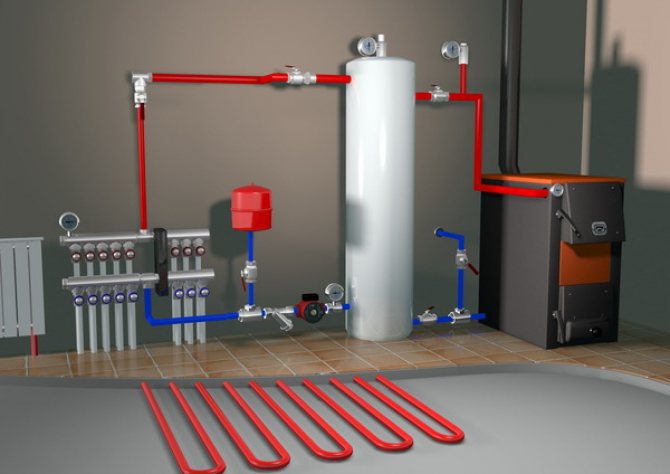

Any living space, be it a private house or apartment, is equipped with heating systems. Without this, it is impossible to live in our harsh climatic conditions.

House heating

A heating system is installed in each apartment or country house. But without filters that ensure the purity of the coolant, the system will quickly fail. Filtration of water extends the life of the heating system.

Features of filters for home heating systems

Another name for this filter is "sump". It consists of a unit where the direction of flow of the coolant through the filter changes.

Filter

The device is equipped with a mesh that prevents the spread of debris through the pipes. Dirt settles on the filter element. It is necessary that there is an unobstructed approach to the device for its maintenance.

Ion Exchange Resin Filter

The main component of this heating filter is granular resin saturated with sodium ions. Installed directly behind the coarse filter. Required to reduce water hardness. It is known for certain that hard water is a big problem and an immediate threat to all household appliances. The heating system is no exception.

- Water softening will significantly extend the service life,

- Reduces scale formation or stops this process altogether.

- In addition to scale, the filter is able to fight chlorine impurities, oxidation, iron, and salts.

Such a system takes up a lot of space and requires frequent maintenance. When installing, make sure that there is enough space not only for installation, but also for routine maintenance. Undoubtedly, such a system is necessary in every home.

In this video, we talk in detail about the application of the ion exchange resin filter (watch from 14:15):

To replace the filter load, you can call a specialist, or do it yourself. When the cleaning system stops working properly, it is necessary to dismantle the system and use a high pressure of water to flush the filler, then load gravel or table salt. Add filler. Pre-shut off the water supply to the heating system and drain off the residues.

Selecting the correct ion exchange resin filter can only be done after analyzing the water. Only after passing a sample to specialists and knowing the composition, you can choose a filter that is suitable for its characteristics. Contact the professionals.

Each of the filters takes its place in the chain, complementing each other and jointly creating a single cleaning front. Protects valuable equipment, extends service life and saves you money on maintenance. Such a filtration system is recommended to be used not only in the heat supply system. Water treated in this way can be drunk, it significantly extends the life of a washing machine, dishwasher, faucets and other equipment associated with water. Equip your home correctly to get the most out of modern technology.

For normal operation of a gas boiler, soft water is needed, the supply of which is ensured by installing special filters. Today there is 3 types of devices: electromagnetic, cartridge and polyphosphate.

Where does the dirt in the system come from?

The water contains many metals and lime compounds, which form deposits in the form of scale on the pipe walls.And if the pipeline has been used for a long time and at the same time has never undergone maintenance, then the layers increase, narrowing the channel for the passage of the coolant.

But this is not the only reason for the lack of movement in the pipes. Clogging can be caused by other debris. These can be pieces of thread, metal particles or grains that have come off the inside of the pipeline.

The most unpleasant surprise can occur if metal pipes have been installed in a private house for a long time and are still in use. Iron corrodes even after periodic cleaning.

Small particles come off along with the coolant flow, are directed to the outlet of the system and enter the boiler filter of the heating system, where they settle.

Recommendation! In case of deterioration in the operation of the heating system, as well as in case of insufficient liquid circulation, the boiler filter must be inspected.

Benefits of using a heating filter

Among the advantages that the installation of cleaning elements for heating carries, it is worth highlighting the following:

- the filter provides high-quality protection against any kind of contamination;

- draining the water in the system and filling the circuit with a new coolant does not need to be done often;

- installation of a mud collector definitely allows you to save financial costs;

- a system equipped with such a filter will work for a long time and reliably.

Thus, the list of advantages of the cleaning element only confirms the fact that its installation is a guarantee of the stable operation of the entire heating system and the absence of the need for any repair work.

1. 2. 3. 4. 5. 6.

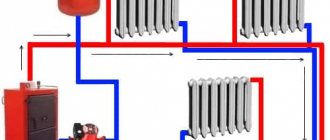

The quality of work of heat supply systems may deteriorate over time, for sure most people had to deal with this at one time. Many people now have to live in houses built at least twenty years ago.

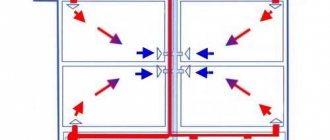

It is in such buildings that this problem most often occurs. Poor circulation of the coolant, the role of which is most often played by water, causes poor heating. The corrosion process degrades the quality of the water, in which impurities are deposited on the inner walls of pipes and radiators, preventing the normal passage of heat.

There is, of course, a way out of this situation - either, for more "neglected" cases, its chemical purification (

Filter types

Filters differ in the type of cleaning.

Sump filter

The device has an angular shape with a filter mesh inside. The design provides for a side outlet where debris settles. With the help of such a device, the coolant is purified from particles of large and medium fractions.

Rough cleaning

Device design

Filters for gas boilers installed on water are divided by design type:

- The connection to the heating pipe is made using a flange, threaded, or welded to the pipe.

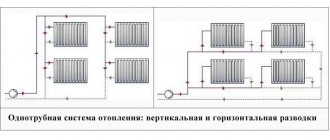

- There are two types of device placement: vertical and horizontal.

Vertical arrangement

The heating device can be manufactured:

- Brass. Capable of withstanding high temperatures.

- Of steel. Short-lived, wears out quickly.

- Made of plastic. Adapted for low temperature indicators within +90 ⁰С.

There is a more advanced filter design for the heating system. It has a flask with a sump located in the lower part of the device, and a grid is fixed above the flask. When the flows of the coolant bring debris, it settles on the mesh, and it falls down under the influence of gravity. The main accumulation of dirt is retained in the lower part of the filter - the flask.

Also, the device is equipped with a separating element. Its main task is to get rid of accumulated air in the system.When this happens, the drain valve on the device (at the top) opens. This is how the system gets rid of air congestion.

Operating principle

The device is equipped with a mesh element, which is placed in the inner part. The mesh blocks the free passage of the coolant flow. Due to this, all large and medium-sized particles settle on the mesh element, cleaning the coolant. Liquid comes into radiators without impurities.

The installation cleans the coolant from dirt, increasing the service life of the heating devices.

Benefits

Advantages of the improved designs:

- The device is equipped with a flask, so the device cannot be disassembled for cleaning from debris.

- There is a drain valve at the bottom of the device for removing water with dirt particles.

- Air plugs are removed through the valve. In this case, the water circulates normally, and the system does not become overgrown with foreign particles.

Place and features of installation

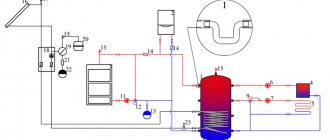

Depending on the type of heating system, the installation site of the device is determined. Installation in autonomous circuits is carried out in front of a gas boiler, on a bypass or at branch points.

A high-quality installation guarantees the correct operation of the device. Before installation, it is necessary to clean the coolant from debris.

In the event of installation errors, the device quickly fails, and the heating system wears out.

Improper placement of the filter or complete refusal to use it can provoke a breakdown of the pump that pumps water in the heating system. Debris will settle on the blades, damaging the entire device.

Fine filter

The filter element for the circulation pump is mounted as an additional element that cleans the coolant from debris with a smaller fraction.

Fine cleaning

Device structure

Filter types:

- A metal mesh is inserted inside the device. Cell size up to 5 microns.

- A cartridge made of fabric that has been folded several times.

- The cassette contains a polymeric porous filler.

- Mineral sorbent filling.

Operating principle

Installation is carried out after a large debris sump. The element that filters small debris cannot be installed as the main link in the cleaning system, since it very quickly clogs up from particles of a large fraction.

The cassette filters small debris particles, and the coolant circulates through the pipes in a cleaned state.

Benefits

By removing dirt from the liquid, the service life of the entire heating system is extended. Reduces the risk of corrosion deposits on the inner walls of pipes and radiators. This is the main advantage of the fine cleaning device.

Where is mounted

The fine filter is designed in such a way that its location can only be horizontal. During installation, it is necessary to install a faucet behind and in front of the device, one at a time, so that in the event of a device breakdown, it can be dismantled without draining the water from the entire system.

If the pipeline is filled with antifreeze, then the installation of a fine filter is not necessary, since antifreeze does not pass through it.

The installation of a mud collector is carried out along the flow of the coolant flow, reducing damage to the heating system.

Magnetic models of mud collectors

What is a magnetic filter? This is a device consisting of two magnets in parallel with different polarities. Its main task is to clean the coolant from metallic impurities.

Magnetic

Types of devices

The filter can be of the following types:

- Detachable design. The device has two plates that are installed opposite each other. The fixation is done on the pipe. Among the advantages is the quick replacement of the entire device.

- Non-removable device. In shape, it is a pipe made from ferromagnetic alloys.

Operating principle

The plates of the device are positioned in such a way that metal particles in the coolant are attracted to one of the sides. This prevents the heating system from clogging and prevents premature rusting.

Benefits

Positive sides:

- Particles of metal are contained in small quantities, so the device is very rarely cleaned.

- Metal cleaning of the system reduces the formation of scale and rust build-up on the inside of the pipes.

- A clean coolant increases the service life of heating devices by several years.

Installation rules

The device is installed strictly in front of the entrance to the circulation pump. For installation, it is desirable to find a place where the cross-sections of the pipe and the filtering device will be identical. If the dimensions differ, you can use adapters.

When installed, the device is placed vertically and secured with brackets.

Coarse filter

The filter is installed when the heating system is connected to the central water supply. It is a flask with a filter element inside. The connection can be flanged or coupling, depending on the diameter of the water supply pipes. Essential for filtering coarse dirt. Effectively retains dirt, sand, large abrasive impurities. It will reliably protect the heating system from large elements, but will let small ones through. It is also not capable of chemical purification or water softening. Cannot purify water to the desired state on its own. Doesn't take up much space. The coarse filter is the first line of defense for your home's water supply.

Places of installation of filter elements

A dirt filter removes large debris from the coolant. The device is placed at the entrance to the system or in front of the pump. In a large house, it is necessary to install several "mud traps" in the heating system.

The task of the fine cleaning device is to sift out smaller debris, therefore it is installed after a sump that catches large particles.

The function of the magnetic filter is more modest in comparison with previous examples: it filters out metal particles from the water. Installation of such a device is carried out before entering the system in front of the heater.

Where is the dirt in the radiators

As a rule, water is used as a heat carrier. The most common water, which is taken from both a centralized pipeline and from a well or nearby reservoir. In the first case, in most cases, various kinds of chemicals are added to the coolant, which are subsequently deposited on the walls of the heating main in the form of scale. In the second, it is somewhat more complicated. It is good if you have a good filtering station at the entrance to the boiler, which cleans the water from the well (reservoir) from sand, silt and other fine particles. However, not all heat units are equipped with such equipment, as a result of which dirt remains on the walls, layers, as a result of which the passages are narrowed.

It is for this reason that cleaning the heating system in a private house is an extremely important and necessary procedure, without which, alas, heating will not be so effective and economical.

The formation of scale on the inner wall of the heating circuit, the thickness of which ranges from 0.8 cm and more, leads to a decrease in the efficiency of the unit by 35%. A timely cleaning of the heating system will reduce heat loss of such a plan.

Moreover, the presence of foreign bodies in the heating main reduces the operational life of the entire heating unit. And this, in turn, leads to additional costs for the purchase of a new boiler, as well as for the re-equipment of the heating unit as a whole. Therefore, it is worthwhile to prioritize correctly.

And although the rate of pollution does not directly depend on the material from which the radiators are made, the corrosion process should not be disregarded.

How to determine the presence of limescale

Thermal imager data - in the right picture, the battery is 40% dirty

Of course, according to external characteristics, it is extremely difficult to determine the need for flushing the heating system. But at the same time, it is easy to find out if there is scale in the heating main. So, the main indicators of the formation of dirt on the internal surfaces of heating devices and pipes supplying hot water to them, as well as the need to perform such a procedure as flushing heating systems, are:

- reducing the heating rate of heat exchangers;

- the functioning of the heating boiler is accompanied by extraneous sounds that have not been observed before;

- a partially cold battery - cold in the upper part, and hot in the lower part, or vice versa;

- the radiator is completely cold, while the pipe leading to it is warm;

- an increase in the consumption of consumed fuel resources for warming up to the required temperature in the room.

In addition, plaque often forms in the heating circuit a few days after another heating device was connected to it. This is due to the fact that the new elements should, so to speak, "get used" to the work of the entire unit. Moreover, they are treated with special substances that prevent the formation of corrosion. And when the water heated to a certain level passes through them, these paint and varnish components are washed off and gradually turn into plaque, coming into contact with other substances.

How to deal with the problem

Thanks to modern technology, there are mechanical and chemical methods for flushing the heating system.

Mechanical

The old good old-fashioned method, in which the pipes are disassembled and all surfaces are cleaned by hand using stiff brushes, wire and knitting needles. Before proceeding, a thinning chemical (Mole, etc.) is poured into the pipes, which softens the layers and makes it possible to scrape them off quickly. The disadvantage of this method lies in the duration, complexity and understanding of how the system works, how to disassemble it, but most importantly, how to assemble it after cleaning.

Chemical

A modern way to get rid of scale and limestone deposits almost at the height of the heating season. For flushing, a pump is connected to the system, distilling water with a certain chemical composition, depending on the method, acidic or alkaline.

Now in more detail about the most effective methods. By means of which you can clean the heating system with your own hands.

Pulsating water composition

This option for flushing the heating of a residential building is carried out by means of special equipment. With the help of such installations, the heating circuit is filled with a mixture of compressed air masses and water. Ultimately, the cleaning of the inner walls of the pipeline and heat exchangers is achieved by means of active-wave pulsation.

This method of flushing the heating system in a private house is good because it allows you to get rid of accumulated contaminants in the mains and radiators in just 15 minutes. And this, in turn, significantly extends the service life of both the heating element and the entire thermal circuit as a whole.

Timely cleaning helps reduce fuel consumption. Therefore, do not neglect such a procedure as flushing the heating system.

Biologicals

The advantages of this cleaning option are that there is no need to turn off the heating unit. So, biologically active preparations are added to the water, which literally dissolve any kind of pollution, be it rust or scale. And besides, there is no need to call specialized employees, as in the previous cleaning method.In addition, biological products belong to the group of environmentally friendly compounds, both for human health and for the environment.

Technique "Pneumohydraulic impact"

In this case, special equipment is also used, by means of which short-wave, high-frequency pneumohydraulic jolts are created. Despite the reviews of some people who claim that such activities can harm the heating block, you should not be afraid that as a result of this cleaning option, the heating circuit itself will be damaged. And all because the lion's share of the impact force (and this is more than 90%) falls on the coolant flow. This cleaning method is used, in most cases, in enterprises where the risk of plaque and rust is very high, as well as the length of the entire heating pipe.

VIDEO: Cleaning with a Typhoon pneumatic gun

Maintenance of mud filters

Any type of filter requires periodic maintenance, as debris constantly accumulates inside the device.

TO mud collectors

How the device is cleaned:

- The taps located on the sides of the device overlap, in this case it is not necessary to drain the coolant from the system.

- Before disassembling, a container must be installed to drain the remaining water.

- There is a plug on the filter that needs to be removed.

- The mesh is washed and reinstalled.

- A muffler is mounted.

- Couplings are twisted.

- The taps are opening.

Periodic filter cleaning extends the operating life of the entire system.

Universal mesh filter

The simplest heating strainer. Consists of a body (metal), and a cylindrical mesh located inside the flask. The body is closed with a plug or a tap, depending on the type of filter. Connection system - flange. Distinguish between flush and non-flush filters. Non-flushing ones are subject to replacement at the end of their service life. The washers last a long time thanks to cleaning. It is necessary to stop the circulation of water, dismantle the cover, remove and wash the mesh, and install. In addition to the relatively low price, the mesh is attractive for its simple design, easy maintenance and cheap components. Install this filter in front of the fine cleaning system. This is the penultimate stage of protection. Serves to clean water from scale or solid inclusions. Scale-damaged pipe fittings or pumps will cost tens of times more than a cheap filter. The filter does not take up much space.

Features of installation in the house

The process of installing a water filter for a gas boiler depends on which filter is in question. But there is general order of actions.

Materials and tools

Before installation, you need to prepare everything you need so that the work does not take much time:

- brush for preliminary cleaning of pipes leading to the boiler;

- tool for threading plastic pipes;

- fum tape;

- tow;

- pliers;

- a device for soldering plastic pipes.

All of the listed tools must be present in the arsenal during installation. And also you need to have on your hands installation instructions a specific type of device in front of a gas boiler.

Site selection and preparation before installation

Equipment installed directly in front of the pump, since editing elsewhere would be meaningless. The pipes into which the filter will cut must be free of dirt and scale, so they should first be clean with a brush or a special brush.

Important! The place where the device is supposed to be installed must be accessible for further maintenance of the device.

Installation

Installation involves several stages:

Important! When installing an EMC filter, take into account the ability to connect to the mains.

It is recommended to check in advance if the diameters of pipes, filter and valves are suitable for each other. In addition, experts advise mount pipes and filter on special brackets, thanks to which the installations will be held securely.

Starting the DHW system and checking

After the filter is installed, check the DHW system. To do this, first include water: if nothing leaks anywhere, connect the gas.

The operation of an electromagnetic device will immediately be clear, since it operates from the network.

But how effective a filter of another type is, it will be possible to understand only after the expiration of time.

In order to avoid mistakes, both for installing the filter on the boiler, and for checking and starting the system, it is better to invite an experienced specialist.

Why use filters for gas heating boiler

The main purpose of the filter for purifying water entering the gas boiler in the house is uninterrupted flow of water purified from impurities into the devicethat will not leave limescale.

In the process of passing water through the device, it is purified from salts.

If you do not use the device, then decrease the throughput of water nodes, the automatic valve, if present on the device, breaks down, and over time the consumption of gas and electricity will increase.

How to understand that the device is clogged?

These devices serve to remove large impurities:

- scale;

- rust;

- mud.

Therefore, they are called "mud collectors", and the particles retained by them have sizes from 20 to 500 microns.

As a rule, a coarse filter mesh filter consists of 200 - 300 µm mesh. Consequently, the smaller particles pass through the pipes to the appliances and faucets.

If other filters of finer cleaning are additionally installed, they may clog too.

For example,

the mesh is often clogged - the aerator at the end of the spout ("gander") of the mixer, decreasing the intensity of the water flow. You can verify this by opening the water on several mixers. If water does not come from all specimens, then the problem is not in them.

Having found out that the aerators of the mixers are in order, and the water flows through the risers in normal mode, it should be recognized that the coarse filter is clogged.

Important. Before you do anything with your plumbing, you should go to your neighbors, higher or lower in the riser, and find out how things are with water pressure.

You also need to keep in mind that these devices (pre-filters) are often sealed together with the meters, so it is not always possible to remove the device just like that.