Needlework

06/25/2018 Anastasia Prozheva

There are many ways to make a stained glass window with your own hands. This article provides information on the most famous methods that can actually be performed at home.

Many designers offer the idea of decorating glass as, in addition to the style of the premises, and various methods of making stained-glass windows, have found their application in various objects, from the traditional stained-glass window on the window to amazing volumetric glass products in the form of chandeliers, sconces, shades. Stained glass style is performed with paints, as well as pasting with colored translucent film.

The main secret of technology

The manufacturing technology of any stained-glass window does not require deep knowledge. But you definitely need an accurate eye, a loyal and firm hand and utmost accuracy. The smallest errors, accumulating as they are manufactured, end up giving the product a not quite attractive, if not just sloppy look. So the main conditions for success are skill, ingenuity, training. If, after three trial compositions the size of a large book, you get a good real one, you are a nugget.

Stained glass in the cathedral of st. Vincent in Blois

Production of stained glass paints

If you make a stained glass window together with a child, it will be even more interesting for him when the process starts from the very beginning. Namely, from the manufacture of stained glass paints. Vintage paints can be prepared in several ways. Each of the recipes is simple to prepare, and also very economical. The material at home will turn out to be completely safe and of high quality.

The basis for the manufacture of paints can be:

- PVA glue.

- Gelatin.

- Solvent.

All cooking methods are very simple.

Base PVA glue

Before starting production, it is necessary to prepare suitable utensils. Any small container is suitable for this purpose, for example, an empty gouache jar. The containers should be taken as much as it is supposed to prepare shades for the composition. Pour 2 tbsp into each empty container. l. PVA glue. Next, you need to add a coloring pigment to the glue, that is, a dye. Any colorant can be selected as a pigment.

About sketches and scissors

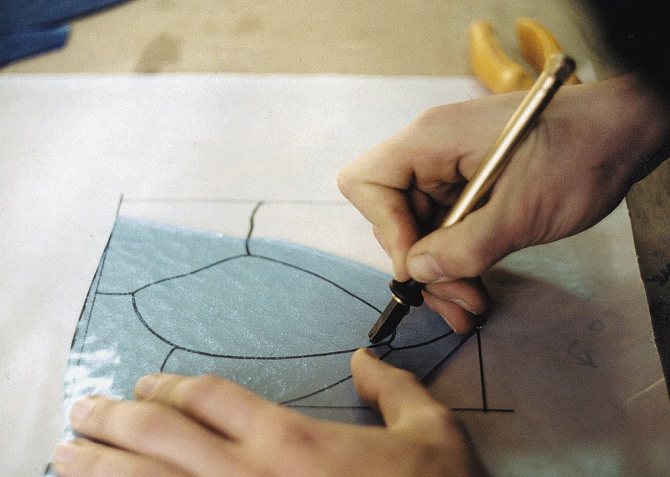

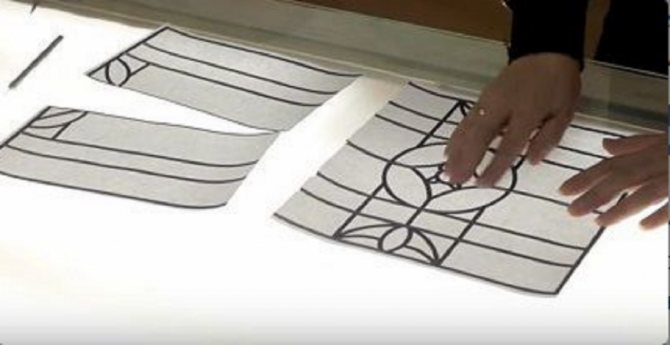

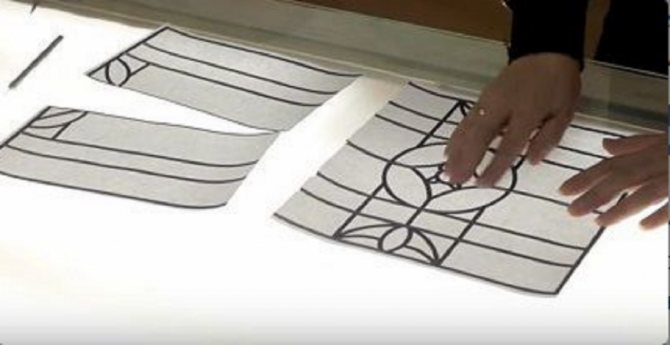

The basis of any stained-glass window is an element-by-element sketch. Stained glass sketches are always made in duplicate. If they are made on a computer and printed, there is no problem: the printouts are absolutely identical.

However, for a large panel, the sketch has to be drawn by hand and then copied on a blueprint machine. Despite such a serious name, the simplest photocopying machine is just a sheet of glass (which will then fit into the base), laid on two chairs, and a light bulb under it.

To make a stained-glass window without errors, you need to firmly remember: the assembly is carried out according to the PRIMARY, most accurate sketch, and a copy from it will go to the templates. Otherwise, inconsistencies are inevitable, and adjusting the fragments along the way complicates and spoils the work.

Scissors are needed not simple, but special template, with three blades. The third cuts out a 1.76 mm wide strip. Before cutting, the secondary sketch is glued onto a sheet of thin but dense cardboard (ideal case - 0.5 mm electric cardboard) and a paper-cardboard puff is cut. Otherwise, when making fragments, it will be very difficult to trace the contour on soft paper.

When gluing, be careful - paper soaked from any glue stretches when smoothing, and you need to glue it over the entire plane. Each ready-made template is verified according to the initial sketch.By the way, the pieces of both sketches must be uniformly numbered before cutting.

Useful Tips

Example of painting

If the object that you are painting comes into contact with food or drink, then make sure that the drawing is strictly on its outer side, and the edges in contact with the lips are free of the paint layer

When firing water paints, an important rule must be observed: the work is put in a still cold oven and is removed from it only after it has completely cooled down. The firing time is about 1 - 1.5 hours, the temperature is about 160 degrees

The exact manufacturer's recommendations are usually found on the paint bottle. Make sure that all contour lines are completely closed. It is necessary to remove flaws - bubbles, excess paint, etc., even before drying. Remove excess paint with a cotton swab or adjust closer to the contours. It is convenient to pierce the bubbles with a toothpick. If the contour is smeared, it's okay, just wipe it off the glass and try again. If the paints have thickened, then they should be diluted with thinners of the same brand.

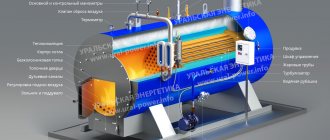

Types of stained glass

Classic or glass stained-glass window is a window made of a multitude of multi-colored glass, transparent or milky; dairy in this case means - opaque colored in the mass. The frosted glass is “rough” on one side, and is transparent at the fracture.

Fragments of stained glass are sometimes called stained glass smalts, so as not to be confused with smalts, from which glass mosaic is assembled. Stained glass is also derived from mosaics. Sometimes they even say simply "smalta", tk. there are many more stained-glass windows than glass mosaics. Further in the text smalt - stained glass smalt everywhere.

Each smalt is framed by a U-shaped profile made of lead, tin, copper or brass. Then the smalts are laid directly on the original sketch, and the seams are soldered. It turns out a bound window made of H-shaped profiles. A brass corner frame is immediately applied to it, for strength, and they are already soldered along the contour. The resulting picture is inserted into a window frame or into a backlit opening. In this case, smalts are taken matte or milky.

Classic stained glass

The figure in the previous section is one of the world's greatest stained glass masterpieces, the stained glass window in the south window of St. Vincent in Blois. The picture above shows modern stained glass windows of the classic type. Both there, and there is a combined technique with the use of fusing, see below. Classic stained glass is very difficult to work with, time consuming and not particularly durable. They were not placed in the swing windows - they could crumble from the cotton of the open sash.

Little tricks

Stained glass is a decorative picture that can be made in any style.

Masters are often silent about some, in their opinion, insignificant trifles. Here are some tips to help you make your stained glass window:

- never start learning from the most difficult, start from the simplest. Never tackle a large drawing with many small details at once. Try a simple pattern first, and when you master the technique a little, you can take complex drawings.

- use different types of paints for work, they all also fall on the drawing in different ways. The brightness and light transmission of the picture depends on the number of layers of paint.

- Use ear sticks and cotton pads to make accurate adjustments to the pattern.

- use a sharp knife or razor blade to remove faulty lines.

- use wet alcohol wipes on your hands.

- lighting should be good both below and above the work in order to immediately reveal the color shade and the density of the coating.

- one of the main components of a beautiful and accurate work is its fast execution. For example, if you apply the line paint too slowly, it will differ in both color and thickness.When pouring slowly, the paint will lie in an uneven layer and this will affect the quality of its surface.

Related article: Crochet coat: schemes and description for beginners with photos and videos

From simple to complex

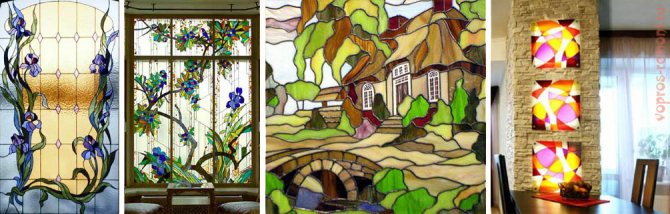

Film and ceiling

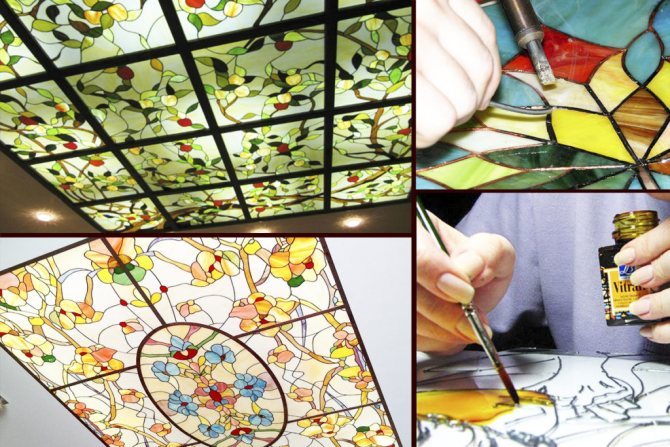

Film stained glass (the first on the left in the next figure below) refers to false stained glass: on a glass base, transparent, matte or milky, in one way or another, a pattern is applied with imitation of borders between smalts. In this case, it is just a self-adhesive film; we will talk about imitation of contour borders below, it is not at all difficult.

It is no more difficult to make a stained glass window from a film than to simply paste over something with self-adhesive. The main thing is to degrease the glass well with a solution of dishwashing detergent in water 1: 5-1: 20 and then rinse with distilled water. Bubbles on the film are pierced with a needle and fall down without a trace in a day or two.

Modern films are quite durable, but close up it is immediately clear that this is only an imitation. On the other hand, it has no appearance at all. Therefore, film stained-glass windows are most often installed on the ceiling. There they are just in their place - cheap and cheerful.

Previously, ceiling stained-glass windows were not common: the base is heavy, fragile, and extremely traumatic when it collapses. According to the properties of the material, the stained-glass window on the glass should not be hanging at all. Now the best base for stained glass ceiling is acrylic.

Try bending or breaking the computer disk. This is the strength of acrylic plastic with a thickness of only about 1 mm. A person throws a sheet of acrylic 3x3 m 2-3 mm thick with his hand, and under his own weight it does not sag for many years. And suddenly it falls out - it quietly plans, swaying. And the film on the acrylic is very strong. True, acrylic is much more expensive than glass.

Types of stained glass

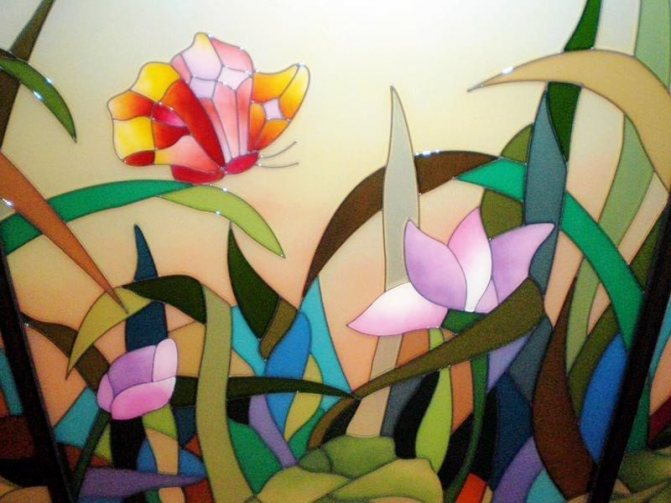

Jellied

The second pos. on the left - stained glass with paints, or filler. From the face, it is already very similar to the real one, but from the inside, a fake is still noticeable, even if it is issued at the same time as the face in a mirror image.

We will take a closer look at the technique of the flooded stained-glass window: from skilled hands, such compositions come out very effective from the face, but it is not so easy to get them. To complete the effect, you need a double passage of light rays through the base glass; hence - a smooth or textured reflective surface underneath. Therefore, the most common application of the filling technique is a stained glass window on a mirror.

The fact is that the paint, when properly filled, forms a meniscus, see below. The rays, direct and reflected from the mirror film, pass through its sections with different curvatures, and the stained-glass window plays with colors with might and main. Diffraction at the borders of the border also affects, so it is better to make it dark, but shiny, also see below. The "fill" is especially effective on acrylic mirrors with a reflective tantalum-niobium substrate.

Tiffany

Tiffany stained glass (next from left to right pos.) Is already a real, full-fledged stained glass window made of glass smalts. The only difference from the classics is that the binding is not made of cast or forged grooves, but is formed right along the end of the smalt from metal soldered foil (folia), which in the Middle Ages was not yet known to be made.

When using brass foil, hard fusible solders (which in the old days were also not available) and semi-active tiffany fluxes, it turns out to be quite durable. It will also go as a stained-glass window on a window, incl. swing or French, and at the door. The tiffany technique allows you to "stained glass" volumetric rectangular and curved structures. For this, the side faces of the smalt are beveled at 45 degrees or at the angle required by the curvature. No industrial equipment is required for this. We will also discuss the tiffany technique further.

Facet

Faceted stained-glass window, penultimate pos. - an indispensable sign of a prestigious interior. Facet - wide, at a low angle, optically precise polished chamfer on a thick glass plate from 6 mm.The angle of the facet must be precisely matched to the optical properties of the glass in order to obtain the so-called. diamond facet giving the highest light refraction.

Smalts of faceted stained-glass windows are made transparent, colorless or colored, from special types of glass - potash (light, with a lower refractive index) and lead (heavy, with high refraction). Particularly effective are the beveled stained-glass windows made of skillfully selected combinations of both (crown flint bevels).

Facet smalts are collected in special, piece-made profiles from durable aluminum alloy, due to their high weight. In general, beveled stained glass requires high craftsmanship and industrial conditions for its manufacture. Most often, smalts are ordered in batches at optical-mechanical enterprises, and they are collected already in small / medium-sized production.

Fusion

Fusing stained glass, or stained glass fusion (from the English fuse - to melt, melt; the last position) is made from heated to softening (300-1200 degrees, depending on the type of glass) smalt, laid out on a stencil on a heat-resistant plane. The entire set is rolled, due to which smooth color transitions are obtained, which is unattainable in other stained glass techniques.

Fusion is the aerobatics of stained glass art. Even when manufactured by robots in an industrial environment, due to rolling, each product is unique. Large stained glass fusion costs a lot of money; however, with the development of robotization, prices are steadily falling, here, as they say, two circles, China is ahead of the whole world. The very same fusion technique has been known since ancient times; it is according to her that smalts with faces, etc. were made and are made. for classic stained-glass windows.

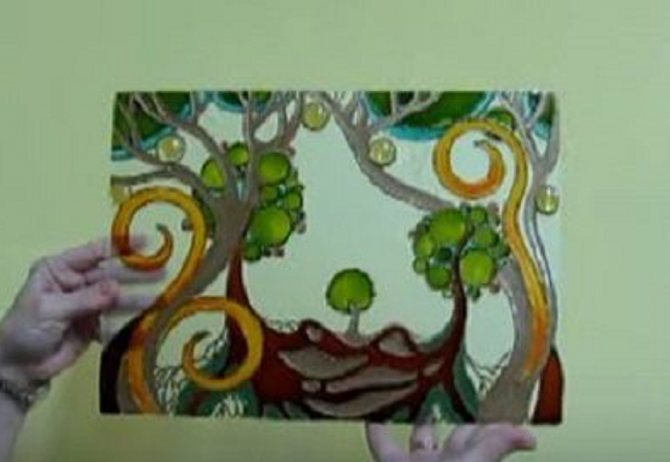

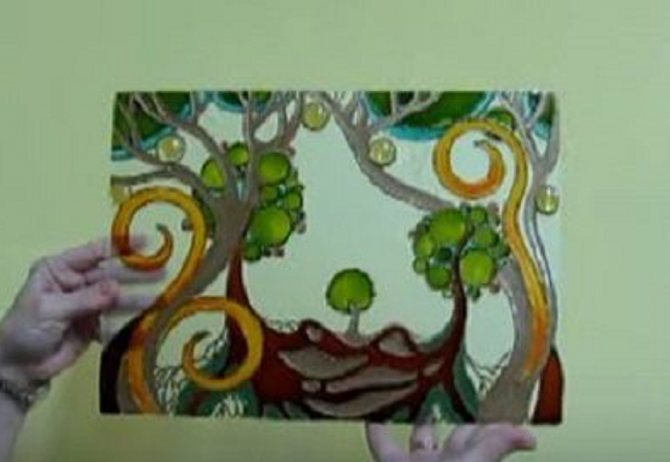

Video: stained glass with fusing

DIY stained glass creation

First, think over, and then imagine on paper what you want to get in the end. Based on this idea, stock up on materials.

Selection of materials and tools

To paint stained-glass windows (one of the most accessible techniques for a simple layman) you will need:

- acrylic paints, matched to the color of your sketch;

- a solvent suitable for such materials;

- brushes of different sizes;

- contours for stained glass work;

- cotton swabs;

- BBQ sticks or toothpicks;

- ferrule.

Acrylic paints have long gained great popularity among needlewomen in different directions. And this is no coincidence, since they are easily washed off (when applying unnecessary strokes), they fit well and mix with each other, there is no chemical smell when working with them.

It is very easy to embody a stained-glass window on a glass surface using the film technique. To do this, you need to find a special film that differs from the usual self-adhesive and is a high-tech imitation of colored glass. Between the two transparent layers is a colored substance that is resistant to sunlight, temperature range (from -45 to +135 Celsius). The colors presented by the manufacturers of such material help to bring any idea to life.

The stained glass film is cut with ordinary scissors, you do not need any special devices. The fragments are glued together using a special lead tape. There is another option - the easiest - to use the film already with the printed pattern, ready-made. But in this case, you will have to say goodbye to your idea.

The choice of technology and related materials is yours.

Making a stencil

If, nevertheless, the embodiment of stained-glass windows in a painted version is closer to you, then you will need a stencil for work. This is especially necessary for people who do not have sufficient experience and certain artist skills in stock.

Stencil selection

A sketch, previously drawn by you or downloaded from Internet sources, must be transferred from a thin sheet of paper to a denser "medium" - cardboard, Whatman paper, etc.

If the stained-glass drawing is supposed to be used several times, that is, there is a logical reason to make a stencil out of plastic, then it can serve more than once.

Having securely attached the template drawing to the glass surface, you can not worry that you will not reproduce your idea exactly. All you have to do is draw, following the template designations.

Imitations

It has already been said about the film stained glass window, and there is nothing complicated about it. But, before moving on to the colorful, let's talk about the imitation of the lead binding; it is common in both cases. A decent-looking imitation of a stained-glass window is largely determined by the similarity of an overhead border to a natural metal binding.

Curbs

There are three ways to simulate the binding of a classic stained-glass window for both film and paint:

- Sticking the borders of the fragments with lead tape. Specially sold for stained glass cases;

- Contouring with soft wire, see below;

- Guiding the contours with contour paste.

The first way

Lead tape is a real, without quotes, tape: a tape about 1/8 inch wide of lead foil, an adhesive layer the same as on regular tape, and a protective film. Unwinding the roll, spread it along the contour, cut it off, remove the protective film, apply it, press down - that's all. For film stained-glass windows - after gluing, for jellied - before pouring.

Second way

Enameled wires

The contour is bent out of the wire and glued (film - after; filling - before) PVA. But not simple, but dishware. It is a little more expensive than "paper", and the label says: "For gluing glass and porcelain." Reactive adhesives are not suitable, especially cyanoacrylate "Superglue". In addition to everything, it is unusually liquid, it flows numb wherever it is not needed.

The wire for this technique is traditionally used aluminum and then patinated, as for tiffany, see below. But the author of this article has repeatedly successfully used a copper winding wire in high-strength enamel insulation (enamel wire). It bends more easily, and in radio stores and radio markets it can be found with insulation of literally all colors of the rainbow, see fig., Round with a diameter of 0.02 to 2.5 mm and flat (tire) from 1 to 16 mm.

The tire is rare and expensive. But each contour curved from a round wire can be leveled and slightly flattened by tightly squeezing in a locksmith's vice between two even flat plates of steel with a thickness of 8-12 mm. The insulation of even the almost pre-war PEV does not deteriorate from this.

Copper wire circuits are especially good for pouring stained-glass windows on mirrors; this has already been discussed. If you need dullness and patina, it is enough to shirk on the finished one with sandpaper, and the exposed copper will soon be covered with the most real, not induced patina.

Third way

Cooking a contour paste according to the recipe:

- Tableware PVA - 50 ml.

- Natural black ink (the best is Dutch) - 20-30 ml.

- Aluminum powder (silver) - 30-40 gr.

Introduce mascara into PVA, stir thoroughly and add silverware in small portions while stirring until a creamy paste is obtained. If you need a binding for brass, we replace the silver with bronze powder. "Leadiness" depends on the ratio of the carcass to the silver; it is checked with a test, completely dried drop.

The pasta is prepared as needed, it is not stored. When using, you need to stir all the time - the silver floats up. It is applied along the contour with an artistic brush, gaining abundantly so that it fits with a sausage of equal thickness, a good skill is needed here. It is more convenient for a beginner to use a small confectionery syringe-gun, but then, even after rinsing, it is unsuitable for its intended use.

Video: do-it-yourself English film stained glass

Step-by-step master class

Creating a stained glass window

It is actually not difficult to make stained glass windows yourself, it does not require special skills.Film and painted techniques are best suited for creating a stained-glass window with your own hands. We will consider them step by step and make a simple stained glass window in each of these two ways.

Painting technique

Base for stained glass

1

In order to make such a picture, first of all, it is necessary to remove the dimensions of the glass, which will later turn into a stained glass window. Then, according to the size, a template is selected or drawn by hand with a pencil or marker. If the drawing is taken from the Internet, and the size of the glass is larger than A4, then it must be printed on sheets of paper, and then these sheets must be connected together into a single whole. Also, cardboard is suitable as a base, it is more dense and the glass will slip less.

2

In this example, consider the option of creating a picture yourself

It is important that all lines are clear.

Drawing for stained glass

3

Glass with a small thickness is laid on paper with a ready-made pattern. It must be degreased with an alcohol-based or ammonia-based product, or with plain alcohol.

Glass degreasing

4

The surface must be completely dry, so the degreaser is carefully wiped off with a soft cloth.

Drying the surface

5

The next step is to draw the outline of the stained-glass window, that is, the template is outlined on the glass. Black paint is most often used for this, as it is best seen. You can also take a contour paste, ready-made from a store or homemade, which includes PVA glue, ink and silver

Important: only stained glass or acrylic paints are recommended for creating stained glass, which are sold in tubes. Let the contour dry completely so as not to lubricate anything in the future.

Contour drawing

6

The contour of the painting is filled with color. You need to work carefully. The dye is applied with a brush or sponge if the area is large enough and you want to make a textured image.

Fill a path with color

7

If the drawing is to be voluminous, then it is better to apply shadows and lights after the base coat has dried.

Applying shadow and light

8

After complete drying, the stained glass window is ready.

Stained glass ready

Film technology

Sketch on different sheets

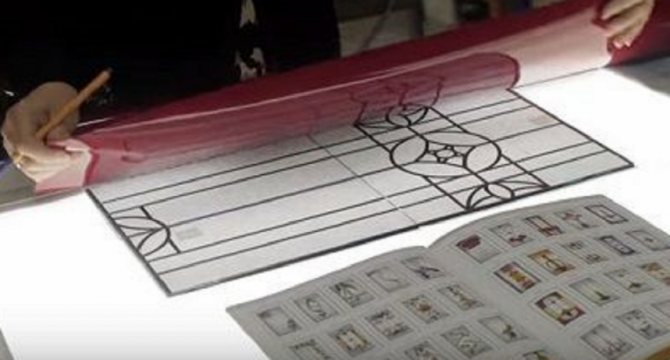

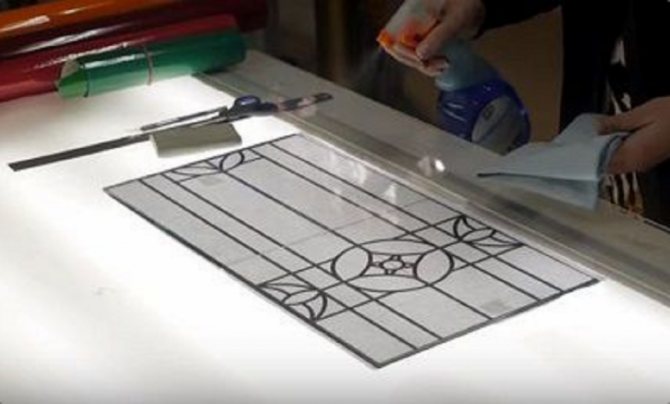

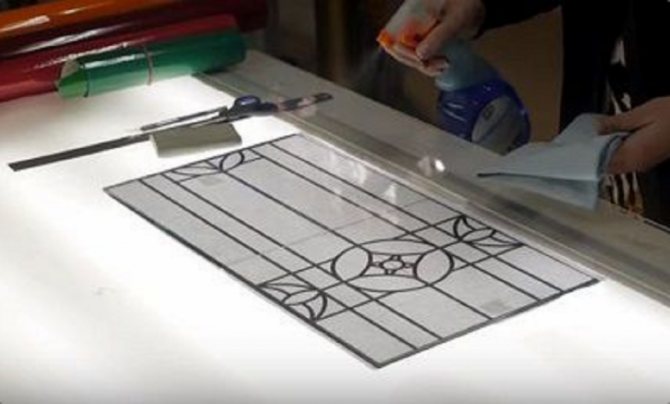

1

Most often, a sketch is printed on a printer on different sheets, and then connected, as in the previous example. If the work is being done for the first time, then you should not take too complex patterns. It is also necessary to equip the workplace with illumination so that the light of the lamp is directed to the sketch from below, otherwise it will be quite difficult to work.

2

All parts of the sketch must be glued so that the lines coincide, as shown in the photo. We cut off the excess fragments, if any, with scissors.

Sketch stitching

3

The glass is cleaned, degreased from the side of contact with the sketch and wiped thoroughly.

Glass cleaning

4

The glass is applied and fixed so that there is no distortion. To do this, you need double-sided tape.

Glass fixation

5

The glass is degreased from the outside and wiped dry.

Glass degreasing

6

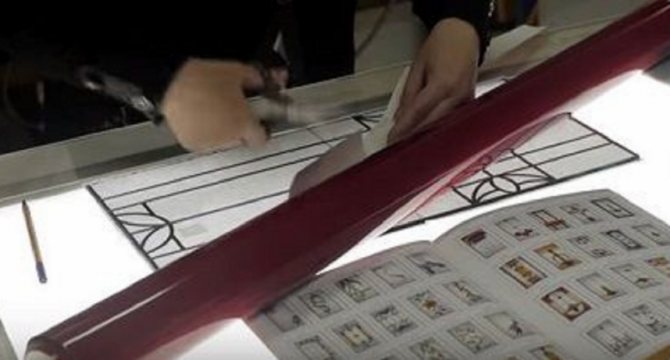

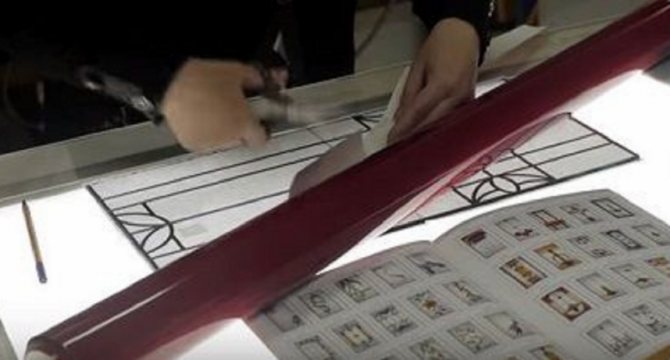

In order to make a stained-glass window using this technique, you will need a self-adhesive film. For each fragment, a suitable piece is cut out, in our case, at the first step, these are strips.

Film strips

7

Before gluing the film, the place is once again degreased and wiped dry.

Re-surface preparation

8

Then, the backing is carefully removed from the edge of the film fragment, this edge is fixed on the glass and smoothed with a squeegee.

Removing the matte

9

With a quick movement so that dust does not have time to get on the glass, the film is pressed and smoothed. Leftovers can be trimmed with a knife, if any.

Film application

10

The film should go over the contour visible from under the glass.

Film over the outline

11

Further, the process follows the same principle.

Repeating the process

12

When all the colors are stacked, lead tape is applied for the framing.

Frame sticker

13

The entire tape is rolled with a roller.

Rolling with a roller

14

At the end of the work, all joints are pressed with a special clamp, the surface is thoroughly wiped with a detergent. The stained glass picture is ready.

Finished stained glass

How to make a patio in the country with your own hands: a variety of design, decoration and arrangement options (85+ Photo Ideas & Videos)

"Zalivnoe"

The filling stained glass window is performed in the following sequence:

- We are preparing an assembly table: an even board covered with white coarse calico, felt, a bike or flannel.

- We put a stencil on it - a numbered primary sketch.

- We degrease the glass - the base and put it on the stencil. We take the ends with our hands in new textile gloves; you cannot use the suction cup and leave your fingers on your face.

- We bend, flatten and flatten the contours, one at a time from the left (for left-handers - right) upper corner.

- We adjust it as needed and glue it with dishware PVA. We dry for a day.

- Fill with paint (see below). Adjacent cells of the same color are poured alternately as the previous ones dry: suddenly it leaks, the dried drip can be easily removed with a safety razor blade.

- We dry another day after filling the last cell, insert it into a metal frame - ready to install!

For the preparation of paints, see the trail, but for now let's dwell on the filling; this is the most responsible procedure. Pour the paint with a generously soaked brush or syringe from the inside along the contour, but in no case touching the border (see fig.)! The paint should naturally flow into the meniscus! If the color comes out a little watery, after drying, pour it again in the same way.

Filling a stained glass cell with paint

Pouring / refilling paint in the middle is unacceptable. If you need a thicker stain, you need to outline it and pour more into it. In this case, two fillings into the frame (along the outer and inner contours) are made without delay, one after the other.

The point is that the "blyamba" in the middle will break the refraction. The "boke effect" known to photographers will appear, and a single such element will break the integrity of the perception of the composition. And if there are a lot of them, then the whole stained glass window will turn out to be sloppy.

Paints

Homemade stained glass paints are known in four types:

- On PVA and aniline - the easiest to prepare and the most unstable;

- Soviet-rarity - on BF-2 glue and paste for ballpoint pens;

- Gelatin-aniline - fragile and fade in direct sunlight, but give an ideal meniscus;

- Nitro-oil - the most expensive, but have all the advantages without disadvantages.

First. PVA-aniline paints are prepared simply: dilute 50-100 ml of glassware PVA twice or three times with distilled water. Then, in hot distillate - aniline dye for fabric according to the instructions for the tablet, and filter it through calico, gas or thin women's tights. We drip a few drops into the PVA emulsion, stir, put a drop on the glass and check the color scheme. Lightened - add a pigment solution; overshadowed - emulsions.

Second. BF-2 is diluted in half with acetone and pen paste is added dropwise to the solution with stirring. Kohler is checked with a test drop, as indicated above. Gives an excellent meniscus, stance, bright, but - alas! - the turnover of pure acetone is limited, because it is used in the artisanal illicit drug production. And you cannot replace it with a nitro solvent or alcohol.

Third. 6 gr. edible gelatin is diluted in 200 ml. distillate at 40-50 degrees. A solution of aniline dye, the same as for the first paint, is added dropwise after cooling to the same temperature and the color is also checked. Strength and resistance to fading can be slightly increased by covering it with transparent acrylic varnish after drying. Aniline with PVA - it is impossible, it will float.

Fourth. We prepare a composition of 60% by volume of transparent furniture nitro-varnish and 40% 647 solvent. We squeeze the artistic oil paint directly from the tube with pea-sized balls, stir, check the color for a drop. Suitable for acrylic coating; at the same time, the strength is acrylic, and the durability is practically unlimited.

Notes:

- Sometimes the paint is not stirred, but curdled. This means - the manufacturer is a deceiver: it is not prepared with natural hemp oil.

- Colors can be mixed, as artists do, but following the rules for mixing mineral oil paints. Otherwise, it may turn out, as with Ozerov's paintings.

Video: master class on filler stained glass

How to make a stained glass window with your own hands - practical advice.

Preparatory work.

So, we need: 1.6 mm aluminum wire, white glue (PVA emulsion) and special stained glass paints. The latter can be replaced with aniline dyes - dyes that are used for dyeing fabrics.

However, before starting work, carefully consider what result you want to achieve in the end: whether it will be some kind of drawing on glass (birds, fish, animals, people, fairy-tale characters, flowers, or other) or is your goal simply multi-colored ornament. Then on whatman paper (cardboard or graph paper) draw the outline of the pattern, indicating on it where and what color will be used. You can do the sketch yourself, but if in doubt, you can ask for help from more artistically gifted acquaintances.

Now remove the glass from the place where it is (door, window opening, frame, etc.), and degrease with a tuck and acetone, the side where the stained glass will be made. After that, on the back of the glass, fix the previously prepared sketch.

First step.

Next, our glass must be placed strictly horizontally; to minimize the error, use a level or a small ball. Then we bend the contours of the necessary elements with wire. Gently but abundantly grease the wire with glue and press it against the glass, placing a metal plate with a load on it. We leave everything motionless for 1-1.5 hours so that the wire has time to stick.

But this time we do not sit idle, but prepare paints (colors). If aniline dyes are used, then they should be dissolved in distilled water and filtered (this will get rid of possible solid particles or lumps), and then mixed with PVA glue. As a result, you should get a solution that resembles cream in consistency, otherwise it will not be very convenient to work with it.

Second step.

Now we check the color saturation on a piece of glass, for this we apply a little paint there. When the paint is dry, you will see what shade you get. If the colors are too bright, you can muffle them by adding emulsion there, and the pallor, on the contrary, will be corrected by the added dye. But remember, the amount of intense and pale colors should be balanced, so don't try to make all colors as bright as possible.

Having prepared all the colors and shades, pour them into glass jars and cover with lids, this will protect them from drying out. You can proceed to the most important and crucial stage of work - applying colors to glass, or rather to the areas marked on it. To do this, you need a little practice (you can do this on an unnecessary piece of glass) and a clean brush. Colors are applied to the elements of the stained-glass window, starting from the wire (part outline). Moreover, adding new portions of color, it is necessary to constantly monitor the thickness of the layer of the entire element, this will determine the uniformity of the color of the element in the future. Also remember that you cannot apply color over the existing one, since the paint tends to dry out, so all your extra touches will be very noticeable and lead to a defect in the entire canvas.

Step three.

If, for one reason or another, something did not work out the way you wanted, then in no case try to fix anything. Better to completely wash off the unfortunate area, let the glass dry and try again.

Only after fully understanding one color, proceed to another. And in order to avoid leaks, new elements should be painted over only where the nearby parts have already dried out.

After finishing with all the elements, examine the back side of the stained glass window. If everything went well, then I hasten to congratulate you, the work is over, and the stained-glass window can be fixed in its rightful place. But often not everything goes so smoothly. It happens that the places where the wire is glued do not look very neat. Do not despair, take white enamel paint and draw thin white stripes in these places (wire attachments), of course, degreasing the glass there beforehand.

Now that's all for sure. Well, if you want to make your stained-glass window more durable, I recommend covering the resulting work of art with varnish.

Tiffany

Tiffany stained glass is an order of magnitude or two more difficult in the work of the above, so we will deal with them in stages. There are difficulties and subtleties at all stages, except, perhaps, patina. And neglecting the technique on any of them will ruin the work. In addition, you need to acquire some special tools and materials.

Tool

Glass cutter

The main key to success when working with tiffany is a glass cutter, because you need to cut out small curved pieces of glass, and stained glass is very viscous. Therefore, only a diamond cutter is needed. Advisers to make do with roller victorious ones are unlikely to be able to cut a piece of glass into the window themselves.

Diamond glass cutter for curved cuts

Diamond glass cutters are of two types: with a sharp point (diamond pencils) and with a curved cutting edge. The former are suitable only for straight cuts, and the latter for curved cuts. The type of cutting part and the cutting method are indicated in the certificate for the tool, and in appearance - a glass cutter with a curved edge is necessarily massive, with a backing for tapping / breaking, see Fig. After cutting with a pencil, the cut piece simply breaks off.

It is undesirable to buy from hands - in 90% of cases they sell because the diamond is chipped and does not give a sonorous cut (see below). There are also files for glass - thin steel strips with a diamond coating. They produce quite decent curves of cuts of large parts (glass for cabinets, etc.), but they are unsuitable for smalts - you cannot cut a small radius.

Notes:

- Diamond, so you know, although the record holder for hardness, is fragile. The ancient myth of slaves who were promised freedom if they smash a diamond with a hammer on an anvil is just a myth. It prickles, even if dropped on the stone floor. Therefore, the glass cutter must be stored in a standard case and handled with care.

- Glass cutters from different manufacturers are very, very different in cut quality. A sign of goodness - a case made of genuine leather with a felt lining.

Soldering iron

Grinder for smalt

Tiffany soldering is done by capillary method, therefore an electric / radio-technical soldering iron with a long red copper tip is not suitable. Need a tool with a nickel-plated bronze sting; it serves only for heating, and the solder does not stick to it during the soldering process. You can recognize this by the initially short white shiny tip (see below in the figure with soldering accessories), and they go on sale under the Long Life brand. Power - 100 W, no more and no less.

Abrasive

To fine-tune smalt after cutting, it is advisable to have a glass sander, see fig. But it costs a lot, and in any case, for accurate fine-tuning, three grinding stones number 220-240 and a width of 12-20 mm are needed: square, semicircular and triangular. The latter is also necessary in the presence of a machine for sampling sharp inner corners; in drawings, say, with leaves, it is very difficult to do without them.

Notes:

- For smalt volumetric stained-glass windows, a grinder is absolutely necessary. It is impossible to accurately maintain the required bevel angles of the side faces with your hands.

- It is also desirable to have a diamond file of a lenticular section - for finishing the same corners on very small fragments.

Bars should be looked for from natural garnet or corundum, heavy and very strong. The “sand” wonders of powder technologies do not sharpen glass, but grind against it themselves.But to grind smalts, even on the best bar, is necessary under a layer of water, for which the bar is immersed in a bowl, baking sheet or some other suitable pallet during turning.

Patina spatula

We make a spatula for applying patina ourselves - from a toothpick and a piece of dense foam rubber 5-6 mm wide and 3-4 mm thick. We put it on a toothpick and fix it with a thin soft wire.

Materials (edit)

Glass

Tiffany length smalts can be made from ordinary glass by painting it as for "jellied" glass. But it is better to buy special stained glass. Translucent, opaque or milky. It is expensive in sheets, but the same firms sell battle cheaply (the material is valuable), but we don’t need much.

Notes:

- It is not necessary to immediately order cutting into smalts according to the sketch. Expensive, and can't be customized later. You need to cut smalts yourself.

- Since tiffany is assembled on soldering, the temperature of which the paint does not keep, it must first be completely assembled from plain glass, and only then poured. It is possible from both sides with different colors, which will give the picture overflow when viewed from different sides.

Folia

Foil for framing smalt - folia - is sold in art stores especially for stained glass, along with lead tape. Product unit - 4-7 mm ribbon roll. It is undesirable to cut a sheet of foil into strips: the stained-glass window will come out sloppy.

Soldering

Materials for soldering work are shown in the figure, there is also a soldering iron. Pay attention to the inscription: "No rosin". Solder thread with rosin inside (harpyus) is unsuitable for soldering stained-glass windows. Soldering flux (this is a jar in the figure) is needed with a drill or other semi-active, for soldering electronics. Remains of active flux (with phosphoric acid, etc.) cannot be removed from the binding, and it will eventually be corroded.

Soldering accessories

Usually, POS-61 solder is recommended for soldering tiffany due to its fusibility - 190 degrees. Smalts sometimes crack from ordinary tin-lead solders (240-280 degrees). But POS-61 is fragile, very soft. There is also POS-61M with copper additive, 192 degrees, but it is only slightly stronger.

The best solders for tiffany are with cadmium additives: POSK-50-18 (145 degrees, in the figure) and Avia-1 (200 degrees, strength - like duralumin). POSK-50-18 is weaker, but still much stronger than POS-61 / 61M. It is inexpensive, unlike Avia-1, which is readily available.

Patina

Nowadays, art and hardware stores sell various types of blacksmith's patina. It is better to buy liquid, ready-to-use. It will be only slightly cheaper to prepare the composition from the powder yourself, but it is difficult, and the quality of the coating will be worse.

Stages of work

Making a non-monotonic bend

Sketch / stencil

Already when choosing a pattern, it is necessary to take into account the peculiarities of the technology and its weak points. S-, N- and deep U-shaped bends of the edges of smalt are unacceptable: due to the difference in TCR of glass and metal, smalt will begin to crawl out and fall out over time. Ideal smalt is an area bounded by convex smooth curves. If a non-monotonic bend is needed, it must be collected from pieces, albeit of the same tone, see fig. Suddenly the finished composition, due to the binding, turns out to be flickering / clumsy - nothing can be done, you need to change or refine the drawing.

Note: drawings for stained glass - a separate area of pictorial art. On the Internet there are many ready-made for different techniques, but if you want your own unique one, you need to turn to a stained-glass artist or look for creativity in yourself.

Cutting smalt

First you need to make a base, the same as for a stained glass window. With a correct cut, the remainder breaks off from the slightest push, therefore, it is not necessary to immediately bring it to the overhang: after the cut under the glass, a thin strip is slipped over the cut, and lightly pressed with a finger on the remainder. Not broken off - can be tapped on the weight.

Try cutting a piece of regular window glass.If the cut is squeaky, a scratch is visible, but to break it you need to tap it several times, it's too early to take smalts.

With the correct cut, the glass emits a quiet thin ringing, and the crack is not visible at all. To break, light pressure is enough or lightly bump from the bottom. To get such a cut, you need to maintain the angle of inclination of the tool in the direction of the cut (about 45 degrees, or according to the specification for the glass cutter) and keep it strictly perpendicular in the transverse direction.

The second condition is strictly constant pressure. The skill in angle and strength should be worked out to full automatism when cutting lines of any kind. This is called putting your hand.

Note: the exact angle and pressure are individual for each diamond glass cutter. Therefore, aces glaziers do not use other people's tools and do not offer them for rent.

An example of the location of auxiliary cuts

But that's not all. A curve cut on a curve will never crack by itself, even if you crack. It will leave both the side and, according to Murphy's First Law, exactly where it will harm the most. What to do?

The auxiliary cuts along the tangent are denser, the curved, see fig. As a general rule, the deflection arrow between two adjacent auxiliary cuts should not exceed two glass thicknesses. By the way, this circumstance must also be taken into account when developing a stencil. Therefore, if you order a drawing from an artist, then immediately determine the stencil. However, good masters add a stencil to the drawing without anything.

If there is an angle on the smalt, a tangent to the least convex side is required from its beak. From the above, an important conclusion follows: do not try to cut out many single-color smalts at once from a large piece. Almost all expensive material will go to waste. In general, smalts are cut one at a time as the stencil is filled, see below.

Here the question arises: how to trace the smalt templates? The glass cutter is not a razor blade or an assembly knife, but rather plump. And that's what stencil scissors are for. The width of the third, middle, blade just takes into account the resulting indentation.

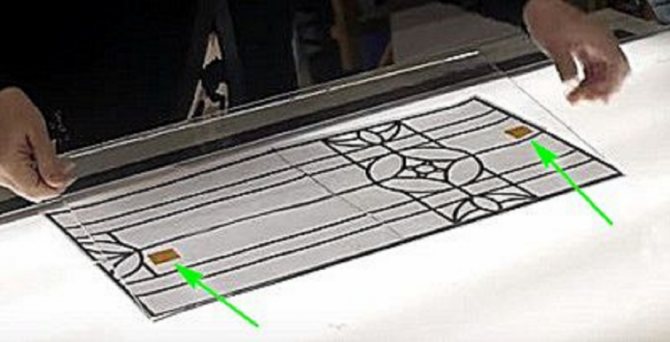

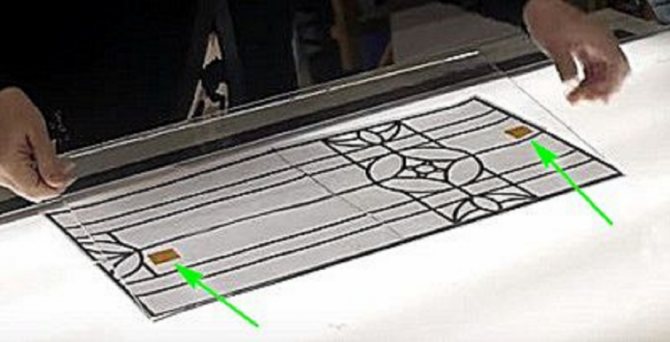

Set to composition

Before starting the set of stained-glass windows, the stencil on the assembly board is fixed with even slats on the left (for left-handers - on the right) and at the top. Smalt is laid from the corresponding far upper corner, see on the left in Fig.

Laying smalt on a stencil

The smalts are cut out strictly one at a time, otherwise the whole set will creep before reaching half. Cutting out one, adjust and calibrate it according to the stencil (you need an indent inward from the contour of 0.5-0.7 mm for soldering). Then they wrap it in a foliage and roll its edges with a round piece of wood or plastic (middle position). After rolling with the same ironing iron, iron the side edge; for internal sharp corners, it is convenient to use a school plastic ruler with a wedge-shaped edge or a plastic knife from a set of disposable tableware, and roll it up.

Now smalt is laid in place already before soldering, pressed tightly against the previous ones or the side, and the template for the next one is checked against the stencil. If necessary, cut the template with curved nail scissors, and only then return to the glass with a glass cutter. On the filled part, there should be no visible gaps between smalts, right pos. in fig.

Note: the best stained-glass windows are obtained when typing on a blueprint machine covered with calico or a bike. The slightest crack is immediately visible.

Crimping and fluxing

After laying all smalts, the composition is neatly squeezed horizontally with slats now on the right (left) and below. If the smalts begin to bulge upward at the same time, they iron and roll the foliage, press down on top. After that, they start fluxing.

The smalt templates used are laid out next to the shield in accordance with the composition and numbering. You don't need to be very precise, as long as the pieces don't get messed up. Now the fragments are transferred to this intermediate stencil, starting from the corner opposite to the initial one, i.e.in the reverse order of assembly. So it is necessary that the flux at the ends of the smalt does not dry out.

Next, the smalts are transferred one by one back to the working stencil in the same way as they were collected. In this case, the folium framing is coated with a thin layer of flux (it has the consistency of petroleum jelly) using a match or a toothpick. Having assembled the composition again in the old place, they are squeezed again, but the right (left) and lower slats are now fixed with carnations. You can start soldering.

Soldering

The main condition for soldering is not to do a lot at once. Due to the difference in TCR of glass and metal, when overheated, the entire composition can swell and collapse. At a time, you need to solder the area into one or two men's palms, then let it cool, and continue soldering. Soldering is carried out in the order of laying.

Tiffany is soldered by capillary method. First, along the contour of the next smalt, pieces of a solder thread in the width of the soldering iron tip are dripped onto the seam with a step of 1-1.5 cm. The operation is carried out on weight, without touching the thread of solder and the sting of the foliage. This is painstaking, exhausting and demanding work, so take your time and take breaks for rest.

Then the seams are soldered. Each drop or sausage of solder on the seam is heated until it all at once goes into the seam and spreads over it inside. If the flux evaporates and burns out earlier, this may not happen, so flux sparingly, but without dirt. The missing flux can be added during the soldering process, then only after the soldered area cools down. You do not need to scatter the set, the flux can be applied on top and slightly heated so that it flows into the seam.

Video: tiffany stained glass technique (eng)

Framing

The composition is also soldered into the frame. It is not necessary to glue on epoxy or acrylic: due to the difference in TCR, the stained glass window will not last more than 5-7 years. The frame is made of brass or bronze corner.

The frame must be solid; one soldered connection is permissible in a patch at the junction of the circuit. Therefore, the U-shaped profile is not suitable: how can you put a stained-glass window into it, one-piece? It is possible, however, to slip it in pieces under the stained glass, but then in the corners you need kerchiefs on soldering, which will be visible on the finished product. However, again - a matter of taste. You can immediately match the pattern with the kerchiefs.

The frame is cleaned from the inside with a school eraser to a shine (the semi-active flux does not dissolve the oxide film on brass) and thoroughly washed with a cotton swab abundantly moistened with alcohol. Then wipe with a new, unused microfiber eyeglass cloth.

Now the frame from the inside, and the edge of the stained-glass window from the face and from the side, is coated with flux, the frame is applied to the composition, and soldered, like smalts, piece by piece. After cooling, the stained-glass window is carefully turned over, the flux is applied to the seamy gap between the edge of the composition and the frame, heated until it spreads, and the gap is soldered. It remains to rinse from the remains of the flux and seal.

Flushing

It is no longer necessary to waste liters of alcohol to remove flux residues: detergents for dishes do an excellent job of removing them. A particularly gratifying circumstance for a non-drinker: from "him, my dear" during alcohol washing such a dukhan ...

They wash the stained-glass window (already stained-glass window) in the bathroom under the shower with a foam rubber sponge soaked in detergent. Particularly stuck flux residues are removed with a toothbrush. They do not give in immediately, so a simple operation turns out to be painstaking: you cannot press hard or cut off. Quite often it is necessary to soak the stained-glass window in a bathtub, into which a whole bottle of "Fairy" is poured, until the flux coke becomes limp and disappears under the sponge.

Patination

The final stage is the patina of the binding. The operation is simple: we cast it into a shallow consumable container, pick it up on a spatula and apply it to the binding. After drying, the excess is washed off with the same dishwashing sponge under the shower without any difficulties.

There is only one nuance when patinating: it is caustic and harmful, this is a ready-to-use blacksmith patina.Therefore, you need to work in a ventilated area, wearing protective gloves, goggles, and, preferably, a petal respirator.

After rinsing from the remnants of patina and drying, the stained-glass window is ready - you can insert it into the frame and admire it.

About matting

Film and filler stained-glass windows used with backlighting look good if the back of the base is matte. Home-builders are sometimes offered recipes for chemical matting, but these recommenders, it seems, did not smell this chemistry themselves, since they are alive: deadly volatile components are used in chemical matting - hydrofluoric (hydrofluoric) acid and its compounds. Matting with silicic acid is no better: you need concentrated sulfuric acid, and poisonous volatile products are also formed.

The easiest way to self-matte the wrong side of the base is to take, and put plastic tracing paper from the inside. Lasts more than 10 years. If the matte base is visible from both sides, then there is a laborious, but completely harmless way:

- We buy 10-50 g, depending on the area, of corundum powder of the smallest fraction (0.05 mm).

- Scatter in small piles over the area of the glass.

- We drip linseed, rapeseed, palm oil or spindle into each pile until a gruel is obtained; the list is in order of preference.

- Rub with light pressure with a burner made of whole, not double, rawhide; a piece of an old, rough, wide waist belt will work well.

- The three front (smooth) side was polished, alternating longitudinal-transverse and circular movements. With some skill, even frosted glasses for photographic equipment can be obtained in this way.

- The rest of the abrasive is washed off with water, dishwashing detergent and a sponge.

Note: you need to flush into the pan, not the bath, otherwise the plumbing will die.

Video: program on making tiffany stained glass

Finally - about aluminum

Someone, after reading the article, will remember: wait, but the glazing of furniture? Isn't it a stained glass window? In standard duralumin profiles, cheap, beautiful, shiny. And you can bend them.

No, there is not a stained glass window. Stained glass is a separate transportable product in a solid frame, brazed or cast. Okay, let's solder it. Aluminum is soldered, and even without argon - there are special "scraping" solders (CSP, for example) and not particularly caustic fluxes on oleic or palmitic acid.

Yes, but the temperature needs 350-400 degrees, glass does not keep this in close contact with metal. If you very slowly heat the entire set on a fire-resistant shield, it swells and disintegrates from the difference in TCR. Give allowances for thermal expansion - it disintegrates and falls apart when it cools.

So "real", not on glue and resins, stained-glass windows in aluminum binding have not yet been obtained. If someone comes up with how to make them, it will certainly be a revolution in the art of stained glass: aluminum alloys are light, and their strength is comparable to steel.