Content

- The main products of the Rockwool brand (Rockwool)

- Specifications

- Forms of issue

- Thermal conductivity

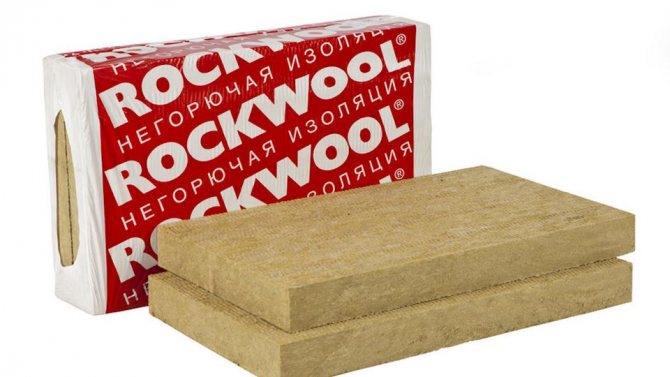

Rockwool stone wool (the original brand name is ROCKWOOL, but in Russia, according to our data, consumers are more likely to request a name in the Cyrillic spelling) - a product of natural origin. This is a natural stone in its composition. It is because of this that the material has become popular for use in all kinds of buildings. Stone wool is used for thermal insulation of any structures - both multi-storey buildings and detached premises, including those with very strict environmental and sanitary requirements, such as children's institutions or hospitals and health resorts.

Rockwool stone wool technology is sometimes compared to the process of volcanic eruption. Once at the plant, the stone is melted in furnaces at very high temperatures (up to 1500 degrees C). A lava-like substance is formed. In a special centrifuge, when processed by powerful air currents, the mass turns into separate stone fibers. A certain amount of binders is added to the fibers. This is necessary to shape the fiber. Also, water-repellent components are added to the composition. The resulting fibers are formed into slabs, which are then left to harden.

If you do not have time to read the article, just watch the visual video, and you will get an idea of the properties of Rockwool stone wool:

Features of mineral wool insulation

Rockwool mineral wool is classified as environmentally friendly materials, for the manufacture of which strong rocks of basalt and gabbro were used without the inclusion of metallurgical waste. The final product is distinguished by high thermal insulation characteristics, excellent operational properties.

To obtain slabs from basalt wool, rocks are melted at elevated temperatures, followed by stretching into fibers, similar to how the material is formed in natural conditions.

Unlike previous generation mineral wool heaters, when the fibers were laid in a strict order in rows, Rockwool basalt wool slabs are created with the fibers in a chaotic manner, which favorably reflects the technical characteristics of the material, reducing the specific weight.

The finished product demonstrates excellent stiffness, flexibility and elasticity while maintaining a stable product shape. Plates throughout the entire service life demonstrate excellent performance in terms of resistance to mechanical stress, do not deform, do not shrink.

Analysis of the characteristics of the insulation, allows us to note its ability to cope with high temperatures - Rockwool plates can withstand temperatures over 1000 degrees Celsius. Insulation is used both in household construction and for thermal insulation of industrial facilities, where the compliance of characteristics with fire safety requirements is of fundamental importance.

Materials based on Rockwool mineral wool are versatile and practical, helping to create and maintain a comfortable microclimate in the room, regardless of the season.

Forms of issue ↑

Rockwool in the form of mats

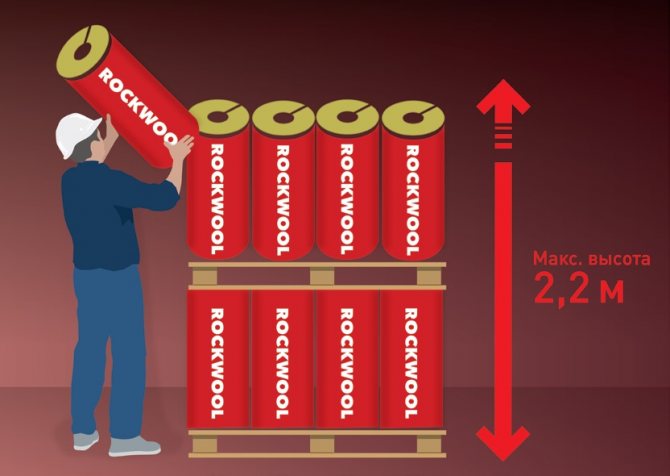

Rockwool products are available in three main types:

mats (rolls);

cylinders;

plates.

Mats are soft materials, cylinders are hard. Rockwool slabs can be soft, hard and super hard.

Rockwool in the form of cylinders is used for thermal insulation of pipes

Application area

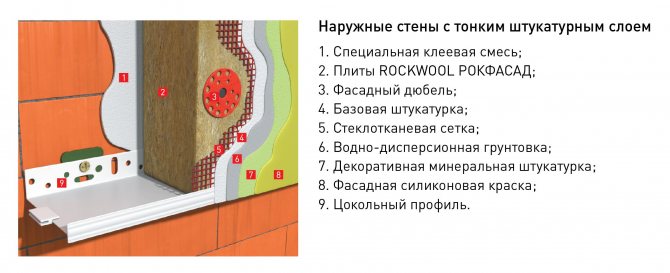

Rockwool in various forms is used for thermal and sound insulation of buildings and structures for various purposes, as well as for fire protection of reinforced concrete floor slabs and thermal insulation of pipelines.

Flammability group

Rockwool stone wool and, accordingly, all products from it are considered non-combustible material (GOST 30244-94).

Density

For most building materials, a direct relationship is characteristic: the more dense the material, the higher its thermal conductivity - therefore, such a material retains heat worse. As for the Rockwool thermal insulation materials, in this case there is no such direct relationship. Suffice it to say that the thermal conductivity of Rockwool materials, for example, with a density of 35 kg / cu. m and 200 kg / cu. m can only differ by 0.002 W / m ° C.

Hydrophobicity

This is the ability of the material not to absorb, but, on the contrary, to repel water. Rockwool stone wool has low water absorption. Water absorption by volume is not higher than 1.5%. It practically does not absorb water from the air. Moisture, getting on the surface of the cotton wool, does not penetrate inside and, accordingly, does not change the properties of the material.

Vapor permeability

The property of passing water vapor through the thickness of the material. It is characterized by a vapor permeability coefficient. The enclosing walls have the ability to "breathe" only when the heat-insulating layer has a high vapor permeability coefficient (above 0.25 mg / (m * h * Pa)). Competent installation and correct operation of Rockwool hydrophobic materials minimize the risk of moisture condensation in structures.

Mechanical characteristics

- Compressive strength with a deformation of 10% is not less than 20 kPa

- Peel strength - not less than 7.5 kPa

Rockwool is made from natural stone and therefore has the ability to provide high thermal and sound insulation of premises. Also, stone wool has good fire resistance, strength and durability.

Fire safety

Rockwool stone wool will prevent the spread of fire.

Rockwool fibers can withstand high temperatures up to 1000 degrees. C, thus protecting structures and structures from fire. Rockwool products do not emit smoke and do not form burning droplets in case of fires.

Acoustic comfort

Rockwool fibers are intertwined with each other in chaotically different directions, forming many small cavities that communicate with each other. Because of this, Rockwool stone wool materials provide good sound absorption and reduce vibration. Rockwool is used for acoustic ceilings, for the manufacture of noise protection screens along busy highways, for interior partitions, for ceilings and floors in order to improve acoustic comfort in rooms.

Environmental friendliness

The Rockwool brand has the right to be proud of the fact that for the first time it received the environmental safety mark - environmental standard EcoMaterial

confirmed the safety of using this material in any type of buildings and for interior decoration of structures and structures (including rooms such as bedrooms and children's rooms).

Durability

The key to the strength and, accordingly, the durability of stone wool is the special structure of the material. Its thin fibers are located chaotically - in horizontal and vertical directions, at different angles to each other. The wool fibers are intertwined with each other, which ensures the special rigidity of the material and the stability of its shape for a long time. Therefore, Rockwool materials do not undergo deformation over the years, Rockwool slabs serve without caking or compaction, and the thickness of the thermal insulation layer of thermal insulation remains practically unchanged.

Advantages of Rockwool mineral slabs

If there is no doubt about the characteristics of basalt wool insulation, usually prescribed on the packaging, then not every consumer knows about all the advantages of the material. The main advantages of the plates include:

- high level of incombustibility;

- low thermal conductivity;

- energy saving;

- hydrophobicity;

- soundproofing;

- resistance to deformation;

- long service life.

Rockwool thermal insulation boards are called non-combustible because of their resistance to high temperatures. Materials do not lose functionality at temperatures up to 1000 degrees, which allows it to be classified as non-combustible.

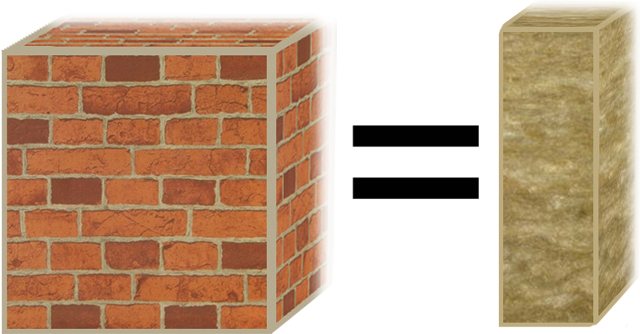

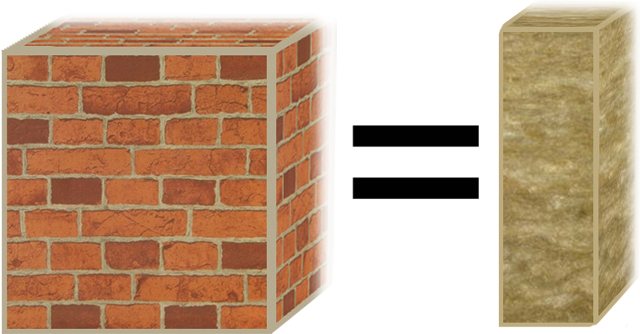

Rockwool mineral wool slabs are distinguished by high rates of thermal insulation. A material with a thickness of only 50 mm in its ability to retain heat is able to compete with a brick wall almost 20 times thicker!

In terms of energy saving, the stoves are no less effective. One meter square Rockwool with a standard thickness of 50 mm saves up to 108 MJ of energy per year.

Rockwool basalt wool insulation has an excellent ability to prevent moisture penetration. Upon contact with the material, moisture does not penetrate into the inner part of the slab, which allows maintaining the level of thermal insulation.

Rockwool heaters do an excellent job of absorbing noise. The material has enhanced acoustic properties, is able to reduce the level of various types of sound waves, improving the airborne sound insulation of the room.

It is not typical for insulation to lose its shape under mechanical stress due to the special placement of fibers in the vertical and horizontal planes, which in turn increases the stiffness indicators.

Among the noteworthy positive qualities, it is worth noting the long service life of the insulation. The material works much longer than analogues, primarily due to its perfect technical characteristics, including resistance to biological effects.

Thermal conductivity ↑

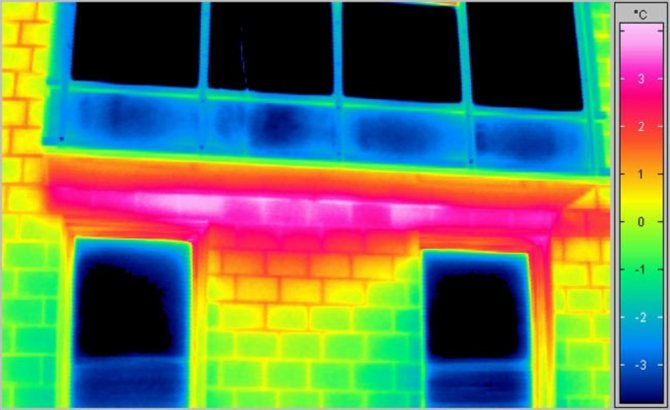

Rockwool stone wool has a very low thermal conductivity coefficient (from 0.041 to 0.045 W / mK). This is achieved to a large extent by the fine-fiber structure of the material. The figure clearly shows the difference in the thermal conductivity of brick and rockwool. Brickwork (left) 96 cm thick against the rockwool slab (right) 5 cm thick

The effectiveness of thermal insulation is shown by the coefficient of thermal conductivity. Based on the specific value, the required thickness is calculated. The values of the thermal conductivity coefficient of ROCKWOOL materials are considered one of the best in their class (0.036–0.038 W / m K). In terms of thermal insulation parameters, Rockwool slabs of the LITE BATTS brand, for example, with a thickness of 5 cm, can be compared with a brickwork with a total thickness of almost 1 meter.

All ROCKWOOL stone wool products have a low coefficient of thermal conductivity, because they do not conduct heat well. Almost the same amount of heat passes through the 1 meter thick Rockwool stone wool insulation as through a 196 cm brickwork or a 44 cm thick timber wall.

Stone wool production technology

History in Russia , No. 1 manufacturer of thermal insulation materials in the world, has been producing stone wool at ISOVER factories in Germany, France, Spain, Czech Republic, Poland and Romania for 80 years. In 2011, the company acquired a basalt wool plant in Chelyabinsk. Two years later, stone wool ISOVER appeared on the Russian market, meeting modern quality standards and all requirements for general construction insulation. This was preceded by investments in modernization of production, attraction of the best highly qualified foreign and Russian colleagues with many years of experience in similar factories in other countries, interaction with independent research institutes and work based on customer feedback.As a result, in 2013 ISOVER became the first and so far the only manufacturer of two types of mineral wool.

Application area

ISOVER provides a wide range of thermal and sound insulation mineral wool materials for all types of buildings and structures.

ISOVER materials cover all structures requiring insulation and sound insulation.

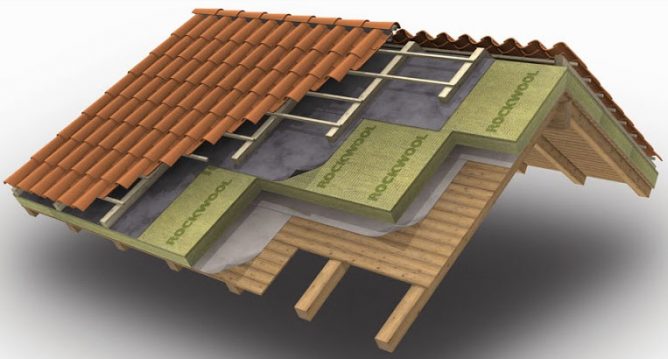

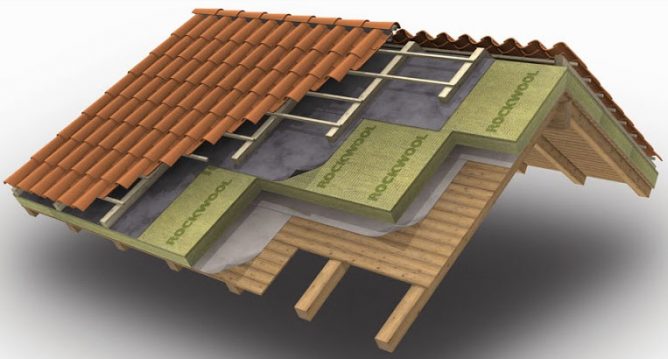

You can opt for one material that is suitable for insulating walls, floors, suspended ceilings and pitched roofs, or you can purchase products designed for each individual structure.

Roof insulation: ISOVER Optimal, ISOVER Ruf, ISOVER Ruf B Optimal, ISOVER Ruf B, ISOVER Ruf N Optimal, ISOVER Ruf N. Wall insulation: ISOVER Acoustic, ISOVER Venti, ISOVER Facade, ISOVER Light, ISOVER Standard. Floor insulation: ISOVER Optimal, ISOVER Flor.

Thermal insulation ISOVER based on stone fiber meets all modern requirements for general construction insulation and has the necessary certificates (hygienic, fire, as well as a certificate of compliance with GOST R and TS).