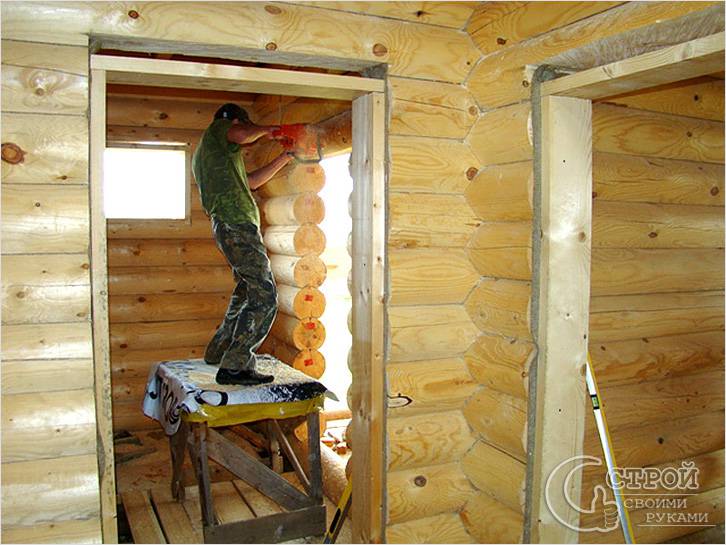

Plastic windows in a wooden house - inside view

Window opening in a log house under a plastic window - outside view

How much does the house shrink

It all depends on the time of year when the craftsmen collected the timber. For example, if the assembly was carried out in the summer heat, you will have to wait 1 year, and the arrangement of the dwelling in winter will not require more than 8 months. This is why builders recommend future owners to assemble their homes during the winter season.

In winter, excess moisture evaporates gradually, which means that deformation and changes occur evenly and calmly. If you find yourself in the off-season - the house built in November will complete the shrinkage process by the beginning of summer. And only then can you start installing window openings and double-glazed windows, entrance doors. Finishing work on the design of the building must be started in the same period, haste can provoke cracks in the cladding. The factor of low cost of assembly in winter is also important - the cost is almost 20% less than summer assembly.

The most intense period of shrinkage occurs in the first 3 months; it is possible to say that the house completed the process only 3 years after the construction was stopped.

What is the difference between a shrink house and a turnkey building? Construction readiness. The first option does not provide for the presence of door leaves, windows and cladding material on the inner surface, flooring of the floor plane.

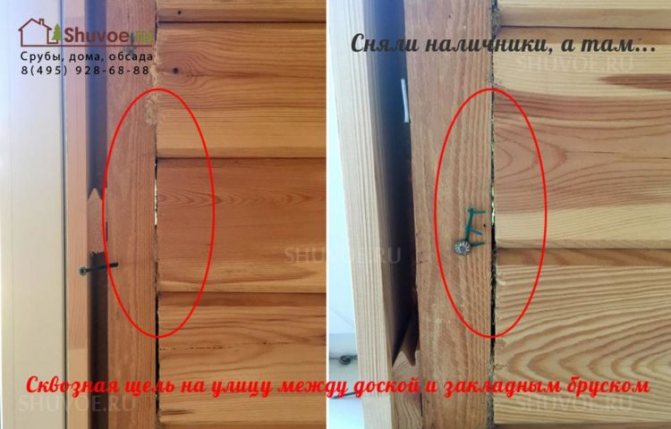

What to do if a low-quality cage has already been installed or not according to technology?

If such problems appear, you can apply under warranty to those who installed the windows for you. There is a chance, but, unfortunately, usually such "specialists" report that they have a lot of work on other objects and they do not get involved with such a "trifle", and then they stop picking up the phone altogether.

In this case, contact ALFA WOOD. Our experienced employees will carry out diagnostics of openings absolutely free of charge, give recommendations on further actions, calculate the cost of the necessary work for guaranteed and expedient elimination of problems with the mound. Call us, we will help.

How to build a house from a bar

Knowledge of the step-by-step technology for building a house from beams can significantly smooth out the shrinkage process. Builders are advised to adhere to the basic rules:

- The logs forming the walls must adhere to each other without creating gaps. To keep the wind out of the joints, dig in the seams with an inter-crown sealant, for this it is better to use jute or tow.

- With the use of non-profiled timber, the assembly requires dowels made of wood or metal. Dowels are vertical rods designed to twist the rails.

- When the drying has come to an end, the craftsmen should carry out another caulking of the joints, this technique will well close the shrinkage voids that have appeared.

- At the moment of drying, the wood in the upper part of the structure squeezes the window and door frames, if you install windows and doors ahead of time, under load they will certainly warp and jam. To avoid this unpleasant incident, make a window - a movable device of openings moving along the grooves simultaneously with the wall structure, this will prevent deformation.

- Above each hole prepared for the subsequent installation of windows and doors, builders leave an expansion joint, the height of which varies from 3 to 4 cm.It is necessary for the upper part to destroy the openings with its weight. When the drying is complete, the gap is covered with a wooden casing.

- The lumber structure will give less shrinkage when using the "Canadian cup" technique, the advantage of which is the wedge-shaped seam, due to which shrinkage does not provoke the appearance of voids, but, on the contrary, seals the joint due to the tight fit of the mass of the upper logs and the roof.

- A house made of laminated veneer lumber practically does not dry out, but its cost exceeds other types of logs.

And finally, if a team of craftsmen does not know how to minimize shrinkage, it is better to lay the roof after the building has dried.

During construction, as well as repairs, various difficulties arise associated with laying the foundation or installing plastic windows.

It is worth noting that the installation of new plastic windows in a house made of timber, including, if it is also old, involves some complex process, during which it is necessary to take into account all the features and nuances, therefore it should be carried out only by professionals who perfectly understand what needs to be done in this particular case.

But the difficulties in installing windows in a house from a bar still play a role and even professionals are often unable to cope with this process without such typical mistakes:

1. The installed product does not fit the opening. Probably the fault is the incorrectly laid out quarter. Although this defect had to be taken into account, and also noticed during the direct manufacture of the window. Another explanation for this case is also possible - the owners of the house from a bar purchased a window in advance, foamed up the gap on their own and laid it with foam. Accordingly, the opening area has decreased, so the size of the window does not fit. Yes, the assembly seams can also remain open. Then there was no point in installing such a window, since the destruction of thermal insulation automatically occurs.

2. The builders did not install steel drip tides, which provide drainage of sediments. Perhaps this happened by order of the owners, who understand little about the installation of windows. Therefore, the consequences will overtake you almost immediately - the decorative facing of the slopes will crack in the near future. It will not be possible to install a standard radiator under the window, so they will fog up even at temperatures above zero.

3. The installers managed to beautifully close up the seams, but at the very low tide they left even a small hole. It was through this, as it seemed in fact, rather small and inconspicuous hole, that water would seep into the seam and then flow along the slopes. Well, this is for the time being, until the owners still do not guess what is the matter.

4. When installing windows in a house made of timber, it is imperative to take into account the temperature expansion of the profile. Some windows are not always lucky. Most likely, the installers installed the fasteners very low. If the blocks were installed at a positive temperature, then when frosts come and the temperature drops, the plastic will shrink, as a result of which the PVC profile will rupture.

5. The builders, for some unknown reason, did not install the casing. When the blockhouse "shrinks", the logs will begin to press on the frame, making it difficult for you to open the doors or even impossible. Also, the window profile can easily deform under heavy weight and the double-glazed windows themselves are likely to collapse.

6. Incorrect installation of the window can lead to excessive pressure of the frame on the window structure. It is needed in order to preserve the independence of the window profile from the walls of a wooden house, thereby protecting it from the effects of other factors, for example, shrinkage of the house.

Installation of windows in a house made of laminated veneer lumber is a process that includes a number of components:

- careful design;

- knowledge of the specifics of installing windows in wooden houses;

- design (harmonious combination of windows and other elements of the house, color palette, shape)

The company Russian West employs professionals who do everything, the selection and installation of windows, and do it at the highest possible level.

Curtain decoration

A simple but very interesting option for decorating a doorway with curtains is a look into the past. Several decades ago, people delimited living space in this way, decorating the passage with wooden or fabric curtains. The desired effect was achieved: the boundaries of the room were visually outlined, while the space was not closed.

But such solutions are still popular now, but the variety of shapes and materials has become much larger. Most often, bamboo sticks are used, which are very durable and make a pleasant sound when colliding with each other. You can paint them yourself in the desired shade or choose a ready-made version for your interior.

You can use curtains anywhere, even on the border of the hallway with the bathroom, although it is a little intimate, but if the homeowners are interested in this option, then why not experiment.

Design

It is a beautiful building with many windows located at different levels. Each window has its own place! This location is determined by agreement between the architect and the client.

Our company develops glazing systems for any house made of laminated veneer lumber. Individual solutions are made for clients, taking into account their wishes.

First, we determine the number of windows in the house; then we calculate their location and size. We calculate both the total number of windows and the height at which they will be located. We do all this at the stage of project preparation.

In the course of negotiations, it happens that the number (and location) of windows for a house made of laminated veneer lumber can vary significantly. After all, there is always a chance to improve the project, to come to a more harmonious solution.

When drawing up a glazing plan, the architectural features of the house are taken into account - the complexity of the structure, the presence of different levels, balconies and other nuances.

The stage of "drawing" includes determining the size, opening plane, structure (shape) of the window.

Also, as a result of negotiations with clients, we determine the material from which the windows will be - wooden or plastic.

Opening preparation

The preparation process for the work surface differs due to the materials chosen as finishing materials.

- If it is decided to refine the opening with a decorative mixture, it is necessary to make a rough finish using ordinary plaster. After that, all surfaces must be thoroughly cleaned with fine sandpaper. This will avoid peeling off the plaster layer. The use of a building level or a plumb line will save on finishing material.

Leveling the opening with plaster using a rule and metal corners

- In the case of using overhead elements (stone tiles or PVC panels), leveling of the opening is not required, it is enough to hide obvious flaws - bumps and pits.

- If a crate is being erected, there is no need for a rough finish: everything will be hidden under a strong wooden or metal frame.

Drywall on the frame Drywall is another option for covering the doorway, as a result of which a perfectly flat surface is obtained. It does not require additional processing, you can paint or glue the wallpaper immediately after installation and grouting of the joints.

Plasterboard leveling without frame with glue

A recommendation for everyone who carries out repair work with their own hands: be sure to use a primer to create the best adhesion to the wall surface and decorative mixtures.

Features of installing windows in houses made of laminated veneer lumber

The main feature of any wooden house, including one made of laminated veneer lumber, is the shrinkage process. At the same time, the shrinkage in wooden houses is traditionally greater than that of mansions built of brick and concrete. True, the shrinkage of houses made of laminated veneer lumber is several times less than, for example, of rounded logs: it fluctuates within 1-1.5%.

With any, even minimal shrinkage, deformation of the walls occurs, which affects the windows. To prevent this from happening, Russian West complies with all installation technologies.

What do we do to avoid deforming the windows? We provide reliable protection against stress, which traditionally occurs during the natural movement of the supporting structure - the walls of the house. We mount the so-called casing (another, widespread name - "okosyachka") - a wooden box that is installed between the wall and the window.

We paint the casing before assembling the casing.

Important nuances

Installation of plastic structures in a wooden house has its own characteristics.

We suggest you familiarize yourself with: When to cut brooms for a bath from 9 materials [PHOTOS]

This is one of the reasons why casing cannot be dispensed with.

In the space between the upper window strip and the wall, it is not always worth using polyurethane foam, since it becomes quite rigid when it dries and also creates unnecessary pressure on the structure. In this case, all the benefits of casing are nullified.

If you do not take into account the gap between the frame and the wall, having calculated the wrong dimensions of the window, you will have to increase the opening, since it will not be possible to install too large a window without negative consequences. After foaming the gaps on the outside, it is better to mount the PSUL tape, it will not only protect against ultraviolet rays, but also against moisture.

Polyurethane foam, with all its advantages, quickly degrades and loses its properties if not protected. Inside the dacha from a bar, this must be done with the help of a vapor barrier, and waterproofing will help outside. Most of the skewing of the window is observed when it is installed out of level. Fittings in this design fail twice as fast and require replacement.

We must not forget about the cold zone, in which the window begins to freeze from the side of the slopes, and condensation appears inside.

Manufacturers emphasize the tightness of PVC structures and an excellent sound insulation indicator as one of the main advantages of this type of window. In fact, the wooden frame has natural ventilation, so that the level of humidity in the room does not increase, the same cannot be said about PVC windows.

During their installation, in order to eliminate the problem with condensation in the future, it is necessary to install the ventilation yourself, and if there are no special holes, you will have to try hard.

The situation is greatly simplified by supply valves, which are special profiles installed on a plastic window.

The ease of installation cannot but please. The user will need to remove the seal that is already in the window structure and place the valve on the sash. It is easy to fix it with self-tapping screws, but you will need to think over the exhaust hole, otherwise there will be no sense from the system.

No one will be happy that companies that install plastic structures in a wooden house do not give guarantees for their work, since they cannot fully predict the behavior of PVC. Even if you follow all the norms and requirements, there is no guarantee that after several years of operation the window will not stop working.

Installation of windows

We proceed to the installation of windows immediately after finishing the polishing and painting of the house.

We make careful measurements of window openings. This is done by an engineer with special equipment.

Then, with the accuracy inherent in the Russian West, the sizes of the windows are checked again; all numbers are checked for strict compliance.

This is followed by the most important, one might say, culminating stage - directly, installation work.

It is important that the first steps for future installation are carried out at the factory, when the groove for the eyelet is cut.

The casing assembly is attached to the lug bar. And then the installation of the window is already carried out.

The final stage of work is finishing the windows with platbands.

What do we do to competently prepare window openings in houses made of laminated veneer lumber

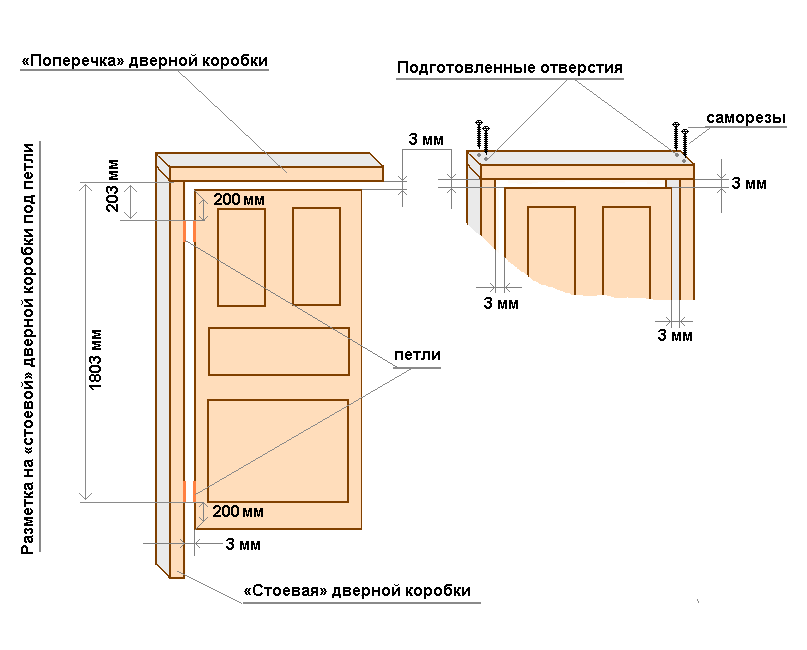

First of all, the distance from the floor to the window sill is determined. The standard version is 90 cm; it is determined that this is exactly the height that is comfortable for a person.

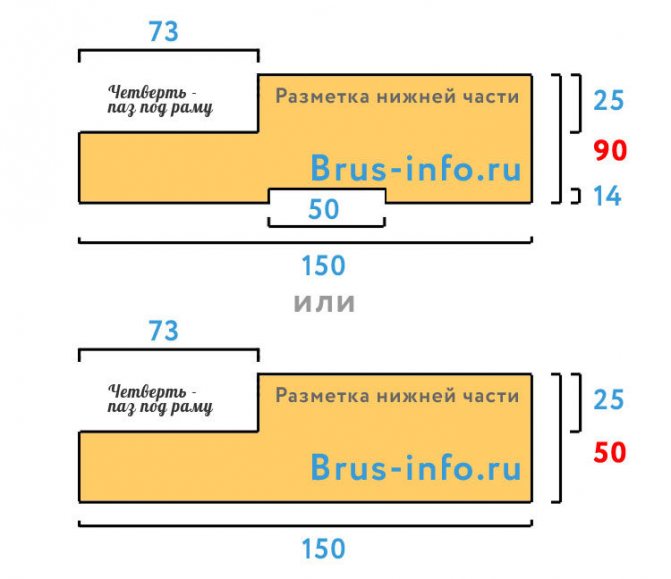

The second argument is the optimal height for installation under a kitchen or desk window. Then the marking of the window opening is done. The window opening should be larger than the window by 12-14 cm in height and 10-12 cm in width (excluding casing). Why?

In the window opening, in addition to the window, you need to fit mounting foam (a couple of centimeters around the entire perimeter), a window sill (up to 4 cm from the bottom), a cage (4 cm from above and 5 cm from both sides).

In addition, we provide a distance for the shrinkage of the timber.

The use of natural wood in construction is gaining momentum due to safety in relation to the environment and human health.

The exterior of a house made of timber differs from the banal brick "boxes". To make it aesthetically pleasing, it is important to choose and install the windows correctly.

Photo gallery

A doorway without a door, with proper decoration on both sides, can look very attractive and become an integral element of a design idea and a design highlight for two rooms at once.

Korovin Sergey Dmitrievich

Master of Architecture, graduated from the Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

One of the most common options for visually increasing the space in a room is to dismantle interior doors. This solution allows you to visually expand the premises, create a single space in the interior. In this case, an important task arises - finishing the doorway. In this article, we have collected the most popular and non-trivial ways to solve this issue.

Features of installing plastic windows in a house from a bar

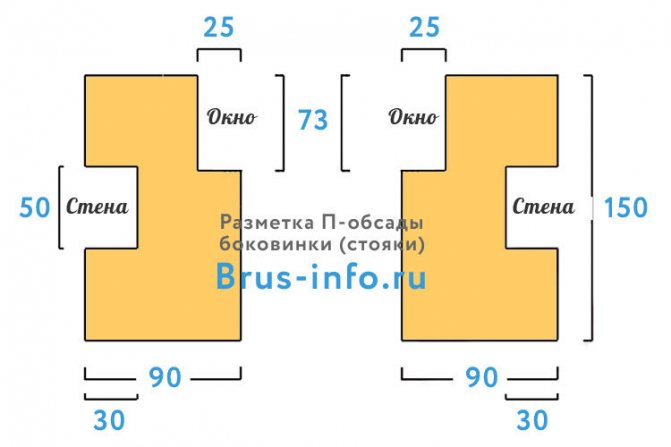

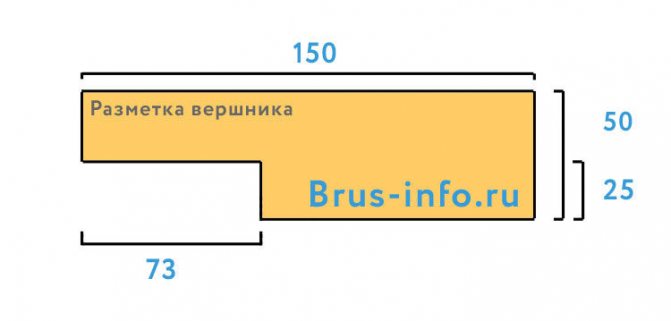

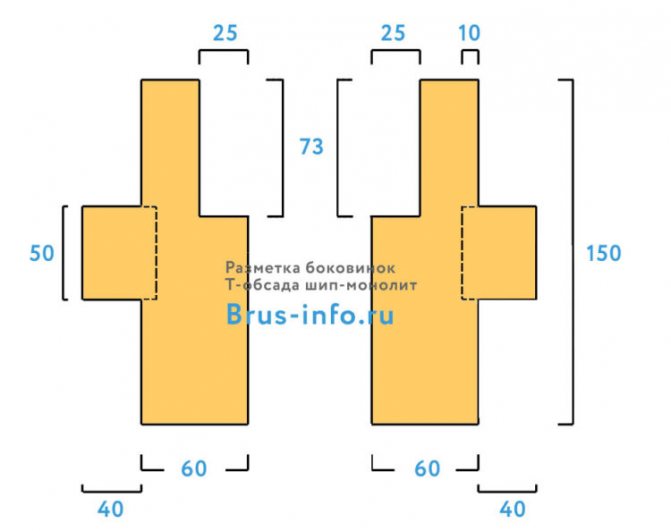

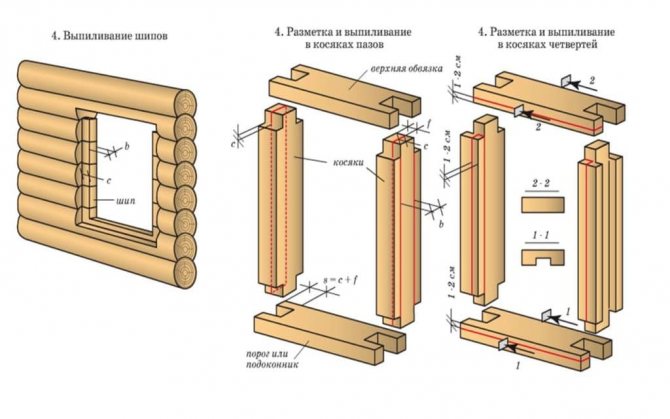

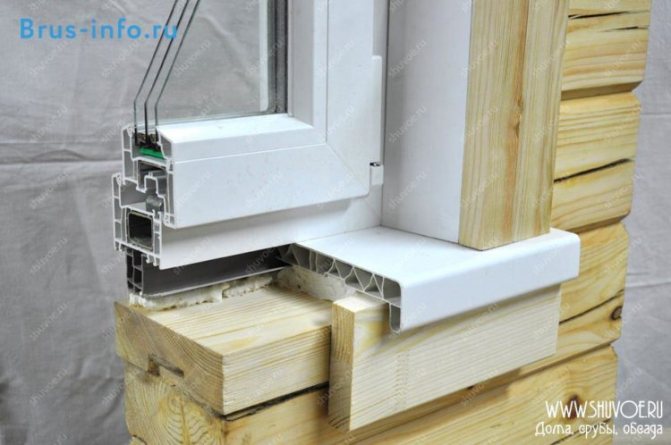

Having completed the main construction, the owner of a wooden house asks the question: to put plastic windows on their own, while saving finances, or to entrust the installation to professionals. The answer is unambiguous: it is better to order the installation from specialists, since it requires a certain technology. Companies specializing in such services know how to insert a double-glazed window into a timber structure in order to avoid negative consequences in case of installation errors, and the work will take a minimum time. A plastic window cannot be simply inserted into the opening; first, a special design is created. It is several centimeters larger than the glass unit itself in case the wood dries out and will not allow it to be squeezed out or squeezed. The upsetting, or squiggle, strengthens the wall and takes the load on itself. Using this technology, there is no need to wait for the shrinkage process, but you can install double-glazed windows immediately after the completion of the construction of a wooden house. Stages of casing manufacturing:

- Special combs are cut out in the window opening.

- A window carriage with a groove is put on.

- The upper part of the casing is attached to the carriages with self-tapping screws.

Important: the design of the window should be 8 cm less in height than the window opening itself. After fixing the casing, they proceed to the installation of double-glazed windows.

The peculiarity of installing plastic windows in a house from a bar is that the platbands are attached to the casing, and not to the wall. Even if they are damaged, it is easier to replace the platband itself than the entire glass unit. The main functions of the casing:

- Installation of an independent construction of the window opening from the walls of the house.

- Installation of the gap between the window and the top beam.

- Installation of connections of vertical beams to each other in the window opening.

Checking products before installation

If the customer takes out the finished windows from the manufacturer's premises on his own, then this check must be carried out at the place of manufacture of the products. As a rule, the managers of the company themselves propose to do this, so that later the customer signs in the act of completed work that he has no complaints about the quality of the products.

The measurement results are indicated in the measurement sheet.

It is necessary to check the dimensions that are indicated in the act, and for reliability check them with the dimensions in the measurement sheet. A copy of it is given to the customer along with the contract, which sometimes specifies the maximum permissible deviations. If there is a discrepancy, the act is not signed, and the product is given to the manufacturer for alteration.

If everything is fine with the dimensions, then the next step is to check the plane of the product - it should be even, without bends and deformations. The window system is delivered fully assembled, so it is important to check the sash control mechanism. Then the integrity of the glass unit and the tightness of the sealing elements inside are checked.

Prices for wooden and plastic windows: which is preferable for use?

Prices for wooden and plastic windows differ for each individual manufacturer. Prices for PVC products are, on average, 30% lower. Sometimes this is due to the use of wood with a high cost, and sometimes unreasonable wrapping on the part of the manufacturer. The price of each specific product depends on the raw materials that were taken as a basis.

Plastic windows are presented by manufacturers with a large assortment: from economy models to exclusive options. Therefore, the price range is wide. The market offers double-glazed windows made from cheap raw materials, which are characterized by low quality and health hazards. Such models will not last long, so it is important to purchase windows only from trusted manufacturers. The service life depends on how high-quality the product you ordered, how correctly it was installed and how exactly you followed the rules for care. On average, wooden windows serve 50 years, and plastic ones ─ 45. But it is wrong to focus only on the operating time, it is important to know some other points.

Installation of a PVC window. Siege. Okosyachka.

Another criterion when choosing windows is reliability. When comparing, it turns out that PVC products win in all respects. The wood frame takes on a dark shade when exposed to sunlight. It is prone to rapid combustion. Scratches formed during operation are extremely difficult to repair. In wooden windows, beetles and other insects are often found, which are subsequently difficult to remove. Scratches on the plastic frame can be easily removed, it is less whimsical. Over time, such windows can be laminated.

Comfort in the home is important to everyone. Another argument in favor of buying plastic windows is the installation of additional functions:

- ventilation valves allow air to penetrate even in the closed position of the window;

- the mechanism "winter / summer" allows you to adjust the amount of air flow.

An important component for the long-term service of PVC windows is a high-quality installation and subsequent finishing of window openings. For this, the features of wooden structures must be taken into account.

Pros and cons of plastic windows in a log house

If the differences in pricing policy did not help you make your choice, then after studying the pros and cons of plastic windows in a log house, it is much easier to make a decision.

PVC double-glazed windows are used in construction much more often than alternative options due to the absence of significant disadvantages. But they are still there: Installation of plastic windows in a building made of timber differs from the typical installation method. It is more labor intensive and time consuming.Some companies use cheap plastic in their production, so they should be ordered only from companies that have a license and quality certificates. There are much more advantages when installing such double-glazed windows in wooden houses: The variety of choice of colors, shapes, designs, fittings and components. White windows are not always in harmony with wooden walls. But specialized stores offer a wide assortment: brown or wood imitation double-glazed windows, which will harmoniously fit into the style of the house. Excellent thermal conductivity. In timber with plastic windows, heat is well retained. The owner of the log house, having chosen PVC double-glazed windows, can safely count on high sound and thermal insulation, which reduces heating costs. Unpretentiousness in care and durability of use are the main arguments in favor of buying plastic windows.

At first glance, installing PVC plastic windows in a wooden house may seem like a simple process. But, as practice shows, sometimes the installation of plastic windows (double-glazed windows) in wooden houses is subsequently complicated by rather annoying moments that could have been avoided. The fact is that the construction of a log house from a log or a bar is associated with a number of technological features. It is known that a wooden frame shrinks after erection.

During the first year after construction, the shrinkage of the log house is 3-5 cm for every 3 meters of height. The complete shrinkage of the log house takes 3-4 years. The process is explained by the drying of the logs and the pushing of the sealing material between the crowns.

In the future, the house behaves like a real living organism. It constantly, although almost imperceptible to the eyes, changes its shape: in damp weather the tree swells, and in hot weather with moderate humidity it dries out.

With such a mobile nature of the frame, the question naturally arises: "How to install PVC plastic windows in a wooden frame in such a way that the windows do not experience the deforming effect of the shrinkage of the frame?"

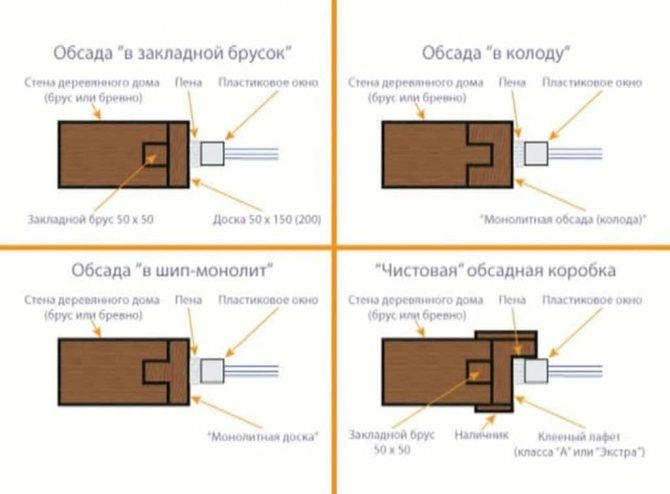

Installation of plastic windows in a wooden house provides for the use of such a design as OKOSYACHKA or, in other words, the CASING BOX.

The casing box allows not only to firmly fix the window in the opening, but also to prevent the impact on the entire window structure of loads arising during the shrinkage of the load-bearing walls. Simply put, the log is successfully used to equalize the pressure of the logs on the windows.

Materials used to make the casing:

Lumber:

- a bar (section 50x50 mm) is used as a guide for vertical movement of the log house;

- timber (section 150x150 mm and 150x200 mm) is used as a vertical stand of the casing in the construction technologies "in a log" and "in a thorn-monolith";

- edged board (50 * 150 and 50 * 200) is used in order to make a casing box using the “embedded block” method.

Linen is a material made of linen fiber and batting, made using needle-punched technology, which is laid between the crowns of the house to insulate the seams. Flax is laid in a box as a sealing material for insulation.

Materials for the "clean slope" technology:

solid wood of conifers, chamber drying, 1st grade, up to 250mm wide;

glued all-lamellar carriage of coniferous species, class "A", width up to 350mm .;

glued carriage of "Extra" class from Angarsk pine without knots, inlaid up to 350mm wide.

Studding of window and door openings

The finished log house (box) must not be left without ventilation. Therefore, cut through at least one food for air access. The dimensions of the opening are taken taking into account the thickness of the casing. The opening is marked in such a way that the notch goes into the whole logs by at least a third of the diameter. If you cut any crown, the rigidity of the whole structure will be broken.

- Vertical grooves are cut at the ends, swarms are driven in.During the shrinkage of the frame, they do not allow the logs cut into two parts by openings to move. The swarm must go up and down the ends of the grooves.

- After the house has shrunk, openings are cut out for all windows. Notching the grooves for the side spikes is called a stud. First, mark the vertical lines at the ends. With a chainsaw, cuts are made, the wood remaining between them is removed.

- Workers can use the chainsaw by cutting the wood inside the groove at an angle. The excess is removed with an ax. If the vertical cuts are too deep, the groove is not chosen for the entire depth, but only for the size of the swarm.

- Chisels are taken to align the groove.

How to make a groove to the exact size? Well-equipped construction crews use a special spike cutter. In a smooth groove, they immediately put a finishing box "in a thorn".