In any apartment building, even during construction, a ventilation system is designed. It is designed for comfortable living of all residents of a multi-storey building. Well-designed ventilation ensures the flow of fresh air into each apartment, while removing waste, carbon-dioxide-rich air, as well as unpleasant odors and dust particles.

During the operation of the ventilation system, the draft may change, and air from neighbors may enter the room. To prevent this from happening, you need to install a check valve, which closes automatically when the direction of the air flow changes.

The do-it-yourself valve technique is not complicated. It is also not difficult to find the necessary materials and tools for work. Following step-by-step instructions and expert advice, all work on the device and installation of the valve can be done independently.

The need to install a check valve

Ventilation check valve for natural look ventilation allows air to pass in one direction. In the event of a change in direction, the sash closes, which is an obstacle to the entry of air masses into the room. A similar phenomenon most often occurs in multi-storey buildings, where a complex ventilation system, in which several air ducts are connected to a common shaft. Therefore, a change in air pressure in any shaft can lead to backdraft.

It is necessary to make a ventilation check valve in the following cases:

- The supply ventilation is not working well (clogged or broken), so air masses will come from the exhaust shaft.

- The exhaust pipe is not installed correctly, therefore, it is possible for air to enter from the outside. This phenomenon is especially manifested if the house is located in the wind zone.

- If a high-power fan is running in one of the apartments of a multi-storey building, then air movement in other apartments may be disrupted.

- A stove in a private house contributes to the reverse air movement, by increasing the combustion draft.

- The simultaneous operation of several fans in an apartment can lead to increased traction in one of the ventilation channels, which can also disrupt the outflow of air masses.

In these cases, a properly assembled check valve for ventilation will be able to prevent the flow of air.

Safety check valve for a compressor: types, design, do-it-yourself manufacturing

In order to ensure the correct operation of compressor units, which are used almost everywhere today, a number of additional technical devices are used, one of which is a check valve for the compressor. Such a valve, which is equipped with the majority of compressor units today, also protects them from premature failure and ensures smooth start-up.

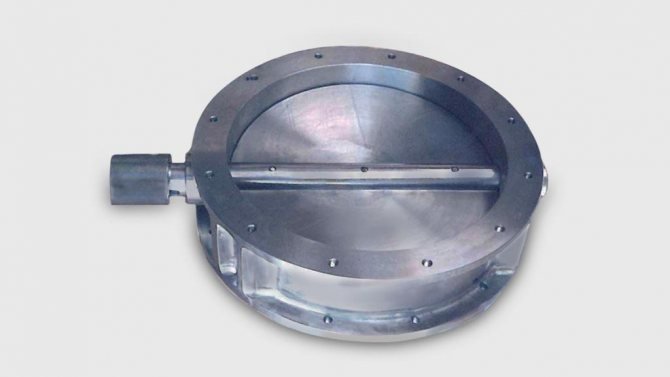

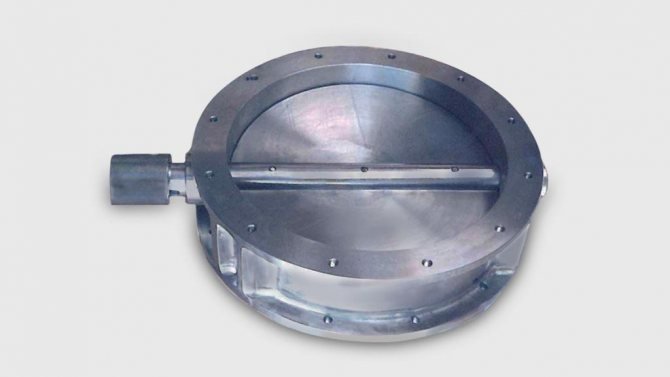

Compressor check valve

Purpose, design features and scope

The check valve, installed at the outlet of the compressor head, allows compressed air to pass only in one direction - to the receiver or any other tank. Thus, this valve prevents the return of compressed air in the receiver or other elements of the pneumatic system back to the compressor.The greatest risk of compressed air returning from the pneumatic system to the inside of the compressor during the break in the operation of the device (if the compressor discharge valves do not fit tightly to the seats), as well as at the time of its start-up.

The design of a typical compressor valve consists of the following elements:

- metal case;

- an inlet, which is closed by a valve (to prevent the latter from skewing during its operation, guiding ribs are specially made on it);

- rubber ring;

- a spring that slides over the valve guides;

- bung;

- sealing gaskets.

Compressor check valve device

In the body of the check valve, in addition to the hole with which it is connected to the compressor by means of a union, there is one more thing: the compressor unloading valve is connected to it. The purpose of such a relief valve on the compressor is to prevent overpressure in the working chamber.

The principle of operation of compressor check valves is as follows.

- The compressed air generated by the compressor enters the valve inlet.

- Under the influence of compressed air pressure, the spring is compressed, opening the valve and letting air into the pneumatic system.

- After the compressor is turned off and the air pressure in the working chamber has dropped, the spring expands and closes the air line.

Air Check Valve Working Principle

If the air pressure in the working chamber at the moment when the compressor is turned off exceeds the allowable value, the safety valve, also installed at the outlet of the device, is triggered. The compressor unloader or relief valve design uses a ball-type locking element that is pressed against the edges of the inlet by a special spring. If the force created on such a ball by compressed air exceeds that to which the spring is adjusted, the valve opens, due to which the pressure is normalized.

Safety valves in pneumatic systems can also be installed on tanks, in particular on receivers. In this case, the purpose of such valves is to prevent a decrease in the pressure of the compressed air pumped into the reservoir.

Brass Check Valves for Compressor Units

Devices operating on the principle of a check valve, that is, cutting off the flow of the working medium when it moves in the wrong direction, are used in various fields. In particular, they are used for installation in:

- systems designed for the suction of liquid media;

- pipelines through which hot gases are transported;

- piping systems used in refrigeration plants;

- air conditioning and ventilation systems;

- sewer systems.

The check valves used in fluid handling systems are designed to prevent these media from entering the compressor, which can become unusable from this. When transporting hot gases, these devices are also used in order to prevent gases from entering the rest of the system.

Check valve (siphon) for the air conditioner. Designed to connect the drainage pipeline to the central sewerage

Check valves, which are installed in air conditioning systems, simultaneously solve two important tasks:

- provide a targeted passage of the refrigerant from the warm part of the evaporator to the cold part;

- prevent the formation of reverse condensation.

Such devices are very actively used in ventilation, where they also solve several problems:

- improvement of draft in the ventilation system if it consists of several branched sections;

- preventing cold air from entering the premises;

- protection of rooms served by the ventilation system from extraneous odors;

- protection of industrial premises from toxic and explosive environments entering their atmosphere;

- preventing the ingress of combustion products into the room, if a fire has occurred in the building in which such a room is located.

The non-return valve for ventilation is a blade fixed on the axis

A reverse-acting air damper used in ventilation systems is installed not only in industrial and office buildings, shopping centers and other public buildings, but also in apartment buildings. It protects apartments from extraneous odors by cutting off the air flow from outside.

Main varieties

Check valve systems, depending on their design, can be:

- direct type;

- angular;

- spring;

- ball;

- installed with flanges;

- folding;

- soldered;

- made for dismantling.

Straight type check valve for high pressure stations

The material of manufacture can also vary, which depends on what media such a device will come into contact with during operation. In particular, it can be both metal alloys of various types and plastic.

Depending on the type of shut-off element used, check valves can be:

- with a locking element made in the form of a flat valve;

- ball;

- membrane;

- petal;

- with gravity grid.

Devices of the last three types are used for installation in ventilation systems. Among the check valves and safety valves installed on compressors, the most popular devices are ball-type devices, since they are less critical of the contaminants present in the working environment.

Check valves with conical (a), flat (b) and spherical (c) shut-off elements

Among the most modern valve systems, it should be noted devices of the electromagnetic type, in which the movement of the valve is controlled not by a spring, but by an electromagnet. Meanwhile, due to the rather high cost and not too high reliability, such devices are not very popular, yielding to cheaper and time-tested spring counterparts.

Selection recommendations

When choosing a check valve, there are a number of parameters to consider. These include, in particular:

- the intensity of the air flow that will be transported through the system;

- the performance of the air exchange device on which the check valve will be installed;

- the power of the air pumping device, which can be a compressor or a fan;

- the degree of contamination of the working environment, which will be transported through the elements of the system being created;

- temperature mode of operation.

In addition, it is imperative to take into account the type of medium with which the elements of the valve device will come into contact. This parameter has a direct impact on the choice of valve material, which must have the required durability.

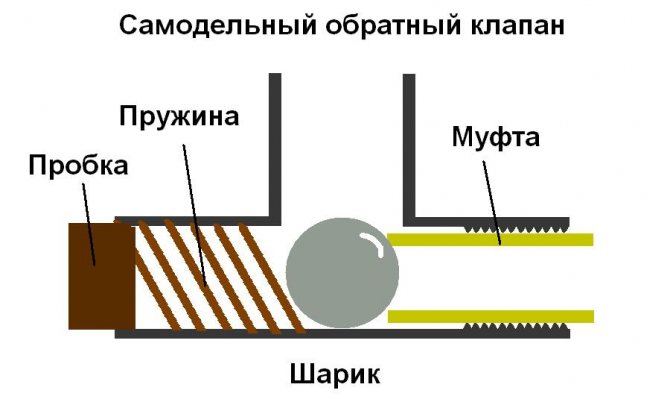

How to make a check valve for a compressor with your own hands

There is a wide variety of check valves on the market today for compressors of various types and capacities. Meanwhile, if you want to save money, you can make a valve for the compressor yourself. In order to make such a valve, it is not necessary to know the structure of an air compressor, it is enough to understand how such a compressor works. Moreover, you do not need expensive consumables and complex equipment, as well as special knowledge, skills and experience in performing such work.

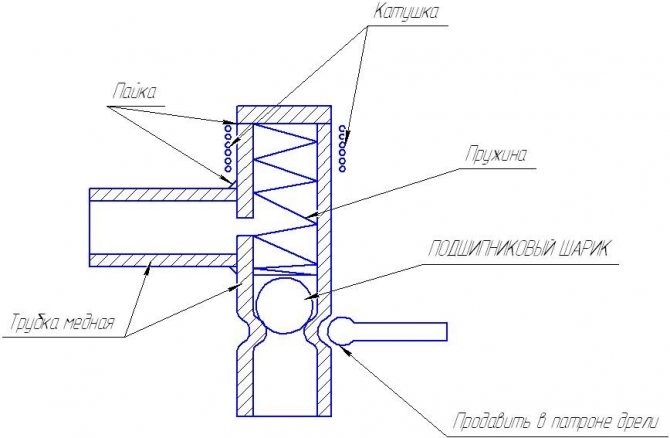

To make an air check valve for a receiver, compressor, vacuum chamber or any other element of the pneumatic system, you will need the following materials and tools:

- regular fitting or squeegee with thread 15;

- fittings, which are equipped with hoses for connecting plumbing devices;

- a bolt with a diameter of 3 mm and a length of 40-50 mm;

- two nuts of the corresponding diameter;

- a piece of rubber cut from an old car tube;

- spring, the diameter of which corresponds to the transverse dimension of the bolt;

- standard set of locksmith tools.

The valve connection can be taken from an old plumbing or gas hose

A do-it-yourself check valve for the compressor is made according to the following algorithm.

- A rectangular plate is cut out of a metal sheet of small thickness, which will act as a stop for the bolt used to fix the valve. In the middle part of such a plate, a hole is drilled into which the bolt should freely pass.

- A seat is cut out on the end part of the fitting-squeegee, on which the fixing plate will rest.

- A valve of the appropriate diameter is cut from a piece of the car chamber, in the middle of which a bolt hole is made.

- A metal retainer plate, a spring are put on the bolt, and then a nut is screwed onto its threaded part, a rubber valve is put on, which is fixed with a second nut through a washer.

- The assembled structure is inserted into the fitting-squeegee and fixed on both sides with nuts removed from the plumbing hose.

The pressure at which such a check valve will operate is controlled by the spring rate. Of course, the device made according to the above scheme has a simple design, but it works quite efficiently and can be used to equip compressors and vacuum chambers.

met-all.org

Checking the ventilation

To check the performance of the ventilation system, you need to open the window in any room in order to create an air flow. Then bring a lighted candle or lighter to the ventilation hole. If the flame tilts towards the duct, it means that the ventilation system is working properly. Otherwise, you will have to clean the system or produce a ventilation check valve device.

This method is fire hazardous, therefore, representatives of the fire and gas services prohibit the use of an open flame for testing, especially in houses with a main gas pipeline.

There is a safe method for checking traction. Having opened the window, it is necessary to bring a sheet of thin toilet or tissue paper to the ventilation. If the paper sticks to the grate, the draft is good.

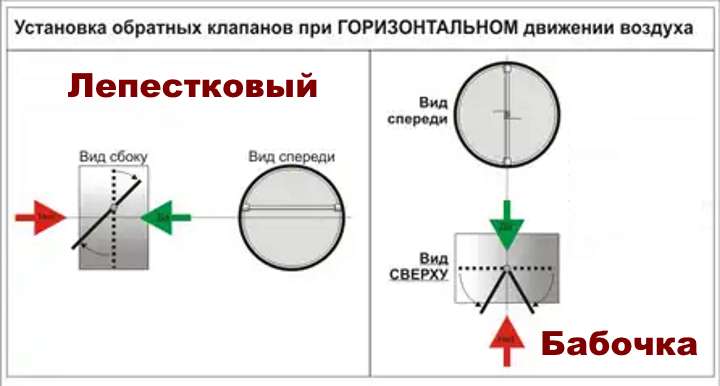

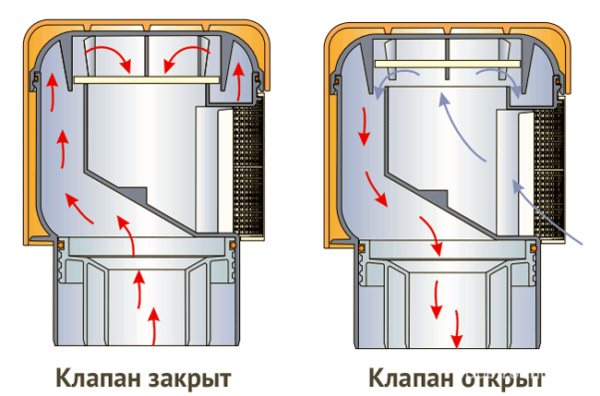

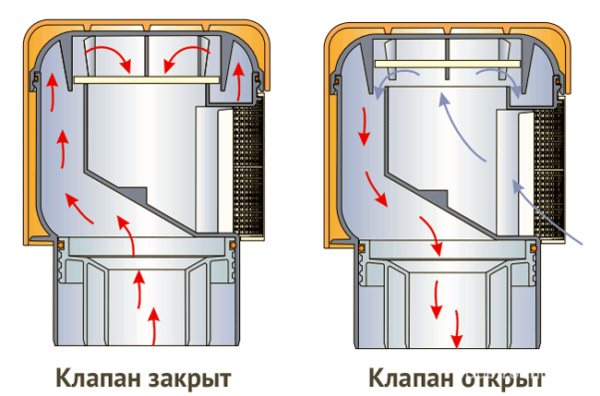

Petal valve

This kind of ventilation check valve for natural ventilation is popular due to its compact size. A petal valve is made in the form of a damper located on the axis. In the presence of a direct air flow, the damper opens, and when the air masses move in the opposite direction, the flaps of the check valve close for natural ventilation.

The axis of the petal valve can be located both in the horizontal plane and in the vertical one. The normal position of the petal is closed.

Air valve device

Most often, this part of the sewage system is made of polyethylene of different brands, for this reason it is inexpensive and easy to install. Most often, its component parts are:

- Housing.

- Side opening for installation to the sewer system.

- A stem that reacts to the appearance of overpressure in the system.

- Rubber gaskets that help the stem run smoothly, thereby limiting its movement.

- A cover that protects from outside contamination.

There are automatic valves, they are mainly installed in private homes to remove air and odor from individual plumbing fixtures. They have a small bandwidth and, accordingly, you should not count on significant bandwidth.

Anti-vacuum are used to ventilate a large number of pipes in the sewer. They can work on both the outlet and the inlet. There are also combined ones that combine the advantages of the two types.

For installation, it is necessary to choose an installation location, cut a pipe section of such a size from the system to fit the device, and mount it in accordance with the instructions.

A check valve for the sewer system is important; it is recommended to install it in apartment buildings for residents of the first and second floors. Such a valve is able to prevent damage to property in the event of an emergency in the sewer system. And in order to provide it with the necessary ventilation, it is advisable to use a ventilation valve.

Any check valve for sewerage, vertical or horizontal, blocks the flow of water in the opposite direction. The check valve for the pressure sewage system has inlet and outlet pipes of various diameters with a chamber between them. Due to the difference in the cross-sectional area, different pressures are created in the nozzles, and the ball in the chamber freely passes water.

Ball Type Sewer Check Valve

In other models, the shut-off "plate" in the presence of pressure rises and passes wastewater, and then immediately takes a vertical position, thereby preventing the possible passage of wastewater in the opposite direction.

The photo shows the principle of the check valve

These devices have a bolted cover and a seal. It is quite easy to open it if necessary to clean the device. Often, a check valve in the sewer system is fitted with a shut-off valve.

A plate instead of a ball as a shut-off device can be used in models of large diameter, such as, for example, a 110 mm drain check valve, although this condition is not mandatory.

Diaphragm valve

The diaphragm valve works on the flap principle, but the flap is very thin and very sensitive to small air flow. This type of check valve is most often used in rooms with natural ventilation.

A rather thin membrane passes even a very small flow of air masses in the forward direction, while it fits very tightly to the plane of the hole, closing it at the slightest change in the direction of the flow. The most common ventilation check valve size is 100 mm.

Selection tips and approximate price

It is necessary to choose shut-off valves for water depending on the parameters of the hydraulic system itself, the contamination of the transmitted medium, installation dimensions and the method of fastening. For heating systems assembled from rolled metal pipes, the rotary check valve model is more suitable. They are less sensitive to the contamination of water flowing through steel pipes that rust over time. Modern metal-plastic pipes are not susceptible to contamination, so a disc device with a coupling mount can be connected to them.

The material from which the device is made is also of great importance. Polypropylene structures cannot be installed on hot water pipelines, as they exhibit poor resistance to high temperatures. A model made of durable metal would be a suitable option here. Plastic products are more suitable for cold water.A useful video on choosing a model for a pump can be viewed on the video:

The prices for products from manufacturers are different and are set depending on the nominal diameter, design and features of the production process.

The approximate cost of devices from the most famous manufacturers is shown in the table:

| Manufacturer | Design features | Diameter, mm | Price with VAT |

| Danfoss | Brass, spring, coupling | 15 | 530 |

| 20 | 694 | ||

| 25 | 908 | ||

| wafer, stainless steel body, disc | 15 | 4385 | |

| 20 | 4838 | ||

| 25 | 5310 | ||

| bivalve, wafer type, cast iron | 50 | 7580 | |

| brass, male thread | 15 | 3298 | |

| 20 | 3310 | ||

| stainless, spring-loaded, flanged | 40 | 2261 | |

| 50 | 2292 | ||

| 65 | 2997 | ||

| Valtec | with brass spool, spring-loaded | 15 | 230 |

| 20 | 298 | ||

| 25 | 500 | ||

| spring | 15 | 195 | |

| 20 | 270 | ||

| 25 | 400 | ||

| Itap | MET horizontal | 20 | 206 |

| Spring-loaded, clutch - clutch | 32 | 484 | |

| 80 | 3369 |

Butterfly check valve

In many ways, such a valve is similar to a petal device. The presence of two valves located on the axis resembles a butterfly. The principle of operation of the butterfly valve is very simple: with direct air movement, the flaps open, and with reverse flow, the ventilation hole closes.

Basically, the system with a butterfly check valve is used in forced ventilation, since the flaps do not shrink with a weak air flow.

Advantages and disadvantages

Installing a check valve will effectively solve the following tasks:

- stabilize the operation of the water supply system,

- minimize the risk of air intrusion into the system,

- reduce energy costs, if such a device is equipped with a hot water supply system heated by electrical appliances,

- ensure the water supply for some time, even with the pump off.

In addition, such devices have the following advantages:

- light weight and length,

- high degree of tightness and reliability,

- ease of installation.

The disadvantages include the fact that the device requires regular maintenance.

Gravity grid valve

Externally, such a device is a grill with a check valve for ventilation. Such louvered grilles are installed directly on the wall of the building and do not require additional decorative overlays.

The principle of operation, like all previous types, is to open the flaps with a direct air flow, and close them when the fan is off.

The ventilation grill with a non-return valve is mainly used in industrial plants. According to the method of louvre arrangement, valves with a gravity grid can be either horizontal or vertical.

There are rectangular and round check valves for ventilation.

Sewer check valve: how it works, do-it-yourself device

Clogs often occur in the sewer system. As a rule, such phenomena occur due to the ingress of various waste into the pipe or due to improperly assembled sewage system. This problem eventually becomes the cause of flooding of apartments located on the lower floors of apartment buildings. The exact same process can occur with the owners of private plots. Naturally, there are no homeowners who would not care about the problem of being flooded with sewage, because after that the building will have to be repaired, and the cost of this operation is very high. The sewer check valve can solve the problem.

Check valve material

Do-it-yourself check valves for ventilation are made of the following materials:

- Small thickness galvanized steel. Models with galvanized valves are more often used in manufacturing plants or in office buildings. Durability and resistance to corrosive environments of galvanized steel, allows to operate the check valves for a long time. Also, the requirements for fire safety at industrial enterprises determine their widespread use.In domestic conditions, metal valves are not practical, since their operation is accompanied by a characteristic knock, and over time traces of rust may appear, which spoils the appearance of the device.

- In apartments, it is better to install the non-return valve itself, made of plastic for ventilation. It is easy to choose such valves for any interior style of the room, as they have an aesthetic appearance. In systems with natural ventilation, plastic valves show good performance, as they are sensitive devices.

- In the valves of the combined type, the body is made of galvanized steel, and the leaf is made of plastic. The valve sensitivity is very high, which makes them suitable for natural ventilation systems.

In addition, valves are available with and without heating. Heated valves are installed on the outside wall. In the event of temperature fluctuations, a heated valve prevents icing of the leaflets.

Standard sizes of check valves for ventilation are 100, 125 or 150 mm.

Requirements for a quality valve

Today the market provides many modifications and types that we mentioned above, but the essence of their work is the same: to prevent the backflow of the contents of the sewer pipe. Before buying and installing this or that model in your own apartment, you need to read the reviews about it on numerous forums. Regardless of the type, the sewer valve must meet the following requirements:

- Have a reliable design, resistance to aggressive environments, durable materials and ease of maintenance. Namely: it should be easily removable with a cover to read the body and flap.

- The mechanism must provide automatic blocking of the return drain.

- It has a manual adjustment that can be done in the event of an emergency.

- The valve contains protection against the penetration of unpleasant odors into the home.

- Does not allow rodents to enter the room through the membrane.

installation of a check valve at the outlet of the drain into the riser

Before installing a check valve on the sewer, you need to decide on the installation site and choose the right type. It can be installed both horizontally and vertically. But this will primarily depend on the type of valve chosen. So, for example, the crane is only mounted horizontally.

The check valve can also be installed on separate equipment, which is rational to do both for residents of the first two floors of an apartment building, and in general on the sewer system of the dwelling.

Before making a choice, measure the diameters of the pipes, check the volume of wastewater and the place of installation. In any case, whichever type you choose, free access to the valve is important in order to be able to clean it and replace it if necessary.

Recommended reading: How to clean a sewer using a hydrodynamic method?

- Pay attention - on any model of a check valve, the direction of flow is indicated by an arrow. It must be mounted in accordance with this mark, otherwise you can get the opposite effect.

- During the installation process, the arrow must be directed to the sewer collector, and this is the only way, otherwise it will not work correctly. In other words: the arrow indicates the normal direction of the drains towards the riser.

- Before installing the valve, carry out a tightness test to avoid further problems.

- The valve must be cut into the existing sewer system. In this case, the diameter must correspond to the diameter in the system, if this is not the case, then adapters should be used.

- If there is a decrease in the tightness of the membrane that is responsible for blocking, noise and vibration will appear. In order to eliminate this, it is necessary to remove the cover, remove the shutter and replace it.Another way out is to change the sealed edging: in this case, the shutter does not have to be changed.

- You do not need to choose a very cheap valve, since having saved in the beginning, you can spend much more money in the future.

We suggest that you familiarize yourself with How to properly store dried fruits at home

Check valve selection parameters

If you decide to buy a valve in the retail network, then you need to familiarize yourself with the main characteristics that must be followed when choosing a device.

The main selection criteria:

- The natural ventilation grill with a non-return valve must match the size of the ventilation duct opening. It is better to find the right device than to tinker with the channel.

- For natural ventilation, it is necessary to select a non-return valve with a high sensitivity. If the pulling force is low, then it is better to install a fan.

- The valve size must match the fan rating. If the non-return valve for ventilation is 100 mm, then the fan must also correspond to this size.

- Temperature conditions must also be taken into account, as some devices have poor performance at low temperatures. Such valves are installed only indoors.

- If the air duct is rectangular, then the check valve must also be rectangular.

In the event of an incorrect selection of equipment, ventilation in the room may be disrupted or the air direction may change.

Types and designs

Depending on the type of working elements and on the method of fastening, there are spring, petal, ball and lifting types of valve designs. The choice of one or another type depends on the characteristics of the pumping station, on the diameter of the pipeline and on the characteristics of the working fluid.

Spring clutch

In models of this type, a disc acts as a working element, which in the absence of flow is held by a spring in a position pressed against the seat. Devices of this type are easy to install and unpretentious. It is recommended to install it on pipes with a cross section of 15-200 mm, where water, gas or other non-aggressive heat carrier acts as a working fluid. The disc can move forward and backward only along the flow axis, while constantly remaining in the flow area. This reduces the throughput of the device.

Spring Loaded Coupling Valve.

Rotary petal

In petal-type devices, a steel disk serves as a working element, which can be radially displaced in the presence of flow. As soon as the water supply is interrupted, the steel disc falls onto the seat by gravity. Due to this design feature, the valve should be installed only in horizontal pipe sections; the device will not work in a vertical position. The main advantage of this type is that the valve can work regardless of the type of heat carrier or working fluid.

Ball model

The working element of the ball check valve is a heavy ball made of cast iron. With a direct flow of liquid, the ball is displaced into a chamber located outside the device passage. When the fluid moves backward, the ball returns to its place under the action of its own gravity, blocking the passage. These devices are distinguished by tightness of closure and ease of installation. They also have low requirements for the quality of the working fluid, they can work even with viscous heat transfer fluids.

Lifting type product

Lift valves are equipped with a shut-off element which, in the absence of flow, is in the “closed” position by gravity. Some manufacturers supplement the design with a spring.

Spring models can be installed both vertically and horizontally. A direct stream of water presses on the valve from below, lifting it. And the reverse flow presses from above, pressing the plate even more against the saddle.Thus, the backflow of water is blocked. The advantage of products of this type is ease of installation and unpretentiousness to the quality of the working fluid.

Step-by-step instructions for making a valve

You can make a check valve for ventilation with your own hands by examining similar factory models. Following the instructions, it is not difficult to make a homemade membrane-type valve, which, in terms of its characteristics, will not be inferior to industrial models.

Instructions for self-manufacturing of the valve:

- First, you need to make a plate, which will be the main element of the valve, the flaps will be installed on it. The plate is cut to fit the size and shape of the ventilation channel. For the manufacture of the plate, you can use durable plastic or textolite with a thickness of 3 to 5 mm.

- To connect to the fan and fix the plate in the exhaust ventilation channel, holes are drilled along the edges of it. Holes are also drilled in the central part to allow free passage of air flow. The ability of the system to pass air will depend on the number of holes.

- Further, with the help of a sealing gasket and a hermetic means, the plate is fixed in the exhaust pipe. In the places where the plate is fastened with screws, it is recommended to install gaskets made of soft material or rubber, this will reduce vibration and noise level in the ventilation system.

- The next step will be the manufacture of flaps for the check valve. To do this, a piece is cut out of a dense film, in size and shape corresponding to the size of the plate. The film is glued along the edges of the plate. It is from this film that two valve flaps will be made in the future.

- We cut the film into two equal parts, these will be the valve flaps. Make the cut straight.

- We install the pipe with the plate and the film into the ventilation duct and fix it with dowels.

- We seal the gaps between the exhaust pipe and the walls of the ventilation duct.

The principle of operation of a diaphragm valve is quite simple:

- nothing interferes with the air flow in the forward direction, since the flaps are open;

- when the direction of the draft is changed, the sashes close, preventing the penetration of air from the outside, thereby protecting the room from extraneous odors and dust.

Compressor check valve: types, how to choose, installation

There are a number of situations when, for a number of reasons, the correct operation of the compressor is disrupted, which leads to periodic failures in the operation of the device.

The air compressor check valve protects the device from unauthorized damage.

Purpose of the device

A safety check valve for an air compressor performs its main and paramount function - it prevents the transported product from returning to the working space of the compressor itself.

This can occur during start-up of the device or during any other intervention in the operating mode of the unit.

A safety check valve for an aquarium air compressor is essential just when a certain amount of water is being transported.

Those compressors that transport water resources often start to malfunction.

In cases where water remains inside the hose, and the unit itself is below the water level, water begins to seep in the opposite direction.

It, according to the laws of physics, penetrates into the interior of the compressor, which often leads to a breakdown of the device.

At such moments, there is a high probability of a short circuit, which leads to the failure of the unit.

Application area

The air safety valve is widely used in many industries. Often this is:

- Suction liquid lines;

- Hot gas pipelines;

- Refrigeration pipelines;

- Air conditioning systems.

Due to the presence of special enlarged fittings, the possibilities and scope of application of the air check valve are significantly expanded, they can also be mounted by hand.

The minimum pressure relief valve for the compressor helps to create a targeted refrigerant path from warm to cold evaporators.

Air relief valve

In addition, the presented safety unit effectively prevents the formation of reverse condensation.

The effectiveness of these actions is due to the presence of a special spring, which can form a pressure inside the system equal to 0.3 bar.

Along the path of the discharge line of the air compressor, the check valve is equipped with a damping piston.

This device ensures that the valve is correctly positioned in the pressure pulsation line. Such pistons have a large number of variable designs.

They are used in refrigeration plants, which are equipped with compressors operating in parallel.

Thus, the air check valve is presented in the form of protective pipeline fittings, which prevents the change in the direction of movement of the internal working medium.

This device is mounted only on a horizontal section of the pipeline. With this unit, you can clean the entire line and vessels that work under pressure.

Thanks to the use of this device, leakage and the level of losses of the working medium from the system are significantly reduced.

The unit is widely used in ventilation, water supply and heating systems. For ventilation systems, the unit is an extremely necessary element, and can function not only as a shut-off device, but also as a regulating device.

The non-return valve is mounted to the pipeline by means of a flange mount. From the outside, it is almost invisible.

Often the presence of a check valve for the compressor is felt during the winter season, in ventilation systems.

This device helps to effectively prevent cold air, snow and other precipitation from entering the system.

This device is recommended to be installed on emergency fire ventilation systems and in related communications.

Types and features

Today there are many varieties of check valves for compressors. They can be:

- Straight;

- Corner;

- Spring loaded;

- Ball;

- Folded;

- With flange connections;

- For soldering;

- For dismantling.

Those devices, the installation of which provides for installation in systems pumping ammonia, in most cases are made with the use of steel.

Some versions are equipped with a damping piston. This allows the units to be used within the working environment of the discharge pipelines.

In some cases, such valves can be used in situations where it is important to timely and quickly close the bore.

Such requirements for the unit are associated with high differences in internal pressure in the mechanism. Sometimes it can reach 0.1 bar, while in conventional devices it can be between 0.03 and 0.06 bar.

Aquarium safety device

However, there is one significant drawback - such a check valve installed on the suction pipe has a very negative effect on the overall cooling capacity.

Regardless of the modification and purpose of the device, it is necessary to carefully observe that foreign particles do not fall on the gap element (saddle).

Otherwise, even in the closed position, the shut-off valve will not be able to fully ensure its functionality.

By the way, those valves that are equipped with a ball-shaped shut-off element are not so sensitive to contamination.

This is due to the wide clearance angle between the seat and ball angle. The unit is widely used in the field of compressor construction for industries such as metallurgy, chemical and petrochemical industries.

All types of devices presented are divided into two main types: horizontal and vertical.

In order to install each of them, you should carefully consider the parameters and configuration of the system.

In addition, these units differ based on the characteristics of their shape, (square and round), and the material from which they are made.

Each of the materials used has its own characteristics. Based on this, many systems are equipped with plastic devices, and some are equipped with metal units.

Now the most common type is the plastic valve. The capacity of this device is 4-6 m / s.

This value is formed based on the complete absence of noise during the opening and closing of the rotor blades.

This type of unit is capable of functioning both with the assistance of a valve installed for the hood, and autonomously.

It is worth noting that such a modification as a solenoid valve is not very popular among consumers due to displacement by cheaper counterparts.

Now you can buy the most common type of valve for compressors - this is the so-called "butterfly".

Non-return valve

These units are manufactured using steel, and on top are covered with a thin layer of galvanized coating.

The device is equipped with two rotating blades that are mounted on a central axis. When the suction channel is turned off, the blades close. The butterfly valve is available in several modifications, the dimensions of which are 10-30.5 cm.

How to choose?

Before you buy a check valve, you must first take into account such a not insignificant factor as the intensity of the working air flow.

In alternative systems, this can be liquid or gas. This factor directly affects the start and correct operation of the installed valve.

In addition, it should be borne in mind that the performance indicators of the air exchange device closely correlate with the power indicators of the pumping device, be it a pump or a fan.

When choosing a valve, take into account the temperature conditions in the room and the environment in which the unit will be installed.

The degree of environmental pollution is also important. For example, a butterfly-type device, when exposed to a flow of cooled air, begins to significantly slow down.

This can lead to an undesirable combination of the duct and the device as a whole. The price of a check valve may fluctuate slightly, and directly depends on the technical characteristics and the manufacturer of the device.

Compressor check valve with receiver, Valuetex:

- Maximum admissible pressure: 16 bar;

- Body material: brass;

- Operating temperature range: from -15 to +90 ° С;

- Internal thread: ¼ inch;

- Price: $ 4-5.

Small check valve for compressor

Valve, non-return, direct, Airway:

- Maximum admissible pressure: 14 bar;

- Body material: steel;

- Operating temperature range: from -20 to +100 ° С;

- Internal thread: ½ inch;

- Price: $ 5-6.

Non-return valve, angle, Viton:

- Maximum admissible pressure: 12 bar;

- Body material: brass;

- Operating temperature range: -10 to +70 ° С;

- Internal thread: ¾ inch;

- Price: 3-4 $.

Diy check valve (video)

https://youtu.be/RQfNEtJXVmw

Installation features

When installing with your own hands, a standard sequence of actions is used. Before starting the installation with your own hands, you should choose a place to install the device.

Do-it-yourself installation (using the example of an aquarium water supply system) is carried out with an orientation to the following algorithm:

- The hose is connected to the spray gun.

- There is a spray bottle in the aquarium.

- The hose is laid along the wall.

- The check valve is inserted taking into account the direction of the arrow on the body.

- The other end of the hose connects to the compressor.

- A test run of the compressor is in progress.

In most cases, this place is located between the pumping station and the receiver, and the unit is connected using a squeegee.

HomeBuild2.ru

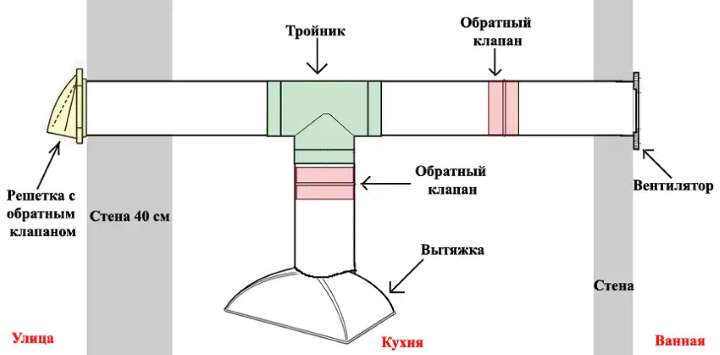

Features of the use of valves in the kitchen

In the kitchen, the system is additionally arranged with an exhaust ventilation system above the stove. This prevents contaminated air from spreading throughout the entire kitchen area.

When the fan is on, the system draws in smoke from the surface of the stove. But when the fan is powered off, odors from neighbors can enter the room. Installing a check valve on the hood is a prerequisite for maintaining clean air in the kitchen.

It should be remembered that there is another hole in the general ventilation system in the kitchen. Through this channel, polluted air can be returned to the room. Therefore, it is recommended to install a reverse device in a common shaft. The butterfly valve is mounted on the exhaust ventilation from the stove, and on the natural ventilation a diaphragm valve.

It is recommended to install a check valve in the bathroom, which will not let cold air into the bathroom from the outside, and can also reduce the humidity of the room if there is an influx of air masses from neighbors.

Valve installation

What is a valve in the sewer for?

So that when a blockage occurs, the drains of the upper floors do not fall into the rooms of the lower ones. The principle of communicating vessels works here: as soon as the outlet to the well or collector ceases to perform its functions, wastewater begins to pour out through the plumbing fixture located below the others. It is worth installing a valve in front of it - and the sewage will have to look for another way.

In addition to the reverse movement of drains, the valve flaps exclude the movement of rats and mice through the sewers. In the absence of drains, the damper is completely closed, and when the water is drained, it rises just enough to allow the flow to pass.

The work of the vacuum valve for the sewerage.

Where exactly are the valves installed?

- Their most typical location is at the outlet into the well of the basement or basement floor sewer network. Such rooms should be equipped with a separate outlet; alternatively, the outlets can be combined after the check valve. When backing up the yard sewage, the sides of the plumbing fixtures will be below the edges of the well; however, thanks to the valve, the room will not be flooded;

- In an apartment on the ground floor of an apartment building, closures can be installed after individual plumbing fixtures. So, a 110 mm PVC check valve for sewage can be mounted after the toilet, and 50 mm devices can be installed on the taps for connecting a bath, washbasin and sink. An even simpler solution is to install a common shutter with a diameter of 110 mm at the entrance to the apartment, immediately after the tee or cross;

Installing the valve for the toilet bowl outlet.

- In a private house connected to a central sewage system, the valve can be installed before discharge to the well from the inside of the foundation. Of course, its location should be convenient for maintenance: every 3 - 6 months the hatch of the device is opened to clean the saddle and flap from grease and other deposits.

Outlet to a well equipped with a shutter.

I strongly advise against putting a vertical valve (as well as various trash traps blocking the mesh pipe under revision covers and other handicraft devices) in the break of the sewer riser.

A riser check valve is a bad idea.

What is the instruction related to?

Due to the fact that the damper, even in the fully open position, is an obstacle to drains, an unevenness inside the pipe. She will inevitably collect bulky garbage traveling along the riser, first of all - rags dropped into the toilet bowls. Yes, getting them into the sewer is a gross violation of the norms of its operation; however, we live in a far from ideal world, and we have to put up with reality.

The damper is quite capable of stopping a rag or bulky debris that has fallen into the riser.

As a result, the valve will cause frequent blockages in the riser at the level of your floor. Where it leads?

- To the flooding of your own apartment, but no longer through plumbing fixtures, but from above - through the ceiling;

- To the inevitable, like the collapse of capitalism, damage to the valve flap when clearing the next blockage. Sewer wire is a fairly durable tool that allows great efforts when used;

- To drawing up an act on unauthorized change in the configuration of the public utility network with invoicing for the restoration of the riser, and, possibly, for repairs from the neighbors from above.

Why am I paying so much attention to improper installation of a valve in a riser? Yes, simply because, as a plumber, he often had a big and bright feeling with a variety of valves and traps installed so that the upper neighbors themselves reap the benefits of improper use of the sewage system. Alas, they do much more harm than good.

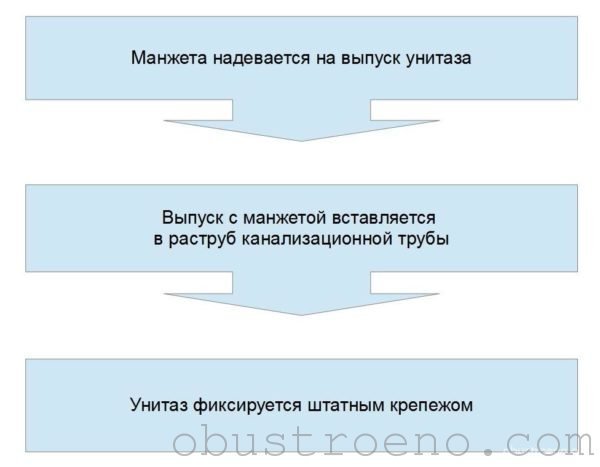

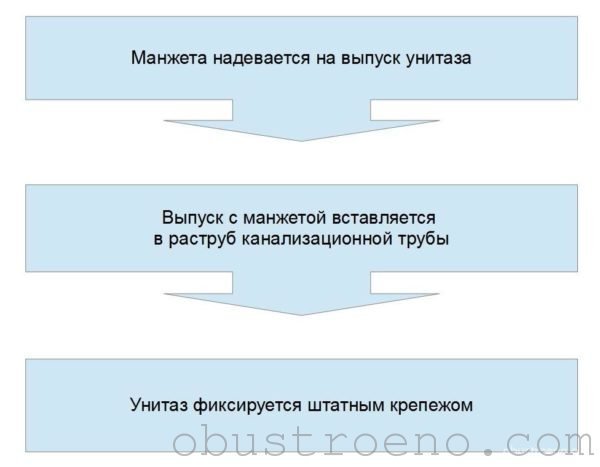

How to install a non-return valve correctly? The simplest case is to install a cuff valve after the toilet.

Toilet cuff with non-return valve.

Valve installation - cuffs.

As always, there are a couple of nuances:

- The toilet must be connected to a pipe with a straight section after the socket. The damper should not rest against the branch wall;

- You should not collect joints on sealant and put the toilet on cement or mastic. Sooner or later, the valve will need to be cleaned.

The damper should be free to rise and fall without resting on the pipe bend.

Flare check valves are installed in the same way as any other plastic fittings: a smooth beveled section is inserted into a bell ring with a rubber O-ring. Liquid soap or any other water-based lubricant can be applied to the seal for ease of assembly.

Of particular interest is only the installation of the valve in the gap of the previously assembled sewer section. In this case, we need an additional shaped element - a compensating pipe. It is a short pipe with an elongated socket.

The photo shows a compensating pipe with a diameter of 110 mm.

There are a couple of nuances here:

- On the cut pipe, the burrs are necessarily cleaned from the inside, and the outer chamfer is removed. Burrs can trap debris during drain operation, increasing the likelihood of blockages. The chamfer will help to assemble the socket joint with minimal effort;

Burrs inside the pipe can cause blockages.

- After assembling the sewage system, the flare of the check valve must be fixed with a separate clamp. Thus, we will prevent spontaneous undocking of the connection when the sewer is backed up: the compensator is able to move up the pipe.

Can a check valve be installed where there is no socket? Of course. To do this, in addition to the compensator, we will have to purchase a sewer sleeve.

It is mounted on a cut-to-size pipe below the valve installation site. Further actions are no different from those described above.

Choosing equipment, you need to take into account all the parameters. Installation includes the following stages:

- Choose a place for installation according to the rules indicated above.

- If installed in an existing system, a section of pipe is cut out and measured according to the size of the device.When installing a new system or replacing it, the valve is installed in the right place.

- The check valve is mounted to the pipes in accordance with the instructions and the type of device.

- After installation, it is necessary to check the tightness of the connections. To do this, you need to open the water in the riser and observe the junction. If vibration is observed, it is necessary to check the quality of the connection and, if necessary, redo it.

We offer you to familiarize yourself with Hazel as growing

Manufacturers are now actively working to improve the check valve system. This is mainly about automating the process. Such an automatic valve is powered by a 220 V network. Some of them have batteries, they will protect you if there is a power outage. This valve is clearly more convenient to use.

Recommended Reading: Make a waterproof septic tank out of concrete rings

check valve working principle

Principle of operation: counterflow fills the sewer pipe, when 70% fullness is reached, the probe in the middle signals this. Then the sound and light accompaniment immediately turns on, which warns of problems in the sewer system. Also at this moment the damper closes and guarantees 100% reliability.

Do-it-yourself installation of a check valve on the sewer can be done in various ways.

- Models with large capacity can be used for installation on a common sewer pipe. Such options are suitable for private houses, summer cottages and cottages, but not for an apartment in a high-rise building.

- Installing a valve at each drain point in an apartment will prevent an emergency situation and is especially recommended for residents of the lower (first and second) floors of multi-storey buildings, which are most at risk of flooding when the sewer system is clogged.

- On sewer lines with a reverse slope - it is mandatory to ensure the normal functioning of the system.

Sewer check valve installation diagram

In stores, you can find various designs of a sewer check valve, but the principle of their device is almost the same. It looks like a pipe, inside which a plate with rubber seals is installed. It is this plate that acts as a lock, a spring is attached to it, which does not allow drains to pass in the opposite direction.

In order to periodically clean the valve, a removable cover is provided on its body. There is also a lever on the valve, with which you can manually open or close the plate. In this case, if the valve is opened, the plate will be in a stationary state when open. It also happens if you close it manually, the plate will always be closed.

Check valve device

When the drains pass from the plumbing fixture, they open the plate with their pressure and freely pass into the sewer. Then a spring comes into play, it closes the hole with a plate and prevents the drains from going in the opposite direction. The cymbal itself is larger than the emphasis on which it rests. This allows the valve neck to be hermetically sealed.

Smaller valves sometimes use a different system. In this case, the inlet and outlet pipes are at different levels. There is air between them. If a reverse flow occurs, the air bubble presses on the membrane and closes the return pipe, which prevents the flow of waste water.

Check valve installation expert advice

It is not difficult to install a check valve in the ventilation system. This does not require special tools, just a punch for drilling holes in the wall, as well as a screwdriver or a simple screwdriver to tighten the screws is enough.

It is always easier to get a quality job done, taking into account the advice of the specialists on the installation and operation of the valve:

- Self-assembly of the valve should begin with determining the direction of the air mass flow. Only after this action can you proceed directly to the installation of the equipment.

- To prevent insects from entering the apartment through the ventilation system, it is recommended to glue a piece of nylon or a special fine-mesh plastic mesh before installing the shutters. It is preferable to use nylon, it is easier to clean or replace.

- The valve will be installed better if you choose a device with a convenient mounting system (flange or clamp).

- For a structure installed in the outer wall of a building, it is better to purchase an electrically heated check valve. This will prevent the sash from freezing at low temperatures.

- To avoid jamming of the blades from dust and dirt, it is necessary to periodically clean the flaps from plaque.

What is it for?

To avoid flooding with fecal matter, a sewage check valve is installed. Its principle of operation resembles a nipple - the liquid flows freely in one direction, but does not pass in the opposite direction. If your sewage system gets clogged, then such a device will prevent the drains from reaching your home.

Sewerage check valves are manufactured in various diameters. When purchasing such a device, you need to know the place of its installation and the pipes used. As a rule, a sewer riser is 110 mm in diameter, and other pipes are 50 mm in diameter. In accordance with this, the check valve is selected.

Crankcase ventilation

The use of a non-return valve is not limited only to the ventilation system of the apartment room. For example, consider the action of the crankcase ventilation check valve, internal combustion engine.

When the engine is running, exhaust gases and vapors of gasoline, oil and water enter the crankcase. The accumulation of such gases will destroy the metal parts of the engine.

The operation of the crankcase ventilation system uses the vacuum principle. A valve is needed to regulate the pressure of the crankcase gases. If the vacuum is negligible, the valve is open. At high vacuum, the valve closes.

Remember that the check valve not only protects against the penetration of polluted air and dust into the home, but also maintains an optimal microclimate in the room, preventing cold air from entering the room. Thus, it is possible to ensure comfort and the absence of foreign odors.

Tips & Tricks

When choosing a check valve model, you need to take into account a number of parameters arising from one another:

- The flow rate of the source cannot exceed the pump capacity.

- The submersible pump delivers pressure sufficient to supply all consumers.

- The section of the hose and pipeline corresponds to the capacity of the pumping equipment.

- The capacity of the valve is equal to the parameters indicated above.

When assembling the system with your own hands, you need to take into account that all connections must be absolutely tight. Otherwise, a leak will form, and water will flow out of the pipeline even with the valve closed. For sealing, special rubber gaskets, FUM tape, sealants, and thread mastic are used. When using the latter, it must be remembered that difficulties may arise during dismantling.

Using check valves with brass, rubber, polymer, etc. body, do not tighten the thread too much. It is best to tighten it by hand to test its fluid retention and, if necessary, turn it a quarter turn until the leak is eliminated. Excessive zeal will lead to a break in the structure.

A valve is a device that creates a temporary obstruction to the flow of liquids or gases in a variety of systems and devices.A choke in a gas stove, a nipple in a car or bicycle tire for a foot pump, a plug in an air mattress or a mud pump valve are just a few of the valve applications.

Let's take a closer look at this device.