Equipping a brick wall oven is easy enough. And this is an extremely profitable solution, since the efficiency of such heating structures is very high. Here, the wall acts as a heating coarse, so it is inside the room that more heat remains due to the combustion of solid fuel. And what is important, it is not necessary to allocate too much free space to equip such furnaces. In most cases, a 30 cm layer of heat-resistant foam concrete will be sufficient. This is an excellent heat accumulator that does not collapse due to thermal deformation (with frequent heating / cooling). How to equip a stove in an opening between several rooms?

The efficiency of brick heating stoves is very high.

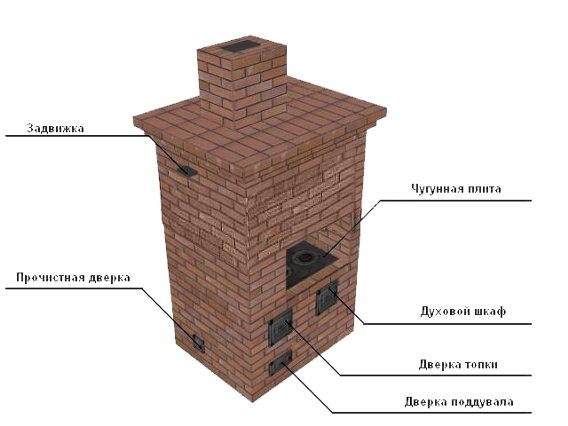

Structure structure

So, if exactly brick flat masonry is used, then the easiest option for mounting a heating stove is to install a metal independent frame with a blower and chimney (more precisely, access to it).

All this remains to be overlaid with red heat-resistant brick (preferably red-hot, which has already passed through heating up to several thousand ° C). The laying structure can be either flat or with a coil (that is, a curly bend along the chimney, which allows you to leave more heat in the room than with a direct blowing system).

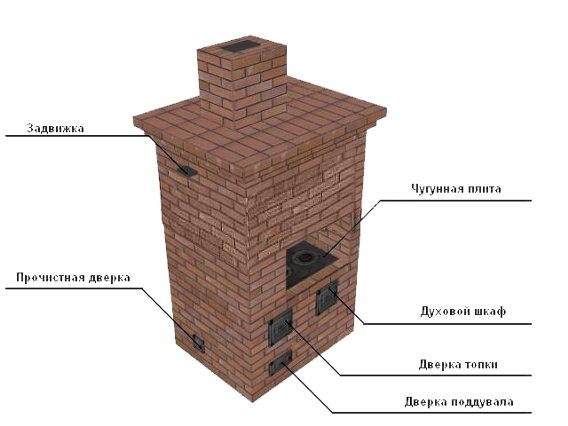

Diagram of a brick oven.

Similar systems can also be used when the stove is being set up in a bath. In this case, the structure is arranged in the opening between the rooms, where the most ordinary tree is used as a partition (meaning a blockhouse). Here the arrangement of the stove is complicated by the fact that it is necessary to isolate the wooden base from heat and heat. Here again you can use ceramic tiles and the most common heat-resistant bricks. The distance from the base itself (rough) and the slab should be at least 15 cm of the air gap. Only in this case can we say that the safety precautions have been fully complied with.

It is worth noting that after installing the stove, the adjacent wall is by no means covered with a layer of decorative plaster or similar building material. The best option is to cover it with tiles in a dark shade or make an air gap inside. But the last option is to reduce the performance of the heating structure, so it is better not to focus on it.

Protective non-combustible wall cladding

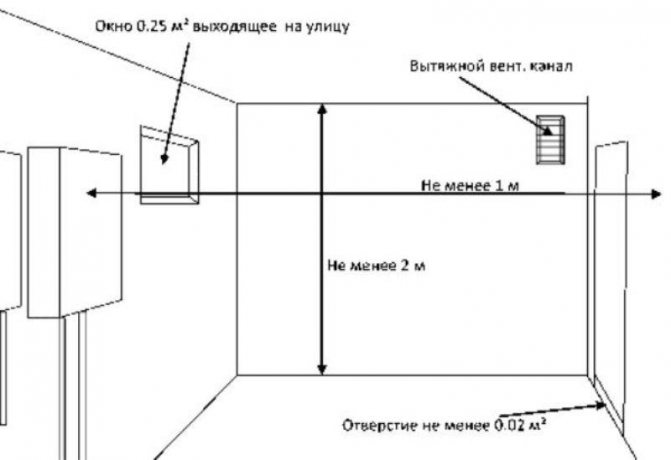

The walls adjacent to the hot oven walls are susceptible to spontaneous combustion. To prevent them from overheating, special skins are used, consisting of heat-insulating and non-combustible materials.

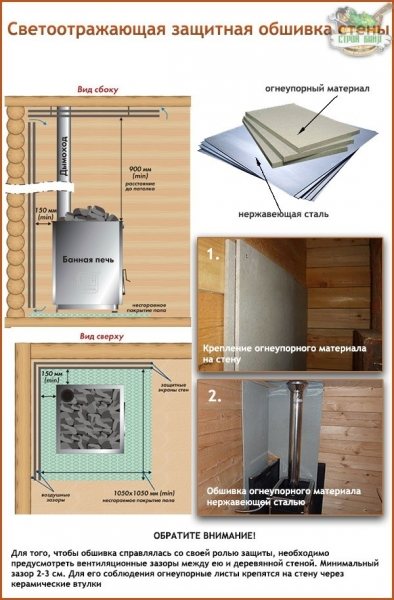

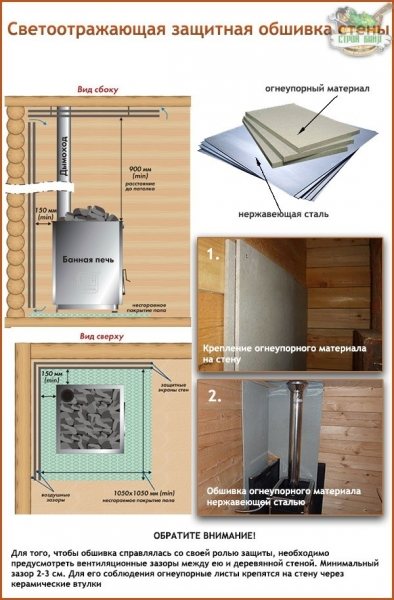

Option # 1 - reflective sheathing

Claddings consisting of a combination of non-combustible thermal insulation and metal sheets are effective. At the same time, thermal insulation is attached to the wooden surface, which is covered from above with a sheet of stainless steel. Some people use galvanized for these purposes, but, according to some reports, when heated, it can emit harmful substances. It is better not to risk it and purchase a stainless steel sheet.

To be effective, the metal sheet of the screen must be well polished. The mirror surface helps to reflect heat rays from the wooden surface and, accordingly, prevents it from heating.In addition, a sheet of stainless steel, directing infrared rays back to the steam room, turns hard radiation into a softer one, better perceived by a person.

As thermal insulation under a stainless steel, you can fix:

- Basalt wool - it has high thermal insulation properties, it is absolutely safe when used in a bath. Has increased hygroscopicity, does not burn.

- Basalt cardboard - thin sheets of basalt fiber. It is used as a fireproof, sound and heat insulating material.

- Asbestos cardboard - sheet refractory heat insulator. Possesses high strength and durability, protects combustible surfaces from ignition.

- Minerite - non-combustible sheets (slabs) specially made for shielding stoves, fireplaces, easily combustible surfaces in baths and saunas.

A popular example of cladding using a metal sheet is such a "pie": wall - ventilation gap (2-3 cm) - insulation (1-2 cm) - stainless steel sheet. The distance from the wooden wall to the stove is at least 38 cm (SNiP 41-01-2003).

Ceramic bushings are used to fasten the cladding to the wall. They do not heat up and allow the formation of ventilation gaps between the insulation and the wall.

If the distance between the wooden wall and the stove is minimal, then the cladding is made of two layers of refractory insulation, for example, minerite. In this case, the sheets are fixed through ceramic bushings with a gap of 2-3 cm. The top sheet is closed with stainless steel.

Option # 2 - cladding with cladding

Of course, the protective sheathing with stainless steel perfectly protects the wooden walls from heat and fire. But it can spoil the impression of the most expensive finishes. Therefore, if the steam room is designed in a decorative style, the fireproof cladding is masked with heat-resistant tiles. The tiles are laid on heat-resistant glue, for example, produced by Terracotta.

The best materials for wall cladding near the stove:

- Terracotta tiles - made of baked clay. Differs in strength, heat resistance, durability. Terracotta tiles can be matte or glazed (majolica) and range in color from pastel yellow to brick red.

- Clinker tiles are also made of clay, they look like facing bricks. Unlike terracotta, clinker tiles are denser. The color scheme covers almost all colors, from white to black, including green and blue tones that are unusual for clay.

- Tiles are a kind of ceramic tiles. Usually it has an embossing on the front surface in the form of a pattern or ornament.

- Porcelain stoneware is a heat-resistant, durable tile. Depending on the method of processing the front surface, the tiles can imitate natural stone, brick, wood. The range of colors includes all natural shades, from white to black.

- Talcochlorite is a grayish or greenish rock. Possesses fire resistance, water resistance, durability.

Fastening refractory tiles directly to walls will not have a thermal insulation effect. The wall will still heat up, which is fraught with spontaneous combustion. Therefore, the tile is used only as an element of the protective "pie" of the following design: wall - ventilation gap (2-3 cm) - refractory sheet material - tiles. It is recommended to maintain a minimum of 15-20 cm from the tiles to the walls of the stove.

Any material from this list can be used as a refractory element in cladding:

- Refractory gypsum board (GKLO) - gypsum board supplemented with fiberglass fibers. Resists heat stress without structural deformation.

- Minerite is a fiber-cement board, absolutely non-combustible. Minerite slabs are moisture resistant, do not rot, do not decompose.

- Glass-magnesium sheet (MSL) is a material in the form of plates, made on the basis of magnesia binder and fiberglass.It has heat and sound insulating properties, does not deteriorate under the influence of water and temperature extremes.

The protective sheathing with the mandatory observance of the ventilation gap has a very low heat absorption coefficient, so the wall under it practically does not heat up. In addition, the use of cladding makes it possible to disguise the protective "cake" and maintain the finishing of the steam room in the same style.

Arrangement of a stove in a brick wall in a residential building

So, if the wall is brick, then it is not necessary to prepare a recess in it for installing the stove. If there was a doorway in it earlier, you can use it. Everything will be much easier here. It is enough to cut a through hole with a side of 40-60 cm. A metal support is installed below, on which the entire structure will be located. Further, a box is formed from the back of the wall (naturally, you will have to make a rather long ledge under the chimney, because it also requires at least 40-50 cm). If necessary, an indent of 20 mm is made between the support and the floor. This is also needed for fire safety purposes. It remains only to install the stove in the wall and line it with bricks. Experts recommend doing this either white or red heat-resistant, but in half (that is, when the brick is placed lying down).

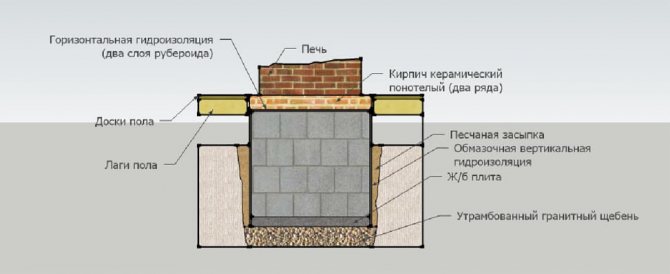

Foundation for a brick oven.

In the bathhouse, the stove is mounted in the same way if one of the walls there is also brick (for example, which is located between the changing room and the steam room). The only difference in the algorithm for installing the stove in a residential building and in a bath is the distance from the base of the floor. If in a residential building it is customary to put the stove as low as possible, then in the bath - higher in order to quickly fill the upper part of the steam room with warm or hot air. But still, there are no clear rules on how the stoves should be located in the bath. And not only traditional stoves can be used there, but even fireplaces, and even electric stoves, in which heating is carried out by convection of hot air.

Protective screens near or around the oven

Shields are insulation shields that cover the side surfaces of the oven and reduce the intensity of heat radiation. Screens are metal and brick. Typically used for metal ovens.

The most common shields are factory-made steel or cast iron sheets. They are installed around the stove, at a distance of 1-5 cm from the walls of the firebox. Depending on the need to isolate one side or the other of the oven, side or front (front) screens can be purchased. Many metal furnaces are initially manufactured with protective shields in the form of a protective casing.

Protective screens allow reducing the temperature of external metal surfaces to 80-100 ° C and, accordingly, reducing the fire-safe distance to 50 cm.The total distance from the firebox to the wall (together with a gap of 1-5 cm) will be 51-55 cm.

Installation of protective screens is not difficult. Thanks to the presence of legs, metal shields are easily bolted to the floor.

The brick screen can cover all the side surfaces of the metal furnace, representing its outer skin. Then the stove will be in a brickwork casing. In another case, the brick screen is a wall separating the oven and the flammable surface.

For laying the protective screen, solid fireclay bricks are used. The binder is cement or clay mortar. It is recommended to lay in half-brick (120 mm thick). But, with a lack of material, it is possible to allow the wall to be a quarter brick (60 mm thick), although in this case the thermal insulation properties of the screen will be reduced by half.

In the lower part of the shield, small holes are left (sometimes with furnace doors) for air convection between the brick wall and the stove.

The brick walls of the screen must end at least 20 cm above the top surface of the oven. Sometimes the laying is carried out all the way to the ceiling.

The brick screen is installed not close to the walls of the stove, the optimal distance is 5-15 cm. The acceptable distance from the brickwork to the flammable wall is 5-15 cm. Thus, the use of a brick screen allows reducing the distance from the stove to the wooden wall to 22-42 cm. (oven - ventilation gap 5-15 cm - brick 12 cm - ventilation gap 5-15 cm - wall).

We offer you to familiarize yourself with: Roof of a house made of corrugated board

Correct laying of the stove

How to start laying a stove in a brick wall with your own hands? As mentioned above, from the formation of a depression under the chimney, the stove itself was blown. If the chimney has not yet been formed, it is done first. The best option is to form it from heat-resistant bricks at the maximum height, that is, without transitions. It is desirable that the upper part of the chimney is also located at about 4.5 m or higher. If it is lower, it will often blow into the furnace in a strong wind outside. Because of this, the smoke will go back into the blower and into the house, and not outside.

If the stove is mounted in an opening between a wooden wall, then part of the building structure will simply have to be removed. In this case, the wall is supported by a spacer. By the way, if the installation of the finishing of the stove will be carried out in one go, then it is allowed not to make thick inter-slope seams. You can do without them by simply increasing the density of the mortar (adding more concrete) and reducing the distance of the masonry along the seam (instead of the usual 10 mm, make 5 or less).

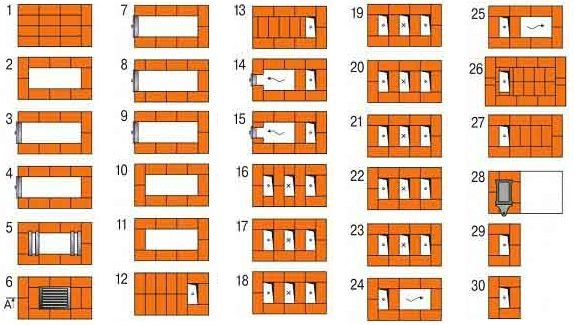

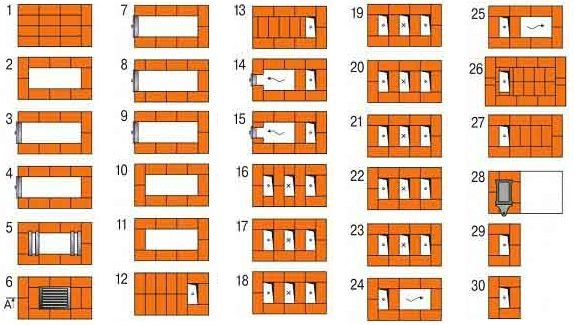

Layout of the oven rows.

If you look at the shape of the furnace from above in section, it turns out that it consists of 4 compartments. This is the best option. Can be reduced to 3:

- blew;

- the combustion chamber;

- chimney (coil).

The fourth chamber in question is where the soot accumulates. This part can be completely abandoned only if the stove is mounted in a bath. There, the chimney must be cleaned 1-2 times a year anyway, since due to the accumulation of moisture, the outflow of smoke decreases, and sometimes the air duct becomes clogged. In this case, the stove accumulates all the soot in the chimney. It is recommended to make a removable door in the elbow (transition at a right angle) - it is there that all debris and other residues of solid fuel combustion products will accumulate.

When laying the stove, it is advisable to make the distance from the blower to the combustion chamber as much as possible. At the same time, it is better to make the transition between these chambers as narrow as possible - this way the speed of movement of air masses increases.

It will not be possible to build such a structure only from bricks, therefore experts recommend installing special metal nozzles.

Fortunately, they are relatively cheap. There are several advantages to this design. Firstly, the speed of the air flow increases, and secondly, the consumption of solid fuel and the efficiency of the heating structure decrease. Roughly speaking, this increases efficiency.

//www.youtube.com/watch?v=NRuK86L1VkI

When is protection needed at all?

The need to install protective skins and screens does not always arise. If a fireproof distance is maintained between the stove and the nearest flammable surface, additional protection is not needed. At this distance, the infrared rays are scattered, weaken and the amount that the wooden wall receives can no longer lead to its damage.

It is believed that the safe distance from the wall to the brick kiln (quarter-brick masonry) is at least 0.32 m, from the wall to the metal kiln (not lined) - not less than 1 m.For a metal kiln lined with brick or chamotte from the inside, the distance decreases to 0.7 m.

Thus, compliance with fire-prevention distances is more possible in large saunas, where the issue of saving space is not relevant. In family steam rooms, where every centimeter of space counts, installing a stove 0.3-1 m from the nearest walls is impractical.In this case, the established safety distances must be reduced by means of screens and skins.

Operation of the stove in a brick wall

Does the operation of a stove in a brick wall differ from the usual one, which are mounted in residential buildings together with a gas heating system? Firstly, here the change of the type of fuel cannot physically take place. Secondly, the heating must be distributed over the entire wall in order to prevent the brick from burning in the rough (this can even provoke a fire). Thirdly, the combustion chambers that are placed in such stoves have a shallower depth, but a wider width for convenient stacking of firewood. Those that are placed in the bath have a great height. The reason is the same, that is, for the convenience of stacking firewood and other solid fuels.

During operation, the heat-resistant brick will warm up to 1200 ° C. This factor should be taken into account, since the inside of the chimney will have almost the same temperature. In the event that a reverse air flow is allowed (due to an incorrectly formed chimney coil), this will certainly lead to a fire.

//www.youtube.com/watch?v=I4up-2P_lkc

In any case, a properly formed furnace is the key to its safe operation on any type of solid fuel. In a stove that is mounted in the wall, the main thing is to observe the correct supply of oxygen to maintain the burning of wood or coal. And the nozzles that are placed between the combustion chamber and the blower perform exactly this function.

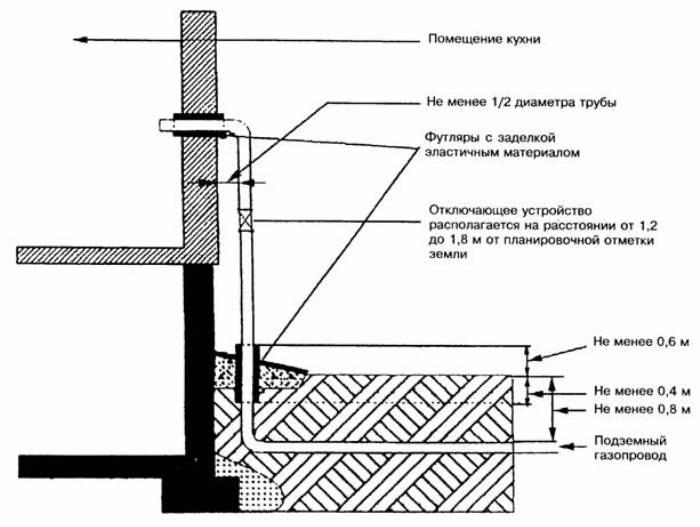

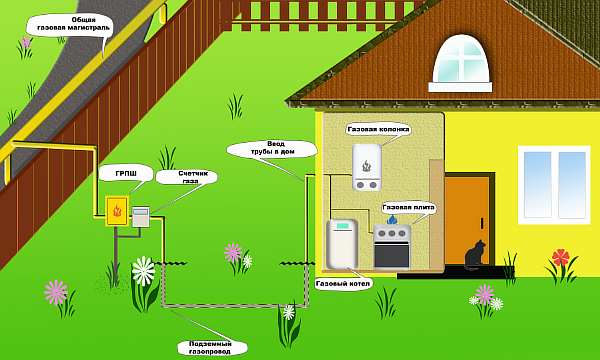

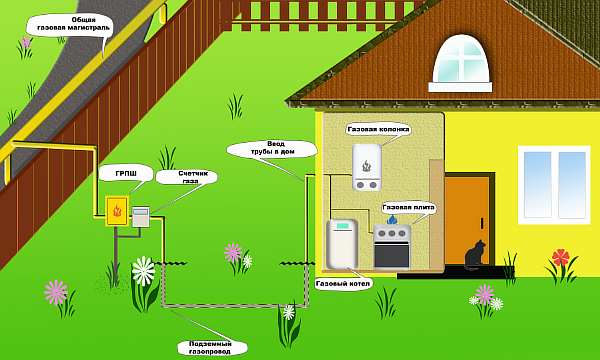

Required distances between the pipe and buildings

When determining at what distance from the gas pipe you can build a house, it is necessary to take into account some of the nuances. When building in an urban area, difficulties may arise due to the inclusion of communication branches with different levels of pressure in the gas pipeline. Therefore, SP 62.13330.2011 establishes different requirements for aboveground and underground structures, as well as for the value of pressure when supplying:

- aboveground is not regulated, but requires the creation of a security zone of 2 m on either side;

- from the foundation of a residential building to a low-pressure gas substation, a distance of at least 2 m is provided;

- the distance between two pipes with medium pressure cannot be less than 4 m from the building for living;

- high pressure of gas supply requires a distance of at least 7 m;

- the pipe for supplying gas to the house should be at a distance of 50 cm from the door and 20 cm from the window, and the same distance should be from the roof.

The distance from the intake to the high or low pressure gas pipeline is not specifically regulated. It can be calculated according to the standard parameter of 3 meters or positioned so that the fence does not enter the security zone.

However, neighbors may require that the distance to the fence be greater, since the construction of fences and fences around overhead communications is prohibited, and they may consider even a one-sided restriction a violation of the norm.

Regarding the fence and structures on the neighboring site, you should adhere to the standards established in SP 62.13330.2011: you will have to plan the location of the gas pipe in such a way that the distance to the residential building is no less than that dictated by the regulatory guidelines. If the neighboring house is located at a distance of 3 m from the fence, then you need to adhere to planning, which will allow you to comply with all the requirements of the joint venture.

Technical characteristics of the coaxial chimney

The maximum length of a coaxial chimney, if there are no specific instructions in the attached instructions, is no more than five meters for vertical design, and from one to three meters for horizontal design.

Coaxial chimneys for a gas boiler have three main dimensions: the diameters of the inner and outer pipes are 60/100 mm; 80/125 mm; 100/150 mm.

When installing a coaxial chimney, a slope of three or four degrees must be maintained to prevent condensate from stagnating in the pipe.

The flue gas dispersion zone, depending on the design features of the coaxial chimney, starts from two meters or more. You can read an overview of the types and characteristics of chimneys here.

Conclusions and useful video on the topic

What is electric ignition and gas control, is it really necessary to combine gas and electricity:

Thus, the PUE and the joint venture, which normalize the distance to the gas pipeline, are clearly stated and do not allow contradictions in practice. However, the fact is that all these rules were developed not at all in order to complicate your life, but to save it, as well as your property, life, health and belongings of other people living with you or nearby.

Did you comply with the standards when designing gas and electricity supply equipment in your house or apartment? Share your experience with us in the comments, as well as ask questions of interest on the topic of the article.

Gas is supplied to the cooking stove, gas boiler included in the heating system, and other equipment using pipes, which in most cases are made of low-alloy steel. What is the distance to the gas pipe in the area or indoors? What are the rules and regulations for the placement of pipes and additional gas equipment? Read on.

Indoor gas supply piping

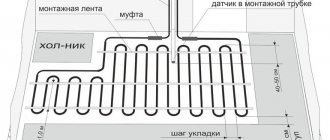

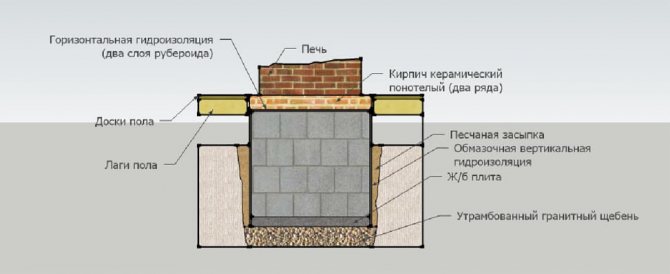

Floor preparation before installation in a wooden bath

When the total weight of the furnace is less than 7 centners, there is no need for a foundation, but still a kind of "pedestal" of brick is being erected. It's good when this happens during the construction period. You can again calculate the position so that the base lies between the lower beams under the floor... But it happens that you have to remodel the old base for a new stove in an old bathhouse. Then you cannot do without opening the floors and checking their strength... We advise you to read the relevant paragraphs of this article, where you will find tips for strengthening beams and lags, and tables for calculating their "endurance".

Furnace preparation

Before you tackle the chimney, the stove should already be in its intended place. But before it follows the first time heat in the yard. Doing so necessarily, because during the first fire, industrial heat-resistant paint usually sets and partially burns out. It "smokes" a little during firing and smells. This is normal and it should be.

By the way, new stones It was also nice to try it in the yard - it happens that a stench comes from them too, stinging the throat and eyes. It is better to experience this in the fresh air, and not in the steam room.

Assemble the stove according to the instructions, install it on a flat and solid base, put some piece of at least a ventilation pipe on the chimney pipe (length at least 2 meters) and heat it well once. At the same time, find out if there are structural defects, whether it smokes, in general, get acquainted.

Ceiling preparation and chimney installation

Many fires started from the section of the ceiling where the chimney runs. There are many errors associated with arranging the passage of the chimney through the ceilings. The cause of the fire can be:

- overheating of the pipe;

- cracks in the pipe through which sparks escape;

- errors in the distances between the pipe and the combustible cover.

If you did not design the position of the oven in advance, then there may be a beam above it. In this case part of the beam will have to be cut and fasten with jumpers to adjacent beams. The empty space above the center of the pipe passage must be about 90 cm in diameter.

Ceiling slabs are cut with a square for installation chopping box, which is a tin box, closed at the bottom and top with stainless steel sheets, in which a hole is made for the pipe (see photo above).

The chimney is mounted from the branch pipe coming out of the oven.

whether

monotube larger diameter, you will have to put on the pipe adapter... But anyway the first pipe going through the steam room will be a monotube. It is mounted on gate, then it continues again, but without reaching (this is important!) Before the overlap, a "start" is put on it - an adapter from mono to a sandwich pipe, which will go through the overlap. Pipe connections must not enter the ceilings.

It is worth noting here that sandwiches are, of course, the most common, but this is a dangerous type of chimney - so what if the gap between the two pipes is clogged with a thermal insulator? it does not prevent the inner pipe from burning out, if the owner will often rush to heat the bathhouse. And the properties of insulation, when condensation forms in it, will not be those that are stated - it will perfectly let heat through, overheating the outer pipe.

Alternative to sandwich pipes - ceramic or brick lined chimneys, but both are heavier and more expensive. Therefore, the majority prefers to risk the whole bath.

Okay. This means that through the hole in the stainless steel, the sandwich pipe enters the chopping box.

There is a space around it that can be filled:

- expanded clay;

- mineral wool;

- sand.

Outside the box can be wrapped basalt cardboardso that it does not touch the tree.

Further, the pipe is led out through the roof, through a hole with a larger diameter than the pipe. From the outside, the area next to it is coated with sealant, put on top master flash, fixed on the roof with self-tapping screws at intervals of up to 5 cm, the connection of the flush with the pipe is also sealed. It remains to install an umbrella or deflector.

Installing an iron stove: choosing a base

Nobody just puts a metal stove on the bathroom floor. And here's why: the thing is heavy, and therefore it would simply become sag over time... And I would do it unevenly. BUT when the oven is not level, it may crack... Therefore, under it they make or a brick base, or even a separate foundation with horizontals adjusted to the level to prevent the destruction of the furnace.

To determine whether you need a lightweight or full-fledged foundation, you must first make a calculation of the mass of the furnace with all that is due. You will learn how to do this from our article - you are reluctant to repeat yourself, but everything is detailed there.