How to dilute lime

Lime is a popular wall decoration material that has disinfectant properties and is not susceptible to mold and mildew. Such a finish is mainly found in public places where a coating that is resistant to abrasion and mechanical stress is required.

General information about lime

Lime is a mixture of substances that are the product of calcination of limestone rocks. On sale most often you can find lumpy quicklime and slaked fluff. Lime is considered the most hygienic type of finishing, since it destroys all microorganisms that get on it. In addition, it has a high moisture resistance and strength. When the limescale coating is completely dry, a film forms on it, which ensures such a long-lasting lime whitewash. It is also worth noting that the cost of lime is quite low compared to other types of finishing materials.

Do not forget about some of the shortcomings of this material. If the master performing the work does not know how to properly dilute the lime and makes the solution in the wrong proportion, then bubbles, streaks and streaks will appear on the treated surface. When dry, a very thick solution will begin to bubble and fall off, and too liquid will not give the desired color on the wall. That is why it is necessary to dilute lime strictly according to the instructions and in the right proportion.

In construction, this material is often used as a plasticizer for cement mortars. Lime perfectly binds the solution and prevents it from cracking. It is an indispensable ingredient in plaster mixes. In addition, it helps the coating adhere to stone and wood surfaces. But for this you can only use slaked lime.

Lime is also used in horticulture to treat trees and reduce acidity in the soil. To whiten trees, lime should be mixed with copper sulfate. Animal skins are also treated with this substance, water is softened and disinfected with it, and bleach is used in medicine for disinfection of premises, devices and water.

How to dilute lime for whitewashing

Now it is quite difficult to find a master who will take on this work, because the work is not the cleanest, and no one will work for low pay. So you have to whiten yourself. Do-it-yourself whitewashing is not at all a difficult task, but very unpleasant, and most importantly, dirty. Before work, it is necessary to cover the floors and furniture with foil, if it is not possible to completely empty the room. Also prepare protective clothing.

The consumption of whitewash, first of all, depends on the method of its application and on the surface to be treated. If you apply the whitewash with a brush, the consumption will increase. Brick walls will require more material than smooth walls. Approximately 0.5 liters of finished whitewash will be needed per 1 sq. m.

In shops you can find slaked and quicklime. Slaked is sold in the form of powder - fluff lime, and in the form of lime dough. Fluff lime should be diluted in a proportion of 3 liters of water per 1 kg of powder. Accordingly, from one package of fluff weighing 2 kg, you will receive 6 liters of whitewash, which is enough for about 12 square meters. m of surface, only if it is not brickwork. Dilute the finished lime dough in the ratio of 3 liters of water to 1 kg of dough.

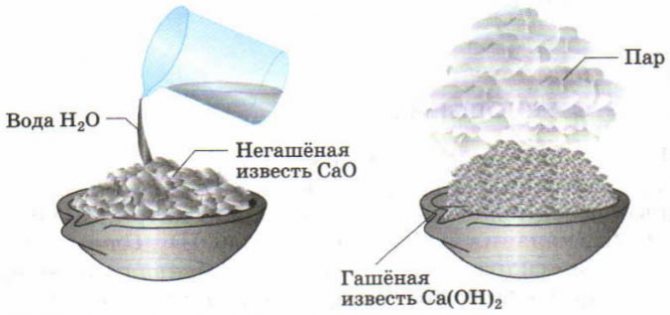

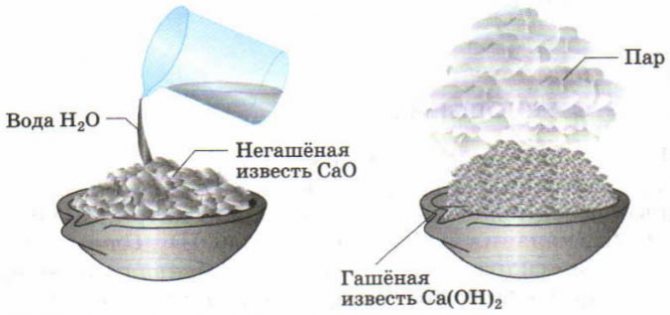

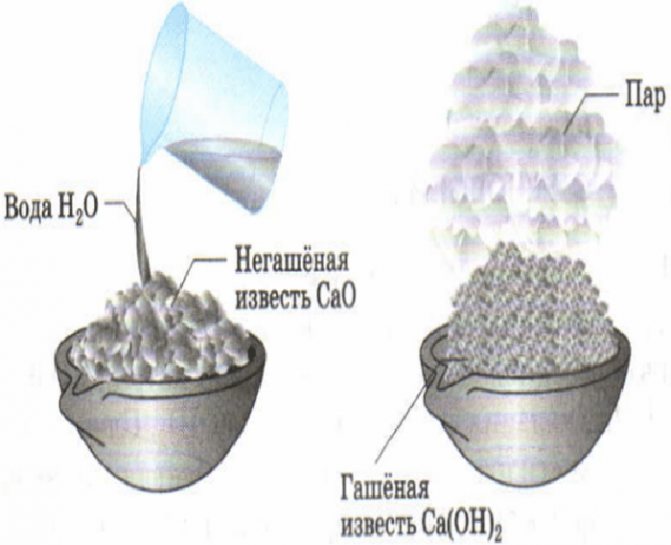

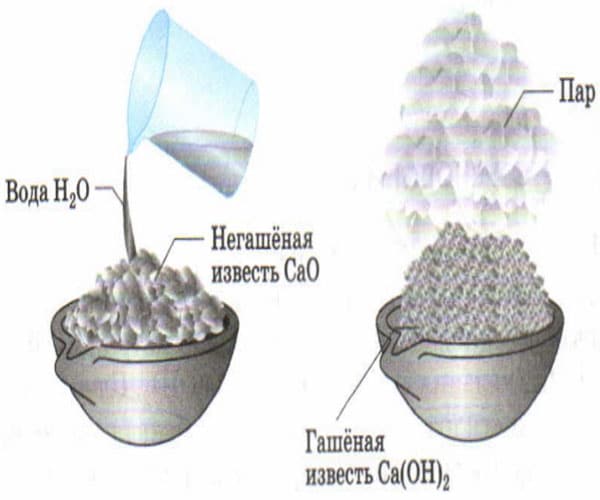

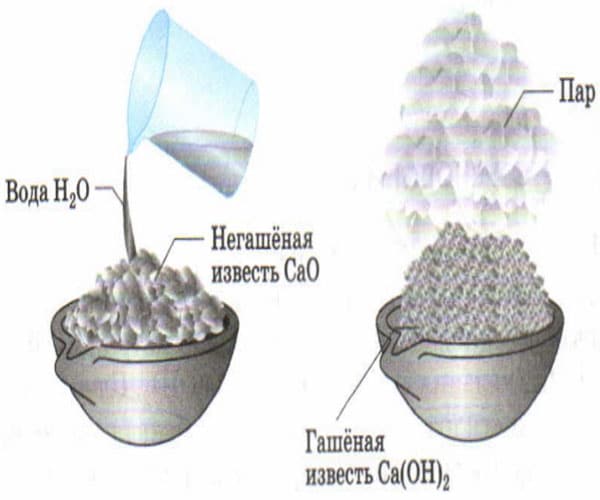

Quicklime, lumpy, must first be extinguished, and only then diluted with water. To do this, lime must be poured with water in a 1: 1 ratio.As a result, you will get a powder, and if you add three times more water, you will get a lime dough. After that, the resulting powder or dough can be diluted with water. From 1 kg of quicklime, approximately 10 liters of whitewash are obtained, ready for use. You will not calculate the whitewash consumption up to the square. Lime is an inexpensive material, so you can easily buy a couple of extra packages.

Observe precautions when slaking lime. Extinguishing produces a lot of heat and steam. Slaked lime can be sprayed out of the container. In this case, rubber gloves, goggles and heavy clothing will help prevent scalds from getting on your skin. After quenching, the solution must be allowed to stand for at least two weeks, and only after that it can be diluted with water and start whitewashing. It is advisable to buy slaked lime, because it is much easier, faster and safer to prepare it for work.

In the diluted lime, at the rate of 10 liters, you need to add 2 tablespoons of drying oil, 100 g of table salt and paint blue. But before that, salt and blue should be diluted in hot water. These components give the whitewash whiteness, and the drying oil promotes better adhesion of the whitewash to the surface and gives it strength. The saturation of the solution mainly depends on the method of its application. If you apply whitewashing with a brush, then make the solution thicker, and when applying whitewashing with a spray, make a more liquid mixture and be sure to filter it through several layers of gauze.

You can refine the composition of lime by adding additional ingredients to it. So you get a paint with completely new qualities and even properties. In addition to water, water glass can be mixed with lime. glue, soap, salt, milk, flour, egg whites and any color scheme. When adding color, you can get any shade and your whitewash can easily turn cream, yellow or even brown. In some cases, linseed oil is added to lime, most often this technique is used to whitewash very smooth surfaces on which paint does not fit well, for example, furniture. Glue is added to make the lime more viscous, and after drying, it does not stain things so much. As you can see, an inexpensive lime wash can be a great paint for all surfaces. Its main drawback is that it is poorly suited for whitewashing walls, since it sticks strongly to hands and clothes. This method is appropriate if it is the upper half of the wall.

paints and varnishes

50 votes

+

Voice for!

—

Against!

Water emulsion is good, but fluff is cheaper and better for disinfection. This is due to the fact that in addition to its coloring ability, lime has an antiseptic property, therefore it prevents the formation of fungus and the appearance of mold on any surfaces. The article will focus on the preparation of lime.

Lime composition

- Lime is usually called materials after firing and a special technology for processing such natural materials as chalk, shell rock, limestone and other carbonate rocks. Lumps of rocks heat-treated in different types of furnaces at +1000 - 1200 degrees turn into pieces of various shapes.

- For further use, they undergo special processing without any chemical components or catalysts. Therefore, a 100% natural material is obtained, in the composition of which a small content of mineral additives and clay impurities is allowed.

- Lime is most often used in construction. And not only. Special grades of lime are widely used in ferrous metallurgy, food, pulp and paper, leather, chemical, textile and sugar industries. Lime is also used by agricultural workers and environmentalists to neutralize flue gases or water drains.

The popularity of lime

History has not preserved the name of the one who first thought of using the unique possibilities of lime. It is quite possible that it was one of the first finishing materials for decorating the homes of our ancestors. Obtaining patents and copyrights for innovations appeared already in the times of modern history. Now he would be among the richest oligarchs in the world.

Indeed, according to experts, about 300 million tons of lime are produced annually in the world. Of these, 120 million tons are sold on the market. Russia is among the leading manufacturers of this finishing material. About 10 million tons of lime are produced annually in the country. Of these, 4 million tons are for construction.

- Longer than all decorative materials and more often lime is used for whitewashing. Using it does not require special skills and physical effort. It is reliable and not too burdensome for the family wallet.

- Whitewashing with lime mortar of wooden structures or walls of houses is a tool used and tested for centuries. It was made not only for decorative purposes, but also to prevent wood decay, fire protection.

- Today, in metropolitan areas, almost no one covers the walls of rooms with lime. However, in the rural outback, they still prefer to use it to cover hidden beams, invisible rafters or internal purlins.

Varieties of lime

Silicates impart hydraulic properties to lime. Depending on the degree of their content, lime is considered air or hydraulic. Hydraulic lime has the ability to enhance the hardening process and maintain the strength of solutions both in air and in an aqueous medium. Depending on the content of clinker minerals, it can be weakly hydraulic or highly hydraulic.

Air lime is intended to ensure the hardening of the mortars used in construction and to maintain their strength at normal humidity levels.

According to the level of oxide content, they are distinguished:

- calcium;

- magnesian;

- dolomite.

By the type of processing, lime is:

- lumpy, so-called boiling water;

- ground in the form of a powder obtained by crushing the burnt lumps;

- fluff, which is a slaked material obtained after slaking lumps with water;

- lime dough - a product of quenching lumpy raw materials;

- lime milk - a white suspension.

In addition, lime is subdivided into:

- quickly extinguished within no more than 8 minutes;

- medium quenching - no more than 25 minutes;

- extinguishing slowly for at least 25 minutes.

Powdered lime is available with or without additives. The most famous type is quicklime. It is widely used in the manufacture of concrete, construction, finishing, binding and antiseptic solutions. With its help, an artificial stone is produced.

When using different technological parameters of burning rocks, lime lumps are obtained with different degrees of strength:

- hard burnt;

- softly burnt;

- intermediate option.

As a material for construction work, softly burnt lime is often used, in which:

- smallest grain size;

- lower density;

- minimum blanking time.

Heat is generated during the quenching process. If the safety precautions are not followed, there is a risk of severe burns.

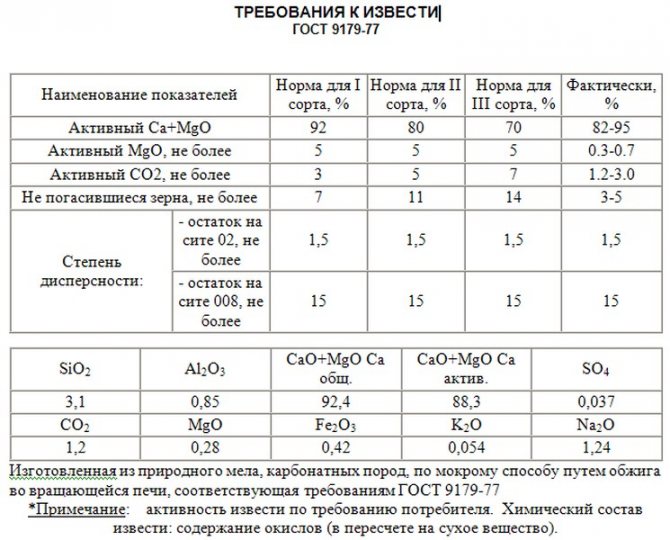

From the certificate of conformity for the quality of lime, you can find out about the type and condition of lime, the percentage of impurities. This document is issued only to organizations that comply with GOST in the manufacture of material.

What lime is made of

The type and grade of lime determines the main scope of its use.

- Lime for construction works made from rocks containing a large percentage of calcium and magnesium. It is used as a plasticizer in concrete mixes and bonding solutions. Such a brand is sold with lime dough or in lumps and fluff.

- For the manufacture of hydraulic lime by firing, limestones with 6-20% content of clay impurities are used. This grade is used for the production of low types of concrete, because it has a low plasticity, in contrast to a high level of strength. Hydraulic lime is more often used in the construction of structures that will be operated in high humidity conditions.

- Lumpy lime used as a semi-finished product for the preparation of powders or solutions. Store it in closed warehouses to protect it from moisture. It is implemented most often for the preparation of whitewash solutions.

- Garden lime used to enrich acidic soil with calcium. Without a sufficient amount of it, plants grow and develop poorly. Slaked and quicklime are added to the soil in rainy spring or autumn weather. Sediments contribute to better dissolution of limestone.

- Porous white mass soda lime is caustic soda mixed with slaked lime. Another area of application is the production of gas masks and pressure chambers, equipment for divers.

- As part of bleach free chlorine and calcium hydroxide. It has powerful disinfecting and whitening properties.

Lime properties

- Low cost... In the rating of materials, lime in lumps is rated quite high. It is almost impossible to find materials for finishing works with the same combination of price and quality.

- Disinfection... Bacteria that get on the lime film die.

- Moisture resistance.

- No unpleasant odor.

- Versatility... Can be used both on old whitewash and on new surfaces.

- UV resistant.

- Dye friendly.

There are two main disadvantages of lime:

- Risk of occurrence streaks and streaks, bubbles, if the rules of the percentage ratio for the preparation of a solution for whitewashing or concrete are not followed. A very liquid consistency will not paint the surface to the required saturation, and a thick whitewash solution, drying, will turn into bubbles and crumble.

- Extreme caution is required due to causticity when handling lime..

DIY lime

Lime for whitewashing is used on facades after plastering, surfaces of walls and ceilings in basements and rooms with high humidity or dry, kitchens, toilets. The lime composition is firmly indifferent to the effects of water and temperature changes. For example, ceilings are whitewashed with milk of lime, and smooth walls after plastering are painted with lime-based paints.

- Lime is used for primers and water-based paints for finishing surfaces inside and outside, not only as a paint, but also as a binding element. However, for tinting lime mixtures with an alkaline character, only alkali-resistant pigments are used. For example, for 1 kg of lime, no more than 100 g of soot or chromium oxide, mummy or umber is added. These dyes are diluted with water to a thick porridge. After 5 hours of exposure, stirring vigorously, add color to the fluff, which is diluted to the consistency of milk.

- It is more rational to buy dry lime. It lasts long enough. It doesn't take long to get ready for use.

- Before mixing lime, large lumps must be crushed and extinguished. Depending on how the solution will be used, a fluff (powdery solution) or dough is prepared. To do this, you need to take a different amount of liquid.

- To prepare a fluff for whitewashing a surface with an area of 2.5 squares, you must take a sufficiently deep container without rust. This is necessary because during the slaking of lime with water, the volume increases 2-3 times.

- Place 1 kg of lumps of lime in a bowl. Pour 0.75 - 1 liter of cool water. Cover loosely to allow steam to escape. If you take little water to slake lime, it can “burn out”.If there is too much water, the lime lumps can "suffocate".

- The procedure should be carried out with extreme caution, because the solution heats up to about 140-150 degrees. The boiling mixture fizzes and splashes, so it is better to play it safe and wear protective glasses and gloves before extinguishing the lime.

- During the 8-30 minute boil, stir the bubbling mass thoroughly with a wooden stick.

- When the extinguishing process is completed, you need to close the container with a lid and put it in the cellar for 15-30 days. Only after such exposure does the material acquire the most effective, disinfecting and reliable properties.

- On the day of whitewashing, you need to dilute the fluff with water. Whitewashing walls or ceilings is done with milk of lime, obtained from thoroughly mixing 3 parts of water with 1 part of freshly slaked lime. The liquid should be added so that on the stick with which the solution is stirred, a perfectly white lime remains in the form of a dense and even film.

- For the preparation of lime dough, the operating procedure is the same. In addition to the amount of liquid, which will require much less.

Five tips from the professionals for working with lime

- To increase the strength of the coating and prevent swelling of the plaster layer, 10-15% of paint with a latex base or wallpaper glue is added to the milk of lime.

- For a tighter adhesion of the lime milk solution, green soap (1 tablespoon) is added to ½ bucket of whitewash solution.

- To give the decorative whitewash additional durability, linseed oil (1/3 of a full tablespoon) and table salt (about 5 g) are added to this volume. Everything is thoroughly mixed, and then filtered through a fine sieve to remove undissolved lumps and grains.

- A light bluish tint that favorably sets off the ceiling surface in daylight can be obtained by adding blue (20 g).

- Painting with lime dyes should be done on cold or damp days.

Lime consumption

- Whitewashing the surface of walls, ceilings or other building structures is considered the most inexpensive finish. Consumption depends on the selected application technology and surface smoothness. More whitewashing is required when using a brush. Perfectly aligned walls will take less milk of lime than painting brick surfaces. Approximate consumption for 1 m² of flat walls is 0.5 liters of ready-to-use whitewashing solution.

- Usually, professional craftsmen estimate whitewashing 1 m2 of walls in one layer at 50 rubles and more. The price depends on the need for cleaning from dirt or paint, the surface structure, the number of layers.

Lime consumption for whitewashing

In terms of cost, it is more profitable to use lime than to paint the walls with water-based paints or decorate with other materials. And in terms of quality characteristics and antiseptic properties, it surpasses many of them.

How to whitewash a house

Plastering the walls before whitewashing will allow you to get even, beautiful ceilings. But whitewashing with lime is considered a cheap finish, so walls are usually not leveled or putty. In order for the whitewash to lay down evenly and not peel off after a week, it is necessary to clean the surface and remove all dirt. When whitewashing the ceiling with lime, the chalk whitewash will have to be completely removed. The old whitewash can be left in the event that it adheres well or partially removed. Yellow spots on the ceiling that remain after flooding neighbors can be washed off with whiteness. A solution of copper sulfate is very effective in removing stains. But you need to remember that for further repairs, if you paint the ceiling with water-based paint. stains may appear again. Only already green.

The surface for whitewashing must be absorbent; whitewashing cannot be applied to oil paint.Under no circumstances prime the ceiling and walls with an ordinary primer, as it creates a film on the surface, along which the whitewash will roll or collect in drops on the ceiling.

At the next stage, according to the selected recipe and taking precautions, whitewashing is prepared. Now you can start applying the first layer. The work surface needs to be slightly moistened so that the lime can carbonize, which will determine its strength. The first layer on the walls and ceiling should be applied in the direction from the window, and on the oven - with horizontal lines. If you do this with a spray, then spray the solution in a circular motion in the selected direction.

It is very important to apply the second coat before the first coat is dry. Now the whitewash must be applied in the opposite direction so that no roller or brush marks are visible. It is generally better to use a special brush for whitewashing. Since the first layer lays down well with a roller, but when the second layer is applied, problems begin, since the whitewash stretches behind the roller and lags behind the wall. They are successfully used for whitewashing and spray guns, in this case the lime evenly falls on the surface, while the consumption is much lower than when working with a brush. It is advisable to whitewash on cloudy days or in the evening so that the sun's rays do not hit the surface. Such work is not recommended in the hot season, as moisture evaporates too quickly, and the layer becomes weaker. In general, the lime coating is reliable and durable, it will last about 4-5 years.

https://estroyka.com

Whitewashing is a time-honored way of treating the surfaces of walls and ceilings. Despite the range of modern building materials, lime does not leave the store shelves. What's the secret?

Whitewashing with lime or chalk: which to choose?

Whitewashing as a way of finishing the surfaces of living quarters is becoming less popular. Modern materials are increasingly appearing in our apartments, and there is no longer any special desire to mess with the bleach solution. But, nevertheless, there is still a demand for lime and chalk whitewashing. This finishing method is widely used in educational and medical institutions, in utility rooms, etc.

Whitewash can also be found in apartments, for example, on the ceiling in the kitchen or bathroom. Quite often, a bleaching solution is used to decorate a garage, shed and cellar in backyard areas. And if you go outside the city, then in the villages you can still find neat white houses, in which, of course, the stove takes the central place. Whitewashing the kiln with lime is still relevant today.

If there is a need for whitewashing, then first of all you need to choose the material on the basis of which the bleaching solution will be made. The most common options are chalk and lime. Of course, each of the options has its own positive and not very good properties. What do you know about them? Nothing? Then meet:

Lime is a material that is obtained in the process of burning carbonate rocks. It is used both in construction and to obtain various chemical compounds. For bleaching, slaked lime is used, which is obtained by combining lime powder with water. Possesses the following positive characteristics:

- affordable and low cost of material;

- has bactericidal properties;

- resistant to temperature fluctuations;

- moisture resistant;

- able to seal small cracks;

- adheres well to brick, stone, wood and plaster.

Whitewashing also has negative aspects:

- defects (stripes, streaks, stains) are possible;

- there is a possibility of getting burned.

Since lime is a sodium alkali, precautions must be taken when working with it in order to protect your health.

Chalk is a common and familiar material of natural origin. Advantages of the chalk finish:

- affordable price;

- environmental friendliness;

- deep whiteness of color;

- easy to rinse off - easy to remove the white layer;

- simplicity and safety in work.

Disadvantages:

- easy to wash off - not suitable in a humid environment;

- defects (stains, streaks, bubbles, etc.) are possible.

Chalk or lime

What is lime anyway? Lime is a material obtained from the burning of carbonate rocks. Lime has found practical application both in construction and for the production of various chemical compounds. To whitewash the surfaces, powder lime is mixed with water. The positive qualities of the material include the following:

- Affordability and low price.

- Antibacterial.

- Does not lose its properties with changes in temperature.

- Moisture resistant.

- Penetrates small cracks.

- Has good adhesion to many materials.

However, there are also disadvantages to lime. It:

- When whitewashing, streaks and stains appear.

- Care must be taken when handling lime to avoid scalding.

Chalk, which is a natural material, is also popular and is used to whitewash walls. Pros of chalk:

- Cheapness and availability.

- Environmental friendliness.

- Very good whiteness.

- It just rinses off the surface.

- Safe to work.

Minuses:

- Loses its properties in a humid environment.

- When working with chalk, certain skills are required, otherwise stains, bubbles, etc. cannot be avoided.

As can be seen from the comparative characteristics, lime and chalk for whitewashing have their own priority of use.

How to extinguish lime for whitewashing correctly and safely?

In the event that lime turned out to be a more suitable option for finishing the necessary surfaces, then you need to familiarize yourself with the rules for its preparation and extinguishing. You can buy this alkali in a hardware store in slaked (powder, dough) and quicklime (lumps). In the first case, it can be immediately added to the solution, and in the second, it can be pre-extinguished.

Before extinguishing lime for whitewashing, you need to make sure that all precautions are taken and there is no danger to health. For safe work, you must:

- put on overalls and rubber gloves;

- protect your eyes with special glasses, and your nose with a respirator;

- extinguish lime only in metal containers;

- choose a well-ventilated area for this procedure.

In case of contact of lime on the skin, rinse immediately with plenty of running water for 15 minutes, and then be sure to consult a doctor.

After following all the safety procedures, you can start slaking the lime. Slaking is a chemical reaction in which lime is combined with water. As a result, you can get fluff (powder) or lime dough, which will depend on the amount of water used.

To get fluff, you need to take 1 part of lime and 1 part of water, i.e. 1 kg of lime lumps per 1 liter of water. Lumps are placed in a clean deep container, which are then filled with cold and clean water. When reacting, the lime heats up very much, which is accompanied by hiss and splashes. It will take about 30-40 minutes for the alkali to calm down. After that, you need to stir it with a wooden stick. As a result, after evaporation of moisture, you get a powder.

Lime dough is a plastic mass, for the preparation of which you need 1 part of alkali and 3 parts of water. The further process is not particularly different: water is added in small portions to a container with lime lumps and gradually stirred. During the reaction, moisture evaporates, but its content in the final product will be higher, which will allow you to get a pasty consistency. With the help of the test, cement-sand mortars are strengthened and mortars for plastering are prepared.

How to dilute lime for whitewashing at home depends on the form in which the alkali is, it can be prepared according to several recipes.Required ingredients in all formulations are water and table salt, so you should check for their presence. And then we choose a recipe, adapt it to the required volume and prepare a bleaching solution, the approximate consumption of which is 0.5 liters per 1 m2 of surface.

Recipe 1. Fluff - 400 g, water - 600 ml, table salt - 5 g, drying oil - 0.3 tbsp. Mix all ingredients thoroughly and pass through a sieve to remove lumps. To give a bluish tint to the resulting solution, you can add ultramarine - 20-25 g.

Recipe 2. Dough - 3 kg, water - 10 l, table salt - 100 g. The dough is diluted in half the volume of water and milk of lime is obtained. Salt is diluted separately in 1 liter of hot water, added to milk and mixed thoroughly. Coloring compositions are also soaked separately in water and gradually poured into the solution. Before use, the bleaching mass is brought to a volume of 10 liters by adding the required amount of water.

I will note right away: I am not going to prove the usefulness or uselessness of this venture. On the Internet, two camps have long been formed, which are constantly fighting among themselves, proving points of view to the point of loss of pulse.

Someday I will study the issue, but not in this article. It is intended for those who want to learn how to dilute lime to whitewash trees, and get an idea of how to do it correctly, according to science.

How to extinguish lime

If you decide to stop at lime for wall protein, you need to be able to properly prepare it by extinguishing. In retail chains, lime is sold in two versions: slaked in the form of powder (or dough) and quicklime in the form of lumps. Slaked lime can be immediately dissolved with water and used for its intended purpose, but the quicklime analog will have to be repaid first.

The most important thing in this process is to protect yourself from the harmful effects of lime, when extinguished, gases harmful to human health are released. What should be done:

- In addition to clothing, be sure to wear gloves.

- Protect your eyes with special glasses (buy in a store).

- It must be remembered that lime is slaked only in a metal container.

- Work should be done outdoors or in a well-ventilated area.

- If, in the process of extinguishing, part of the lime still gets on the skin, it is necessary to rinse the problem area with water for 15–20 minutes, and then consult a doctor.

After taking the above measures, you can start slaking lime. As a result of quenching and depending on the amount of water, a powder (fluff) or lime dough can be obtained.

To produce powder, water is added to quicklime in proportions of 1: 1, that is, if you take 1 kg of lime, then you need to use 1 liter of water. The water should be cold and clean. The reaction occurs with hissing and splashing, the temperature of the mixture rises to +50 ºС. However, after forty minutes everything calms down and after the water evaporates, a powder is formed, which must be mixed with a clean wooden stick.

To obtain a lime paste, the mixture should consist of one part of lime and three parts of water (1: 3). The process is similar to the first one with the only difference that water is added gradually and is also gradually mixed. After the excess moisture has evaporated, you get the expected product.

In conclusion, we can say that the powder is used to prepare the whitewash solution, and the "dough" is used to prepare the solution and to strengthen the cement-sand mixtures used for plastering.

Why whitewash trees?

Most gardeners, answering this question, will say: "to protect trees from sunburn." This is true. But there are still factors that become whitewashed.

Frost protection

Frostbites are damage to the bark that resembles deep cracks. In severe cases, they can reach the middle of the tree, which leads to its death.They are formed with fluctuations in day and night temperatures in winter, especially in February.

During the day, it warmed up to 1 0 C, and at night there was a frost of -15 0 C - a phenomenon familiar to the regions of Russia. The bark of a tree, warming up from the sun's rays during the day, cools sharply at night. This is equivalent to immersing hot glass in cold water.

Whitewashing wood leads to the fact that the bark heats up and cools down evenly. From physics we remember that dark color absorbs solar heat, light color reflects. This property is used in our case.

Destruction of pests

Even slaked lime is an alkali that kills most insects, especially their larvae. Many diseases of garden trees are caused by these pests, and whitewashing can reduce risks, reduce the use of chemicals, and preserve the harvest.

Inexperienced gardeners complain that whitewashing does not help. They say that there is no difference between treated wood and untreated wood. Yes it is possible. But only if you take a brush and apply the lime mortar without proper preparation. I will talk about it below.

Sunburn protection

This factor is the cause of numerous controversies on the forums. Forestry people argue that sunburn occurs only on some species of coniferous trees and never on deciduous trees.

Maybe so. But it's better to play it safe. In theory, whitewashing can protect the bark from burns as well as frost damage. The same principle of intense reflection of the sun's rays works.

The benefits of lime for trees

Lime is the main component of the whitewash mixture. After the composition dries, a film is formed that provides protective functions:

- protection of the bark from cracks due to temperature changes in winter;

- pest control;

- neutralization of the harmful effects of the sun's rays;

- healing of wounds from lichens and mosses.

Instead of whitewashing, you can use chalk.

Frost protection

The defect is represented by longitudinal cracks along the bark, usually on the north side of the tree. The problem arises from temperature fluctuations during the day and night. Additional risk factors are excess moisture, late planting of seedlings in the ground. Whitewashing will protect the plant: heating and cooling of the trunk will take place evenly.

Pest control

An unkempt tree with massive bark is an ideal place for the development of pathogenic organisms. Slaked lime by its chemical composition is an alkali that kills pests and their larvae. The treatment reduces the risk of plant diseases, and you can save money on the chemical treatment of the garden.

Sunburn protection

The white color of the bark reflects the rays of the sun, protects the trunk from high temperatures. The opinions of gardeners differ - some experts believe that the problem of overheating concerns conifers.

Preparing wood for whitewashing

At this stage, I will dwell in more detail. Many gardeners make a mistake here, or rather, they do not prepare the tree in any way. The result is pests, burns, and sadness.

Remember. You cannot whitewash the tree without preliminary cleaning and disinfection. Yes, it will be beautiful. But there is no benefit.

Before cleaning, take a plastic wrap and spread it around the tree, close to the trunk. This is necessary to prevent pests and debris from entering the soil. Then proceed as follows.

- Prepare wooden or plastic scrapers (metal tools cannot be used).

- Examine the surface of the trunk and main branches for cracks.

- Carefully peel off loose bark, mosses, lichens.

- Cover deep cracks and hollows with garden varnish.

- Prune the tree if necessary.

- Treat the barrel with a disinfectant solution.

Disinfection is best done with a sprayer or trigger. In this case, the solution will penetrate even the smallest cracks. With a brush, this effect cannot be achieved.

After disinfection, the film must be carefully collected, taken away from the garden and burned.

Disinfectant solutions

Most often, a 3-5% solution of copper or iron sulfate is used in horticulture. It prepares like this:

- take 300 g of powder (for a 5% solution - 500 g);

- pour in the same amount of hot water;

- after dissolving the vitriol, bring the volume of water to 10 liters (you can use warm or cold);

- mix thoroughly with a wooden stick.

Spray the main trunk and skeletal branches with this solution. If you missed the time and the tree began to bloom, make a 2% solution.

If, while examining the tree, you find colonies of moss or lichens, vitriol will not help. Treatment with salt solutions is necessary, which can be prepared by dissolving one of the following ingredients in 10 liters of water:

- edible salt - 1 kg;

- urea - 600 g;

- nitroammofosk - 650 g;

- potassium carbonate - 550 g;

- potassium chloride - 350 g.

These solutions are applied to the areas of growth of mosses or added to the lime mortar.

If you are an ardent opponent of chemistry and do not want to poison the garden, you can use a solution of stove wood ash for disinfection. It is prepared according to the following recipe:

- take 3 kg of ash;

- add 5 liters of water;

- bring to a boil;

- cool, add 50 g of shabby laundry soap;

- mix thoroughly.

Spray the trunk and branches of the tree.

Trees can be whitened 3 days after treatment. If it rains at this time, repeat disinfection.

Lime fluff cooking technology

Fluff is prepared by spraying lump of quicklime with water and immersion of lump of lime in water. In both cases, it is advisable to use air calcium lump lime of the 1st and 2nd grades in accordance with GOST 9179 - 77, containing a minimum amount of non-extinguished grains. Lump lime is usually delivered to the place of slaking in a dump truck in bulk.

To prepare fluff by spraying lump lime with water, equip a platform (Fig. 1). To extinguish 5 - 6 tons of lump lime near the construction site or on its territory, a 3 × 5 m area is fenced off and a high canopy of boards is erected above it, covered with a layer of roofing material on top. On one side of the plot under the canopy, a 2 × 3 m area is leveled and tamped.Next to it, outside the canopy, several metal or wooden barrels of 200 liters each are installed. For spraying lime with water, prepare 4 - 5 watering cans, 15 liters each. If the construction site has a water pump or plumbing, a pipeline with a valve, a rubber hose and a sprinkler (shower) is laid to the site under the canopy.

The delivered lump lime is unloaded under a canopy. The barrels are filled with water. 1 m3 of quartz sand is imported and stored. Make sure that the shovels and rakes are in good working order. Check instruments for measuring the temperature of the slaked lime. If there is a water supply system, make sure that the valve is in good working order and check the water pressure in the pipeline.

The fluff is prepared in the following sequence. An even layer of lump lime 0.2 m thick is thrown onto the compacted earth with a shovel, over an area of 2 × 2.5 m, it is evenly sprayed over the entire area with water from a watering can or using a hose with a spray gun. At the same time, about 900 kg of lime is in the layer, and about 500 liters of water are consumed for slaking it. A new layer of lime 0.2 m thick is poured over the moistened layer and again sprayed evenly with the same amount of water. The operations of throwing a layer of lime and moistening it are repeated 5 - 7 times until the total height of the stack is 1.5 m. A thermocouple connected to a millivoltmeter is placed in it at about half the height of the stack.

How to properly dilute lime for whitewashing?

You can only find quicklime in stores. These are white stones, less often sand, which have a strong alkaline reaction.When interacting with water, a strong release of heat occurs, and three types of solutions can be obtained:

- fluff;

- lime dough;

- lime milk.

What you get depends on the ratio of quicklime to water. According to the technology, you first need to get fluff and only then prepare a solution for whitewashing.

Fluff recipe

Be careful when handling quicklime. During interaction with water, the temperature rises to 150 0 С, and the solution itself boils and "splashes". If you are not careful, you will get chemical burns to your eyes or skin.

Therefore, work with gloves and protect your eyes from lime penetration. The step-by-step recipe is as follows:

- take a deep container (a bucket will do);

- pour 2 kg of quicklime;

- gently pour in 2 liters of water;

- wait for the violent reaction to pass;

- mix the contents gently until smooth.

You can use a different amount of lime. The main thing is to observe the ratio of 1: 1 or 1: 1.5, where the first value is quicklime.

How to make a whitewash solution

If you just dissolve the fluff in water, the whitewash will be washed off with rains in a month. Therefore, I recommend whitening the trees with the following solution:

- 2.5 kg of fluff;

- 9 liters of water;

- 60 g (3 tablespoons) flour paste.

Mix everything thoroughly and apply to the barrel with a brush. Instead of paste, you can add 1 kg of clay.

Note. You should have a creamy mass (milk of lime). A thinner solution will roll off the bark, a thicker one will not stick.

Lime milk is prepared in a 1: 3 ratio. If you want to whiten young seedlings, make a 1: 4 consistency or use a water-based paint.

Lime slaking

Installing a lime screed or plastering walls with lime mortars does not always have good results. Very often the screed turns out to be loose, and the plaster cracks and moves away from the walls. This is due to the preparation of building mixtures from poor-quality slaked lime.

To give the building mixtures the necessary qualities, lime is slaked. Lime is not just filled with water - it is important to know how to slake lime properly. Lime dough is more often prepared, which has a long shelf life. Ready-made dough is used to prepare building mixtures.

The quicklime goes on sale lumpy, or crushed into powder.

On the packaging with lime, the time required for its extinguishing is indicated.

When lumpy lime is mixed with water, a hydration process takes place - calcium and magnesium oxides pass into their hydrates. The process is accompanied by the release of a large amount of heat - the temperature reaches 150 °, part of the water turns into steam. The steam loosens the lime and turns the lumps into fine powder.

Formulas for slaking lime CaO + H2O = Ca (OH) 2 + 65.1 kJ.

In this formula, calcium is given as an example; magnesium may predominate in the composition of quicklime. In this case, the formula will differ in the designation of the chemical element. Magnesium oxide (MgO) interacts with water to form magnesium hydrate (Mg (OH) 2).

Depending on the type and speed of slaking, lime is divided into 3 groups. The slaking time is counted from the moment lime is mixed with water until the moment when the temperature of the mixture stops increasing.

- fast-extinguishing - extinguishing time 8-10 min,

- medium damping - damping time 15-20 min

- slow extinguishing - extinguishing time more than 25 minutes

When slaking lime, it is important that no calcium and magnesium oxides remain in the mixture. If the oxides remain, when the building mixture is mixed with water, the hydration process will begin, which will lead to a decrease in the quality of the building mixtures.

When whitewashing ceilings or trees, lime must be extinguished.

Complete slaking of lime will take at least a day. Lime is slaked within 24 hours, but it is better to extend the slaking process to 36 hours.Slaking lime at home in large quantities is a troublesome process, so it is easier to buy slaked lime.

Lime fluff goes on sale - it is slaked lime. When slaking lime in production, the technology is observed. This allows you to get high quality slaked lime.

When is it better to whitewash trees

It is believed that trees need to be whitewashed in the spring. This is not entirely correct. At this time of the year, the main whitewashing is carried out, but it must be repeated in the fall, when preparing the tree for wintering.

Whitewashing in spring is carried out after the snow melts. In the central regions of Russia, this is the end of March - the first half of April. In the south - early March. The air temperature during this event should not be lower than 5 0 C. But you should not delay with whitewashing - you need to have time to disinfect and whitewash the trees before the foliage appears.

If you hesitate, the soil will warm up, pests will crawl out of it, the procedures will be in vain.

Whitewashing in the fall is carried out after the foliage is dropped. The air temperature should not be lower than 4 0 C. The process is the same as when processing wood in spring - first you clean the dead bark, process the cracks with garden pitch, disinfect, and then whitewash.

Whitewashing in summer is acceptable if you notice that the lime has been washed away by the rains. The best time to do this is early in the morning before the heat starts. There is no need to do any preliminary preparation.

I think I told in detail how to dilute lime for whitewashing and about the technology of processing a tree trunk. If you still have questions - write in the comments or social networks.

We prepare the tree for whitewashing and properly dilute lime

Lime is the collective name for the products of roasting, as well as the subsequent processing of chalk, limestone and other carbonate rocks. It can be slaked (Ca (OH) 2), quicklime (CaO) and soda (a mixture of Ca (OH) 2 with NaOH).

It was not in vain that our ancestors used lime as a whitewash; this material has disinfecting properties, which makes it impossible for fungus and mold to appear on finished surfaces. Until now, almost every one of us is faced with this type of whitewash in our own entrances.

Whitewashing the walls with lime in public places allows not to carry out repeated repairs for as long as possible, because this whitewash, during the drying process, forms a special film that is resistant to abrasion.

In addition, whitewashing the ceiling with lime in baths, bathrooms, swimming pools and showers will protect it from moisture, because this material has good moisture resistance and durability. Lime coating is also used in the decoration of closets, basements, garages, etc. The main factor influencing the choice of this material is its cheapness and environmental friendliness in comparison with other analogues.

TO disadvantages

This coating includes the possibility of streaks, stains, streaks and bubbles when using a solution not compiled in the required proportions. If the prepared bleaching lime is liquid enough, then the color of the painted surface will be unsaturated, and if the composition turns out to be oversaturated, then the coating will bubble and fall off when it dries.

In addition, the quality of the original lime also affects the properties of the coating. The disadvantages of this material include its causticity. Therefore, when applying the composition to the surface, you need to be extremely careful, or better, before diluting lime for whitewashing, dress in old clothes and protect your hands and face with gloves and a respirator, hide your eyes behind special glasses.

Whitewashing the ceiling with lime (using slaked lime)

This type of finish is characterized by a long service life and can be applied to a variety of surfaces. For this reason, when choosing a method for finishing the ceiling, many people stop at lime.

Be careful! Lime whitewash should not be applied to rusty or greasy surfaces. Let's consider step by step how the ceiling is whitewashed with a lime mortar:

- Preparing the base for lime finishing. The surface of the ceiling should be primed and putty. Ensure that the surface is clean and solid before applying the mortar.

- Preparation of lime mortar. To prepare a solution for two and a half square meters of space, you will need slaked lime (0.4 kg) and water (0.6 l). To make the solution strong and water-resistant, you should add drying oil (0.3 tablespoons) and table salt (5 g) to it. Further, the resulting mixture should be mixed well in a metal container and filtered with a sieve to get rid of lumps and impurities. To give the solution a bluish tint, add ultramarine (20 - 25 g) to it.

- Applying lime to the ceiling. The surface of the ceiling should be slightly moistened, after which 2 layers of whitewash should be applied. The second layer is applied over the not yet dried first. These actions will make the whitewash more durable.

An important point! Applying lime whitewash to the ceiling at high temperatures is not desirable, therefore, in the heat it is better not to whitewash the ceiling with lime.

Now, a few words about the moments that affect the quality of the ceiling whitewash.

Lime whitewashing can be made stronger by carbonizing it (saturate it with carbon dioxide). To create the necessary conditions for this process, moisture must remain in the whitewash for some time. For this reason, a prerequisite for applying lime whitewash is the moisture of the ceiling surface. In addition, in order to ensure normal crystallization of the whitewash, its composition should include table salt, which makes it possible for the accumulation of additional moisture from the environment in the composition of the lime film.

How to whitewash - choosing an approach

Before deciding how to whitewash the ceiling with lime and at the same time how to prepare lime for whitewashing, it is necessary to properly prepare the base for applying such a coating. For processing, the substrate must be solid and clean. It is unacceptable to apply this coating on surfaces with rust, efflorescence, as well as bituminous and greasy stains.

If there are cracks on the base, they must be expanded, primed, then putty and smoothed. We clean the old whitewash with a brush. We will plaster and prime the entire surface. Immediately before whitewashing, batteries, platbands, baseboards, and floors are carefully closed. All sockets and switches are sealed with tape.

For application, you can use brushes, rollers, a spray gun, as well as a regular vacuum cleaner. Brushing this whitewash is the easiest and cheapest method. It is usually used when small surfaces are to be treated with lime.

It should be noted that the quality of the layer will largely depend on the condition of the swinging brushes. It is advisable to soak the brushes in water for a couple of hours before whitening with lime to prevent the appearance of brush hairs on the treated surface.

If the surface is large enough, then a special sprayer is a better option. Such a spray should be kept at a distance of about 30 cm from the surface and at a right angle, so that the consumption of lime during whitewashing is minimal.

An ordinary vacuum cleaner can also be used as a spray. The required equipment is usually included with this device.

How to extinguish lime - step by step diagram

Step 1: preparation

You should be aware that for raw materials, the quenching time is at least 24 hours, although to obtain a better material, it is recommended to extend the process to all 36 hours. For this simple ritual, you will also need water and a clean stirring stick.Since this reaction takes place with the release of a large amount of heat, which is quite sufficient for water to boil, you definitely need protection: glasses to prevent drops of oxide from getting into your eyes, a respirator, since there will be a lot of steam with small particles of lime in the air, rubber gloves and thick work clothes with long sleeves and legs.

By itself, calcium oxide is a fairly strong alkali, in addition, boiling liquid can splash on you, so do not neglect safety measures before extinguishing the lime for whitewashing. The quenching container must calmly withstand heating up to 200-300 ° C - this is the temperature the lime particles will have when quenching. A plastic bucket, as you already understood, will not work for these purposes, but a metal one is quite. The reaction should be carried out outdoors or in a well-ventilated utility room.

Step 2: fill in water

We fill in the required amount of lime, but not more than half of the bucket. Prepare water in advance - theoretically, it is necessary to quench 350 ml per 1 kilogram of raw materials, however, during the reaction, a lot of water evaporates, so in practice you need up to 0.7 ml of water. Slowly, in a small stream, we begin to add water, all the while intensively stirring the contents of the container. Just pouring water is not enough - the top layer of quicklime material, having reacted with water, forms dense hydroxide flakes, which will block the access of liquid to the layers inside the bucket.

Step 3: cure the lime

After making sure that the water has penetrated all layers, you can leave the container for 1.5 days in a shaded place. The resulting fluff should be kept in dark, cool rooms for at least two weeks - only after that it will acquire all its characteristics, and it can be used for the necessary purposes. When diluting the fluff to the state of milk of lime, the resulting solution should be filtered through cheesecloth - it contains many pieces of unburned or burnt limestone. Burnt pieces are like pieces of glassy mass, unbaked are small pebbles.

How to dilute lime for whitewashing - everything is quite simple

Very often, novice home craftsmen do not know how to dilute lime in the right proportion

for maximum results. Experts advise to take 0.5 kg of lime and 0.75 liters of water for every 2.5 m² of the treated surface.

To give the whitewash additional durability, you can add a third of a tablespoon of drying oil and about 5 g of table salt to the composition. The entire solution is thoroughly mixed and filtered through a sieve to remove lumps, grains and impurities.

To give the whitewash a light bluish tint that will look advantageous on the ceiling in natural light, you can add 20 g of regular blue to the resulting mixture.

Before surface treatment, it is necessary to properly moisten the base. Such whitewashing is usually applied in two layers. Experts recommend applying the second layer on a slightly damp previous one, because this allows for greater strength.

For finishing work, it is better to choose a cloudy day or evening time, because lime does not like dry hot weather, as well as direct sunlight.

Plain lime for finishing was replaced by more modern materials. But in some cases it is not worth spending a lot of money, for example, if you need to make walls in an outbuilding, a workshop, or add beauty to the borders in the garden. In this article, we will consider how to dilute lime to whitewash the walls.

How to dilute lime

There are two ways to dilute slaked lime to whitewash surfaces.

Method # 1: we take 400 g of powder, add 6 liters of water, 5 g of salt and a teaspoon of drying oil. All this is thoroughly mixed and filtered through a sieve. If you want a bluish tint, add 25 g of ultramarine.

Method # 2: For 3 kg of dough, 10 liters of water and 100 g of sodium chloride are used. Further, the process becomes a little more complicated: the dough is diluted in only half of the water to obtain milk of lime, the salt is separately stirred in 1 liter of hot water and added to the milk. All this is thoroughly mixed and then increased to a volume of 10 liters by adding water.

How to whiten? You can manually use a special brush or roller, or you can use a spray gun, but in any case, you must first prepare the walls for whitewashing.

The process takes place in two stages: the application of the first layer, and after it dries, the second. It is preferable to carry out works in the evening hours or in cloudy weather. This is done so that the liquid does not evaporate so quickly and the layer is more durable.

Use of lime

To whitewash the walls, slaked lime is used. This agent is distinguished by high disinfecting properties, as it has alkaline characteristics, lime prevents the appearance of fungus, mold, and insect pests. No cracks, bubbles or peeling appear on the whitewash, this material is resistant to moisture and temperature changes. To apply whitewash, it is not necessary to remove the previous coating, you can whitewash on the old surface, if it is not too dirty. Also, whitewashing strengthens surfaces on which small cracks appear. The main advantage of the material is its cost, in comparison with other materials it is the cheapest, this is due to the simplicity of its manufacture. With a properly prepared mixture, after applying it, a homogeneous layer is obtained that does not exfoliate.

How to prepare a lime solution?

First, you need to purchase lime powder at a hardware store. Lime fluff is usually used, it is already slaked. To whitewash a room of about 15 square meters, you need one package of material. For concrete walls with a flat surface, a little mortar goes away than for brick walls. In the second variant, the material actively absorbs liquid, and the consumption of the mixture increases. More composition goes away when several layers are applied, so the material is purchased with a margin. For convenient application, it is necessary to properly prepare the mixture, if the material is in the form of a paste, then dilution with water will be easier. To process one square meter, you need about 0.5 liters of the mixture.

To prepare the mixture, you need to prepare 1 kilogram of dry lime, and three liters of water. To prepare the pasta, the dough is diluted with water in a ratio of 1 to 3. You can use quicklime lime, it comes in lumps to make a mixture, the material is poured with water, adhering to a ratio of 1 to 3, the container is covered. After the end of the reaction, the paste will be ready, it must be left for two weeks for a high-quality infusion. Then the paste is diluted with water to obtain the required consistency. When water hits the dry material, the mixture heats up and a reaction starts, so the container should be covered to avoid the release of harmful vapors. It is necessary to add blue to the composition to give a beautiful color, half a glass of salt, and 20 grams of drying oil, this contributes to the high-quality adhesion of the mixture to the surface. About four liters of the composition are prepared from one kilogram of lime. The solution is consumed depending on the type of surface, the maximum amount is about one liter per square. Also, the consumption of material depends on the tool with which the work is performed, thin brushes or bristles leave smudges, and apply the material in thick layers. You can reduce consumption by using a spray gun; sometimes a garden sprayer is used.

Buying lime - which one to take and how much ↑

Before going to the store, you need to find out which lime to buy for whitewashing - slaked or quicklime, how much is required and what other components are needed.This will save you from going back to the building market if suddenly the solution is not enough or its properties do not meet your requirements.

How to cook slaked lime with your own hands ↑

As you already understood, slaked and quicklime are completely different substances, which are united only by the consonant name and the presence of calcium in the composition. Slaked lime is used for household repair work. It is sold by weight at any hardware store or agricultural department.

However, situations are not uncommon when the farm has a fairly large supply of quicklime and it is desirable to use it, and not buy slaked lime. In this case, you can extinguish it yourself, especially since this chemical process does not require the skills of conducting such experiments in the laboratory.

So, how to prepare lime for whitewashing from lumpy quicklime "boiling water". First you need to worry about personal protection. Since you will be dealing with a fairly aggressive alkali, take care of your eyes (goggles), respiratory protection (respirator), exposed skin (closed clothing and gloves). This should be done in the air.

Video: How to prepare a whitewash solution

You will need a deep container such as a bucket and a mixing tool - traditionally a stick. The list of ingredients is short too:

- lumpy quicklime;

- water.

The water must be cold, this is the only condition. Even a first grader will remember the proportion - 1: 1.

- For 1 kg of calcium oxide, take 1 liter of cold water.

- Combine all this in a container and mix. Almost instantly, you will be able to observe the beginning of a powerful chemical reaction with the release of a large amount of heat. When extinguished, the mixture sometimes heats up to 150 degrees, it is not for nothing that the substance is popularly called a boiling water - the solution literally boils.

- When the reaction stops, heat and gas will cease to be released, lime can be considered "fluff", that is, slaked. However, it is not yet suitable for whitewashing.

- The solution should mature within 2-3 weeks under a lid in a dark cool place.

Solution proportions and consumption per square ↑

To start whitewashing with lime with your own hands, you need to prepare at least the following set of materials:

- fluff powder or lime paste;

- water.

In addition, all kinds of auxiliary substances are often added to the whitewash, which give it certain properties. The stock solution is prepared in a 1: 3 ratio. For every kilogram of fluff, they take 3 liters of water. As a result, 4 liters of solution can be prepared from 1 kg of the substance.

Lime consumption per 1 m 2 during whitewashing directly depends on the type of surface on which it is applied:

- The largest consumption - about 1 liter of ready-made solution per square, will go away when whitewashing untreated brickwork.

- A smooth, prepared surface assumes approximately 0.5 liters per square meter of area.

Another criterion that affects the expense is painting tools. Most often they use a regular flat brush or a round one - a brush. These tools are uneconomical, the mass is applied in a thick layer, drips and drops can form. The spray gun can significantly reduce material consumption and operating time. Often, instead of a spray gun, a back-blow vacuum cleaner and even hand-held tree sprayers are fitted.

Read also: Beautiful spruce trees in the forest

How to calculate the amount of fluff and water

Before you dilute slaked lime for whitewashing, you need to perform some calculations. An approximate calculation of the consumption is as follows.

First you need to calculate the area of the walls and ceiling that you plan to whitewash. For example: room 3 by 5 m, ceiling height 2.5 m. It was decided to process the ceiling and part of the walls from the middle of the height to the ceiling with lime whitewash.

Wall area: (3 * 2.5 + 5 * 2.5 + 3 * 2.5 + 5 * 2.5) / 2 = 20 m 2.

Ceiling area: 3 * 5 = 15 m 2.

Total area: 35 m 2.

Based on the average consumption of 1 liter of solution per 2 m2 of surface, it is easy to calculate the required amount for whitewashing - 17.5 liters of lime solution. You can round up to 18, or better - up to 20, because the average consumption is a rather flexible concept.

That is, 20 liters of solution is required, and this is 5 kg of hydrated lime in powder. It is worth noting that the ready-made lime dough, which is sold in hardware stores, is diluted in the same proportion, which means that the calculation is correct for him.

Supplements to improve resistance and combat deficiencies ↑

Since lime has been used in construction for a very long time, there are many "folk recipes" and methods that improve the properties of this substance. Still, modern water-based paints appeared not so long ago, and craftsmen were forced to do chemistry right at their dacha or at home.

The first problem that is solved by adding a secret ingredient to the lime whitewash solution is shallowing. A dried surface tends to stain everything and everyone who touches it. What to add to lime so that it does not smear? This ingredient is found in every home - table salt. It has a good bonding effect. Add 100 g of salt per liter of solution.

Another problem, especially when using whitewash for outdoor use, is the rapid rinsing off of the composition with water. It has long been known what to add to lime so that it does not wash off - a fatty component is introduced into it - drying oil. The drying oil repels water and allows the whitewash to last longer. Proportion 1:10, 100 ml per liter of solution.

They practice adding laundry soap, grated on a coarse grater, PVA glue, wallpaper glue, acrylic primer. All this is done in order to ensure maximum adhesion of the whitewash to the wall, to exclude its swelling and bubbling.

White is not the only possible color ↑

To prevent the lime coating from becoming yellowish, an ordinary blue is added to it - methylene blue. You will need 10-20 g per liter. The whitewashed ceiling will become snow-white. But sometimes it becomes necessary to obtain a lime solution of other colors. This mass cannot be called whitewashing, and not every dye is suitable. Use only those pigments that are resistant to alkaline conditions - mineral, but in no case organic.

Pigments used for lime paints:

- ocher (yellow tint);

- umber (greenish brown);

- red lead (orange);

- mummy (red-brown);

- chromium oxide (green);

- titanium dioxide (white);

- lithopone (white);

- ultramarine (blue).

To prepare good quality lime paints, it is not recommended to add pigment in its pure form - powder. It is preliminarily diluted with water to obtain a paste. Then the pigment paste is allowed to infuse for about 24 hours. And only after that, the dye can be added to the solution. This is because the pigment grains are often difficult to dissolve and can drag behind the brush, forming unsightly streaks of color.

How to prepare the surface?

The main goal is to create a solid and uniform surface with whitewash. To make a high-quality surface, it is pre-cleaned of dirt and greasy stains. If the wall is too dirty, then the layer of material is scraped off to the concrete base, this is the only way to ensure a reliable coating. You can remove oily or yellowed stains from the walls with bleach or whiteness. There is no need to prime the surface, the work is done in the evening or in cloudy weather to avoid sun exposure, otherwise the material may deteriorate.

Where is lime used?

As mentioned above, lime has high antiseptic qualities, therefore it can be used in unheated rooms with high humidity, for example, sheds, garages, workshops, basements, and other buildings.Walls and ceilings in the entrances of apartment buildings, kindergartens, schools, and other public institutions are also treated with lime. Since lime is resistant to precipitation and various temperatures, facades of houses, trees, curbs in the garden are treated with it. Lime is used to change the acidity of the soil, it protects trees from rodents, and gives them a beautiful appearance. You can also whitewash the walls in the foyer, entrance or corridor, while saving on costs, get a clean, neat look. Ceilings in kitchens or public buildings are whitewashed with lime, after the material has dried, it does not emit any toxins, and is safe. If it is necessary to process a large area of utility rooms, and save money, use a lime mortar. It is quite simple to prepare and apply, after drying it forms a white and clean surface.

How to get lime correctly?

Before starting work, it is necessary to calculate how much lime to buy, and what kind of slaked or quicklime it should be, as well as what other components are needed to prepare the mixture. This will help to immediately acquire the right amount of material to avoid repeated shopping if there is not enough solution. Slaked and quicklime types differ not only in the presence of calcium. For ordinary repair work in everyday life, slaked lime is used. It can be purchased in powder form at home improvement stores. If there is already a large amount of quicklime at home, and it needs to be used, then it must be extinguished, and then start to work. For self-repayment, you need to protect your eyes with glasses, and wear special clothing, work is done in the open air, since harmful vapors are released into the air.

How to extinguish lime for whitewashing - concepts

To begin with, let's figure out the concepts, since several compounds are obtained from quicklime, different in their consistency and used for different purposes. Most likely, quicklime raw materials will come to you in the form of small or large lumps - this is the result of burning limestone. It is called quicklime because the chemical reaction that forms the very lime for whitewashing trees or painting walls has not yet gone through. There is only one correct way to bring the quicklime material (calcium oxide) to condition (hydroxide or calcium hydroxide) - add water to it. Do not be afraid, there will be no fire, but upon contact with ordinary H2O, a rather violent reaction occurs with the release of a large amount of heat and carbon dioxide, which is why the process got this name.

As a result of slaking lime with water in a ratio of 1: 1, fluff is obtained.

This is the main material that is suitable for all purposes: preparing a lime mortar, obtaining a solution for whitewashing, for coating wooden elements (saves from decay and fire), and so on. When more water is added, a dough of lime is formed, although in consistency it is more like thick sour cream. Diluting it with even more water, we get milk of lime. When extinguishing, you can immediately go to one form or another by calculating the correct ratio of liquid and quicklime raw materials.

How to extinguish lime?

To extinguish lime, prepare a deep container, and a stick to stir the composition. For one kilogram of lime in lumps, one liter of cold water is used. Pieces of lime are put in a container, and they are poured with water, then they are carefully altered. At the same time, the mixture begins to hiss, as if boiling, which means that a reaction has begun to occur. After the hissing ends, the lime becomes in the form of a fluff, but it is not yet suitable for whitewashing, it is left for up to two weeks, and then used in the preparation of the solution. The extinguished material is removed to a cool place for settling.

Thus, you can prepare a lime whitewash solution yourself. If necessary, lime is slaked or purchased already slaked. To prepare a high-quality mixture, all proportions must be observed when making a whitewash solution. If everything is done correctly, the composition will adhere firmly to the surface, without cracks and delamination.

How to cook lime fluff

First, 1 part of cold water is added to the tank (basin, trough). Then, to obtain lime, fluffs take one dose of lumpy chalk lime and immerse it in the same container. That is, the proportion of water and lime is taken in a 1: 1 ratio, that is, for 3 kg of lumpy lime, you will need to take 3 liters of water. When interacting with a liquid, the resulting solution is heated to a temperature of 150 degrees.

Be careful - the resulting mixture reacts violently during boiling - sprinkles with hot drops and hiss.

Therefore, you need to be very scrupulous and cautious about this process. It is best to stock up on personal protective equipment (gloves, glasses, a canvas suit) before preparing the fluff. The boiling mass must be stirred with a stick throughout the entire boiling process, which takes about 8 to 25-30 minutes.

It is not advised to immediately use slaked lime. Cover it with a lid, put it in a cool place, for example, in a cellar, and let it brew for 15-30 days. The specified solution will retain all its qualities, as well as disinfecting properties. In addition, the slaked lime, subject to these requirements, will lie flat enough on the surface.

In order to whitewash the walls or ceilings, you need to dilute the fluff with cold water to the desired condition. If you add cold water gradually, and not immediately pour in the right amount, you can observe the consistency of the solution and stop when you achieve the desired result.