Arrangement of a country house in the absence of communal plumbing and sewerage systems is a daunting task for any homeowner. In addition to providing residents with drinking water, it is necessary to solve the problem of draining gray water and sewage, while not forgetting about the insulation of the sewer pipes of the external sewage system.

This problem is solved in various ways; in order to choose the appropriate option, it is useful to know how the pipes of the external sewage system are insulated in the ground and to study this technology. This will allow for correct and long-term insulation of the sewage system with minimal time and financial losses.

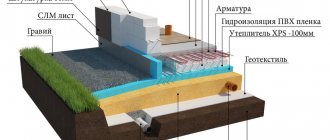

Fig. 1 Sewerage of a private house - device

Is it necessary to insulate the sewer and problems with freezing pipes

When draining sewer and gray waters of a private house at subzero temperatures of the external environment, they can freeze, and this will cause the following unpleasant consequences:

- Frozen water will impede drainage from the home, thus creating significant difficulties for private living in the winter.

- Also, when defrosting, water expands, which causes damage to pipelines and clogging of the ground with sewage, which worsen the ecological situation.

- Ice plugs that prevent the outflow of contaminated water will cause it to stagnate in the drainage system - as a result, unpleasant odors will appear in the home, interfering with comfortable living.

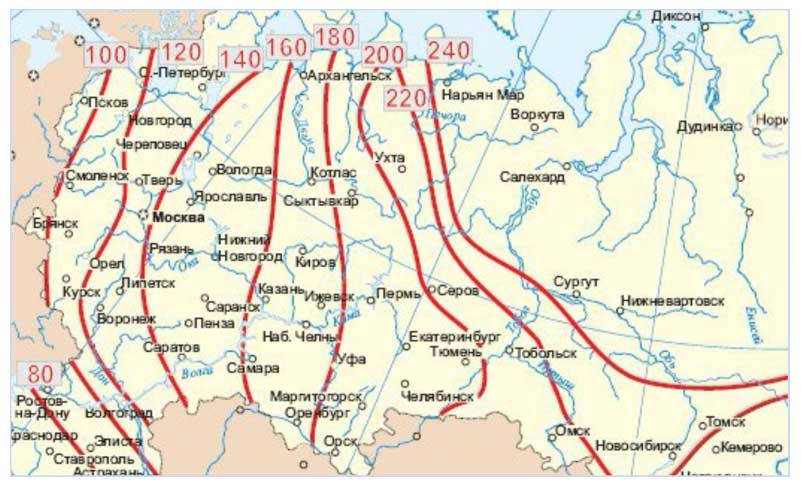

Fig. 2 Map of the level of soil freezing - an example

Insulation of sewer pipes of an external sewage system - generally accepted methods

When deciding how to insulate the sewer in a private house, they consider a number of methods, the main ones are:

- Deepening in the ground. To implement this method, a prerequisite is placing the pipe on the street in a trench below the maximum freezing point for a given area.

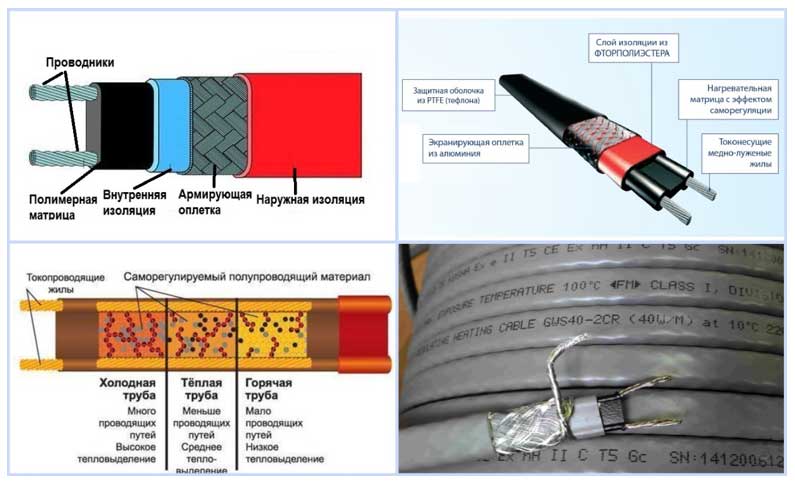

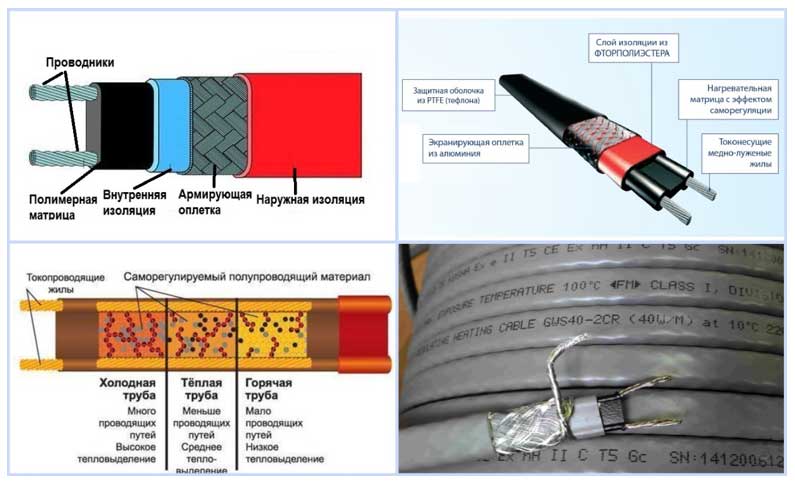

- Using an electric cable. This technology of external sewage insulation is easily implemented thanks to the manufacturer, who produces reliable moisture-resistant electric heating cables that are placed inside the pipeline or special slots in the pipes.

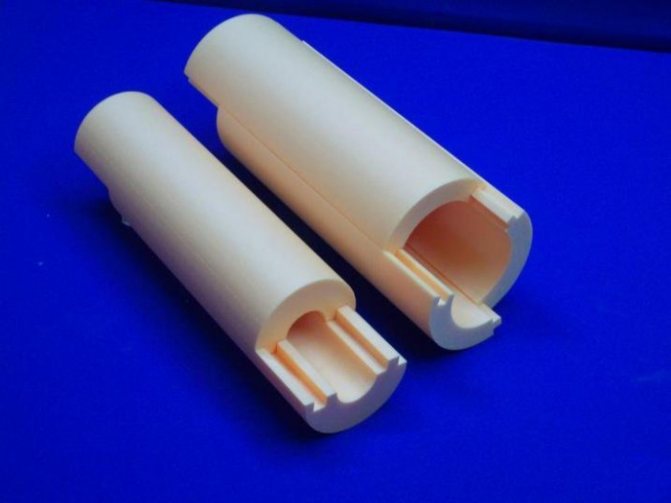

- The use of heaters. This method of thermal insulation can be quite simply implemented thanks to the manufactured casings made of various types of insulation with a diameter suitable for sewerage insulation.

- Combined methods. An excellent solution to thermal insulation of sewer pipelines is the use of additional insulation by placing them in a sheath of insulation at an average depth in the ground. Another common option is to place the heating electric cable in a sheath of insulation, while the sewer main is at a short distance from the earth's surface.

Fig. 3 Installation of pipes in a trench

Warming options

How to insulate the sewer in a country house with your own hands?

The best option is to deepen the pipes into the ground below the freezing level, but in many areas the soil freezing depth is more than a meter. Competent insulation of sewer pipes will allow you not to dig deep trenches in the ground.

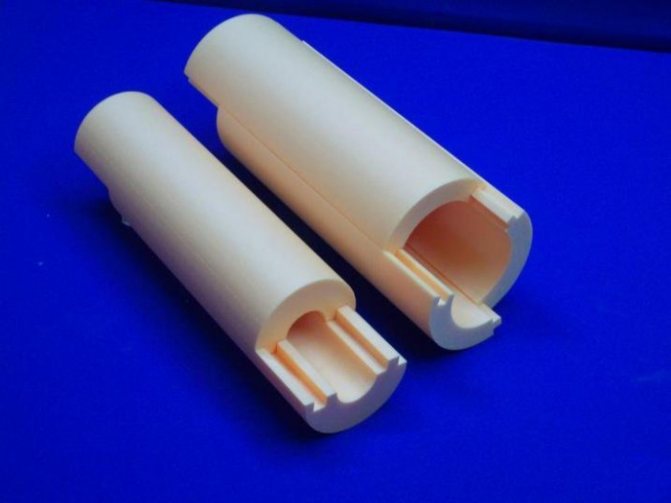

Most often, home owners insulate pipelines with special materials. The insulation is simply put on the pipe. Materials specially designed for thermal insulation can be purchased. You buy a casing of the required diameter, put it on the pipe and get a guarantee that it will not freeze in winter.

There are many materials for insulating sewers, but the following are most common:

- expanded polystyrene;

- Styrofoam;

- extruded polystyrene foam;

- polyurethane foam;

- basalt;

- glass wool;

- mineral wool.

Expanded polystyrene

The production is based on suspension polystyrene. As a result, a foam material is obtained, characterized by high rigidity and consisting of granules fused together.

Styrofoam

Includes moisture resistant granules. Their size ranges from 1 to 5 mm. The granules are sintered to each other due to exposure to elevated temperatures. The insulation is not damaged during physical exertion and retains its characteristics even under a thick layer of soil.

Extruded polystyrene foam

An excellent choice for pipelines operating in conditions with high loads and humidity. The structure is a closed cell.

Polyurethane foam

The main advantages are lightness and strength. It is used as a heat insulator in the arrangement of domestic and industrial sewage systems.

Basalt

The insulation consists of a special basalt fiber. In turn, it is stitched with glass lines, also made of basalt.

Glass wool

Has a good density. Mainly suitable for metal-plastic products. Additional external insulators are required.

Minvata

The material can be purchased as slabs or rolls. The insulation has a low heat transfer, it is easy to fit, but just like glass wool it needs insulation.

Warming with the help of soil when laying the pipeline below the freezing depth

Insulation of sewer pipes in the ground by this method is the most affordable process, because in areas with a temperate climate, the depth of soil freezing is about 1.5 meters. When determining the depth, you can be guided by special maps of freezing of the earth for different regions, laying the pipeline below the freezing depth has the following features:

- When installing the pipeline in the middle lane or northern latitudes, a large amount of excavation will be required - this will lead to high financial costs.

- The volume of land sampling and costs will increase even more if the distance of the sewer main from the house is too large, because there is 110 mm along the entire route. the pipeline must provide a minimum technical slope of 20 mm. per running meter. Compliance with this condition leads to the fact that at a 50-meter distance, the height difference can reach one meter - therefore, the lowest point will be at a depth of 2.5 meters.

- The deep burial of the pipeline makes it difficult to carry out repair work in the event of damage.

Fig. 4 Thermal insulation of the sewer with a heating cable - type of wire

Trench device

One of the most used methods is to insulate sewer pipes in the ground by immersion below the freezing level of the soil. The information is in the geological or meteorological services. Or from neighbors on the site.

Stages:

- The place of the future trench is marked (pegs, ribbons).

- Earthworks are carried out independently or a team of specialists is hired.

- Be sure to observe the angle of inclination Violation will lead to congestion at any time of the year.

- The collector is placed on a sand and gravel pad. This mixture forms a backfill layer up to 30–40 cm thick.

- The excavated soil is returned.

IMPORTANT! In no case should the earth be tamped, there is a risk of damage to the plastic product.

The options are:

OPTION 1. In the trench, apply foam insulation to the collector. The device is carried out over the main line of a kind of overlap made of lightweight insulation.

OPTION 2.Insulate pipes with mineral wool.

NOTE. These heaters must be subjected to additional waterproofing. When wet, a significant part of the thermal insulation properties is lost due to the good heat transfer of the liquid.

OPTION 3. Insulate the sewer pipe with penofol. The latter is a closed-cell polymer structure covered with aluminum foil on one or both sides.

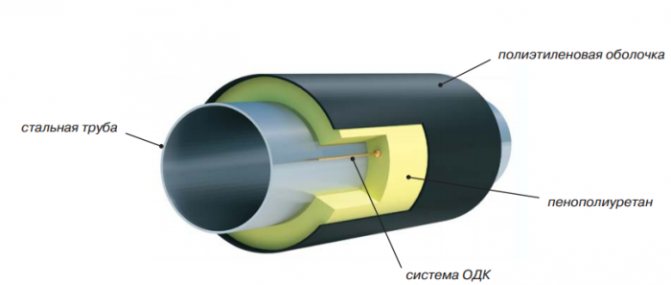

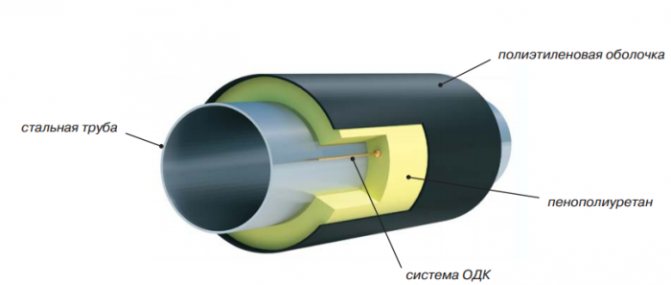

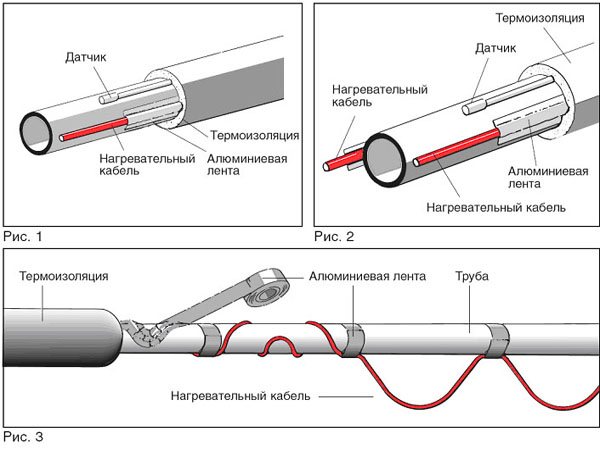

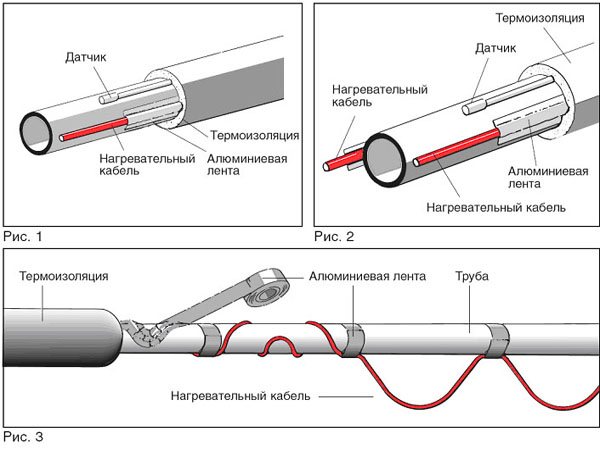

Heating of external sewerage using a cable

When deciding how to insulate sewer pipes in a private house, many choose a heating cable. During installation, it is placed along or wrapped around the pipeline, if strong heating is required, a common option is to place the heating wire inside the line. The use of electric heating has the following features:

- The electric cable is quite expensive, the price of one running meter is about 15 USD.

- With electric heating, it is possible to place the sewer mains in the ground not too deeply, the usual depth of its occurrence is no more than 0.5 meters and can be reduced by using a powerful electric cable with a small winding pitch.

- The heating wire can be placed in pipe channels specially made for laying it or attached to a plastic pipeline with foil adhesive tape with your own hands.

Sewer insulation

Thermal insulation of sewer pipes is carried out using the following methods:

- The deepening of the sewer system below the level of soil freezing. At a given depth, the temperature of the soil becomes equivalent throughout the year. 10-12 ° С, which are observed at a depth, do not allow the nets to freeze. But this option also has its drawbacks. First, trenches are dug to a depth of 1.5-3 meters, which is a laborious process. Secondly, in case of damage to the network (blockage, breakthrough, etc.), you will have to break the trench again. Most often, this method is practiced in the construction of sewerage in apartment buildings, as well as in the installation of a water supply system in the ground;

- Insulation of sewer pipes with materials with low heat transfer. It is more often used in cases where sewer pipes are laid above or on the surface of the ground, or laid in the ground at a shallow depth. The pipeline should be laid with a slight slope towards the storage tank (about 1.5-2.0 cm per 1 running meter of pipe). This will avoid stagnation and the formation of sewage jams;

- Heating with an electric cable. The electrical cable is installed along the pipes, outside or inside. It is recommended to mount it from the outside, which prevents damage to the shell.

Important! Insulation does not heat the pipes of the external sewage system, but only slows down their cooling. Without constant drainage or heating, the system will still cool down to temperatures below 0. As a result, wastewater discharged in small portions will form ice build-ups. Therefore, in case of rare operation of the sewage system, it is recommended to locate the networks below the level of soil freezing, or additionally provide for the installation of a heating cable.

How to insulate sewer pipes in a private house? Which protection option should you choose? Thermal insulation with the help of a heater has become widespread among the owners of private houses. The pipes are located at a depth of 0.5-1.0 meters and are lined with heat-saving material. Combined methods are often used, which gives more reliable protection.

Warming by means of heat-insulating materials

When determining how to insulate a sewer pipe on the street, insulation is often chosen with the help of insulation materials widely used in the construction industry. Usually, for ease of installation, they have a cylindrical shell with an inner diameter corresponding to the standard size of the sewer pipe.

Glass wool

The main heat insulator is long glass threads, which are obtained from broken glass by heating to 40 ° C and blowing from a centrifuge - this significantly reduces the cost of the manufacturing process.

Fig. 6 Glass wool insulation for sewer pipes

Fibers 3 - 15 microns thick. are suspended in an air environment, therefore the material has a low density and high resistance to vibration; in addition, glass wool has the following useful properties:

- The material is non-flammable, has high thermal stability and can withstand temperature ranges from -400 to +700 C.

- Its thermal conductivity ranges from 0.045 to 0.065 W / m * C, which is a rather low indicator, second only to some polymer materials.

- Glass wool permeates steam and is not afraid of moisture, resistant to a large number of aggressive chemicals and biological effects.

- The material is environmentally friendly and harmless to human health.

The disadvantages of glass wool as a heater include its low density, tendency to shrinkage and inconvenience of installation.

Glass wool is produced in rolls and slabs; foil-clad cylindrical shells with a corresponding inner diameter are most suitable for insulating sewers.

When installed under a layer of earth, glass wool will be compressed and can absorb moisture - this significantly reduces its heat-insulating properties and limits its use as a heat insulator for a sewer line.

Fig. 7 Thermal insulation of sewer pipes in the ground with mineral wool

Mineral wool

Mineral wool is produced in two types - slag wool and basalt. The first has a low density and high water absorption, it is not recommended to use it on metal surfaces and in living quarters - due to these properties, it has very limited use.

Basalt mineral wool, which is produced by melting basalt and forming a thin fiber from it, rightfully occupies a leading position among heaters, having the following useful properties:

- Low thermal conductivity 0.04 W / m. * C. promotes the widespread use of the material in the construction industry for insulating various types of surfaces and pipelines.

- The material is non-flammable, resistant to many chemicals and temperature extremes, and is environmentally friendly.

- Cotton wool is resistant to moisture, but can saturate it, therefore it is recommended to use it in a dry environment.

- Unlike glass wool, basalt wool has a higher density, making it easier to install and more efficiently used in conditions of pressure on the surface.

Insulation materials

Insulation for sewer pipes must have the following properties:

- Waterproof;

- Flame retardant;

- Durability;

- Ease of installation.

It is also recommended to choose such heaters for sewer pipes that will be resistant to chemical and biological influences, will not collapse under the influence of moisture. The cost of the material is also important.

Most often, the following heat-insulating materials are used for sewage insulation:

- Expanded polystyrene. The special structure allows you to maintain the required temperature for a long time. A shell is made of expanded polystyrene, which is easy to assemble and provides good thermal insulation. The insulation can be reused to protect the sewer;

- Styrofoam. It is a type of expanded polystyrene. It also provides excellent thermal insulation, water resistance, which guarantees a long service life;

- Basalt fiber. Rolled thermal insulation material, which is obtained from special fibers. Differs in durability, reliability, ease of installation.But he has a significant drawback, which often plays a major role in the choice of insulation - this is a high price;

- Mineral wool. The main advantage of the material is its low price with fairly good thermal insulation performance. However, when choosing mineral wool, you must remember how to insulate the sewer correctly. It is imperative to provide waterproofing, since the material loses its original properties under the influence of moisture. And then the sewer pipes can easily freeze;

- Foamed polyethylene. It differs in small thickness, but at the same time it retains heat perfectly. However, for regions with cold winters, pipes must be wrapped with foamed polyethylene in 2-3 layers. The material is water resistant and can be used several times. But when finishing pipes, you need to be careful, since the insulation breaks easily even with slight mechanical stress. The material is sold in rolls or in the form of tubes of various diameters;

- Penoizol. This material is rarely used in private construction. This is explained by the high cost of insulation and the complexity of installation. Penoizol is applied from spray cans. A large number of such containers are required for pipe processing. Advantages of the material - high thermal insulation capacity, resistance to low temperatures, installation does not require the use of additional elements, fasteners;

- Penofol. It is a multilayer material that consists of foil and foamed polyethylene applied to it. Penofol not only effectively protects against cold, but also provides reliable waterproofing. The material goes on sale in rolls. Insulation of sewer pipes in the ground using penofol has become very common among owners of private cottages and houses;

- Expanded clay. Loose material that has been used as insulation for a long time. It is enough to fill up a trench with sewer pipes to provide excellent protection from the cold. However, expanded clay must be dry, so you should not use it in places where groundwater can get.

Insulation materials that lose their properties under the influence of water must be additionally protected with waterproofing.

When insulating an external sewage system, you can also combine several heat-insulating materials. For example, place the pipes wrapped with insulation on a expanded clay pillow. Cover the top with expanded clay. Such arrangement of the system reduces to zero the risk of freezing of the sewage system.

You can insulate sewer pipes in a private house with your own hands. The installation process is simple and easy.

How to insulate a sewer in a private house

If it becomes necessary to insulate the sewer plastic pipe in the house, you can use all the above materials. From an economic point of view, ease of installation and aesthetics, the largest number of homeowners prefer isolon. It is simply fixed on the insulated surface through a side cut, can be glued or connected with adhesive tape. An additional advantage of the material is its highest noise absorption among all heat insulators.

Fig. 11 Insulation of the sewage system in a private house with isolon

When deciding how to insulate the sewer in the ground, they proceed from climatic conditions, the convenience of work, the cost of materials. The optimal choice of heaters for underground sewerage with a wide variety is not too large - it can be an electric cable or a shell made of solid materials that do not allow moisture to pass through - foam or foam. Often a combination of heating cable and insulating shell is used for thermal insulation.

Types of materials for insulating sewer pipes in the house

The variety of materials for insulating sewers is quite wide, so it is worth choosing taking into account the terrain and the peculiarities of pipe operation. Styrofoam is a compound of granules with a size of about 0.5 centimeters. The granules are combined when exposed to temperature. Such insulation is a hollow cylinder that is put on the pipe and fastened with construction tape or clamps. Styrofoam is easy to use and safe.

Penoplex or extruded polystyrene foam consists of a foam with a large number of granules. Penoplex can withstand significant loads underground. It has a high stiffness and is used in humid conditions. Penoplex, in addition to insulating sewer pipes, is used to insulate the foundation, basements and blind area.

Foil isolon quite often it is used to insulate communications. It allows you to guarantee the protection of pipes from freezing and destruction for many years. This high-quality and inexpensive material is quite easy to mount on pipes. The roll is cut into strips and spirally wound around the tube. The insulation is fixed with electrical tape, adhesive tape, plastic clamps.

Insulation of sewer pipes is often carried out using ready-made or sprayed PPU (polyurethane foam). PUF is applied using a special installation. Instead of an expensive sprayed substance, you can purchase ready-made blocks with any suitable diameter. Blocks are fastened with clamps, aluminum tape or other connecting materials. This material is resistant to moisture and dampness. It is easily removable and lasts a long time.