Corrugated stainless steel pipe has become a real breakthrough in plumbing engineering. Thanks to a number of advantages and a wide range of applications, this innovation has rapidly gained popularity in the construction industry. It is used to lay a variety of communications. Practicality and flexibility allow the use of corrugation in a variety of, even the most difficult conditions.

Corrugated stainless steel pipe

Corrugated stainless pipe: the history of invention

An invention such as a stainless steel corrugated pipe appeared at the end of the twentieth century. Its authors are Japanese scientists who were looking for the best option for laying communications in conditions of increased seismic activity on the islands. This is how a versatile product was created that combines the flexible qualities of rubber and the strength of steel. It took world experts very little time to come to the general conclusion that flexible metal pipes have a number of advantages over their counterparts made from cold-rolled sheet steel, as well as over polypropylene and metal-plastic pipes.

Flexible stainless pipes instead of steel and plastic pipes

In this regard, almost immediately after the invention of corrugated pipes, their serial production began in Germany, and then in South Korea, which is currently the leader in the production of flexible stainless steel pipes. Gradually, enterprises in different countries began to specialize in the production of corrugated products, and their use became ubiquitous in the installation of engineering networks and other communications.

Features of Corrugated Stainless Steel Pipe

Flexible stainless pipes gradually replaced steel and polypropylene structures, as well as metal-plastic communications used in the creation of plumbing, heating, ventilation and even gas systems. The strength of the material is ensured by the fact that only high quality stainless steel with impurities of nickel, chromium and carbon is used in the production process.

The degree of concentration in the alloy of additional elements such as nickel, chromium and carbon is calculated with the utmost precision. This guarantees the strength, durability of the corrugated pipe and its corrosion resistance.

The material must comply with a certain list of characteristics that guarantee certain product quality standards, in particular:

- Normal operating pressure is 10 atmospheres with a permissible maximum load of 60 atmospheres.

- During operation, the corrugated stainless steel pipe withstands the temperature of the passing substance from 0 ° C to 100 ° C. In this case, the maximum limit can reach 150 ° C and above.

- Pipelines for the organization of construction work and individual repairs, depending on the scope, are produced with a diameter of 15, 20, 25, and 32 mm.

High-quality steel is used in the production of corrugated pipes

Corrugated Flexible Pipe Manufacturing Process

The versatility and high quality indicators of stainless steel corrugations are due to strict adherence to its manufacturing technology, which, surprisingly, is quite simple. The production process itself includes the following stages:

- The pipe is formed using a special steel tape.

- Workpieces are cooked using tungsten electrodes. At this stage of production, special automatic TIG equipment is used.The process takes place at high temperatures, which can reach 1150 ° C.

- The reliability of the seams is checked on a special laser installation.

- Corrugation is formed using special shafts of various diameters.

- Heat treatment of parts is performed. Different types of pipes lend themselves to a certain degree of temperature exposure, since the annealed pipe has a higher degree of flexibility.

- Products are packaged. Pipes are divided into sections of a certain length. Products with a small diameter are rolled into coils, and thick parts are packed in groups.

- They check the quality and filter out defects in the form of products with microcracks. For this purpose, a metal corrugated pipe is placed in a liquid under high pressure. At the same time, a special device is attached to each bay and the pressure is gradually increased to 10 atmospheres, then it is gradually reduced.

The main advantages of flexible stainless steel pipes

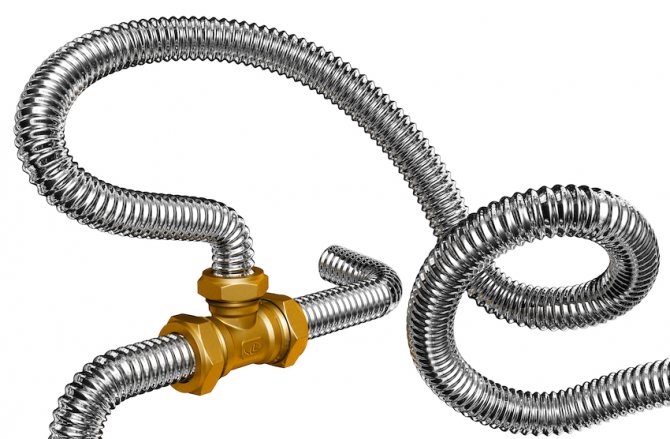

The special design in the form of a corrugation provides this type of pipe with a high degree of flexibility at different bending radii, which does not entail a narrowing of the flow and does not lead to deformation of the product. Moreover, after unbending, the pipe does not bend, but takes on its original flat appearance. Installation of a corrugated stainless steel pipe does not require special efforts and the organization of additional manipulations using bending equipment. In the process of work, you only need fittings to connect parts and special fasteners.

Installation and connection of corrugated pipes

In addition, the stainless steel pipe provides a high degree of wear resistance. Products can be used in a wide temperature range. In this case, the minimum indicator is -50 ° C, which allows substances with a low temperature, for example, liquid nitrogen, to be passed through them. The upper temperature mark can reach 150 ° C.

Advantages and disadvantages

The advantages of stainless steel flexible corrugated pipe are:

- high strength indicators;

- long service life (more than 20 years);

- resistance to changes in temperature conditions while maintaining geometric parameters;

- ability to withstand water hammer;

- resistance to corrosion subject to operating requirements;

- frost resistance;

- environmental friendliness of the composition;

- resistance to damage by fungus, mold.

The pipes do not require regular maintenance, painting, or protective coatings. During operation, only the replacement of the plastic rings is required. Products can be placed behind wall panels, stretch ceilings, decorative inserts.

Corrugated pipes are not clogged with deposits, therefore, they do not require the use of cleaning systems. The products are lightweight, flexible, ensuring comfortable transportation, storage and installation.

The disadvantage of the products is the susceptibility to mechanical deformation; in some cases, it is required to install a protective casing. The material is distinguished by high heat transfer and is optimal for radiators of heating systems, however, in areas responsible for heat supply, thermal insulation protection is required to conserve thermal energy.

External corrugated surfaces are difficult to clean and require special brushes in addition to a damp cloth. The material is susceptible to electrochemical corrosion, in some areas it is necessary to add neutralizing protective shields.

The corrugated surface requires adjustment with finishing panels. Protective decorative plates are installed on radiators made of corrugated pipes.

Disadvantages of corrugated flexible pipe

In addition to the listed technical characteristics, it is worth mentioning the convenience of transportation, storage, installation of structures, as well as the advantages of the pipe during operation, which consists in environmental safety, resistance to the effects of rodents, the appearance of fungus and mold.At the same time, do not forget about the weak points that this versatile and practical product has, the main ones are as follows:

- Due to the small thickness of the pipe walls, there is a risk of damage in places where strong impacts are likely. Therefore, as a precaution, sometimes a protective cover should be fitted.

- The high degree of heat transfer, characteristic of a corrugated stainless pipe, will be a plus for heating, but in places of heat supply, installation of thermal insulation will be required in order to save thermal energy.

- The corrugated surface is quite difficult to clean, so a simple sponge or cloth will not work here - you need to do this with a special brush.

- Corrugated stainless steel, despite all its anti-corrosion properties, can still be unstable to the effects of a number of substances, as well as undergo electrochemical corrosion, therefore, during its installation in such places, it is necessary to use neutralizing screens. In order to protect against stray current, it is worthwhile to provide grounding and install dielectric gaskets.

- The appearance of corrugated pipes is not very attractive, and therefore it is advisable to hide them behind the decoration on the walls, and the radiators should be covered with decorative panels.

Disadvantages of corrugated stainless steel pipes

Classification of stainless steel corrugated pipes

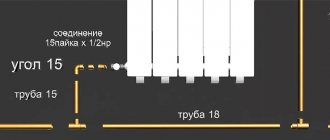

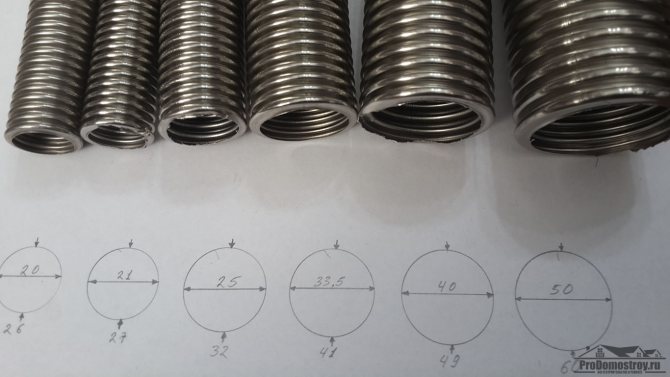

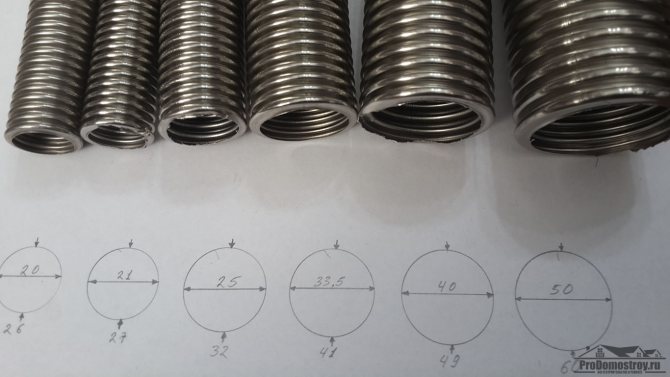

Corrugated stainless steel pipes have their own classification. Pipes are divided into types depending on the diameter, scope and degree of flexibility of the corrugation. In the installation of household communications and for industrial needs, as mentioned earlier, pipes with a diameter of 15, 20, 25 and 32 mm are mainly used. These are the most popular models, but they are no exception.

Products of different diameters are produced, including pipes with a meter section. Such products are used to transport various liquids in production. Models of other sizes can also be made to order, but the price of a corrugated stainless steel pipe made in this way will be much higher.

Depending on the purpose of the pipe, its properties are determined, products are classified into the following types:

- corrugated annealed stainless steel pipe - characterized by increased flexibility, to achieve this effect during production, it is subjected to a special heat treatment;

- unannealed pipe - does not lend itself to heat treatment, therefore it has less elasticity and weighs a little more;

- stainless corrugated pipe with a protective polyethylene coating - designed for gas supply, for systems that are subject to concreting, and also used for laying communications underground.

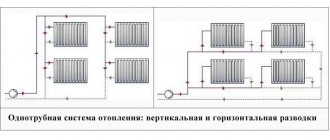

Depending on the purpose, corrugated pipes in household construction are used for the installation of heating, water and gas supply.

Production of corrugated stainless steel pipes

The creation of corrugated pipes is a rather complex technological process, therefore its implementation is fully automated. First, the sheet is formed into a cylinder using a forming conveyor. Next, the workpiece is fastened with a weld seam, as a result of which an ordinary round pipe is obtained.

To give a ribbed texture, rolled products on rollers of various sizes are used. The inherent flexibility of the corrugation is achieved through heat treatment, which can be carried out in several stages.

Scope of application of corrugated stainless steel pipe

Corrugated pipes are distinguished by their versatility, therefore they are widely used in the installation of both centralized and autonomous water supply and heating. This is possible due to the properties of stainless steel to withstand high pressure, although the walls have a maximum thickness of 0.3 mm.

With the help of flexible corrugated pipes, you can implement a system of any complexity

Corrugation perfectly tolerates high temperatures, under the influence of which it does not deform. In this regard, corrugated pipes outperform analogues made of polypropylene and metal-plastic. Therefore, a corrugated pipe for heating and hot water supply is the best fit. In frosty conditions, such a stainless steel product does not suffer from compression and expansion of the material, therefore freezing and thawing does not affect its flexibility. The flexibility of the material is so high that the hoses, depending on the diameter, can bend with a radius of up to 30 mm.

Thanks to these unique advantages, stainless steel pipelines are used in a wide variety of applications. They are used by builders, repair workers, electricians and utility mechanics as:

- flexible pipes for heating;

- wall and floor insulation systems;

- corrugated pipes for plumbing and hot water supply;

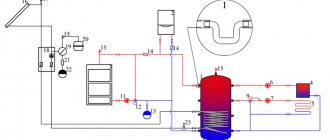

- pipes for piping boilers;

- channels for connecting meters;

- heat exchangers;

- gas distribution pipes;

- corrugated pipes for ventilation, chimney and air conditioning.

Corrugated pipe selection rules

Flexible pipes for heating are made using a complex and expensive technology, so there are no fakes of these elements on sale. However, when choosing, you need to carefully check the element, because no one is immune from factory defects.

Attention! Corrugations made of stainless steel for heating systems are made in accordance with GOST 3262-75.

When buying material, first of all, pay attention to obvious damage and dents on the surface. All segments must be flat throughout the pipe. Flex and unfold the element. It is important how easily the segment returns to its previous shape. After bending and straightening, there should be no creases, cracks and surface defects. The length of the pipeline is calculated in advance.

To calculate the amount of coolant circulating in the pipes, you need to accurately mean the diameter of the element:

- in a wiring with a cross section of 1.5 cm, 0.22 l / l.m. circulates. heat carrier, and the area of one running meter of the element is equal to 0.064652 m2;

- if the diameter of the pipeline is 2 cm, then in 1 lm. there is 0.45 liters of liquid, and the area is 0.095004 m²;

- with an element diameter of 2.5 cm, 0.71 liters of coolant circulates in each running meter, and the surface area of a segment with a length of 1 m. is 0.121394 m²;

- if the cross-section of the pipeline is 3.2 cm, then the amount of heat carrier per running meter is 0.98 liters, and the area is 0.15218 m2.

Corrugated stainless steel pipe for heating

The corrugated stainless steel pipe for heating began to be used relatively recently, but it has already managed to prove itself perfectly in this area. Due to the fact that the product has the ability to adapt to temperature and pressure drops, it is installed both at the heat supply inputs and directly in heating systems.

A special advantage of the corrugated pipe is that the installation is carried out without the presence of special equipment and tools. In this case, the products are bent at different angles without narrowing the ducts.

When purchasing a corrugated pipe for heating, you should heed some expert advice, in particular, it is recommended to study the markings on the coil label and indicate the scope of application, since it is impossible to apply it to the pipes themselves. If the integrity of the packaging is violated, you must beware of substitution. The real price of a fake corrugated pipe can be an order of magnitude less than the cost of the original.

Corrugated stainless steel pipe for heating

Thus, high-quality corrugated products are distinguished by the following properties:

- the price of heating pipes is slightly higher than the cost of water pipes and is an order of magnitude higher than the price of products for chimneys;

- pipes have a very high degree of flexibility;

- the seams must be even, without visible violations;

- it is difficult to detect defects by visual inspection.

Advantages and disadvantages of corrugated pipes for heating systems

The product has the properties of stainless steel and the flexibility of the corrugation, which facilitates the installation process. The corrugated pipe for heating is suitable for the installation of small sections of highways, for example, for piping to the boiler, radiators. Longer sections will require additional fasteners, which will increase costs, therefore it is not always effective in stand-alone heating systems.

Advantages of stainless steel corrugated pipes:

- You don't have to use additional tools to shape it, the product bends without disturbing the diameter of the inner tunnel. The minimum bending is up to 3 pipe diameters, therefore, with a section of 20 mm, the pipe can be bent up to 60 mm. The indicator differs for each product, it is calculated taking into account the pipe diameter.

- Reduced number of joints. Flexible pipes can be laid out in any shape without the use of joining parts. The property reduces material costs and increases system reliability.

- Products are produced in coils of 50 m, if necessary, you can join the corrugations, lengthening them to the desired value.

- High resistance to corrosion is the main advantage of stainless steel, which is also found in flexible pipes. To minimize the risk of electromechanical corrosion, it is necessary to ground the pipeline, and in the case of an external installation method, use an outer cover or sheath (possibly made of plastic), which will provide protection against aggressive external influences.

- Products tolerate pressure surges, temperature drops in heating. Corrugated stainless steel pipes can be defrosted without loss of performance, and this allows the products to be used in harsh climates.

- Flexible pipes make installation quicker and easier to dismantle the system.

- Brass fittings with sealing silicone or fluoroplastic rings are used for joining with radiators and other elements of the system. Attaching parts requires only an adjustable or open-end wrench - the work is available for novice craftsmen.

- Roughness coefficient 0.008. A low indicator ensures low slagging of the pipeline and the absence of lime, salt deposits on the inner walls.

- Pipes serve for a long time, but much depends on the fittings and the tightness of the joints.

Light weight, sound insulation, relatively low cost and ease of installation in any shape are additional advantages.

But the stainless corrugated pipe has a number of disadvantages:

- low resistance to mechanical damage requires additional protection by a casing or sheath;

- aesthetic unattractiveness;

- the use of detachable fittings requires regular inspection of the system for leaks;

- the need for regular cleaning due to the accumulation of dust in the folds of the corrugation;

- compulsory grounding, the use of dielectric gaskets due to the high electrical conductivity of the material;

- increased heat transfer requires good insulation when laid out in a closed way, but with open installation, the pipe can become an additional source of heating the room.

Advice! To reduce the time required for cleaning the pipe from dust and dirt, it is recommended to use protective boxes. They will also help to increase the thermal efficiency of the pipeline with a hidden installation technique.

Stainless steel gas corrugated pipe

To connect heating boilers, gas stoves, gas-type water heaters to the gas supply system, flexible connections are most often used recently. There are several types of products that differ in size, material and price of corrugated stainless steel pipe. Flexible gas connectors can be manufactured:

- made of elastic material and braided with stainless steel;

- made of stainless steel, and have the form of a bellows.

Experts advise using a flexible hose of minimum length to connect gas appliances, which guarantees reliability and safety. It is better to move the slab as close as possible to the pipe than to use a long corrugation.

Flexible hose for connecting gas appliances

The braid of the corrugated stainless steel gas pipe is marked with a yellow stripe. This is done due to the fact that externally flexible hoses for water and gas are very similar to each other, therefore water pipes are marked in red and blue, and gas - in yellow. An inch stainless steel liner is usually equipped with special fittings, which are fixed with nuts at the connection points, and copper or aluminum washers are used for additional tightness.

The price of a stainless steel pipe for gas is slightly lower than the cost of rubber-fabric analogs, but at the same time it is no less reliable. This feature has influenced the increase in demand for corrugated steel products.

The price of a bellows-type stainless steel pipe for water is higher than the cost of products for gas equipment, which is justified by their reliability. The bellows itself is in the form of a corrugated pipe with fastening nipples at the ends. Connect the bellows line using washers and nuts. The connection can withstand a pressure of 6 atm.

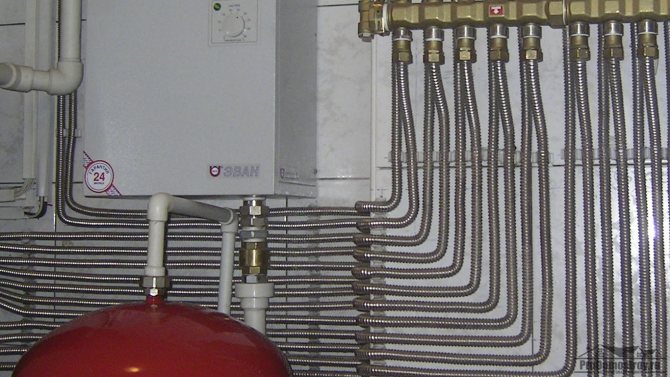

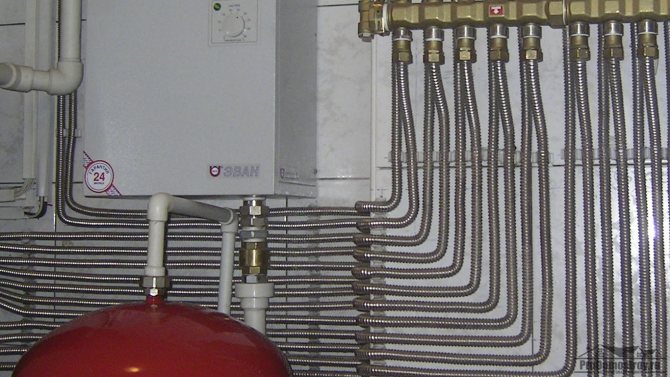

Examples of the use of corrugated stainless pipes in plumbing systems

There is nothing special to add on the installation technology, I will just give a few photos of ready-made systems using a corrugated pipe:

The photo above illustrates well the convenience of a stainless steel corrugated pipe: it was simply stretched behind the sewer riser. It is just as easy to bypass one pipe over another.

Combined system: polypropylene + corrugated stainless steel:

Ideal for using this pipe in confined spaces:

Of course, the advantages of corrugated stainless steel pipe are obvious. The only drawback - and for many people the decisive one - is the rather high price tag. But if money is not an issue, then I recommend that you pay attention and follow installation of internal water supply from it, you will not regret: the corrugated stainless pipe is excellent for both the heating system (including ideal for underfloor heating) and for the water supply system.

corrugated stainless steel pipe for water supply

>

Metal corrugation for ventilation and chimneys

Stainless steel pipes are used as connectors between hoods and ventilation ducts, as well as chimneys. At the same time, the steel product largely outperforms aluminum pipes, although the price of stainless steel and aluminum is almost the same.

Stainless steel exhaust and ventilation pipe

A conventional corrugated stainless steel chimney pipe in diameter ranges from 10 to 15 cm with a compressed length of 60-70 cm. Inside, it is reinforced with a thicker steel wire, which gives it the desired configuration. In expanded form, the pipe can reach three meters. In this case, you can select the required chimney length.

Corrugated stainless steel pipes can withstand temperatures up to 900 ° C, so they can be used in heating systems with various fuels, including coal and wood. It is quite easy to remove combustion products from such pipes. In addition, harmful condensate containing sulfuric acid, which forms inside the chimney, does not have a damaging effect on steel, since it is resistant to chemicals.

Conclusion on the topic

Corrugated stainless steel pipe has a number of advantages. High heat transfer, 40% higher than that of a copper pipe, ease of installation - not all the positive aspects of such systems.A weighty argument in favor of such a corrugation is that it easily tolerates freezing - defrosting cycles.

But, it is worth noting that the cost of such a heating system is higher in comparison with metal-plastic, cross-linked polyethylene. It will be rational to use a stainless steel corrugated hose on certain sections of the pipeline, with increased loads. Or to install a heating system with a short length, local heaters. A convenient option for heating systems for small summer cottages.

Homemade heating radiator from a corrugated pipe

When laying power grids that require an increased degree of fire safety, a corrugation made of stainless steel is irreplaceable. Flexible gas hoses allow you to connect and install gas appliances in such a way that they can be moved.

The technical characteristics of corrugated stainless steel pipe allow it to be used in various fields, as a reliable pipeline.

Related videos:

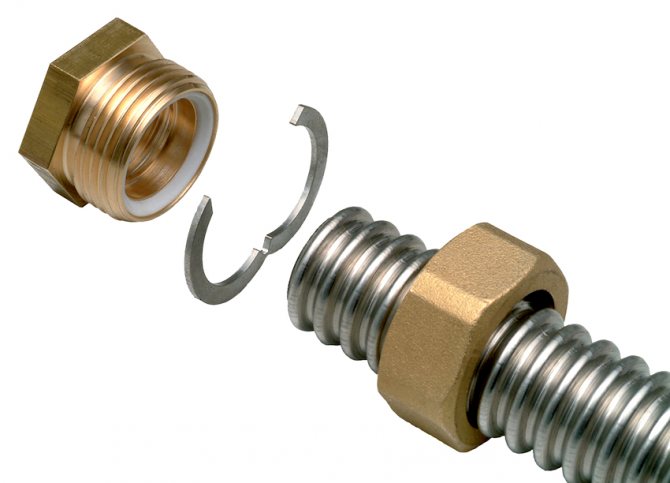

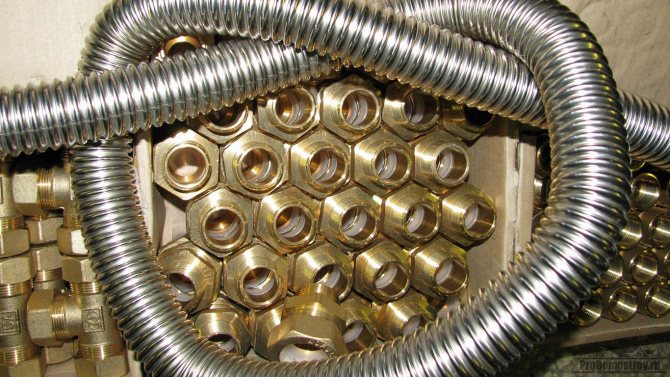

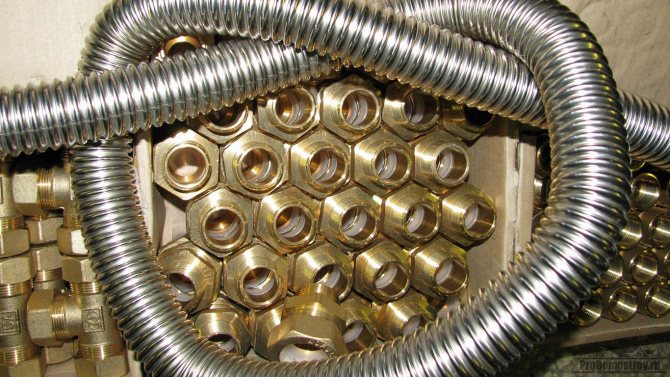

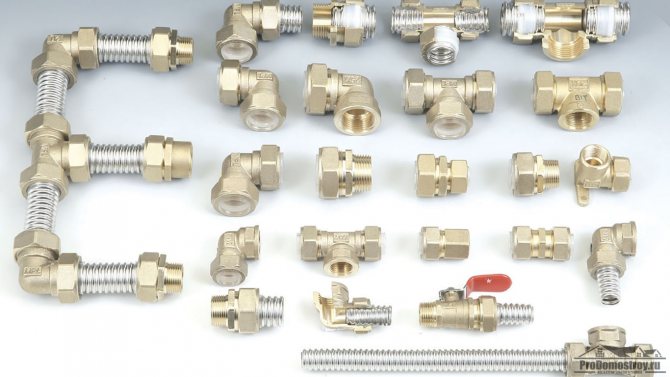

Corrugated Stainless Steel Pipe Fittings

Success in arranging a water supply or heating system using corrugated stainless pipes depends on the tightness of the connections. The smallest leak can not only entail financial costs, but also pose a danger to the health and life of people. To ensure maximum reliability of the connections, special fittings for steel corrugations are used.

Corrugated Stainless Steel Pipe Fittings

Fittings are mounting parts of connecting fittings that perform a number of functions:

- ensure tightness at the joints of the pipeline;

- play the role of adapters between pipes of different diameters;

- change the laying trajectory and improve the existing system;

- regulate the flow of fluid in networks;

- make it possible to increase the length of the system without interrupting its operation;

- allow you to create new branches in any system while it is running.

Corrugated Stainless Pipe Mounting Tools

For cutting corrugated stainless steel, the same pipe cutter is used as for copper pipes:

You can, of course, cut and grind.

Corrugated stainless pipe fittings somewhat more complicated than for metal-plastic or copper:

There are two clamping nuts and there are also sealing washers, but to make such a connection, neither higher education nor any expensive special tool is required - everything is done with ordinary wrenches:

And if we fix the pipe to the wall, then we do it with the help of clips (I hint that walls made of bricks, cinder blocks, concrete, etc. will need to be drilled with a drill or perforator).

It is with such an uncomplicated tool that the entire internal water supply system is assembled from a stainless corrugated pipe.

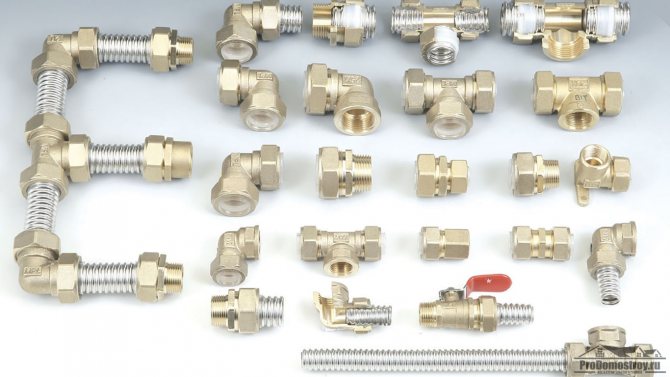

Types of fittings for corrugated stainless pipe

There is a wide range of fittings. They are conventionally divided into two main groups:

- Seamless fittings. These are solid-cast products with a high degree of reliability. When installing them, special equipment should be used, in particular crimping pliers.

- Electrofusion fittings. They are a set of parts that are precisely matched to each other, which allows you to create minimal clearances.

The type of connecting fittings is selected according to the goals set, in accordance with the total cost of the project, taking into account the diameter of the pipes and the installation conditions. The material for the manufacture can be metal or plastic. Metal fittings are more convenient and practical, therefore they are especially popular. For their production, stainless steel and brass are used. Plastic fittings are used at the junction of combined systems, as well as for connection to central highways. For example, they are used to connect corrugated pipes with polypropylene.

Depending on the functions performed, the valves are divided into the following types:

- connecting sleeve - serves for joining straight segments;

- adapter - used for splicing pipes of different diameters;

- pivot angle - helps to change the geometry of the piping system;

- plug - installed in order to cover a part of the system or a certain working circuit;

- tee - allows you to evenly distribute the flow in two directions from the central line;

- cross - used to branch the central fluid flow in several directions.

Corrugated stainless steel pipe installation technology

It should be noted that the installation of corrugated pipes is easy to process. Due to the variety of types of fittings, it is quite possible to assemble any system on your own, without the involvement of specialists. The main thing is to observe the sequence of technological stages and the correctness of the work performed during the installation process, which ultimately will allow you to get a strong, reliable and durable pipe connection.

Directly, the installation technology assumes a clear sequence of certain actions:

- Connecting fittings to pipes and mixers. At this point, make sure that the union nut on the side of the pipeline connection is not tightened.

- Cutting off the required amount of material. This is required to be done using a special tool - a roller pipe cutter. The cut should be neat, without burrs.

- The pipe is inserted into the fitting and the union nut is tightened.

- The pipeline is fixed in the desired position, using for this purpose special fasteners in the form of clips and clamps.

- Checking the health of the system. If a leak is detected, tighten the union nuts a little more.

Installation of corrugated stainless steel pipes for heating

Types of fittings

This type of pipe has not only excellent performance characteristics, but also easy to assemble the pipeline. To do this, it is enough to have a key and fittings, you just need to choose the desired type: a cross, a corner or a tee and start the connection process.

If corrugated stainless steel was chosen for the installation of heating systems, you need to remember a few key nuances. First of all, it is not recommended to abuse the flexibility of this product as repeated bending can lead to cracks or leaks. Therefore, having given the necessary form once, it is undesirable to modify it again.

Pipe to fitting connection

Installation of a corrugated stainless steel pipeline is a way to connect key communication elements using compression fittings.

The main difference is that there is no union in the corrugated fitting (a branch pipe for connecting a pipeline, valves and other parts of liquid and gas transmission and conversion systems). The crimp is done thanks to the internal gasket of the fitting. Before starting the system, it is necessary to conduct a test run and determine if there is a leak at the connection. If the installation work is carried out correctly, corrugated metal will last a long time, remaining strong and wear-resistant.

The installation process can be represented as follows:

- FIRST STEP. Connection of fittings to plumbing fixtures is carried out using gaskets, which should be included in the kit. Next, the nut is checked from the connection side - it should not be tightened.

- SECOND STEP. The pipe is cut with any suitable tool (it is advisable to use a special roller pipe cutter for this). Then you need to check if the edge is smooth or with burrs. If the result is negative, the product is corrected.

- THIRD STEP. The pipe section is inserted into the fitting and the union nut is carefully tightened.

- FOURTH STEP. The pipe is given a suitable configuration, after which it is attached to the wall using special fasteners.

- FIFTH STEP. At the end of the installation process, water is supplied.In this way, it is possible to check the functionality of the pipe under high pressure conditions. In case of leakage, the nuts mentioned above must be tightened. This completes the installation process.

Installation procedure for corrugated stainless pipes

In a similar way, a transition is made from a conventional pipe to a corrugated one. A suitable fitting is attached to the riser or branch, and a corrugated stainless steel is inserted on the other side of it, and then the ring is tightened. You don't even need special adapters here.

It should be remembered when installing corrugated piping that this material is flexible. Fasteners need to be installed more often than when laying the usual shape of the pipeline. Therefore, you should not save on the purchase of clamps - it is better to install them 2 times more often, and the budget overrun will not exceed 350 rubles. with an average length of the heating line.

In this video you can see how easy it is to self-install corrugated stainless pipes:

Tips for the selection and installation of corrugated stainless steel pipes

When buying pipes and accessories for a pipeline system, you should remember that its high-quality installation and long service life depend on a number of factors, which must be taken into account even in the process of purchasing materials. In this regard, the following should be considered:

- When purchasing a product, it must be carefully inspected for mechanical damage and bends.

- The pipe must be strong and bend easily to the desired shape.

- It is better to give preference to proven and well-established brands in the construction market; you should not be seduced by low cost. The average price per meter of high quality stainless pipe ranges from one to three thousand rubles, depending on the type of product and the type of steel used in production.

- During installation, it is necessary to strictly adhere to the algorithm of actions, follow the instructions.

- After installing the system, it is imperative to check it for integrity using the maximum allowable pressure.

- Fittings must be complete.

- When it becomes necessary to connect a stainless corrugated pipe with another material, it is recommended to use brass fittings.

- The use of cheap, poor quality fittings at corrugated pipe joints can lead to a significant reduction in the service life of the system.

- You should not make any special efforts while tightening the plastic elements, as the plastic will simply burst from excessive pressure.

- To organize the installation, it is necessary to prepare in advance special open-end wrenches, as well as metal scissors for cutting pipes at right angles.

Tips for the selection and installation of corrugated stainless steel pipes

Corrugated stainless steel pipes are characterized by practicality and reliability during operation, therefore the popularity of such products is growing rapidly. They are successfully used in various areas of repair and construction: in the arrangement of water supply and heating, as chimneys and connections to gas appliances in the ventilation system. Their installation is quite simple, so if you approach the process responsibly and do not cheapen on materials, you can independently and quickly install a reliable and durable pipeline.

Installation of corrugated pipes for heating systems

A profile pipe is installed for heating using a pipe cutter, keys and a set of fittings - these are tees. You may also need corners, crosses and other elements to securely fix and attach to the elements of the system.

The work algorithm is as follows:

- measure a piece of the desired length;

- cut with a pipe cutter so that the cut is perpendicular to the central axis of the product;

- if the edges of the cut are uneven, they need to be sanded;

- assemble the fitting;

- insert a piece of pipe into the fitting, tighten the nut first by hand, and then tighten it with a wrench until it stops.

The connection of all sections is assembled according to the same principle. And for the transition from a regular pipe to a corrugation, a fitting is fixed to a branch or riser, after which the element is inserted with the other end into a stainless corrugated pipe, the ring is tightened. No adapters are required, it is only important to check the complete set of fittings, to select them exactly according to the section size.

Important! Since the flexible pipe requires a rigid fastening, many fixing parts will have to be used. Material costs increase, but contour strength is maintained.