- Types of sewer pipes and their features

- Connection angle

- Preparing for the process

- We work with plastic pipes: the "in the socket" method

- How to join with an adhesive base or a weld

- How to connect a toilet

- Working with cast iron and ceramic pipes

- We connect a new toilet to a cast iron pipe

Sooner or later, any owner will have to replace the pipes. Since the procedure requires considerable costs, in order to save money, it can be carried out without the involvement of hired workers. But for this you need to know how to connect the sewer pipes.

Since types of pipes made of various materials are used in construction, in order to choose the correct connection method, it is necessary to take into account which of them the product belongs to.

Types of sewer pipes and their features

When installing, you need to take into account all the properties of the selected material in order to correctly choose the method of fastening and calculate your strength.

In modern construction, the following types are most common:

- Metallic. The most commonly used metals are steel or cast iron. The first option has a number of advantages, it is durable and is able to withstand rather high temperatures. Despite this, due to its increased tendency to corrosion, it is used less and less.

But cast iron is not inferior to positions. While being more expensive than steel products, cast iron pipes are undoubtedly better in service. Their ability to resist corrosion combined with their long service life is highly valued. But when assembling, you need to consider:

- installation is very difficult to do with your own hands;

- a large mass creates a lot of difficulties in work;

- the price category makes the purchase costly.

Ceramic pipes for sewerage

- Ceramic. Such materials are used in a wide variety of areas, including sewerage. Such products are mounted according to the same principle as the previous ones, but the lower weight makes it easier to carry out the work.

- Plastic. PVC products are quite versatile, since they have the following properties:

- strength;

- ease of installation work;

- affordable price category.

Products made from propylene have great advantages and increased strength, therefore it is preferable to use them. In addition, at home, the easiest way is to assemble the desired structure using a similar material.

Features of the installation of plastic sewer pipes

Plastic is one of the cheapest materials used to make consumables for sewer equipment. When laying communications in a private house or apartment, the price can become a determining parameter in the choice of pipes.

In addition to being cheap plastic has other advantages:

- light weight, which simplifies the delivery of pipes and fittings and installation of the pipeline;

- the ability to choose the type of plastic and the method of connection, suitable for a particular case;

- the smoothness of the walls and the chemical inertness of the polymers, due to which there are no build-ups on the inner surface and the throughput of the pipeline does not decrease during the operation of the sewage network;

- compatibility with other materials - it is possible not only to assemble the sewer completely from plastic, but also to replace part of the old pipeline with polymers, since there are special connecting elements for combining plastic with pipes made of metal alloys;

However, the installation of a sewer pipeline made of polymer products has its own characteristics:

- plastic is afraid of ultraviolet radiation, so plastic sewers must be hidden from direct sunlight;

- despite the elasticity characteristic of polymers, most pipes cannot be bent; to change direction, it is necessary to use branch fittings;

- Consumables for sewerage are made from polymers with different high-temperature exposure limits: polypropylene (80º), polyethylene (50º) and polyvinyl chloride (40º), the pipe material should be chosen based on the maximum temperature of the wastewater;

- for internal and external sewerage, pipes are made with different strength indicators, which, for convenience, are painted in different colors: gray for in-house or apartment piping, orange for external;

- when laying a deeply buried pipeline in regions with a deep level of soil freezing (more than 2 m), pipes with a corrugated outer surface are used;

- indoors, thin-walled corrugated pipes are used to connect household and plumbing fixtures;

- since for the operation of the sewage network, a slope of 1-3% is required, which allows the wastewater to move by gravity, the sewage system in the apartment is assembled from the riser to the devices, in a private house - from the outlet to the devices, and on the street from the outlet to the collection or discharge point drains;

- the network elements are fixed to the walls with an attachment step of 8-10 pipe diameters in order to prevent sagging and deformation of the pipeline;

- even whole units made of polymer products are lightweight, so it is convenient to assemble large sections of the drainage network and connect them together when assembled.

We recommend that you familiarize yourself with: How to eliminate and prevent blockage of pipes in the bath?

Regardless of the material of the pipes, the connection of the elements of the pipe circuit is always carried out in such a way as to minimize the number of obstacles in the way of wastewater.

Note! Carrying out right angles is not allowed, if you need to turn the pipeline 90 degrees, assemble a node from 30- or 45-degree elbows. The parts of the network themselves are joined so that a thin pipe or branch pipe goes into a wider one, and not vice versa, so that the contents of the drain do not cling to an obstacle, forming a blockage.

Connection angle

Regardless of which option you prefer, some of the preparation steps will remain the same. First of all, keep in mind that it is recommended to lay the sewage system not in one horizontal line, but with a slight angle of inclination. So it will function better, therefore it is necessary that the angle of inclination of the installed system is at least 0.02.

If the amount of available effluents is small, this indicator needs to be increased to 0.03. Basically, this means that for every meter, the difference between the level of the ends should be exactly 3 cm.But make sure not to make a too large angle, otherwise the water will drain, leaving dirt.

Features of the use of plastic pipes for water supply

Plastic pipes are used for laying water supply, sewerage or heating systems. In the modern building materials market, there are a large number of types of plastic pipes for water supply from various materials. They are as follows:

- Polyvinyl chloride. These are products made of thermoplastic material - polyvinyl chloride, with the addition of plasticizers and stabilizers.Polyvinyl chloride is quite fragile and has a low melting point, so products made from this material are not suitable for heating and hot water systems. PVC pipes are mainly used for sewerage systems.

- Polyethylene. Polyethylene pipes for water supply have an extremely low melting point (from 80 ° C), so they should only be used in cold water supply systems. They are quite pliable and soft.

- Polypropylene. They are distinguished by their hardness and strength, they can even be used without reinforcement in the laying of a hot water supply system.

Preparing for the process

Before proceeding directly to the installation, pay attention to some of the nuances that the technology requires:

Sewage pipe

- make sure to purchase a sufficient amount of materials and related products;

- make a plan according to which you will place the sewer system;

- mark up and start cutting;

- the places where the cuts were made should be cleaned in order to facilitate further work, so clean them from burrs.

Get serious about making a plan, mistakes made will be difficult, and sometimes almost impossible to fix. Do not forget that in private construction and in multi-storey buildings, products of 50 or 110 mm Ø are usually used. At the same time, it is worth taking into account how much equipment you intend to connect.

We work with plastic pipes: the "in the socket" method

If you are thinking about how to connect sewer plastic pipes, several methods will come in handy. The process is easy enough due to the properties of the material, but there are many ways to make connections.

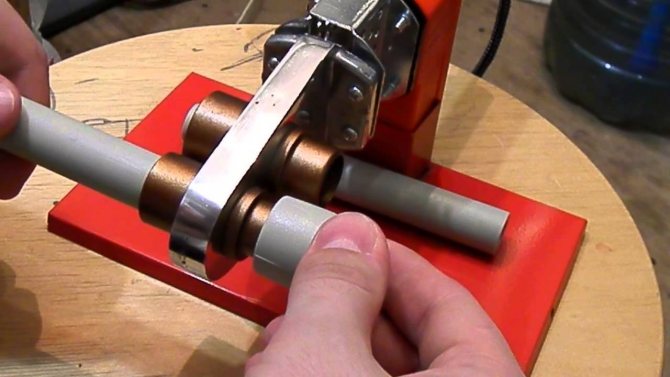

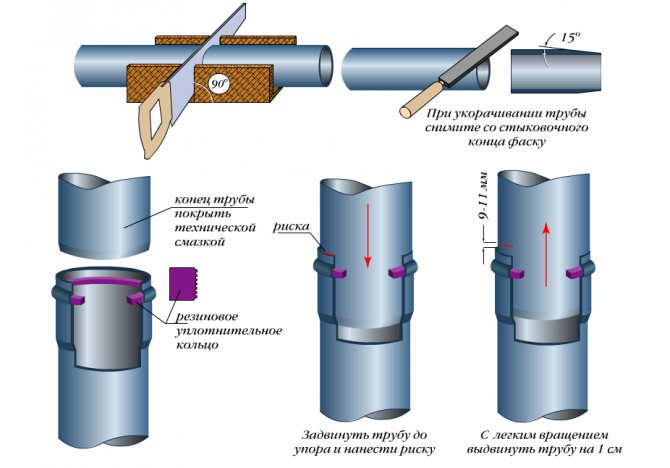

One of them is the flared version. A similar principle is used in children's construction sets. So you can easily assemble almost any equipment. The following instruction will come in handy:

- Clean both the bell end and the spigot end.

- Check for the presence of the seal. This rubber product is designed to ensure tightness.

- Take silicone grease. She needs to spread the smooth part.

- Insert the corresponding part into the socket.

Installation of a plastic pipe for sewage

- Make a mark to mark the injection level.

- Pull the pipe back and slide it out about 1 cm, making sure it goes through the existing seal.

Consider the direction of the future flow, the socket should be located along its course. This method is suitable only for the installation of certain networks, namely gravity.

Pay attention that there are no defects on the surfaces. Sometimes products have deep, large scratches that need to be carefully sanded down with a knife. If you are making a connection to a fitting, there is a possibility that it will have large solder seams. They also need to be removed, otherwise the connection will definitely be loose.

Sometimes the hot method is used. For example, there is no socket on your material, and you need to make a connection. In such a case, you can use a soldering machine and warm up the desired area by gently twisting it. Then connect the pipes in a smooth motion. Sometimes a construction hair dryer is also used. True, this method should not be used when you are mounting the system horizontally.

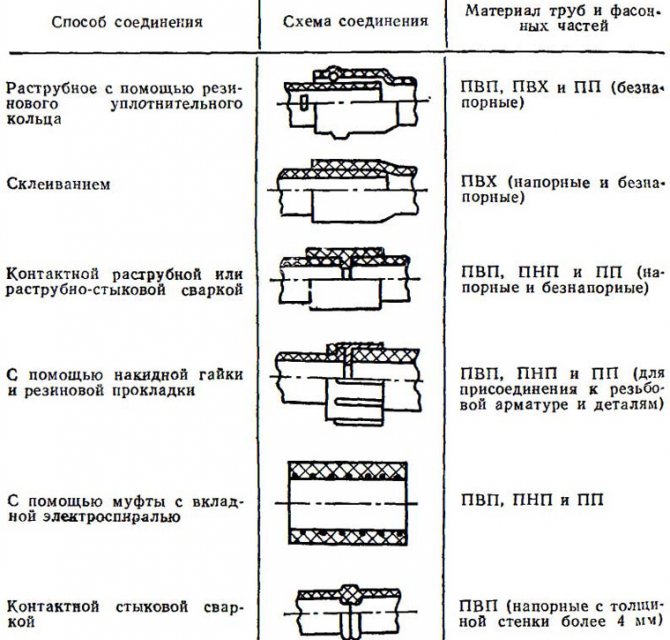

Various types of connections

There are different ways to combine metal with plastic. They have different installation complexity and installation technology.

Threaded type

This type of connection can be used if the elements to be connected have a cross section of up to forty millimeters. Pipes are joined using special parts. There is a metal material thread on one end of the fixture. With the help of it, a steel pipe is connected.The second end of the part made of plastic material is used to connect plastic pipes using a union nut, or the soldering method.

The following types of connecting devices are distinguished:

- 1. With the help of an American woman.

It is considered the most popular method. It is a special part that has a metal end, equipped with a thread on the outside, or inside the case, also from a polymer pipe.

When connecting pipe-rolling made of metal with an American, the winding method is used. The union nut is screwed on with a thread, the plastic part is welded to the second end with a soldering iron. To ensure tightness, rubber gaskets are installed.

The pluses of this design include separability. If necessary, pipe rolling is very easy to disconnect. When unscrewing a metal part, you must try not to spoil the rubber seal.

- 2. by means of a fitting-nipple.

The device includes a polymer sleeve having a soldered metal plate inside, equipped with a thread. A fitting - a nipple with one end is screwed onto the thread outside the metal pipe roll, on the other hand, it is soldered to the plastic pipe roll.

Attention! To seal the joints, it is recommended to use fum tape.

- 3. by means of a metal hose.

The part consists of a flexible hose with sealing collars with union nuts. Its diameter can vary. This docking method is not considered popular. It is used when connecting parts located far from each other. The metal product is mounted on one end of the metal hose, when attaching the plastic product, a fitting - nipple should be used.

Attention! When choosing a fitting-nipple and a sleeve, pay attention to the parameters of the thread.

Flange type

If the pipes to be connected have a cross section of more than forty millimeters, flanges should be used. The connecting parts must be made of plastic, have additional bushings equipped with collars, bumpers to restrict. If there is a flange on a pipe made of metal material, choose a plastic one that matches the size.

Pipes are inserted into the sleeve with collars for joining, with flanges they must abut against the collar. For tightness, rubber, paronite seals should be used. The collar can be made straight, conical in shape. Flanges are attached to bolts, studs. Fasteners are tightened crosswise, without additional effort.

Fitting

The use of Gebo fittings for joining parts is becoming popular. The part shows a ferrule-like ferrule. The fitting includes rings: compression, clamping, sealing, union nut. The rings come in pairs, they are placed on both ends of the coupling.

Attention! This type is used when it is impossible to thread a metal product.

How to connect the parts:

1.Unscrew the fitting.

2.The clamping rings are put on the pipes for connection.

3. A coupling is attached to the pipe, which is tightened with a union nut.

4. Another pipe is prepared as well.

Attention! The connection guarantees one hundred percent tightness, however, it is not recommended to overload the fitting.

Threadless type

This connection assumes a connection method without thread and welding, the use of a crimp-type coupling. The clutch consists of elements:

1.from the body made of cast iron, high strength steel.

2.two nuts, made of either bronze or brass, they are on both ends of the body.

3.Four metal washers inside the case.

4.Rubber gaskets for tightness.

Pipe rolls of different materials should be inserted into the coupling until they touch each other. Then you need to tighten the nuts tightly.

Another threadless method is a connection using a metal hose. The hose is put on the ends of the pipes for connection, it is crimped with clamps.

Attention! There are rubber bushings commercially available that operate on the same principle.

Sometimes the following connection method is used, which does not use fittings. A special iron is used to heat the plastic pipe; heated pipe rolling is screwed onto the metal thread. The plastic cools down to form a single piece.

Attention! The method is not considered reliable, it is not recommended to use it for laying communications in the house.

How to join with an adhesive base or a weld

It is easy to make such an installation if you use the glue intended for this. Clean the surfaces to be connected in the same way, not forgetting to degrease. After that, apply glue, connect the pipes and hold for about 1 minute. This period of time will be enough for the glue used to set.

In conclusion, achieve complete tightness by applying an additional layer of glue for this purpose so that it covers your joint and forms a small bead on it.

Connection of plastic pipes

The weld seam method is often used. If you are in doubt about how to connect PVC sewer pipes, but at the same time you have an apparatus that allows you to carry out welding work on a material such as plastic, the following method will come in handy:

- heat the ends until you notice that the ends are gradually melting (this usually takes a few seconds);

- press the ends and fix them in the desired position until the plastic is sufficiently cooled and set.

You will get the strongest connection, which, if done correctly, will be monolithic.

It should be noted that the purchase or rental of such a device is justified when you are constantly doing such work. In the case when you have to carry out only installation in your own apartment, it is better to give preference to fittings. Do not forget to also use rubber gaskets, and optionally silicone.

Connecting plastic water pipes: types of pipes and connection methods

To create your own water supply system in an apartment or private house, the formation of a pipeline is required. Connecting plastic pipes with your own hands is not difficult and is available to novice craftsmen.

How to connect plastic pipes

Polymer products for the domestic plumbing system are joined in several ways. The following criteria should be followed in determining the appropriate installation method:

- The purpose of the pipeline. For water supply, it is recommended to use welding, sewage is created using sockets, heating is formed using couplings of the appropriate size.

- The material of the elements to be installed. The design of most polyvinyl chloride pipes is supplemented with special sockets, polyethylene lines are connected by compression couplings, mechanical soldering irons are used to assemble polypropylene products.

- The scale of the work carried out. For small volumes, limited by the boundaries of an apartment or your own house, it is allowed to perform the required activities yourself. Welding of large objects requires the involvement of specialized teams.

Threaded fasteners for connecting polymer elements are not used due to the inability to ensure the tightness of the pipeline. Mounting technologies using sockets, couplings and welding are popular.

Connection of polymer pipes with couplings

The assembly of fragments of the water supply system with compression fittings prevents the formation of blockages, ensuring tightness.

To clamp the ends of adjacent elements, cone-shaped nuts and O-rings are provided to withstand the fluid pressure in heating circuits, sewers and plumbing systems.

Rigid fastening to the body of the one-piece pipe is provided by special compression couplings.

It is allowed to use a threaded connection of polyethylene products. A prerequisite is the flaring of the extreme surfaces of the parts to be mounted, which completes the process of putting on the nuts.

Tees, saddles, flanges and valves are used as fittings.

Welding polymer pipes

The method is used to assemble a water supply system from polypropylene elements. Half of all household utilities are created with a welding machine that acts on the molecular structure of materials, providing improved performance for the joints. The consumer's instruction contains an indication of the heating time, determined by the wall thickness.

For pipes of 50-16 mm, small hand-held soldering irons are used. Large-sized products of large cross-sections require the involvement of professional welding machines.

The technology of the method consists in heating the edge surfaces of the fragments to be joined with special removable sleeves. The melted ends butt together, pressing firmly with strong pressure.

Electrofusion welding is considered an improved option. The heating process is controlled by an electronic program. The quality of the connection improves, there is no need for fastening. The heating elements connected inside the fixing device are supplied with voltage through the electrodes of special devices.

Special connection methods

For pipes made of cross-linked polyethylene, a separate installation method has been developed, based on the use of specific fasteners.

Docking of polymer products with push fittings is used in complicated situations, at the intersection with a metal highway, when assembling elements of different sections. Installation activities require a minimum set of tools.

A calibrator and a knife are enough to create an effective connection.

https://www.youtube.com/watch?v=ooY-UcQuIbU

The fixing flange is made of brass and PVC. The sphere of use is the formation of water supply systems and heating circuits. To increase the tightness, rubber rings are provided.

After assembling the product, the pipe inserted all the way into the push-fitting body cannot be dismantled.

The water, included at the end of the docking procedure, pushes and grips the wedge of the fastener, preventing the likelihood of leaks.

The advantages of the method include the absence of the need to use a large number of tools and the high speed of installation work.

Technology selection rules

When determining the optimal assembly option, it is necessary to be guided by the operational characteristics of the system and material.

For the installation of a water supply line made of PVC pipes with a diameter exceeding 6.3 cm, it is customary to use compression couplings. If you find it difficult to purchase fittings of suitable sizes, experts recommend using butt welding. The advantage of the method is the absence of the need to purchase additional parts.

Socket technology has become widespread when self-joining PVC structures of the same diameter. The correct location and giving the correct direction of the pipe line is achieved using scrap iron. Inventive craftsmen use a jack.

For the assembly of non-pressure polyethylene systems, gluing is allowed. Mechanical thread for mounting such products is recommended in special situations.

Methods for connecting polymer pipelines

Choosing the technology for joining plastic pipes, they are guided by the purpose of the line, the type of polymer material and the geometric characteristics of the product.

The following methods were spread:

- Bell-shaped scheme. It is recognized as the best option for sewage with an arbitrarily moving liquid medium.

- Gluing. It is divided into two categories: using standard adhesive and "cold welding". The latter changes the molecular structure of the polymer, melting the top layer of the material with a special composition. It is used for all types of pipelines, with the exception of the heating circuit.

- Threaded fixation. It is considered a suitable method for assembling composite structures that combine plastic and metal products.

- Diffuse welding. An alternative name for the technology is high-temperature compound. It is carried out by joining parts preheated in a specific device.

- Flange mount. It is the best option for combining plastic with metal. Provides for the use of special welded sleeves for flanges or removable metal elements.

- Collet design. The use of a compression fitting with a gasket made of rubber material provides a good fit. The installation process is accompanied by the adhesion of the teeth of the metal tube with the polymer, creating a reliable fastening.

- Electrofusion welding. Requires preliminary preparation of the collected fragments. The cleaned and degreased parts are connected with a special fitting with the electrodes placed inside. Under the influence of voltage, the plastic heats up, the pipes are joined. It is not recommended to use this technology for the formation of heating systems due to the insufficient strength of the prefabricated structure.

To create a polymer pipeline, it is allowed to use various methods both with the participation of a welding machine and without soldering. The equipment is capable of providing effective adhesion of plastic elements. Bonding parts without heating, in a cold way, simplifies the process of installation work.

Joint without welding for various types of plastic pipes

The choice of a suitable technology for assembling polymer main systems for plumbing in a residential area is determined by the characteristics of the material.

In construction, the following methods are used for joining plastic products without a soldering iron:

- The main purpose of compression fittings is to form a single structure with pipeline elements made of polyethylene. Experts note the advantages of the method, expressed by the minimum set of installation tools, limited by a crimp wrench. The disadvantages include the labor required to process each individual joint.

- Coupling of pipes made of polypropylene is carried out by socket welding performed with a specific device. For tapping into the metal part of the plumbing system, threaded couplings are used. Detachable flange connections with union or welded elements are involved in the formation of the overall lines.

- The assembly of metal-plastic pipe products is carried out with push-, press- and crimp fittings. The first variety has gained popularity due to its ease of installation and a minimal set of tools.

- Docking of PVC pipes is carried out using special sockets provided by the design. It is allowed to use an adhesive connection.

- For the formation of water mains from cross-linked polyethylene, coupling technology is used. Flanged clutch is carried out by metal caps or adapter sleeves. It is possible to assemble with compression fittings.

Connection of pipes with a coupling.

Docking of polymer and cast iron pipes is made with special adapters of various sizes. This technology is used to repair sewage.

When plastic products are combined with metal ones in plumbing systems, the corresponding couplings provide increased structural reliability. There is a thread on one side of the mounting element, the other is equipped with a connecting fitting. The increased pressure in the line requires careful sealing, performed by linseed fibers impregnated with linseed oil.

To repair a pipeline with a cross-section of more than 40 mm, it is recommended to use flange technology. Acquiring adapters of the required size is straightforward.

When combining various materials in high-pressure water supply systems, it is advisable to use a metal sleeve. The fastening of the mounting element to the plastic part is carried out with a suitable fitting. A threaded thread is designed for adhesion to a metal pipe.

Practical advice

Polymer products are widespread in the arrangement of engineering networks, finally displacing steel and cast-iron structures. The main advantage of the innovative material is the simplified assembly process.

The plastic pipes used for the installation of domestic water supply systems are lightweight. Resistance to corrosion and resistance to aggressive effects of chemicals provides a warranty period of 25 years.

What materials are plastic pipes made from?

The characteristics of the materials influence the choice of installation technology.

Domestic water mains are made from the following polymers:

- cross-linked polyethylene;

- metal-plastic;

- polyvinyl chloride;

- polypropylene.

The assembly method is determined by the characteristics of each of the varieties.

Polypropylene pipes.

How to connect PVC pipes

The socket technology is based on the gluing method and is carried out as follows:

- for better adhesion, the outer end of one pipe and the inside of the socket are treated with another emery paper, ensuring the roughness of the surfaces;

- degreased edges;

- an adhesive is applied;

- at maximum speed, the product is fully inserted into the coupling, scrolled by ¼ of a turn;

- the elements to be fastened are tightly pressed against each other for 60 seconds.

Correct installation is evidenced by a strip of glue protruding at the junction.

Reinforced-plastic lines are formed using fittings - auxiliary parts that hold polymer products together.

The following types of plastic connectors are used:

- crimp, characterized by simplified assembly;

- push-elements, characterized by high speed and ease of installation, with the exception of probable errors during installation, anti-corrosion qualities, efficiency of seals, the possibility of replacing individual parts;

- press fittings that form connections of increased reliability.

How to connect polypropylene pipes

There are 2 assembly options for this type of polymer products:

- compression fittings;

- welding method.

Welding is done in two ways. For the first case, a socket connection is used using a special coupling. In the second, the ends of the pipes, heated with a soldering iron, are attached end-to-end.

How to connect XLPE pipes

The process consists in performing the following actions in turn:

- a 5 cm area is cut off from the tubular product with a special tool;

- from the side of the connected fitting, a mounting sleeve is put on through the inner groove;

- flaring is performed manually or hydraulically;

- a coupling is inserted into the pipe, the crimping procedure takes 3-4 minutes;

- the tool is applied to the joint area with the utmost accuracy to prevent distortions;

- a sleeve is pushed onto the fitting until it stops;

- a similar process is repeated for the other end.

Universal joint for flexible and rigid plastic pipes

If it is difficult to determine the type of polymer material, the assembly technology is selected depending on the flexibility.

For rigid pipes, it is recommended to combine a coupling with an adhesive joint.

Flexible lines are formed as follows: the strict part of a special hose fitting is inserted into the plastic product, and a special worm clamp is clamped at a distance of 18-20 mm from the end.

Source: https://VodaSovet.ru/vodoprovod/soedinenie-plastikovyh-trub

How to connect a toilet

During the installation of PVC pipes, difficulties often arise when it becomes necessary to connect the toilet. In fact, you can do it yourself without the help of a pro.

First of all, the location of the drain should be noted. In the case when you are making a replacement, it is preferable to choose the same type of plumbing, but there is no guarantee that you will be able to easily get into the drain pipe. A cuff will help to cope with the problem: corrugated or eccentric. It is very simple to make the connection, since the cuff is essentially 2 nozzles with centers that are offset relative to each other.

Working with cast iron and ceramic pipes

Since the methods of working with these types of pipes are not very different, it is reasonable to study them together.

It is not as easy to carry out such work as in the previous case, but sometimes it is preferable to opt for this material. For example, if you do not plan to completely replace the system, it is not always possible to connect a PVC product to old pipes made of metal.

Such pipes are also equipped with sockets, so they are simply inserted into each other. The junction is loose, and the gaps should be eliminated using ordinary tow. After that, you should use any waterproofing agent: silicone sealant, mastic or cement.

Most often, it is cement that is used, due to its cheapness. It is preferable to take a building material marked 400. To prevent cracking at the joint, you need to wet a rag and tie it over your joint, and then moisten. Since the cement, when drying, absorbs liquid, a similar procedure is necessary.

The nuances of connecting a metal pipe with a plastic

When joining parts made of different materials, the sequence must be followed. Installation instructions:

1. it is necessary to decide on the connection method.

2. measure the diameter of the pipes outside and inside.

3.Purchase fittings so that the threads converge.

4. mark the pipeline.

5.Cut the end of the plastic pipe, clean the edge of the metal pipe. If required, a new thread is applied and the old one is cut off.

6.Put a spacer on the metal end.

7. Screw a flange or fitting to the end.

8. when using a flange, move it closer to the seal, connecting it to the second flange using studs or bolts.

9. When using the threaded method, a metal pipe is cleaned of the top layer by applying a sealing material in the form of a fum tape, a gasket. Next, screw the fitting with your hands, insert a plastic pipe into the other end. If required, you can weld on the pipe.

10. you should check the quality of the connection.

We connect a new toilet to a cast iron pipe

All details of the process will depend on how the drains are displayed:

- Vertical release. Installation is elementary, the main difficulties are in choosing a toilet model suitable for your conditions. The connection must be carefully sealed to prevent the spread of odor. For this purpose, it is optimal to use a rubber cuff.

- Horizontal release.For the most part, a similar design is found in imported toilet bowls. It is most appropriate to purchase these models in case of complete replacement of systems or their installation "from scratch". The connection is not difficult - you only need a corrugated hose.

- Oblique release

In this case, the outlet pipe of the toilet to be connected is connected to the inlet pipe. Pay particular attention to sealing and sealing.

Having carefully studied the nuances, you will learn how to properly connect sewer pipes made of various materials. Since their installation will not be difficult, even not the most experienced home craftsman will master it, which will significantly reduce the upcoming costs.

How to connect plastic pipes

After the completion of the preparatory work, they begin to install the pipeline.

There are two ways how to connect sewer plastic pipes:

- detachable (flanged and coupling);

- one-piece (connection by welding, "in the socket", glued version, using fittings).

Flange connection

... In this case, the installation of sewer pipes is carried out using cast iron fasteners and a rubber gasket. It is necessary to cut the edges of the pipes exactly at the junction and put on a free flange, insert a rubber gasket and put the flange on it again. Then everything is fixed with bolts.