Glazing with the help of stained glass windows can rightfully be called one of the most popular works in the construction of any buildings - after all, a stained glass window made of translucent aluminum structures rightfully performs the function of not only the enclosing openings of the structure, but is also able to usefully transmit light into the building, performs a decorative role in the area architecture, for example:

Modern stained-glass glazing using decorative stemalite materials and decorative glass allows you to complete the building and give it a unique decor, moreover, modern architects are able to design a stained-glass window structure with inserts from any facing materials, which can be done by our Architectural Studio Optima

What is stained glass

The production of stained-glass windows using the most advanced technologies is a complex of works using translucent structures, with their filling. Stained glass glazing made of a solid glass sheet allows you to create from it a variety of shapes and sizes for a wide range of applications. In addition, there is a unique opportunity to creatively use a large number of ways to create your own style in making an architectural decision.

Using the post-transom system in the stained-glass glazing device, you can in a short time:

- glaze the entire front surface of the building or part of it;

- to decorate the building with a straight, radius or curved structure, fastening from aluminum stained-glass windows;

- complement the facade with a canopy, balcony, entrance complex or revolving door.

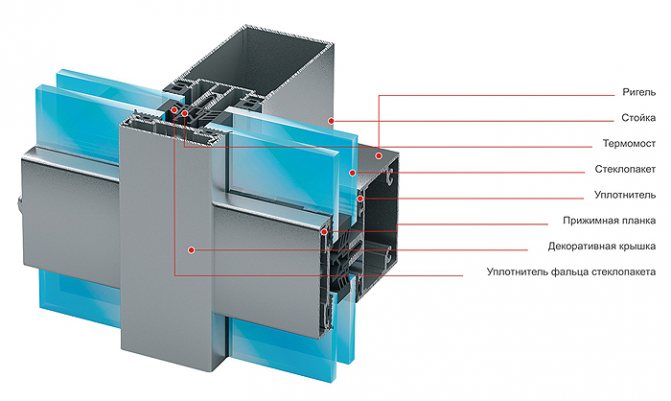

The basis of the frame of the post-transom system is made up of horizontal transoms and vertical posts. In practice, there are the following options for this system:

- classic;

- structural;

- semi-structural.

When ordering a range of services for the design and installation of stained-glass windows from an aluminum profile in Moscow, during the order period, we perform a full range of calculations of technical indicators according to SNiP "Loads and Impacts" characteristic of the location of the area and the location of the object itself, where these glazing systems are supposed to be installed.

Average construction cost per m2

An ambiguous value depending on such factors:

- labor intensity of work;

- characteristics of the material included in the composition;

- their sizes;

- type of construction, etc.

The price is also influenced by jumps in the exchange rate, the entrepreneurial spirit of trading organizations, and other circumstances.

When processing an order, the price per square meter is calculated, and then the price is calculated for the entire volume of work.

| № | Name of work (excluding materials) | Unit measurements | price, rub. |

| 1. | Geodetic survey of the building facade | m2 | 90 |

| 2. | Working project development | m2 | 120 |

| 3. | 3D rendering | m2 | 50 |

| 4. | Production | m2 | 3900 |

| 5 | Insulating glass production | m2 | 2970 |

| 6. | Delivery to the facility (loading, unloading) | m2 | 150 |

| 7. | Installation of scaffolding (electric lift) | m2 | 120 |

| 8. | Installation of vertical-horizontal rack structures | m2 | 690 |

| 9. | Installation of smoke exhaust flaps | m2 | 1300 |

| 10. | Installation of double-glazed windows | m2 | 1570 |

| 11. | Bonding hermo butyl tape | m. | 75 |

| 12. | Installing the pressure plate | m2 | 220 |

| 13. | Trimming, installing hoods | m2 | 120 |

| 14. | Laying a sealing tape around the perimeter (vapor barrier) | m. | 58 |

| 15. | Washing double-glazed windows (using electric lifters) | m2 | 190 |

| 16. | Total | m2 | 7150 |

Types of post-transom system

Classic post-transom system Today, it is the most demanded in the construction and arrangement of facades on buildings of business centers and other structures of urban infrastructure. The design feature of the post-transom system allows the most advantageous (in terms of style and practicality) methods of connections, transitions and other specific installation elements to be used multifunctionally.

The classic system, as a rule, is used in the work on glazing of stained-glass windows made of aluminum profiles, the price for which is formed, depending on the volume and complexity of the individual project. These can be winter gardens and greenhouses, facades with straight and inclined shapes, as well as skylights and glass roofs.

Structural glazing system The structure of the system is supported by a frame base consisting of load-bearing uprights and horizontal support profiles, otherwise called transoms. In addition to them, a clamping profile is used here. It serves as a fixer for double-glazed windows and decorative strips that hide the clamping strips underneath.

Thanks to the development of the latest generation of ultra-strong sealants, in which the main material is silicone, this system of stained-glass glazing of building facades has become often used in construction.

Due to its decorative qualities, the structural system continues to gain in popularity with customers steadily.

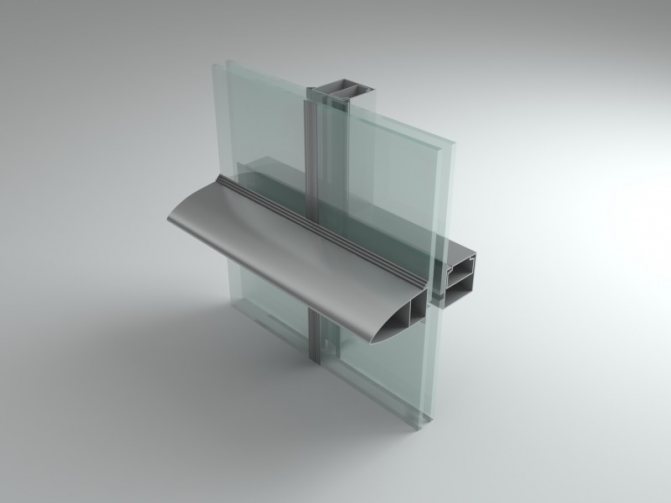

The frame base of aluminum stained-glass glazing systems, in most cases, is formed from a flexible and durable aluminum profile, fixed from the outside of the building. It can also be interfloor floors, which will allow the frame of the translucent structure to be practically invisible from the outside. Double-glazed windows form a solid wall of glass, without the appearance of joints and seams.

Semi-structural glazing system The choice of semi-structural glazing will be the ideal solution for the construction of both vertical and inclined stained glass facades, since this system is more profitable in economic terms, while maintaining the reliability and stability of waterproofing. It is not necessary to use external covers with it, therefore, the semi-structural facade, in terms of its external design, looks aesthetically more attractive than the classic one.

The semi-structural system has modified, that is, it has combined the most functionally useful qualities of the structural and classical (post-transom) systems. The semi-structural glazing system creates an exceptionally flat glass surface from which all precipitation flows freely.

Not sure which type of construction is right for your facade?

Leave a request on the website, and our experts will advise you on your project and the choice of a system for stained glass glazing.

To get the consultation

Advantageous cladding sides

Stained-glass windows fundamentally change the appearance of the building, making it more aesthetically pleasing. This is a practical glazing that has the following advantages.

- Saving. It manifests itself in everything. In terms of time, this is the fastest finishing of large facades. The cost of materials and work is significantly less than when performing similar facades from another material. Installation of stained-glass windows is convenient due to the low weight of the module. There is no debris left after work.

- Long term of use. All glazing materials have been in operation for about 70 years. They tolerate any moisture without any problems, do not rust, do not collapse.

- Light transmission. The large luminous flux area improves the interior of the building and reduces electricity costs.

In the case of the "warm" version, the thermal conductivity and sound insulation are increased. The hermetic design of stained-glass windows protects people inside the building from uncomfortable conditions.

Complies with fire safety standards. All wall elements are self-extinguishing.

One nuance is important in stained glass windows. Before facade work, it is required to carefully study the seismological situation at the site of the building. Considering the light weight of the buildings, there should be a stable situation in the place of the architectural object without fluctuations in the soil.

Translucent filling of stained glass systems

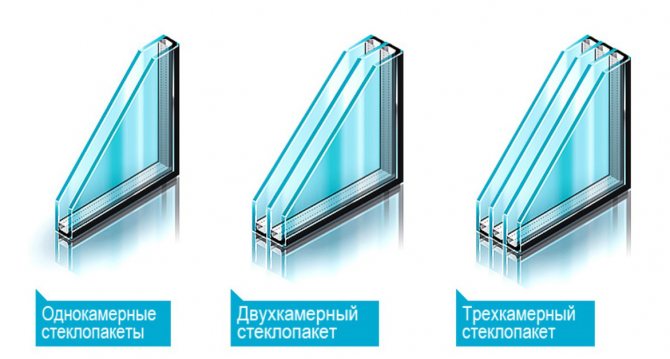

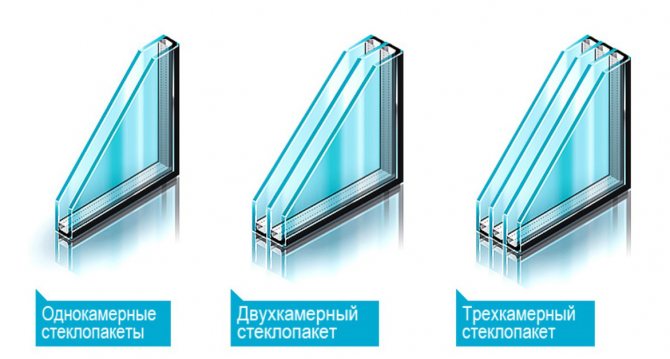

The functionality and appearance of the facade largely depend on the properties of double-glazed windows. When developing a stained-glass glazing project, our specialists select the type and thickness of glass, the type of energy-saving coating and other parameters. Most often, single-chamber or double-chamber double-glazed windows are used in facade glazing. The latter are used when it is necessary to provide a high level of heat saving of the building envelope.

If you are looking for a practical and modern solution that allows you to favorably highlight the facade of a business center and give it a unique and memorable look, then stained glass glazing will be the best choice.

Manufacturing material

In residential buildings, low-rise supermarkets, it is used plastic frame... It is cheaper, but also not durable. Aluminum is used in high-rise large buildings, where large horizontal and vertical loads on the glass and frame are possible over the entire area of the stained-glass window. Accordingly, the type of profile and material is selected for a specific type of glass block. If the unit is multi-chamber, the profile will be aluminum or metal-plastic. Then it will withstand the load. For a one-piece stained-glass window, a conventional plastic frame is sufficient.

Price for stained-glass windows made of aluminum profile

The construction company carries out a full range of works on the installation of stained-glass glazing systems. Our experts will guide you on prices for aluminum stained-glass windows per m2, according to your project. And they will also carry out full support of the project: from the conclusion of the contract to the delivery of the object.

| Name | Price per m2 | Note |

| Stained glass frame AF50 | from 3 100 rubles / m2 | manufacturing, painting according to RAL |

| Glass unit | from RUB 1,700 / m2 | 32 mm |

| Adjacencies | from 250 rubles / m2 | galvanized steel 0.55 mm |

| Installation work | from RUB 1,700 / m2 | without scaffolding |

| Design work | from 200 rubles / m2 | without geodetic survey |

| Total: | from 6 950 rubles / m2 | per m2 |

Step-by-step finishing instructions

It is not difficult to assemble the structure in the glazing according to the following scheme:

- Measurements. The bulk of the work. Correct and quick installation of the facade depends on its accuracy. Measurements are carried out with ultra-precise mechanisms, laser technology.

- Installation of the structure frame. Jewelry work is carried out with devices that accurately determine the set level of the modules.

- Installation of a double-glazed window. Finished double-glazed windows or glasses are inserted into the fixing base.

- Installation of window fittings, fine-tuning the modules to a holistic perception of the picture, adjusting the opening parts.

- The assembly of large-scale stained-glass windows is performed with special equipment (manipulators).

Glass unit

Stained glass is the frame of the outer part of the building, behind which the living quarters begin. They need to be insulated, to ensure good soundproofing and dustproof... Multi-chamber glass blocks will cope with this task. If a stained-glass window is a decorative solution, then a single-chamber one is enough, it performs only an aesthetic and minimally protective function. On the other hand, many installers successfully save on profiles by using plastic rather than aluminum. Aluminum is more resistant to weathering, easier to attach and excellently withstands heavy loads. Plastic is not able to withstand huge loads, only a single-chamber system of a simple type is suitable for it. In any case, a two-chamber package or even more is perfect for stained glass windows. Although it weighs a lot, it keeps the temperature perfectly.

On account of the choice of the type of glass - a dumb decision for the client. You can pick up tinted glass unit, armored, triplex, others. The frame will withstand any loads if you correctly calculate the type of profile and the rules for its installation. You also need to take into account that the steeper the glass, the heavier the whole structure will be. Therefore, it is better to consult with the builders, and approach the specialists of a company that specializes in the construction and restoration of stained-glass windows. Armored glass and triplex is recommended for supermarket stained glass windows. Tinted glass is used in residential and office construction. Simple transparent glass is used relatively rarely in stained-glass windows.

Famous manufacturers

Many design studios actively cooperate with such giants as Rehau, Steko, Veka, GEOID, OknoPlast. All small manufacturers of stained-glass windows buy spare parts from large manufacturers, because a guarantee is provided.

The main names of the best stained glass systems:

- REYNAERS (Reiners, Belgium)

- Tatprof (Russia)

- SCHUCO (Schuko, Germany)

- VIDNAL Prof (Vidnal, Russia) old name Alumax (Alumax)

- Sial (Russia)

- AGS (ASG / Agrisovgaz, Russia)

- NewTec (Newtec, Italy)

- Gcc (Taiwan)

- SADEV (Sadev, France)

Aluminum translucent facade: production and fixing of structures

Stained-glass windows have one more feature - all stages of production from measurements to installation require high qualifications and experience of specialists. Simplified, the manufacturing and installation process includes several stages of work and begins with pre-design preparation, when a data package is determined on the bearing capacity of the foundation, walls, features of the materials of the wall opening, operating conditions, and the specifics of the installation. They carry out the necessary stained-glass measurements, taking into account the technological allowances for the installation, and after the development, coordination and approval of the project in the factory, they carry out a complete assembly of the structure with subsequent disassembly into blocks and assemblies convenient for fixing.

All requirements for filling are determined by the project, and for fixing in terms of design and materials - the current GOST 30971-2002 and GOST R 52749-2007, as well as the departmental instructions of the profile contractor company.

Table. Typical work of a full-cycle production and technological process

| Stage of the production and technological process | Typical work |

| Studying the wiring diagram | Checking the size of the stained-glass window and the wall opening Checking the completeness of the delivered product Study of the place and working conditions Choice of means for fastening structural elements |

| Preparatory Processes | Cleaning the surfaces of object openings from dirt Disassembly of the operating structure (if necessary) Restoration of sections of the opening with defects Fixing fasteners Preparation of the site where the assembly of the structure will be carried out (if necessary) |

| Fixing the structure | Install the aluminum section or module according to the instructions in the place indicated on the project drawings Align the structure in the vertical and horizontal plane with a level and a plumb line Fix the stained-glass window with fasteners according to the project |

| Insulation and sealing of seams | Strengthen PSUL tapes or another type of hydro-, vapor barrier outside the assembly seams Fill technological gaps with polyurethane foam Glue the inner perimeter of the junction of the stained-glass window to the wall opening with PSUL tapes Finish the slopes of the wall opening according to the project |

| Installation of filling (glass, double-glazed windows) | Carry out after setting and hardening of polyurethane foams using special grips for double-glazed windows |

| Acceptance and delivery activities | Remove construction waste from the place of work Check the functionality of the sash and, if necessary, adjust the clamps with fittings Train the owner on the features of operation and maintenance |

Legal subtleties

The decision to arrange stained glass balconies is not always supported by the regulatory authorities.An uncoordinated event could lead to legal action by the housing sector. As a result, it will be necessary to dismantle, restore the previous look.

Read more in the article "Do I need permission for balcony glazing"

It is necessary to apply for permission from the authority in the following cases:

- if the room is located on the open front side of the building relative to the carriageway;

- if glazing is carried out over a busy area;

- if the parapet is a monolithic concrete structure, which may not be dismantled.

After the event, in the case of an affirmative answer, it is often necessary to make changes to the project documentation. This is necessary to legitimize the reconstruction. And it may also be needed for the smooth completion of a transaction for the sale of an apartment.

In the private sector, such issues do not need to be addressed. This is due to the responsibility for the work done, which is assigned only to the owner of a particular house. For landlords, there is a method that, as a rule, allows implementation without approval. It consists in the location of the stained-glass glazing of the balcony from the inner side of the room relative to the railings made of reinforcement. The space is getting smaller, but more often permission is given for such an action.

Main disadvantages

But the stained glass balcony also has several disadvantages. You need to know about them before proceeding with the installation of a panoramic structure.

The most important disadvantages:

- Washing glasses of such an area is not only difficult, it is generally impossible to do it on your own. Especially if a significant part of the windows does not open. For cleaning, you will have to contact a cleaning company.

- In the case when the windows are not tinted, and the apartment is located on the lower floors, then the room will be clearly visible from the street. This is especially noticeable in the evening hours. Also, discomfort will be if the neighboring building is located too close.

- When installed on the upper floors of modern high-rise buildings, the glass vibrates slightly in strong winds.

- If the balcony is located on the sunny side, then on summer days it will be unbearably hot.

In the event that ventilation is not well organized, the glass will begin to become covered with condensation. If you install a good multilayer bag, equip a heating and ventilation system, then you will have to spend a significant amount on this.

Price range

- The price of each stained glass window will depend on the manufacturing method. So, a mosaic stained glass window will cost the most, and an imitation made using photo printing or paints is cheaper.

- It should be borne in mind that it is very difficult to fold a clear drawing from type-setting glass. For those who want to get a beautiful drawing, it is better to choose painting, photo printing or fusing.

It is also possible to combine stained glass techniques: sandblasting with an invoice, mosaic with photo printing, etc. This will simplify complex elements and achieve the desired effect or degree of throughput.

Choose the right way to decorate the window opening. Stained glass will serve you for many years, creating a magical and cozy atmosphere, provided that you use high-quality materials to create it and follow the rules of care.

The fairy tale is closer than it seems