Anyone who loves to independently craft various products and structures often faces the need to bend a profile pipe into an arc. It is impossible to do this smoothly and accurately without special devices, so there is a need to make a pipe bender for a profile pipe with your own hands. Craftsmen have invented a lot of designs for this device. Many of them can be done on your own. Moreover, they do not require large funds and are easy to manufacture and use.

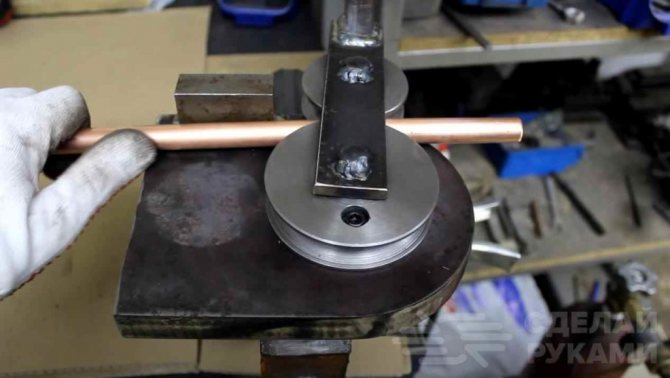

A pipe bender is a device with which you can bend a pipe at the desired angle.

Basic information about pipe benders

Before starting a story about the options and methods for making pipe benders, you need to decide what it is and what it is used for. So a pipe bender is a manual device or a stationary machine that allows you to bend a pipe made of any material at an arbitrary angle.

The pipe can be steel, copper, aluminum or plastic with a diameter of 5 to 1220 mm or profile with any section. Bend angle from 0 to 180 degrees. This article brings to your attention the manufacturing technology of several types of this uncomplicated device, having studied which, in a few hours you can make any copy you like.

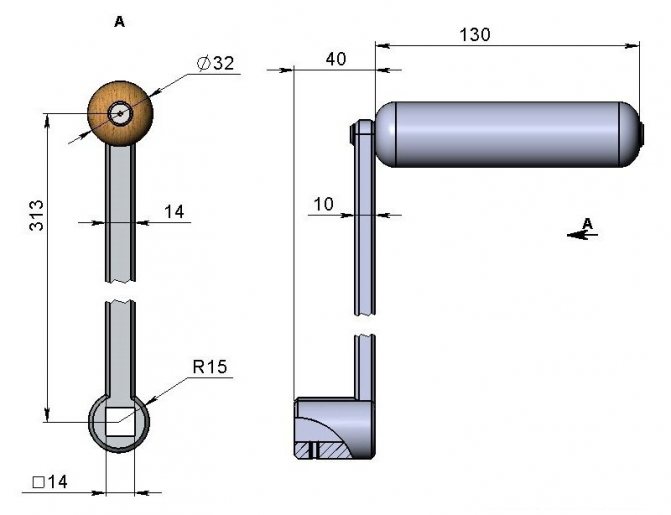

Pipe bender device with shoes for various pipe bending angles

How to make a hydraulically driven round tube bender

If we are talking about performing not just some home repair work, but about professional activities, then you should think about making a more complex hydraulic pipe bender. With its help, when bending pipes, it will be possible to reduce the cost of physical forces, because the load will be on the hydraulic jack.

At the stage of drawing up the drawing of the device, it is necessary to provide for what material the sidewalls will be made of. Optimally, a reinforcement rod with a cross section of 18-20 mm, as well as corners with a side of 25 mm, are suitable for this. In addition, for the sidewalls, you will need 10 mm thick sheet metal with drilled holes to fix the supports.

A tube of appropriate diameter is used as a support, into which a bolt with a section of 18 mm will need to be welded. A semicircular hole will be located in the center of the support, which also needs to be reflected in the drawing. The workpiece will have to abut against this recess, which will be bent on a hydraulic manual pipe bender.

To create the punch, you need 4 mm thick sheet metal, from which you will need to cut semicircular workpieces. The radius of these parts must match the planned bend radius of the pipe. At the next stage, they take a pipe with a cross section of 32 mm and cut it into two parts. One of the parts is bent over the shape of the blank plates, and then all the parts are welded. For additional strength of the punch in a hydraulic pipe bender, jumpers are welded inside it, providing stiffening ribs.

A tube is welded in the central part of the platform. Its purpose is a stop for a hydraulic drive, which serves as a jack. All this must be worked out and provided for in the drawing, according to which the hydraulic pipe bender will be assembled. In addition, such a scheme will make it possible to prepare a list of materials and components with the required parameters. In this case, a number of elements for the tool will need to be pre-ordered from a turner.

Thus, it is not so difficult to assemble one or another type of manual pipe bender.Moreover, there are a lot of options and drawings of finished products that can be adopted in order to make the tool necessary for the household on their own.

Self-made pipe bender device Homemade pipe bender for shaped pipes Hydraulic pipe bender with an electric drive Bending pipes without using a pipe bender

When working with pipes, it is often necessary to change the shape of the pipe, in other words, to bend it.

This can be done using special equipment, or even buy a finished product. But it is much easier and cheaper to make a simple pipe bender with your own hands. Using such a simple tool will greatly facilitate and speed up the work.

What are the types of pipe benders

If we are talking about industrial devices, then they are divided into several types according to the method of implementing the drive, as well as the type of bending.

Drive type classification

There are machines: hydraulic, electromechanical and manual. Hydraulic-driven machines are manual and stationary. Their power is enough to bend pipes even 3-inch diameter. Hydraulic pipe benders are used in professional activities in specialized industries and are capable of performing a very large amount of work.

Hydraulic pipe bender for bending water and gas pipes up to 90 °

Electromechanical devices can be used to bend almost any pipe, even with very thin walls, which is beyond the power of hydraulics. After all, electronics allows you to very accurately calculate the force and bending angle, which prevents the material from breaking. Pipes bent by such devices do not show the slightest signs of deformation.

Electromechanical pipe bender for PEX / AL / PEX pipes and bending angles up to 180 °

Manual pipe benders are used only for bending small diameter pipes made of polymers, stainless steel or non-ferrous metals. They work mainly from the mains. They are easy to use and do not require a lot of physical strength to work. It is quite possible to make such pipe benders for a profile pipe with your own hands.

Hand tool for bending rectangular profiles and steel pipes

Classification by pipe bending method

You can bend a pipe using the device in various ways. Depending on this, the following types of pipe benders can be distinguished: crossbow, spring, segmental, mandrel.

Crossbow devices are equipped with a special shape, which is a bending element. It is designed for one pipe diameter or cross-section. To bend a pipe of a different diameter, the mold must be replaced. The spring devices are equipped with elastic springs that allow plastic pipes to be bent without deformation. Segmented ones are equipped with a special segment that pulls the pipe around itself, bending it at the desired angle.

The principle of bending a profile pipe using a homemade tool

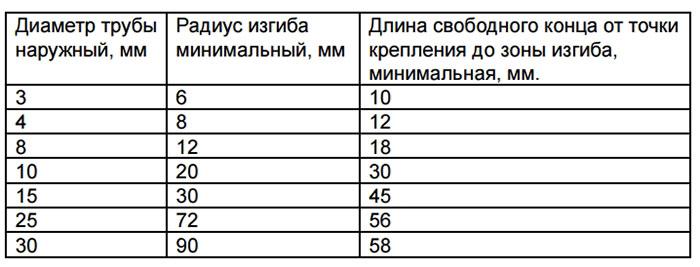

It should be understood that the method and value of the bending angle of the pipe depends on its characteristics. There is even such a value as the minimum bend radius, with a further decrease in which the pipe deforms or simply breaks. This indicator depends on the wall thickness, material and section of the pipe.

One of the options for using a bent profile is arranging a greenhouse

Why do you need a pipe bender?

To understand why a manual pipe bender is still needed in a household and in what work it can be useful, we will single out only a few of the most popular options out of all possible areas of application of bent pipes - these are:

- installation of engineering systems - sewerage, water supply, ventilation and air conditioning;

- installation of fences and nets on the site;

- design and assembly of garden furniture;

- creation of greenhouses;

- installation of a carport.

Important! Depending on the required volume of bent parts and the complexity of the shape, choose the appropriate pipe bender option. This can be the simplest manual pipe bender, profile or hydraulic, the use of which is advisable to change the type of steel pipes. The latter option will also help you quickly cope with the task if you need a large number of non-standard parts.

How to make the simplest manual pipe bender for a profile pipe with your own hands

Now let's look at some homemade pipe benders. The simplest option provides for the possibility of bending the pipe by means of a template to a given radius. This technology is also quite suitable for bending steel pipes, not just aluminum ones. The template is simply cut out of boards, the thickness of which is slightly larger than the diameter or section of the pipe that needs to be bent.

These boards are securely fastened to each other so that the pipe cannot jump out of them during the bending process. To form a gutter, the boards to be fastened are simply cut at a slope for a round pipe. Then, the finished wooden template is attached to a table or other similar base. Next to the template, a stop is attached to fix the pipe.

A do-it-yourself pipe bender for a profile pipe of this type is able to bend even thick-walled pipes if you use a winch. If the pipe is profiled, then the bevels are not made when cutting the boards. Instead, the pipe is secured with multiple stops.

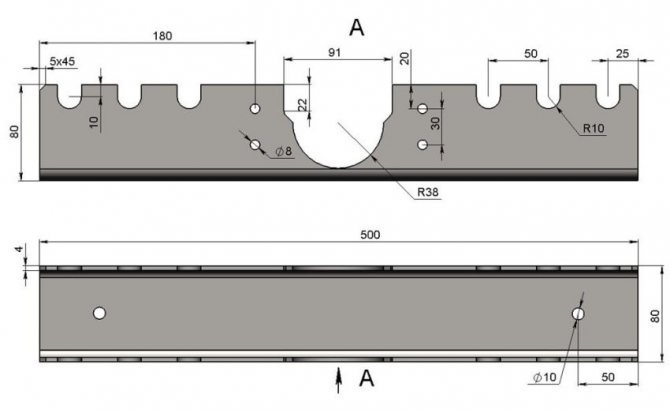

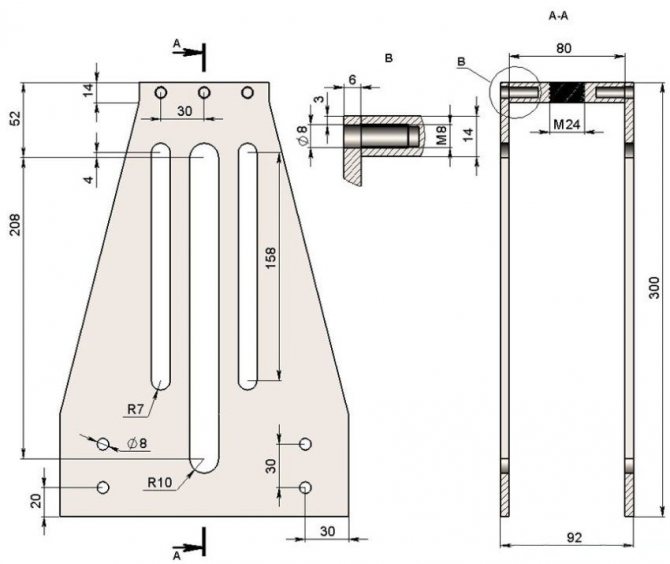

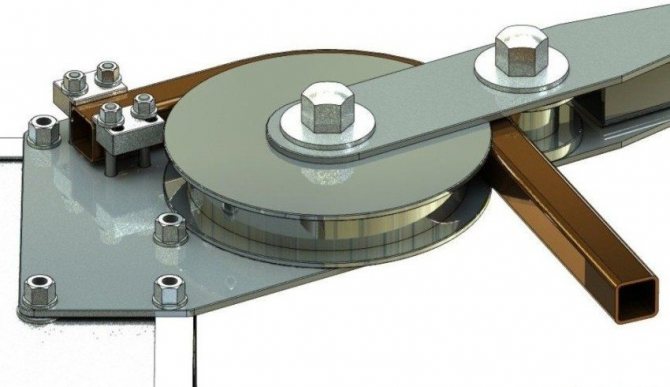

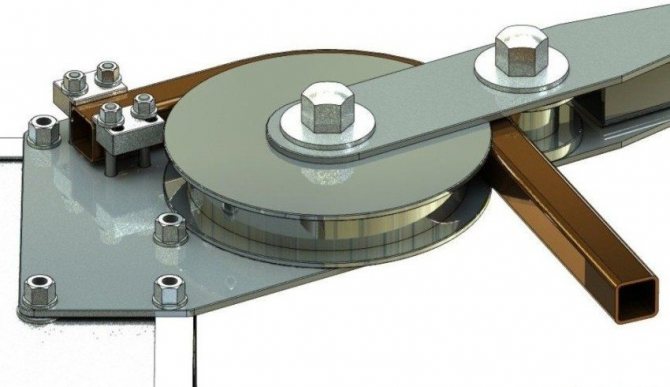

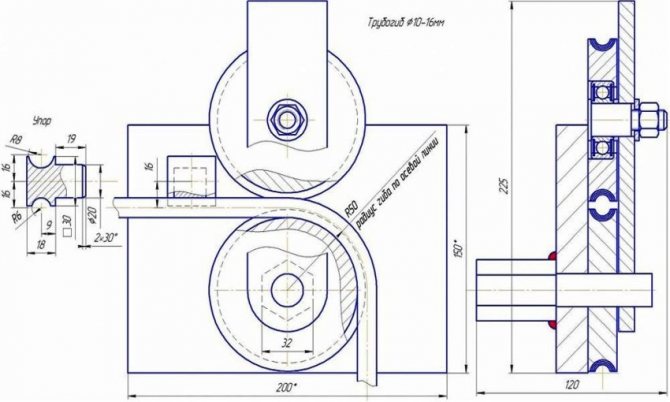

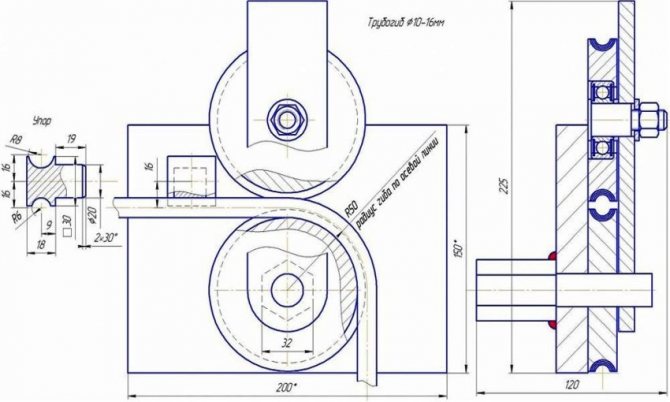

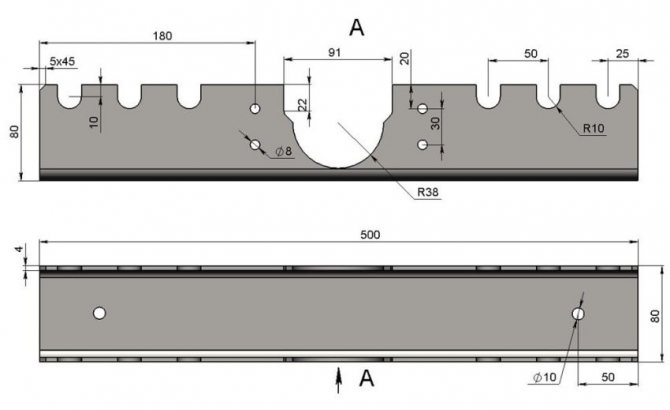

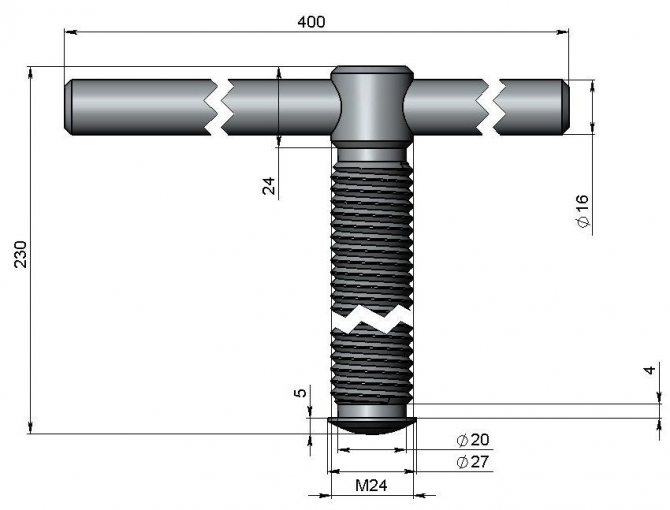

A drawing with dimensions for making a pipe bender with your own hands

Using wood, you can even build a rolling pipe bender if you grind wooden rollers. They can also be made from bearings or polyurethane. In general, the complexity of making homemade pipe benders in a certain way depends on the flexibility of the pipe. Compliant options can be bent on wooden fixtures without much difficulty just by hand, but for rigid pipes, more complex devices with metal parts will be needed.

What does a conventional manual pipe bender consist of?

The complete set of the hand tube bender system will vary depending on the specific type of tool. But at the same time, any homemade manual pipe bender will definitely have:

- frame - open or closed;

- top bar;

- lower bar;

- hydraulic cylinder - if these are hydraulic systems;

- 2 stops.

Important! In more complex devices, the manual pipe bender scheme implies the presence of a special power injection device, which is mounted on the back of the body. In addition, bypass valves and handles can be added to ensure the most convenient and efficient use of the tool. If a manual pipe bender is made by hand from metal parts - gears, shafts, in order to exclude their rusting, violation of the integrity of the external circuit, a special compartment is also installed for supplying oil and grease. All parts are often fastened with bolts, screws and nuts, but in some cases locks and even welding are required.

Making a homemade hydraulic pipe bender

If you decide to make a real hydraulic pipe bender, you need to get a hydraulic jack, channel, two rollers and a shoe. In addition, you will need several metal plates of steel over 3 mm thick.

Scheme and principle of operation of a homemade hydraulic pipe bender using a jack

A rectangular structure is created from the channel using a welding machine, the height of which coincides with the height of the fully extended jack. It is installed on a rigid base and securely fixed with metal plates.

The jack must be selected with a lifting capacity of at least 5 tons. It is designed to act as a pusher. The main task here is to find the most suitable videos.The difficulty is that only with the most accurate girth of the pipe with the rollers can a really high-quality bend be obtained. If you find different rollers and make them removable, you can bend pipes of different cross-sections and diameters.

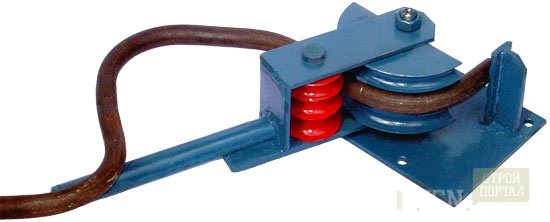

Example of a DIY bending device for metal pipes

The advantages of a hydraulic do-it-yourself pipe bender for a profile pipe are: ease of manufacture, availability and low cost of the jack and parts. Such a device allows you to bend any shaped and round pipes in a cold state with high quality.

Varieties of pipe bending machines

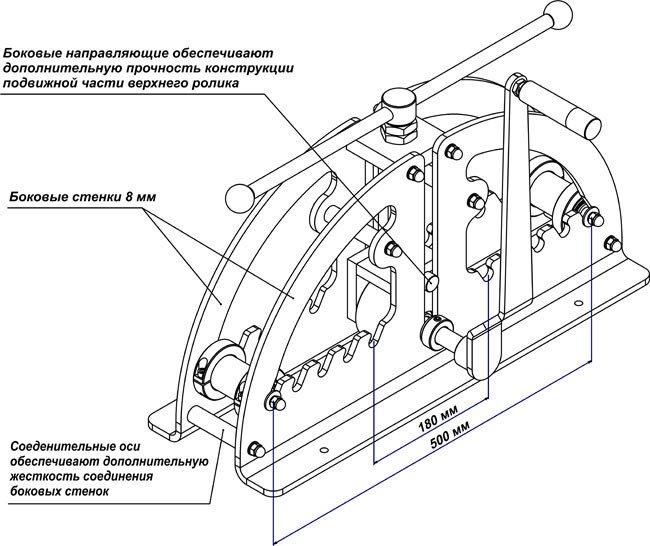

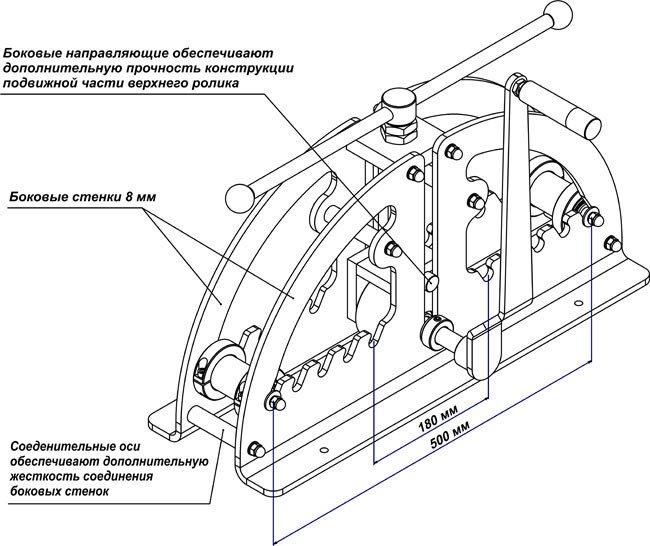

Manual pipe bender with reinforced structure.

With the manual tube bending machine, you can perform operations such as bending arcs and making rings. The mass of a do-it-yourself profile pipe bender is, depending on the design, from 25 to 65 kg. Such a mass of equipment makes it possible to transport the device to the place of work rather comfortably.

With the help of a hand device, you can process round pipes with a diameter of up to 30 mm, square pipes with a size of 40x40 mm, metal strips with a size of 40x10 mm, in addition, with the help of a manual bending device, you can bend square metal products with a diameter of 16x16 mm and a metal bar with a diameter of 16 mm ...

Using special mandrels, a simple hand tube bender can be turned into a profile bender.

The modernized version of the manual tube bender is the manual hydraulic device. This device makes it possible to obtain a greater force exerted on the bent pipe at the point of impact. Facilitation of work is achieved through the use of a hydraulic cylinder in the drive of the equipment.

Electric pipe bending devices are designed to bend pipes of various sections. Most often, such equipment is used on an industrial scale, since such equipment has a high performance.

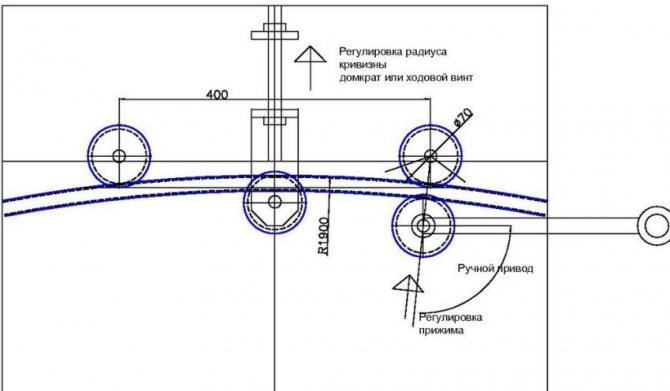

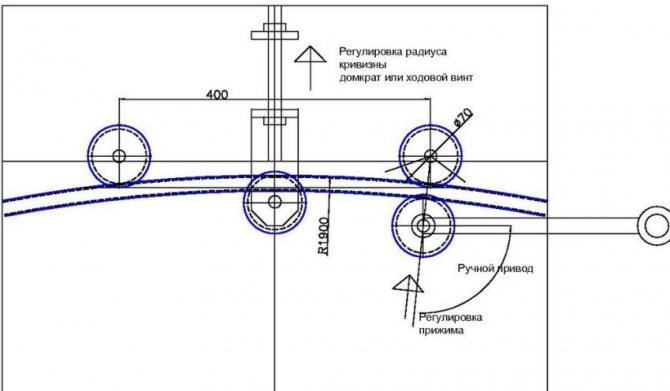

Roller diagram for pipe bender.

High performance of electric tube benders is provided by additional functions, for example, the ability to rotate the rollers both clockwise and counterclockwise. Control of such equipment is carried out using the buttons located on the control panel. Electric pipe bending machines are equipped with replaceable mandrels.

In addition, there are several more specific types of equipment that are used to carry out certain specific operations.

Depending on the conditions of use, experts divide all pipe benders into 2 groups: stationary and manual. Stationary installations are used in production, and manual ones can be easily used in a personal household.

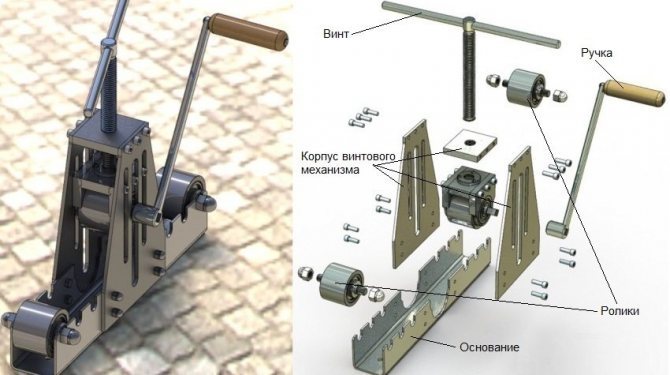

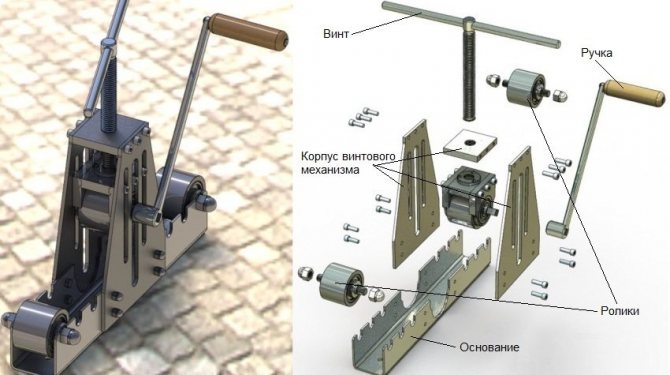

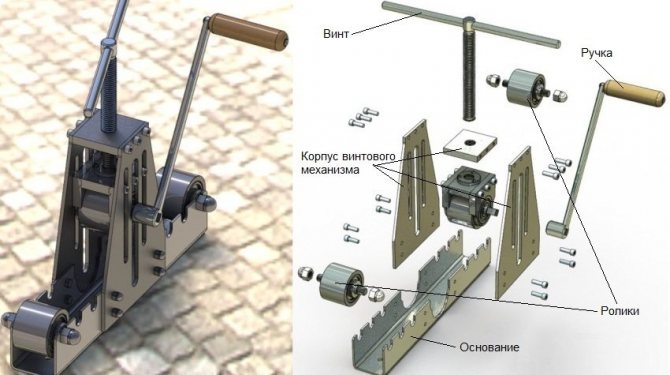

How to make a rolling pipe bender yourself

The pipe bending process in the rolling machine is as follows. The pipe is laid on side rollers, and a third one is lowered onto it from above, fixing the product in a given position. When we begin to rotate the handle, the chain drives the shafts in rotational motion, and the profile or round pipe is bent at the required angle.

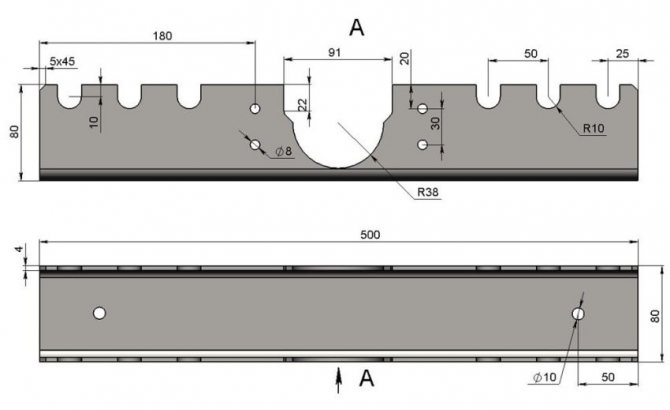

Step 1: creating the base of the pipe bender from a steel channel 80x80x4

To manufacture such a device, you must:

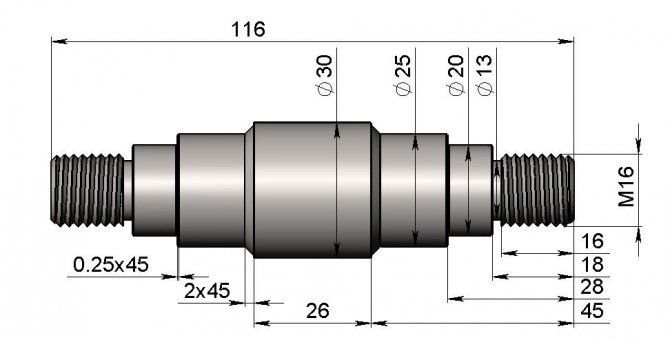

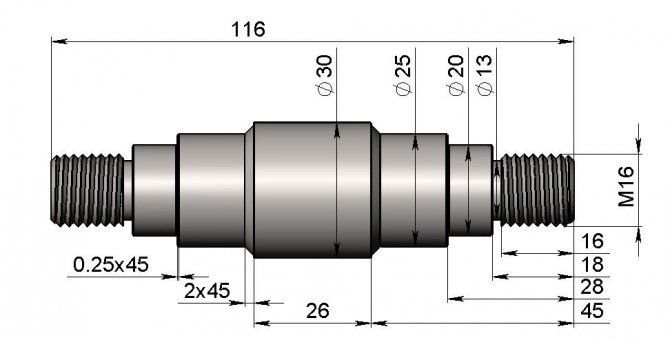

- grind rollers and bearing races. This task can be entrusted to a turner who, according to the drawings, will do the job in the best possible way. The device will have three shafts, one of which is suspended by springs, and the other two are fixed in the sides of the frame;

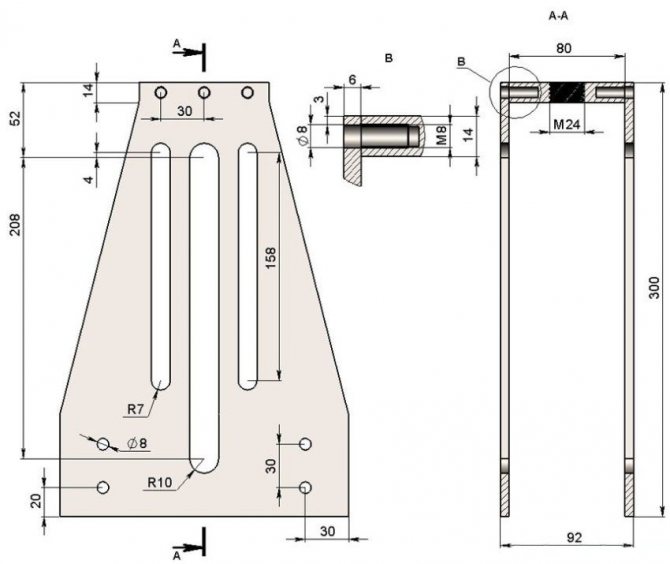

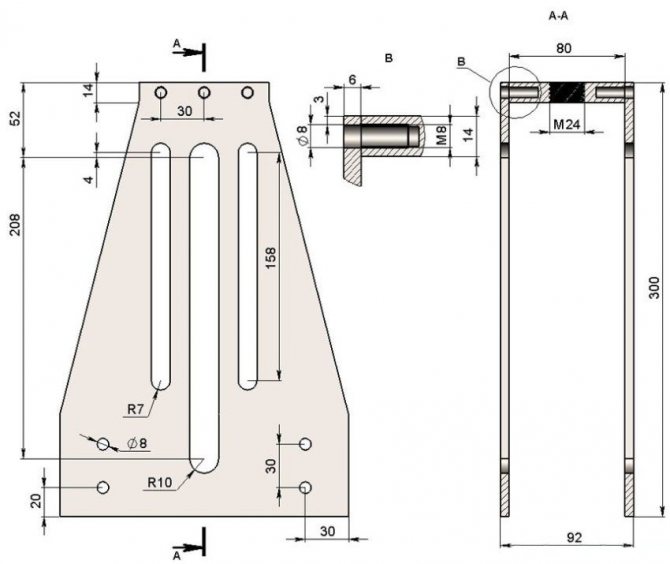

Step 2: making the screw housing

- prepare a shelf from a 50 mm channel. It looks like a rectangle with sides 100x30 cm. Holes are made in it for mounting the shafts and a thread is cut to adjust the position of the pressure shaft;

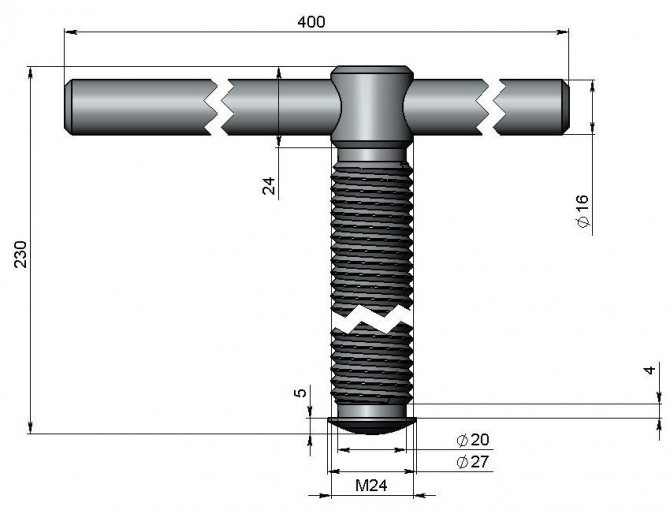

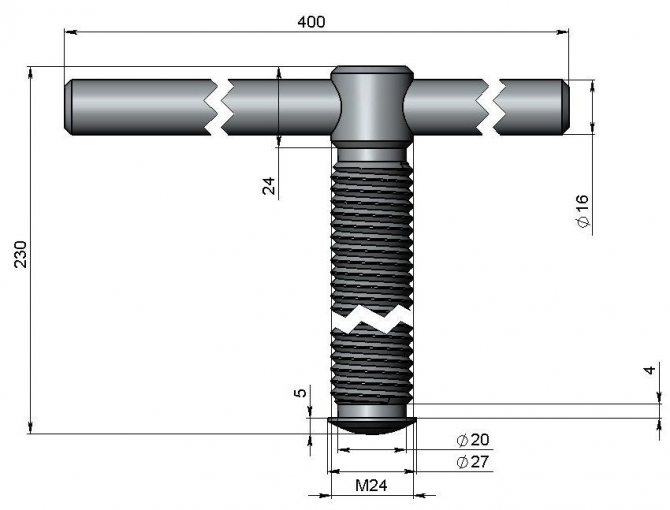

Step 3: create a standard threaded screw

- fasten all parts together with a welding machine;

- the shelf with the pressure shaft is suspended by springs, and the side shafts are connected through sprockets with a chain. A handle for rotation is welded onto one of the shafts;

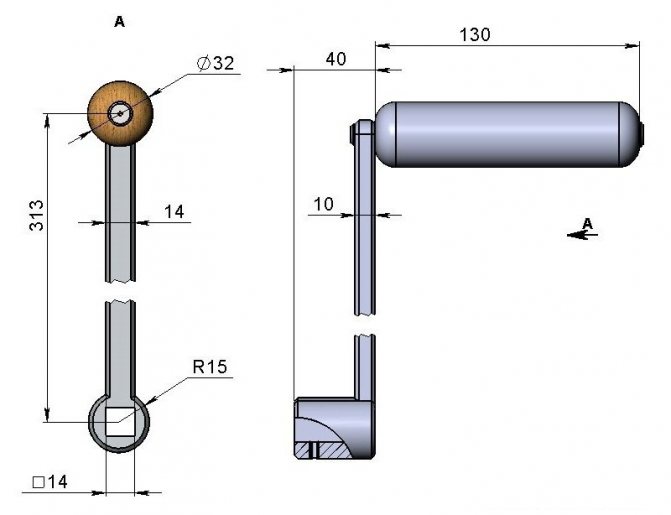

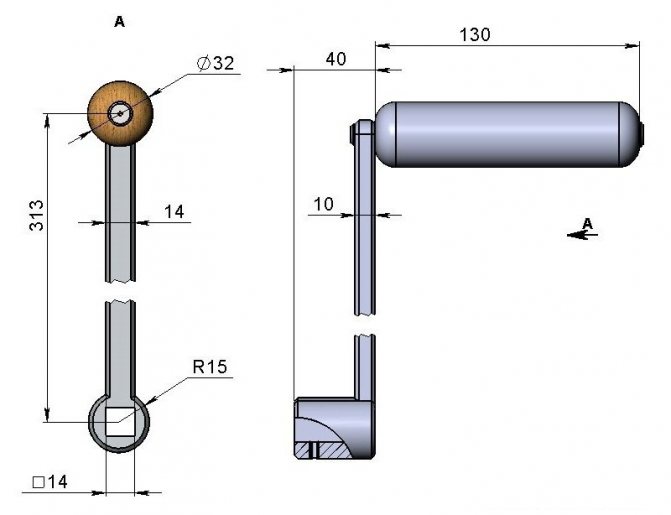

Step 4: making the center drive roller pivot handle

- mount the jack so that it can be used to easily adjust the downforce.

Step 5: assembling all the parts of the homemade rolling tube bender

A pipe bender for a profile pipe with your own hands can be made. Its complexity depends on the purpose for which you need it. If these are only one-time actions, then wooden structures are enough. If you are engaged in the manufacture of products from a pipe on an ongoing basis, then you will need a more complex unit.

Types of factory bending devices

The lineup differs in the presence of elements and purpose:

- Hand-held devices;

- Electrical equipment;

- Hydraulic machines.

Each of them has its own characteristics.

Manual pipe bender

This is a machine, on which bending of pipe-rolling is done by hand. Sometimes it can be a regular hydraulic pump handle. If you look at the photos of the machines, you can see that these are extremely simple types of equipment that do not work with large elements. But even a homemade manual pipe bender can work perfectly with metal, polymer or stainless steel pipes.

Pros:

- Affordable price, if the machine is homemade, then the savings are obvious;

- Experience is not required due to the primitiveness of the device;

- The compact dimensions allow for ease of transport and positioning.

Disadvantages:

Types of electric pipe benders

- Reduced speed of work;

- The functionality is more visible on soft metals;

- Not suitable for bending massive pipes with increased wall thickness;

- 100% bending accuracy is not always achieved;

- The inability to make several bends on a small segment.

As a rule, a pipe bender, where you need to work only with your own hands, applying muscle strength, is used at home. It works very well with copper, aluminum and mild steel. But pipe rolling should be of small diameter. With all the drawbacks, a home-made device is most popular today, due to the savings in finances and ease of manufacture.

Hydraulic bending machine

This is equipment that runs on the network. It can be both homemade and factory-made. The use of equipment allows you to work with large volumes. The technology is simple: by means of clamps, rolled pipes are placed into a machine, where bending takes place without applying any effort. You can only work with your own hands without the assistance of, and the presence of additional rollers helps to process pipes of various diameters.

Equipment advantages:

- You don't need a lot of experience, and even if the user takes up the equipment for the first time, he will perfectly cope with the task;

- The efficiency of processing is due to the fact that you do not need to bend pipes with your own hands, everything is done by hydraulics;

- Rather thick pipes can be bent.

Minuses:

- The ease of use of the device has led to increased demand and price;

- It is impossible to bend thin-walled pipes, the equipment breaks the elements.

It is worth remembering that in order to make a hydraulic device with your own hands, you will need at least minimal knowledge of welding and a certain amount of equipment and materials. But if a large amount of work is ahead, it is best to view the photo, decide on the type of equipment and make just such a pipe bending machine.

Electric pipe bender

This is a bulky design that is a high-precision instrument for performing large volumes of work. Equipment differs from others in processing technology, bending principle, control method.To accomplish the goal, you need to wind the required radius and place the element in the machine, all actions take place in automatic mode, and the bending degree fully corresponds to the preliminary drawings.

Important! It is almost impossible to make such a device with your own hands, since high accuracy of calculations and factory equipment are required.

Advantages:

Types of pipe benders for bending round pipes

- High precision of work;

- The ability to bend workpieces of any diameter;

- Shown to work with round, thin-walled pipes and for thick-walled products of various cross-sections.

Minuses:

- Expensive cost;

- Large dimensions;

- Stationarity of the machine.