Information about the manufacturer Izoroc

Izoroc products are manufactured in compliance with European standards

The date of the appearance of the Russian brand "Izorok" is considered to be 2000, when a large association was created on the basis of the Tambov Mineral Insulation Plant. Further development of this production was supported by investments from a number of foreign companies.

Over time, Izoroc mineral wool has become a very popular product in demand in most areas of construction technology.

To expand the production of mineral wool, the association required:

- significantly expand their production areas;

- acquire modern equipment to automate the work process;

- to master new technologies of waste-free production of insulation products.

Izorok thermal insulation is made on the basis of the finest fibers from a melt of mineral rocks, the individual components of which are held together by a special binder. The need to comply with all the intricacies of the technological chain stimulated the engineers of the concern to improve this process all the time. Today it belongs to the undisputed leaders of the Russian market of insulation materials.

All samples of Isoroc mineral wool insulation are manufactured in compliance with European standards. Since its production is organized in Russia, the prices are attractive for domestic consumers.

Insulation Izorok

ISOROC is a trademark of ZAO Izorok, established in July 2000, a Russian company with 100% foreign capital. The purpose of creating the Izorok company is to meet the constantly growing needs of the Russian market for high-quality thermal insulation materials. For this, on the basis of German technologies and Swedish equipment, the Tambov Plant of Thermal Insulation Materials was reconstructed, which has been producing insulation - mineral wool since 1982. Currently, European quality heat-insulating materials are produced, which are in demand on the Russian construction market. In 2012, the Group became a shareholder of ISOROC.

| Name | Density, kg / m3 | Application area | Price with VAT, rub / m3 |

| Isolite-L | 40 | As unloaded thermal insulation in horizontal and vertical structures: in attic and interfloor ceilings, in interior partitions. | 1450 |

| Isolite | 50 | 1550 | |

| Isovent-L | 80 | as heat, sound insulation, horizontal, vertical and inclined enclosing structures of all types of buildings, including three-layer lightweight masonry when installing curtain walls of ventilated facades | 2550 |

| Isovent | 90 | As unloaded thermal insulation in horizontal and vertical structures: in vertical ventilation facades, in roof structures of attic floors. | 2700 |

| Isoflor | 110 | 3020 |

Product line

The density of Isoflor allows it to be laid under a concrete screed or decorative floor

The line of insulation for Izorok walls contains several subspecies, focused on the characteristics of the protected surfaces and various areas of application. It includes the following names:

- Isolight-L;

- Isovent;

- Isofrol;

- Isoruf in packs;

- Izorok in slabs (in cylindrical shapes).

Samples of Isolite-Lux products have a density of 60 kg / cu. meter and are used to insulate surfaces of various orientations. At the same time, large loads and deformation stresses in the layers of products of this type are unacceptable.The next model in the series, Isovent-L, is distinguished by a significantly higher density (up to 90 kg / cubic meter) and is used for arranging ventilation of building facades.

In the Isoflor modification, the density indicator declared by the manufacturer is close to 140 kg / cu. m. This insulation is used as an intermediate link in three-layer reinforced concrete structures. It is allowed to be used in sandwich panels. For thermal insulation of roofs and concrete floors, another type of insulation material is used, called Isoruf. It is produced with marks H, B or NL, and its average density is 110 kg / cu. meter. Billets of this material or mats without a broaching shell are marked as "MP", and if available - "MP (ST)".

Insulation Izorok in slabs has two modifications with a material density of 75 and 100 kg / cu. per meter, respectively. They are ideally suited for the protection of any horizontal surface, but do not allow the load to be exceeded above the limit. Izorok Cylinders bearing the CF marking are considered as a separate category of heat insulators. Various samples of these products differ in the diameter of cylindrical billets (within 18-273 mm) and are used for insulation of cold water and hot water supply pipes.

ISOROK

Insulation ISOROC

ISOROC is a modern high-quality heat-insulating material based on natural mineral wool, which is produced in Russia. was founded in Russia in 2000, in the same year the production of various types of mineral wool thermal insulation was launched. Today it is already one of the recognized leaders among the leading Russian manufacturers of heaters based on natural mineral fibers. The production of all ISOROC thermal insulation materials is carried out according to the latest German technologies on modern Swedish equipment, which ensures the high quality of the entire line of manufactured materials that fully comply with European production standards. The use of ISOROC insulation significantly reduces the cost of heating rooms and buildings, and creates more comfortable living conditions for a person.

Properties and benefits

- low thermal conductivity and high thermal insulation properties

- high degree of hydrophobicity due to water-repellent additives

- good vapor permeability of the insulation

- incombustibility of the material and high fire resistance

- low compressibility and high deformation strength

- high peel strength of material layers

- excellent sound insulation due to the structure of fibers of different lengths

- durability and long service life

- ecological cleanliness, due to natural components

- high efficiency, significantly reduces energy consumption

Price list, prices for insulation ISOROC

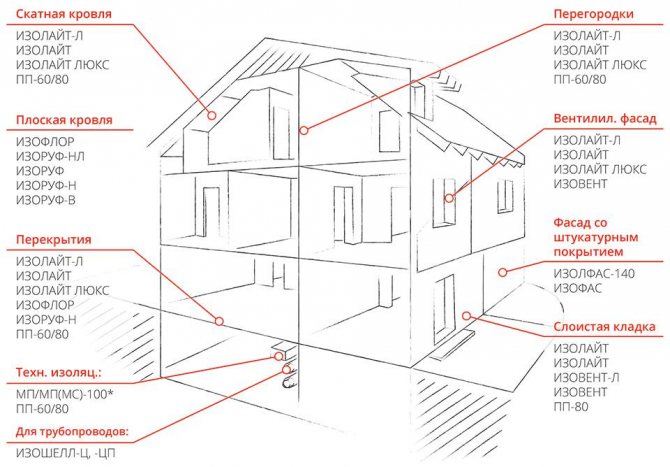

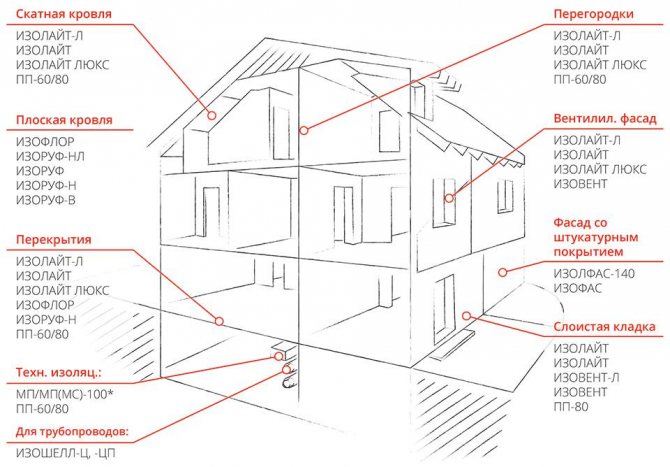

Main areas of application

Insulation material ISOROC has a very wide range of applications, and is used for thermal insulation of walls, partitions, ceilings, ceilings and floors, for thermal insulation of various types of roofs (flat, pitched and operated), for technical insulation of pipelines, industrial equipment, ventilation ducts and mines, and also for thermal insulation and sound insulation of various types of structural elements of buildings and structures, both for industrial and civil purposes.

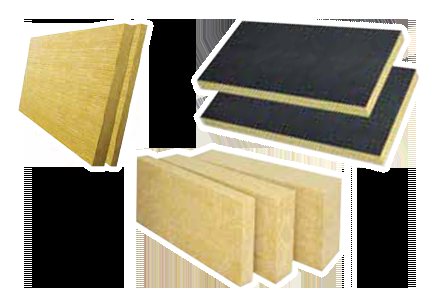

Thermal insulation ISOROC is produced in the following types:

- ISOLIGHT

- ISOLIGHT-L

- ISOLIGHT LUX

- IZOVENT

- IZOVENT-L

- ISORUF

- ISORUF-V

- ISORUF-N

- ISORUF-NL

- ISOFLOR

- ISOFAS-90

- ISOFAS-110

- ISOFAS-140

- ISOFAS-160

- ULTRALITE

- Plates PP-60 / -80

- Plates P-75 / -125

- Mats MP-75, MP (MS) -75

- Mats MP-100, MP (MS) -100

Scopes of insulation

Stone wool cylinders are used in engineering communications

Insulation materials of the Izorok brand are characterized by the fact that they are used not only in construction, but also in other areas. In their classic form, they are used:

- for internal thermal insulation and warming of floors (interfloor floors);

- in order to protect attic rooms and roofs of buildings;

- for sound insulation of premises in apartment buildings.

When choosing products suitable for specific purposes, the density of the insulation material used must be taken into account.

Due to their ability to retain heat well, they are used for thermal insulation of various utilities, including centralized water supply and heating systems.

Insulation materials ISOROC - types and their features

The company "ISOROC" offers consumers a wide range of heaters based on basalt mineral wool. To facilitate the selection, they are grouped according to the application. The group includes thermal insulation materials with similar technical characteristics. Detailed information on each name can be found on the official website of the company.

Materials for insulating a pitched roof

High-quality insulation of a pitched roof allows not only to reduce heat loss, but also transform a cold attic into a cozy living attic.

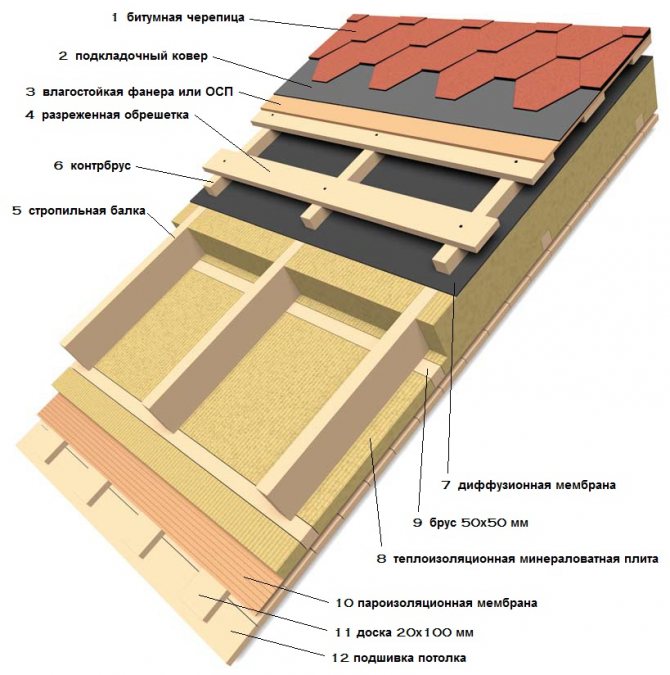

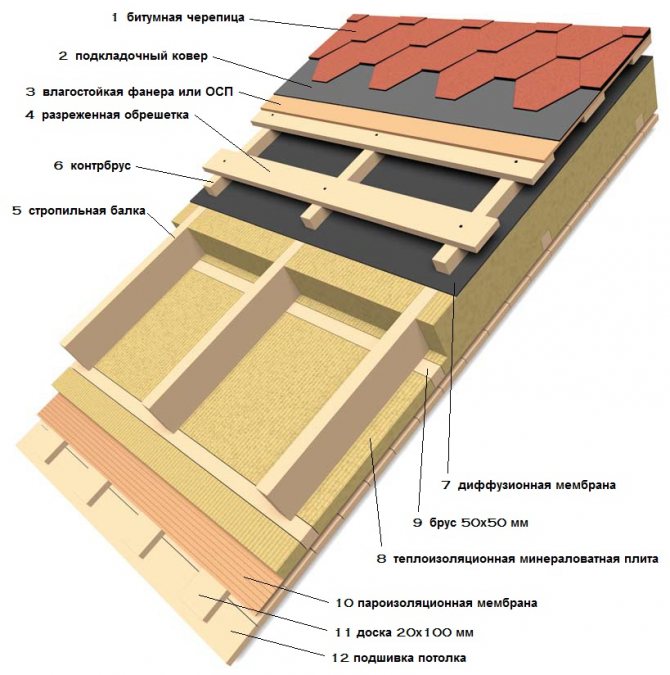

The pitched roof is a system of rafters that transfer the load to the walls and the sheathing. It is in the cells of the latter that the insulation is laid. It must be protected by a vapor-permeable membrane, which is mounted on the inside of the heat-insulating layer. For working with pitched roofs, it is recommended to use the following materials of the ISOROK brand: ISOLAYT, ISOLAYT LUX, ISOLAYT-L, ULTRALITE, PP-60 (-80) slabs.

Ranges of the main technical characteristics:

- Density - 33-60 kg / m3. For PP-60 (80) slabs, it can reach 75 kg / m3.

- Thickness - 50-200 mm.

- The thermal conductivity coefficient at a temperature of 10 ° C is 0.033-0.036 W / mK.

- The maximum compressibility rate ranges from 7-25%.

If the insulation of the pitched roof is two-layer, then for the inner layer the manufacturer advises using the ISOLAYT, PP-60, ISOLAYT-L boards. ISOLIGHT-LUX and PP-80 are suitable for the outer layer.

Useful: Choosing the best insulation for a frame house

Thermal insulation of a flat roof

It is easier to insulate a flat roof than a pitched one, due to its configuration. The difficulty lies in the selection of insulation, which should withstand the load from the topcoat, precipitation... Insulation ISOROC for a flat roof is laid on a ready-made supporting base (reinforced concrete or corrugated board), protected by a layer of vapor barrier.

For single-layer thermal insulation, Izoruf and Izoruf-V slabs are suitable. The ratio of their technical characteristics:

- Density - 150, 175 kg / m3.

- Thickness - 40-50 mm and 50-100 mm.

- Compressive strength - not less than 45 and 65 kPa, respectively.

- The thermal conductivity coefficient at 10 ° C is 0.034 and 0.037 W / mK.

For two-layer thermal insulation it is recommended to use ISORUF-N or ISORUF-NL - for the lower layer - and all the same ISORUF-V - for the device of the upper layer.

Main characteristics of ISORUF-N and ISORUF-NL:

- Density - 130, 115 kg / m3.

- Thickness - 40-150 mm and 50-150 mm.

- Compressive strength - not less than 35 and 30 kPa, respectively.

- The thermal conductivity coefficient at 10 ° C is 0.035 and 0.034 W / mK.

In this way, the top layer of thermal insulation must be stronger and denser than the bottom.

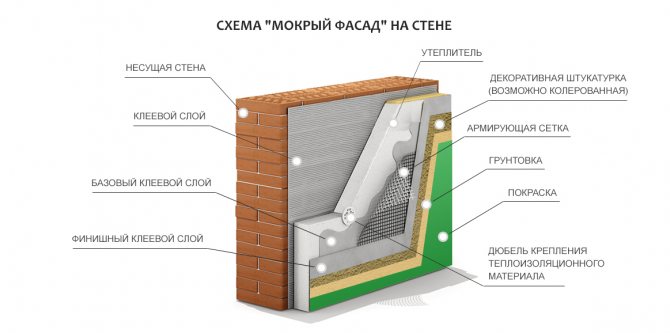

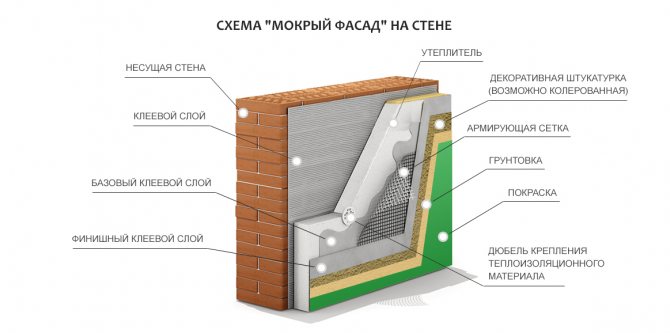

Insulation for plaster facade

Under the brand name ISOROC, the manufacturing plant puts on the market heat-insulating plates of the IZOFAS series (-90, -110, -SL, -140, -160). The digital value is the density of mineral wool boards. Thickness ranges from 40-150 mm... The higher the density of the insulation, the higher its compressive strength. It is 15-55 kPa.The thermal conductivity coefficient is 0.034-0.035 W / mK.

IZOFAS boards are perfect for insulating external walls for their further plastering, since they:

- have increased hydrophobicity;

- vapor permeable;

- do not collapse when mechanically attached to the working base;

- resistant to the chemical composition of facade plasters.

Insulation of facades can be performed:

- under a thick layer of plaster - using welded metal mesh, mechanical fastening of plates;

- under a thin plaster layer - by the glue method of fixing thermal insulation boards.

Due to the carefully verified geometry and exact dimensions, all ISOROC facade insulation easy to use.

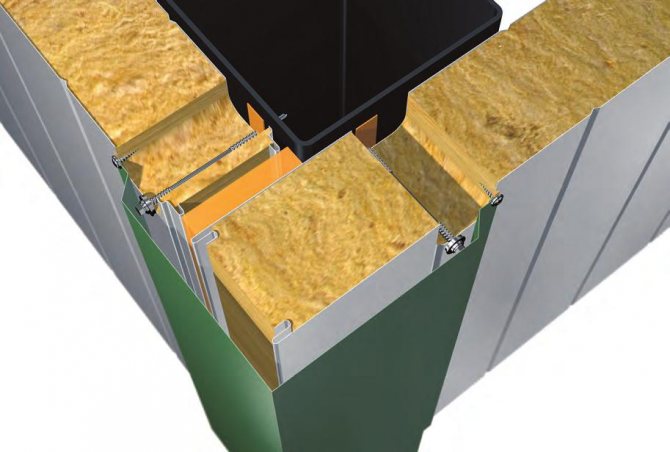

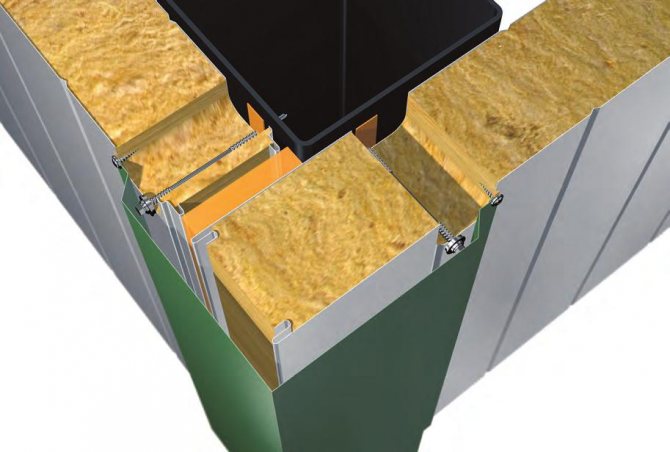

Heaters for ventilated facades

A feature of ventilated facades is the presence of a gap between the cladding and the surface of the outer wall. For its device, a substructure is mounted, in the cells of which insulation is laid. For these purposes, the line of plates IZOVENT (-L, -SL) is suitable.

The range of their technical characteristics:

- Density - 75-90 kg / m3.

- Thickness - 40-170 mm.

- Compressive strength - not less than 10 kPa.

- The thermal conductivity coefficient at 10 ° C is 0.033-0.034 W / mK.

For single-layer thermal insulation with the use of a windproof membrane, the following can also be used: PP-80, IZOLAYT-LUX. With two-layer insulation, a line of insulation ISOLIGHT they are used as the bottom layer, and IZOVENT heaters are used as the top layer.

Useful: Terrace at home: planning, progress of work

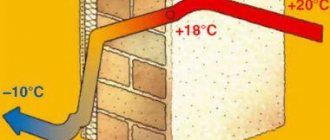

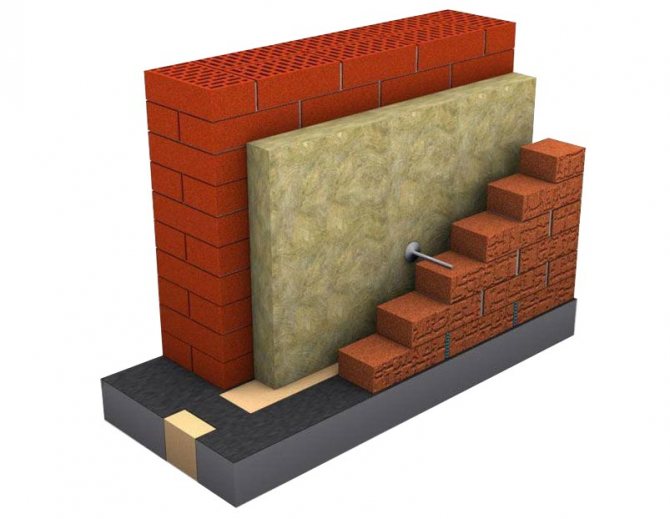

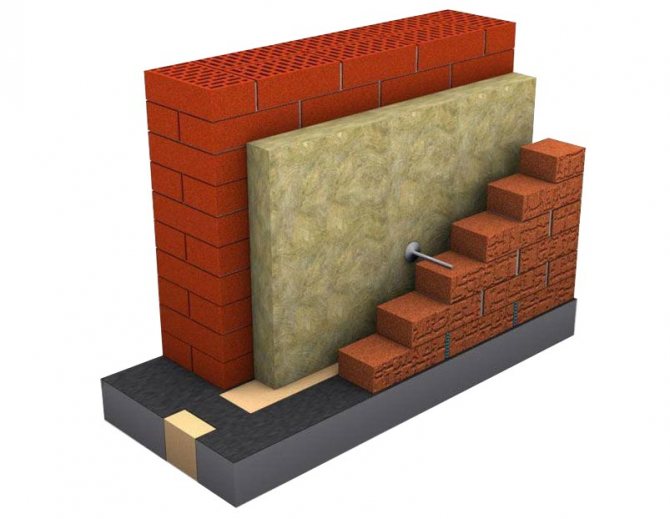

Thermal insulation of laminated masonry

Laminated masonry is a structure in which a load-bearing wall made of bricks, concrete, expanded clay concrete serves as a base, and a brick or other small-piece material is used as a facing. Insulation is placed between them. In this case, the thermal insulation material must have high vapor permeability, hydrophobicity, shrinkage resistance... These requirements are fully met by heaters of the IZOLAYT, IZOVENT, IZOVENT-L, PP-60 (-80) line.

The installation of thermal insulation boards is carried out vertically. A gap of 10-20 mm is left between them and the outer wall.

Materials for floor slabs and partitions

Interfloor ceilings and internal partitions do not experience heavy loads, the influence of atmospheric phenomena. That is why there is no specially designed line of materials for their insulation. Taking into account the peculiarities of a single design, you can use insulation from the available range.

More specific recommendations for thermal insulation:

- For attic and unheated basement slabs lightweight slabs of the ISOLIGHT or PP-60 series are suitable. To obtain a durable structure, it is better to use dense boards of the IZOVENT series.

- For the device of interfloor floors with concrete screed over insulation use ISOFLOR or materials of the ISORUF range.

- Optimal options for installing floors on logs - heaters of the series ISOLIGHT, IZOVENT, IZOVENT-N.

Any low density slabs with good vapor permeability are suitable for insulating partitions.

Materials for sandwich panels and technical insulation

Sandwich panels with a heat-insulating middle layer are widely used for wall cladding in industrial, industrial buildings, as well as in sports halls, warehouses, etc. As a middle layer, it is recommended to use IZOKOR-S, IZOKOR-K boards with the following characteristics:

- Density - 105, 140 kg / m3.

- Thickness - 40-180 mm and 40-150 mm.

- Shear strength (shear) - not less than 50 and 75 kPa, respectively.

- The thermal conductivity coefficient at 10 ° C is 0.040 and 0.042 W / mK.

For the insulation of various pipelines, ISOROC produces heat-insulating cylinders made of basalt mineral wool.

The assortment of the ISOROC company is sufficient for solving any problems related to the thermal insulation of structures of various types.

Main advantages

The Izorok line of heaters, which has a large number of varieties, is characterized by the following indicators:

- low level of thermal conductivity, which reduces the cost of heating the object;

- good sound insulation;

- high strength indicators;

- resistance of insulation boards to deformations and other mechanical influences;

- good water-repellent qualities;

- fire resistance and environmental friendliness of the product.

Another attractive aspect of this material is its resistance to aggressive environments.

Resistance to fungal formations is explained by the inorganic origin of the starting material, and fire resistance is due to the presence of flame retardant additives in it.

Material specifications

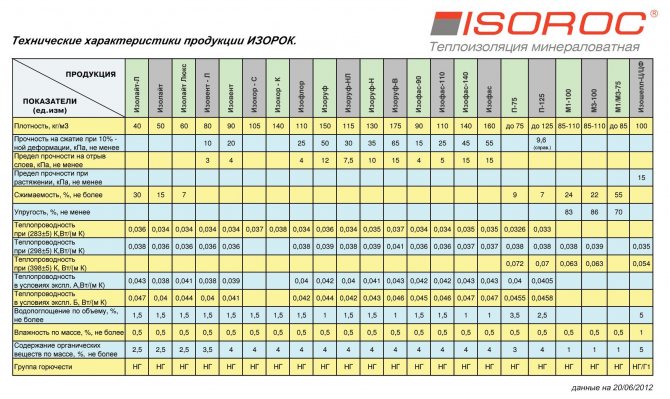

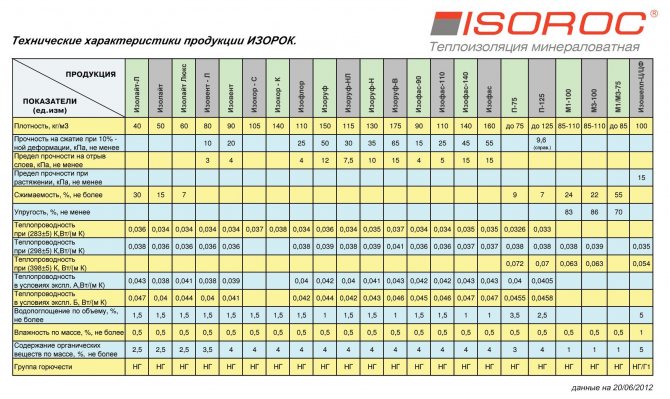

Insulation is produced in the form of slabs of various sizes or rolls, differing in a number of operating parameters. The following technical characteristics of Isoroc insulation are especially important for the user:

- The density of the starting material reaches 150 kg / cubic meter.

- Compression resistance up to 55 kPa.

- Inverse or tensile strength within 15 kPa.

- Thermal conductivity, expressed as 0.075 W / (m K).

- Moisture absorption - no more than 5%.

The last characteristic is understood as the ability of the fibers of the substance to absorb moisture - hygroscopicity.

Installation features

Under the screed, Izorok slabs are laid tightly to each other, without gaps

The peculiarities of mounting Izorok slabs and rolls for surfaces of various classes are manifested in the requirement to adhere to certain rules. They depend on the conditions in which this material is supposed to be used as a heat insulator. However, in any case, its use is permissible only in combination with steam and waterproofing.

Cement floor screed

Installation of insulation on a floor base begins with preparatory operations, which include the following steps:

- The screed is cleared of accumulated layers of dirt.

- All cracks found on the floor are closed, followed by leveling its surface.

- A waterproofing layer is installed, on top of which Izorok mats are laid.

When laying them, you will need to ensure that the workpieces are located end-to-end without noticeable gaps.

On top of the thermal insulation, another waterproofing layer is laid, on which a reinforcing mesh is then placed. The laid reinforcement is poured with a cement screed. When carrying out these works, it is important to take into account that the total thickness of the coating increases significantly.

Thermal insulation of external walls of frame structures

For external walls, a metal frame is formed for mineral wool

Before purchasing Izorok slabs, their total volume is calculated based on the fact that two layers of protective material are formed. Installation works are carried out in the following sequence:

- A lathing is attached to the walls based on wooden battens or a metal profile.

- During installation, the distance between the individual elements must match the dimensions of the insulation boards.

- Laying is organized in such a way that the slabs in layers are staggered, the workpieces of the second row completely overlap the joints of the previous one.

To fix the outer sheets on the walls, mushroom-type piece hardware is used, hammered in at 5 points. Waterproofing is mounted on top of the insulated surface, which provides reliable protection of the formed coating.

Insulation of flat roofs

For insulation of roofs, Izorok material with a high density index is selected, laid on a base made of reinforced concrete slabs or a metal profile. Work order:

- A vapor barrier layer is mounted to prevent moisture from entering between the layers of the heat insulator.

- The edges of the protective film must be folded under the insulation, which does not allow vapors to penetrate into it.

- With multi-layer installation, the joints of the slabs are located with a slight offset.

- For the upper layer, a material of higher density is selected than for the lower coating.

- Waterproofing is installed on top of the insulation.

Isoroc insulation is a reliable and high-quality material used in a wide variety of production areas. Due to the ease of installation and availability, this type of heat insulators is constantly in demand among professionals and people involved in construction at an amateur level.