organization that will monitor the technical condition of the device.

There are many models of heat meters, differing in design and size, but the principle of how a heating meter works has remained the same as on the simplest device that measures the temperature and flow rate of water at the inlet and outlet of the pipeline of a heat supply facility. Differences appear only in engineering approaches to solving this issue.

The operation of the heat meter is based on the principle of calculating the amount of heat using data taken from a coolant flow sensor and a pair of temperature sensors. The amount of water passed through the heating system is measured, as well as the temperature difference at the inlet and outlet.

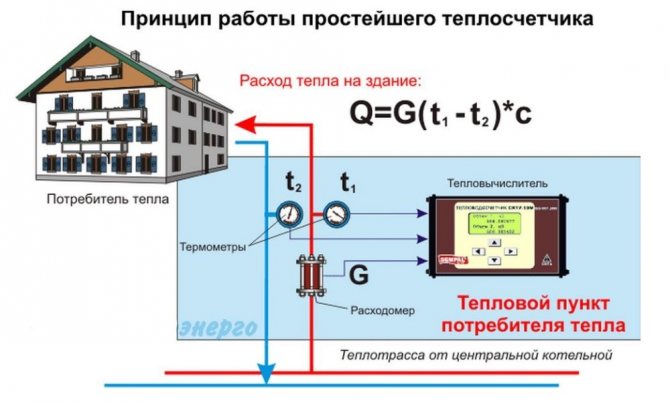

The amount of heat is calculated by the product of the flow rate of water that has passed through the heating system and the temperature difference between the incoming and outgoing heat carrier, which is expressed by the formula

Q = G * (t 1 -t 2)

, gcal / h, in which:

- G

- mass flow rate of water, t / h; - T 1, 2

- temperature indicators of water at the inlet and outlet from the system, o C.

All data from the sensors are sent to the calculator, which, after processing them, determines the value of heat consumption and writes the result to the archive. The value of the consumed heat is shown on the display of the device and can be read at any time.

What affects the accuracy of the heat meter

Techem compact V

A heat meter, like any precise device, when measuring the consumed heat, has a certain total error, which is the sum of their errors of temperature sensors, a flow meter and a calculator. In apartment accounting, devices are used that have a permissible error of 6-10%. The real indicator of the error may exceed the baseline, depending on the technical characteristics of the component parts.

The increase in the indicator is caused by the following factors:

- The amplitude of the entering and leaving temperature of the coolant, which less than 30 o C

. - Violations during installation in relation to the manufacturer's requirements (when installed by an unlicensed organization, the manufacturer removes his warranty obligations).

- Inadequate pipe quality, hard water used in the coolant, and the presence of mechanical impurities in it.

- When the flow rate of the heating medium is below the minimum value indicated in the technical characteristics of the device.

How is the consumed heat measured?

It is customary to calculate the rate of consumed heat in giga calories. The unit of measurement refers to non-systemic, and has traditionally been used since the existence of the USSR. Appliances made in Europe calculate consumed heat in GigaJoules (SI), or the internationally accepted non-SI unit kWh (kWh)

.

How does a heat meter work

Regardless of the type, any such device is equipped with the following devices: energy meter;

- temperature transducer of material resistance;

- primary transducer of heat consumption.

Also, the device can be equipped with optional elements if there is such a need or so desired by the customer. These can be power supplies for individual elements of the heat meter; overpressure transducer.

Heat meter elements

In addition to its main function - control of heating energy consumption, such equipment can be used for the following purposes:

- measuring the operating time of any of the devices, which is installed within the metering area;

- measurement of average temperatures of the coolant over the past hour or day;

- measurement of the energy used for the last hour and in general since the installation of the device;

- the difference between the amounts of coolant at the inlet or outlet from the heating system;

- calculation of the amount of coolant that is required for the normal operation of the heating system.

Heat meter with sensors

As mentioned above, the main purpose of heat meters is to calculate and display the exact amount of heat energy that was used by the consumer to heat the dwelling. The device does not fail, and therefore displays only real figures of energy consumption. A special calculator, which is equipped with each unit of such equipment, gives out the total amount of all thermal energy that was consumed by the consumer in one hour. In this case, the temperature differences in the coolant are displayed, as well as its quantities at the beginning and at the end of the heating system cycle.

Heat meters are equipped with temperature sensors and flow sensors, which are responsible for displaying information. One of these devices is installed in the supply water main, and the other in the return pipe. Sensors take readings, then special computing equipment processes them, after which comprehensive information about the consumption of thermal energy appears on the device screen. The equipment is quite accurate, its error is in the range from 3 to 6%.

Back to content

Breakdowns and repairs

Maintenance of the device is limited to maintaining it in good working order, regular inspection, avoiding causes that cause premature wear and tear. According to clause 80 of the Rules for commercial metering of the coolant, all work on maintenance and control of the correct operation of the meter is carried out by the consumer. On the part of the owner, he does not need special care.

The lithium battery or batteries that power the device are not recyclable and are disposed of if they fail.

If any malfunction is detected in the metering device, the consumer must notify the service company and the heat supply organization within 24 hours. Together with the arrived authorized employee, an act is drawn up, which is then transferred to the heat supply organization with a report on heat consumption for the corresponding period. If the failure is not notified in time, the heat consumption is calculated in a standard way.

The service company will provide services for the repair or replacement of the meter, and during the repair can install a replacement device. The cost of installation and dismantling, repair and other services is regulated by the contract between the consumer and the service company.

Error logging

As a standard, heat meters are equipped with a self-test system that can detect inaccuracies in operation. The calculator periodically queries the sensors, and in case of their malfunction, it fixes the error, assigns a code to it and writes it to the archive. The most common logged errors are:

- Improper installation or damage to temperature sensor or flow meter.

- Insufficient battery charge.

- The presence of air in the flow path.

- No flow if there is a temperature difference for more than 1 hour.

Removal and installation of the heating meter

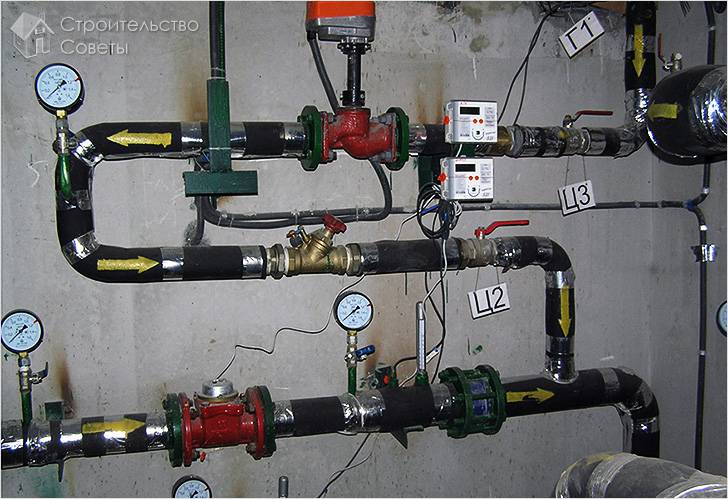

Before installing a meter for heating in an apartment or an apartment building, specialists from specialized companies that have permits for this type of work are invited. Based on the specific situation, they can make the following commitments:

- Develop a project.

- Submit documents to certain authorities in order to obtain permits.

- Install and register the device. In the absence of registration, payment for the supplied heat is made in accordance with the established tariffs.

- Carry out test tests and put the device into operation.

The developed project should include the following points:

- The type and device of the model, which is designed to work in a specific heating system.

- Necessary calculations for heat load and coolant flow rate.

- Heating system diagram with the place of installation of the heat meter.

- Calculation of possible heat losses.

- Calculation of payment for the supply of heat energy.

Checking the flow meter

Bypass surgery Necessary for all electronic flow meters to protect against electromagnetic interference.

With absence complete filling of the measuring section with liquid, manufacturers do not guarantee the correct operation of the flow meters.

Protruding edges of gaskets strongly affect the operation of vortex flowmeters. In particular, you need to pay attention to this point if the gaskets are homemade, square, their corners are visible from the outside of the pipe. There is a possibility that the inner hole is cut in the form of a square, because it is faster and easier to make than a round one. Typically, flow converters are supplied with sets of "native" gaskets - but they also need to be installed carefully, without offset from the center of the pipe.

Deposits on the walls flow path is especially undesirable for electromagnetic flowmeters.

Garbage in the flow path (scale, sand, gravel, rags, gloves, hats, etc.) does not add accuracy to any instruments, but most of all overestimates the readings of turbine and vane water meters. Before them, it is necessary to install filters, which must be carefully cleaned so as not to damage the mesh 2 times a year.

Clogging of flow meters takes the leading place in the list of problems with heat meters.

For all appliancesincluded in the heat meter, it is relevant to check for mechanical damage and failure due to wetting / high humidity.