How to count for a Russian bath

The power of the stove for heating the bath is calculated based on the dimensions and parameters of the steam room. After all, the main task is to create the required temperature for this particular room. It is calculated by cubic capacity, but when calculating, it is still necessary to take into account several additional factors at once, to summarize the figures obtained. As a result, we obtain the required furnace performance for this type of steam room.

It has long been established that, on average, a heat output of 1 kW is required to heat one cubic meter of a steam room. Therefore, first, you need to know the length * width * height of the steam room. Multiplying these values in meters, you get the volume of the room, and, therefore, the minimum performance of the heating unit.

For example, a steam room has dimensions of 3 m * 2.8 m * 2.8 m. Multiplying, we get 23.5 cubic meters. In principle, when choosing, you can be guided by this figure ... But not everything is so simple. It is necessary to consider the following points:

- Is there a window in the steam room. If there is, you need to add 3 kW for each square meter of the window area (this is if the glazing is single), if the glazing is double, apply a reduction factor of 0.5. For example, there is a 50 * 40 cm window with one glass. It is necessary to add 0.5 m * 0.4 m * 3 kW = 0.48 kW.

- If there are brick walls in the steam room, 1 kW is added to each square (the high heat capacity of the brick requires additional heating).

- If there is a non-insulated door (wooden or glass), add about 10% more power reserve.

- Insulation degree. If everything is done according to the recommendations (insulation thickness), with a vapor barrier, the joints are glued with tape, no changes can be made. If the insulation is so-so, you can add 20-30% to the power already found.

- If the stove is fired from an adjacent room, it is also necessary to increase the required capacity by at least 10%.

In general, sometimes a pretty solid increase is obtained. But for a bath, it is better to have a stove with a higher power than a lower one: it is better to stifle the combustion than not be able to heat the steam room to the required temperature. The reserve is especially important for the baths of periodic visits. In winter, in a week, they freeze through and through. When putting them into vaping mode, reserves will come in handy, which in summer seem to be absolutely unnecessary.

Another plus of the stove productivity margin is that there is no need to heat it up red. With such intense heating, the furnace usually burns out quickly. To prevent this from happening, a fairly decent supply is needed.

Another advantage of stoves for saunas of higher power can be considered a large laying of stones, which means more comfortable steaming conditions, longer maintenance of the temperature in the steam room. There are also disadvantages. This is the price and size. Both are not fatal, but unpleasant.

How much oven power is needed to create thermal comfort

Further calculations are related to the specific climatic conditions of the region and your personal preferences. Suppose that the outdoor temperature in your area does not drop below -35 ° C, but you consider the comfortable temperature in the house to be + 22-23 ° C. This means that it is required that the heating unit provides a rise in temperature in the room by about 60 ° C.

Previous calculations showed that 1 kW of power provides a temperature rise of 10 °. Therefore, to raise the temperature by 60 °, power is required 6 times more - 6 kW.

When buying a unit, its characteristics usually indicate the approximate volume of the room for which it is designed.You can get more precise information from the sales company, which usually provide professional consulting assistance.

The video provides tips for choosing a stove for your home

Sauna features

The principle of calculating the power of sauna stoves remains the same: they are calculated by the volume of the steam room, the degree of insulation of walls and windows / doors is taken into account. Just take into account that the steam room is ready with average insulation in 2-3 hours. To reduce the time by 1 hour, it is necessary to increase the power by 60-80% (or improve the heat-insulating properties). But steam rooms in saunas usually do less than in baths. People sit quietly in them, and do not wave brooms. So really, too much performance is not required.

If you look at the catalog of wood-burning stoves for baths and saunas, then they are divided according to the volume of the steam room. This is convenient when choosing (taking into account all corrections for heat loss). If you are going to buy an electric heater for a sauna, then only the power consumption is often written in the technical specifications. In this case, for periodical saunas without constant heating, you can navigate according to the norms:

- blockhouse (log or timber) without additional insulation - 1.4-1.8 kW / m3 with a wall thickness of 100-140 mm, 1.5 kW / m3 is required;

- with a wall thickness of 200-240 mm - 1.75 kW / m3;

There is no error in the given norms: with an increase in the thickness of log walls without insulation, an increase in power is required. This is due to the high heat capacity of wood. And the more wood there is, the more heat will be spent on heating it. If there is good thermal insulation inside the sauna, the power is calculated according to the standards of the frame.

In the presence of constant heating, other standards are used to calculate the required power of an electric stove for a sauna - an average of 0.7 kW / m3 is taken. This norm is true for saunas in an apartment. So, in this case, using electric heaters is not that expensive.

When planning energy costs, please note that electric sauna ovens operate at full power only for the period of "acceleration" of the steam room - until the required temperature is reached. Then they either manually turn off and periodically turn off (cheap models), or automatically maintain the set temperature. In any case, after reaching the set temperature, the power consumption is reduced.

baniwood.ru

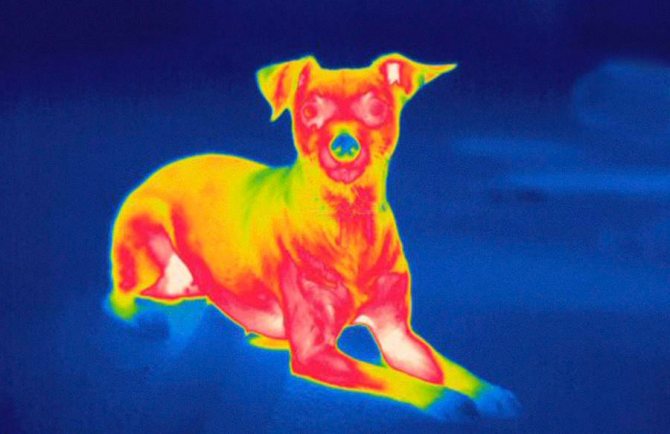

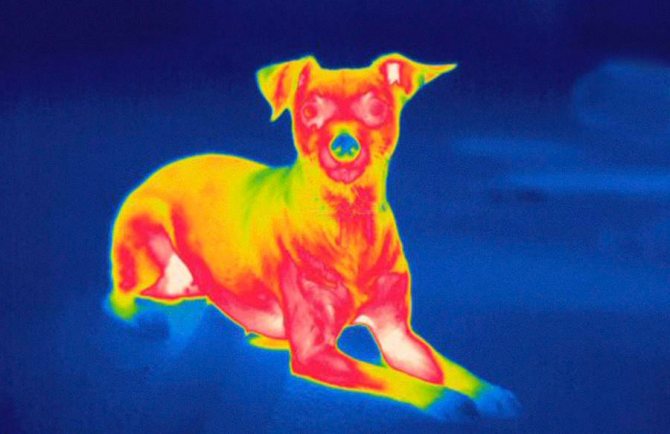

The microclimate of the Russian bath has a characteristic temperature of 60-80 ° C and humidity in the range of 40-60%. The efficiency of a metal furnace is to maintain a microclimate that changes depending on: ● the degree of insulation of the steam room ● heat capacity of the walls and cladding ● the presence of windows, doors, uncovered masonry. At the same time, only that stove, which is selected taking into account the ratio of power to the multi-part area of the steam room, is able to quickly create (and maintain for a long time) the necessary temperature and humidity conditions.

Selection parameters

Since the kilowatts reproduced by the iron stove and the range of cubic meters heated by it are indicated in the list of technical characteristics of a particular model, the buyer can only determine the heated volume of the steam room and calculate the power required for this.

Why are taken into account: ● volume (Vpair) - the product of length, width and height of the room; ● heat loss for heating closed openings (Hdoors, Hwindows) and brick partition (Hwalls). On average, heating them 1 m2 consumes the same amount of heat as is required for heating 1.2 m3 of the internal volume of the room; ● absorption of thermal energy by the walls of the bath (k). Average coefficient for: ➢ non-insulated log cabin - 1.6. ➢ insulated wooden wall - 1 ➢ vapor barrier with foil that reflects infrared radiation - 0.6. According to the formula V = k * (Vpair + Hdoor + Hwindow + Hwall), the estimated volume is calculated, being guided by which you can choose a suitable furnace.

An example of the selection of a metal stove

Let's consider the calculations using the example of a steam room: 1. in a log house, 2. in a log house with external insulation, 3. with a vapor barrier under the inner lining, without emphasis on the main material of the walls. The initial data common to all options: the steam room has a size of 2 x 2 x 2 (m), has a window to the courtyard, a door to an adjacent room and a brick wall without insulation, through which the firebox of a metal stove will be brought into the adjacent room.

Actual room volume (Vpair)

The product of 2.5 m wide, 2 m long and 2 m high is 8 m3

Cubic equivalent of heat loss in areas without insulation

Applying the coefficient 1.2 to the area: ➢ windows 0.5 x 0.8 we get 0.48 m3 (H-windows); ➢ doors 0.8 x 1.8 - 1.7 m3 (H doors). ➢ brick wall 0.8 x 2 - 1.9 m3 (Hwall).

The estimated volume of the steam room and the required power of the stove

The rounded sum of the calculated values (14 m3) is considered the calculated volume of the steam room, only after applying a coefficient to it that takes into account the material of the walls.

r /> ✓ Ordinary log house (k = 1.6) - 22.4 m3 ✓ Insulated wooden wall (k = 1) - 14.0 m3 ✓ Vapor barrier under the cladding (k = 0.6) - 8.4 m3 Based on the fact that to warm up 1 m3 of a steam room for an hour, 0.7 kW of the power of a metal furnace will be required (respectively: 15.7 kW, 9.8 kW, 5.9 kW) - the choice can be made based on this characteristic in the passport of the device.

Equipment selection

Despite the same volume of the room, different wall materials require the use of different heating equipment. That is, for each of the three considered options for steam rooms, a certain model of the stove is required. Due to the fact that the manufacturer is constantly improving the model range, it would be more expedient to indicate only the basic models for the calculation results. ❖ For a steam room in a log house, taking into account the large heat losses, a device with a declared power of at least 15 kW / h is required for heating the estimated 22.4 m3. The Dobrostal furnace Empress Augusta STONE strong (14-16 kWh), designed to work in a room of 10-22 m3, meets these requirements. This model has rightfully taken the 1st place among the sauna stoves of the middle price class. ❖ A similar steam room, but already in a wooden frame insulated from the outside, is heated by equipment with a capacity of 9.8 kW / h.

it is more irrational to purchase 14 m3 for heating. Therefore, Malyutka 500U (9.8 kW / h), with a "working" range of 6-16 m3 is an acceptable option. ❖ The steam room room, which has foil insulation under the casing, requires a stove with a power of 5.9 kW / h. The foil reflects infrared rays, the heat stays inside. The Extra 400U model, with a declared 6.8 kW / h for 4-12 m3, should be considered the most efficient metal stove under the established conditions. Other factors affecting the characteristics of the basic equipment: ● combustion box ● thickness of the walls of the furnace ● design of the door

They affect cost, service life and the level of comfort in service. Therefore, it should only be viewed with your own preference.

www.pban.ru

Posted by: vika_b 1 year, 10 months ago

Calculation of the power of the oven for a bath depending on the volume of the steam room

The sauna stove should be chosen with the optimal power based on the volume of your steam room.

You cannot be mistaken in choosing the power of the sauna stove, because then there will be no good steam: neither in the case when the power is insufficient, nor in the case when the power of the stove is more than required.

If you put a small stove in the bath with insufficient power for a given volume of the steam room, then it will have to be operated beyond its capacity, which will lead to rapid wear and tear of the stove.

If you buy a stove with a margin for reasons that a power reserve is never superfluous, then yes, indeed, the bath will heat up quickly and hot! But in order to bathe in comfortable conditions, it will be necessary to artificially reduce its capabilities while vaping and ventilate the steam room after each call.As a result, balanced steam cannot be obtained due to the fact that the stones in the stove are not so hot. And, if you maintain the desired temperature of the stones (at least 500 degrees C), it will be too hot on the shelf and even in the lower zone, near the floor.

The calculation of the power of the oven for the bath must be done in the following sequence:

1.determine the volume of the steam room by multiplying its internal dimensions: width, length and height. For example, a steam room has dimensions of 3x2m and a height of 2.2m. This means that its volume is -13.2 m3.

2.Calculate the heat loss by cold surfaces such as a glass door, window, brickwork partitions by multiplying the area by a factor of 1.2, assuming that each square meter of such a surface absorbs the heat necessary to warm up 1.2m3. For example, in a steam room there is a window with dimensions of 0.5 * 1.0m = 0.5m2 and a glass door with dimensions of 1.8 * 0.8m = 1.44m2. This means that the heat loss will be (0.5m2 + 1.44m2) * 1.2 = 2.33m3

3. Summarize the calculated cubic capacity: the total volume of the steam room and the heat loss from cold surfaces. The previously calculated figures for items 1 and 2 are added and we get the volume required for heating, equal in our example (13.2 + 2.33) = 15.53m3

4. the correct calculation of the power of the stove for the bath is obtained if we take into account the material from which the bath is built, since the structures of the walls, ceiling and floor also absorb a decent amount of heat. For example, for a log bath, without finishing, you need to apply a coefficient equal to 1.6, and if the inside of the steam room is lined with clapboard, yes with foil, and with insulation, then a reduction coefficient is taken equal to 0.6 (since such a wall does not absorb, and repels heat from itself). So, for logs in a steam room, the design power of the furnace will be 15.53m3x1.6 = 24.85 m3 = 24.85 kW (from considerations that for 1 m3 of the calculated volume of the steam room, 1 kW of furnace power is sufficient).

5. When buying, we choose the oven with a power in the range of 25 kW

The data for calculating the power of the stove for each specific bath may differ in their characteristics due to the use of various materials and designs of the structure itself, or some additional factors, for example, the presence of forced ventilation, etc.

Since steam in a Russian bath is formed as a result of splashing water on hot stones, it is necessary when choosing a bath stove to look not only at its nominal power, but also at the volume (weight) of stones that can be placed in this stove.

Calculation of stones for the stove in the bath

Different sources recommend a different amount of stones per 1 m3 of a steam room with 15 people soaring at the same time for 5 hours.

snake at a minimum: 30kg. Therefore, for our example, you need 30kg * 24.85m3 = 745.5kg.If the steam room is calculated not for 15, but for 5 people, then, accordingly, you need to reduce the volume of stones by 3 times: 745.5 kg / 3 = 248.5 kg ... Something too much for a 25 kW stove and weighing no more than 200 kg (cast iron) .... And what size should a metal stove be to fit so many stones? In another "ancient" book, it is recommended for every 6 liters of water supplied - 8kg of cobblestone and 1.5kg - for 1 m3 of steam room volume. In an hour, 5 people pour no more than 4 liters of hot water onto the stones, so during 5 hours of continuous vaping, they will spend at least 20 liters (which is unlikely). Still, we will reduce the amount of water by 30%, taking into account the pauses for airing and rest. It turns out that you need only 18.7 kg. We will also calculate the number of stones for the bath, taking into account the volume of the steam room: 1.5 kg * 24.85 m3 = 37.5 kg. We add everything up and get: 37.5 kg + 18.7 kg = 53.2 kg of cobblestone. This is already an acceptable figure for an ordinary simple bath. You can make a more complex calculation of stones for a bath, determining the required amount of heat by evaporation and heating ... But .., the task of this article is to determine the required power of the stove for the bath. Therefore, let's estimate how many kW is needed to heat 53.2 kg of stones for 15 minutes (the approximate time allotted for a pause between soaring) to a temperature of 500 degrees:

1kg of stones from a temperature of 500 degrees, cooling down to 200 degrees (a difference of 350 degrees), will give 294 kJ (0.84 kJ / kg * C x 1 kg x 350C).

53.2 kg will give 294 kJ * 53.2 kg = 15640.8 kJ. How much heat will be given off during cooling, the same amount needs to be replenished.

1 kW = 3600 kJ / hour

We convert kJ to kW, we get 4.35 kW per hour

Recalculated for 15 minutes: 4.35 * 4 = 17.40 kW

Conclusion: a furnace power of 20 kW will provide heating up to 500 degrees 53.2 kg of stones every 15 minutes. Let's add another 5 kW to the calculation of the power of the bath furnace to take into account heat losses through structures and cold surfaces. So, for a steam room with dimensions of 3x2x2.2m, a 25kW oven is needed, based on two different calculations:

By the volume of the steam room and cold surfaces

By the number of stones

With a lower flow rate under the supplied water, for example, when steaming not five people, but two, for not five hours, but only a couple of three, you can choose a stove with a lower power (20 kW).

You can always buy from us both heating stoves and stoves for baths and saunas.

follow the link and buy

or order a call back

lefrat.ru

The presence of a high-quality bath is perceived by the majority of owners of country houses as a self-evident addition to the created comfort of their living space. When building a bathhouse "from scratch" or when re-equipping existing premises for it, the question of purchasing a stove-heater for a steam room will invariably arise. The range of these peculiar heating devices is currently extremely wide, and it is possible to choose a conventional wood-burning, gas or electric stove, depending on the specifics of the conditions available.

However, the stove should be chosen only by the type of fuel (energy carrier) used, appearance, dimensions, ease of use, although these criteria are extremely important. Even the most expensive and beautiful heater will become completely useless if it is not able to cope with its direct task - creating and maintaining the required temperature in the steam room, that is, that very specific bath microclimate. And you can make a mistake in choosing one or the other. A low-power oven simply will not be able to "catch up with steam", and a device with too high heat output values is an unnecessary waste both when purchasing and during operation. How to be? A calculator for calculating the thermal power of a stove for a bath will help in solving this issue.

We recommend that the reader, before proceeding directly to the calculations, read the explanations given below the calculator itself.

Calculator for calculating the thermal power of a stove for a bath

The specifics of calculating the power of a bath stove

First of all, let's figure out the units of measurement.

Power, more precisely, the calorific value of a heating device is measured in kilowatts. It is believed that to ensure a healthy bath microclimate, it is necessary to spend about 1 kW for each cubic meter of steam room volume. However, it is undesirable to proceed only from such a ratio, since it is easy to make a mistake.

- The sauna stove has a special design - it is supposed to have a stone insert, external, which can be located on top, along the walls and / or along the initial section of the chimney, and sometimes also internal. Stones play a very important role in the heat output of a sauna stove, and their number must correspond to the parameters that are mandatory specified in the device's passport.

- In addition, in most cases, the power of the stove is also used to heat water - a hot water tank is hung (attached) to the stove, or the design of the device is equipped with a built-in heat exchanger

All this is said in order to understand correctly - the "pure" indicator of the power of the device sometimes does not show the real picture.If you familiarize yourself with the technical characteristics of the sauna stoves, one cannot fail to notice that the manufacturer usually indicates the range steam room volume, which is guaranteed to be warmed up by this model. Therefore, they try to choose the stove in such a way that the available parameters of the steam room fall approximately in the middle of this specified range. For example, you need a sauna heater of 14 m³. The optimal model will be a model with a passport range - from 10 to 18 m³.

It would seem that there is nothing simpler: multiply the length, width and height of the steam room - and here's the finished volume ... No, and this is not entirely true. The fact is that any steam room can also have its own characteristics, which sometimes make very significant adjustments to the required indicators of the thermal performance of the furnace. This is taken into account in the proposed calculator.

- So, first of all, the user is asked to enter the linear dimensions of the steam room - its length, width and height of the ceiling. The values are indicated in meters (with an accuracy of 0.1 m).

- In the steam room, they always try to perform the most effective thermal insulation, using various insulation materials for this, including those with a foil covering facing the room. And only then the surfaces are sheathed, as a rule, with a natural board or clapboard. No power adjustments in this regard are expected. However, when the bathhouse is made in a log cabin, or its walls are assembled from a bar, sometimes the inner cladding is simply neglected. This approach, of course, is understandable, but in this case it will be necessary to increase the power of the furnace, since a significant amount of heat will be spent on heating massive wooden parts with a very high heat capacity.

- The stove can be located completely in the steam room, but it is more convenient and safer to use devices in which the fuel window is placed in the dressing room. But this is already a "gap" in the overall thermal insulation of the room, which also requires an amendment to the calculation, since some of the heat will simply be lost, heating the air in the adjacent room.

- If the door to the steam room has internal insulation and is very well fitted to the opening, then significant heat loss through it is not expected. But they are often limited to a simple wooden panel board, and recently glass door leaves are also actively becoming fashionable. It is already necessary to make an amendment on this score.

- It will require adjusting the power indicators and the presence of a window in the steam room. Moreover, the magnitude of the correction will depend on the area of the window and on the type of its glazing. If this type of calculation is selected, additional fields for entering values will open in the calculator.

- And, finally, there are often sections of surfaces in the steam room (it does not matter if it is a floor or walls), faced with stone or ceramic tiles, fragments of brickwork. The heat capacity of these materials is very high, and they will "pull" a certain amount of thermal energy onto themselves. Therefore, this amendment is also included in the calculation.

- The final result will be issued, so to speak, in given the volume of the steam room, which includes its real dimensions, and all the necessary adjustments for the specifics of the room. It is on this value that one should be guided when choosing a furnace.

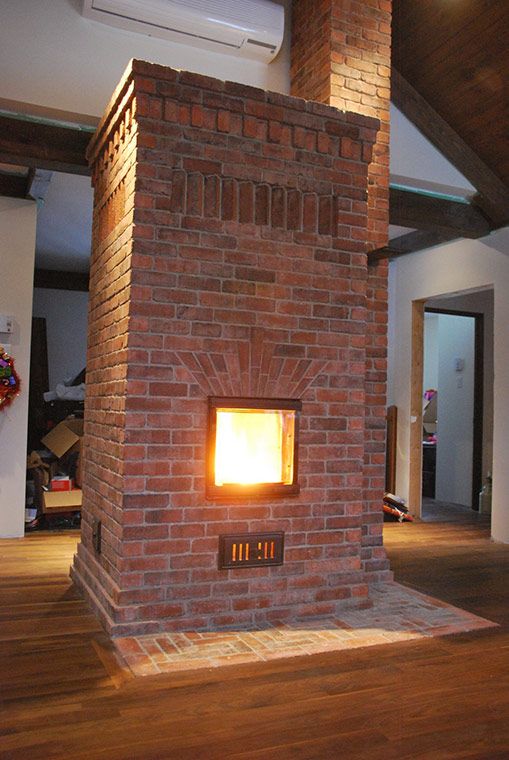

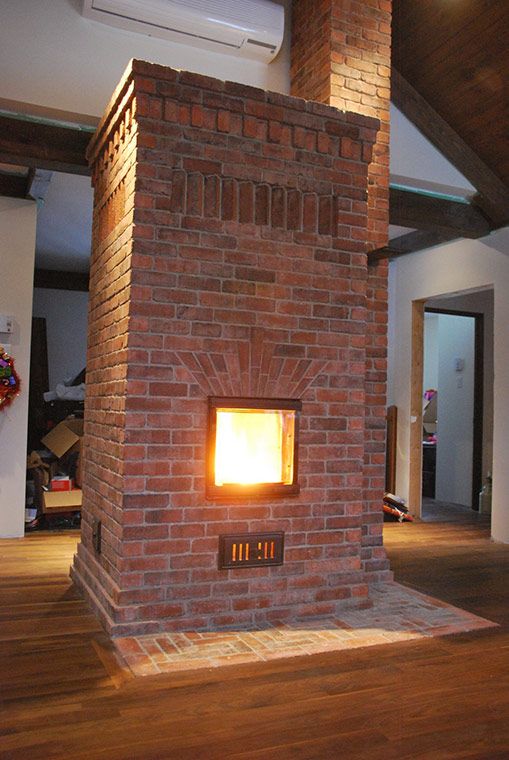

Brick the sauna stove? - no problems!

Some sauna stoves have a very rich external finish, but simpler, cheaper models with an unprepossessing appearance can also fit into the interior of the steam room by making a brick "case" for them. How to brick a sauna stove yourself - read in a special publication of our portal.

stroyday.ru

Power of brick oven and cast iron

Why is the power of brick ovens so small

While small cast iron stoves for heating produce an average of 10 kW of heat, large brick stoves provide 3-4 kW of heat and it can be difficult to understand why this is happening. Either the heat transfer calculations are different, or in general everything is different.

Energy

We used to call energy electricity, which is the most popular in our use. Each of us who uses a device with a rechargeable battery or batteries uses electricity, not to mention other household devices. Electricity is used by us everywhere, so most often we remember about it.

By definition, Energy is a scalar physical quantity that is a single measure of various forms of motion and interaction of matter, a measure of the transition of the motion of matter from one form to another. That is, this is a single measure of the interaction of substances, for example, the burning of wood as a chemical reaction as a result of which heat is released, that is, thermal energy.

Wikipedia lists ten types of energy. We will not delve into this topic. We are more interested in another question: heat energy or the amount of heat released when burning wood. We will talk specifically about firewood, although there is still coal in its varieties, which is not so widely used, and in general, is not suitable for heating modern stoves.

There is another popular article on our website: What is furnace power and why in kW? If you are interested in this issue, then you can start with it, and for the issue under consideration here it will be enough to pay attention to simple numbers and features. So you noticed that small cast iron stoves have 10 kW of power, while large brick stoves only 3-4 kW?

Features of notation

Let's remember that it is correct to indicate kW ∙ h, that is, kilowatt per hour. If we consider just such an indicator, it will become clearer why the power of brick ovens is lower. Cast iron stoves transfer heat faster, and a kilogram of dry birch firewood, when burning, usually releases 4 kW per hour of heat, then in an hour they burn we get about 80% of the heat from them, that is, 3.2 kW. The rest of the heat is spent on heating the chimney and its draft.

The construction of brick ovens is more based on heat accumulation. Brick transfers heat slowly. The efficiency of heat transfer in bricks is lower and the area of the material (furnace) on which heat loss occurs is larger. The efficiency indicators of brick kilns are not clear, since these are not factory products. There are many discussions on this issue on the Internet.

Approximate calculation for heating an area of 80 sq.m.

Let's take for an approximate calculation the optimistic efficiency factor of a brick kiln of 60%, although most often it is no more than 50%. Let the brick oven be small, without complications, in the form of a column, aimed only at heating the house. Moreover, its mass will still be about a ton. All this brick mass rests on a concrete foundation that takes and transfers cold from the ground. Also, the street part of the chimney lowers the cold into the house below the roof level.

Starting to heat a brick oven, you need to spend a significant part of the fuel to warm up this oven, say 20-30 kg. On average, 25 kg multiplied by 4 kW will be 100 kW, 40% of which will be spent on heating the brick mass, and 60% on heat accumulation. Now we expect that the oven will give us heat for 10 hours. Part of the accumulated energy will also be spent on maintaining the heat of the furnace itself, which will go to the foundation and along the walls of the chimney to the street.

As a result, we will be able to get 40 kW of heat from a brick oven in 10 hours, not counting the hours of warming up. Thus, we can count its power as 4 kW per hour. Of course, these are very approximate calculations, you can say "an estimate", nevertheless, they are close to the truth. The room will gain heat in 5-6 hours after kindling and after another five or six hours it will cool down to an uncomfortable level. That is, a few hours after the brick oven warms up, it will be necessary to warm it up again and spend another kilogram of 10-15 firewood.

The difference between cast iron stoves

A 10 kW cast iron stove usually weighs 120-150 kg. The consumption of wood in such a furnace will be about 3 kg per hour. It will take 2-3 hours to warm up the room and 9 kg of firewood will be spent. The furnace body heats up quickly.After half an hour, the furnace will be well warmed up, and after an hour its temperature will reach the normal operating temperature of the cast iron furnace (about 250 ° C). A modern insulated chimney will also warm up during this time to operating temperature.

Further, to maintain heat in the room, you will need half the amount of firewood. Even if we consider the option of large heat losses in the house and the constant use of the stove, then over the next 7 hours about 11 kg of firewood will be spent on maintaining heat. Although, in practice, it is required to heat a cast-iron stove in the morning and in the evening to keep the house warm.

To preserve heat in the room, for many modern stoves it is possible to connect external air from the street to the combustion. Thus, the stove does not use internal air from the house, does not create a draft. Even if you put six kilograms of firewood in the stove, they will burn twice as long, that is, 2-2.5 hours.

The intensity of combustion depends on the amount of air supplied for combustion, however, for this, the furnace must be with a sealed combustion chamber, when the supply of combustion air is controlled by the user and there are no arbitrary inflows of air. It is better to inspect the selected furnace model several times and clarify all questions with a sales assistant.

The main characteristics of the sauna stoves

To choose a sauna stove, you need to decide on several characteristics and their combination:

- heating method (type of fuel);

- maximum heating power;

- dynamic range - the ability to adjust the heat output;

- thermal inertia, the ability to stabilize the temperature in a steam room;

- heat transfer rate, surface temperature;

- dimensions;

- vaporization;

- the ability to use heat to heat water.

The stove can be made of metal or made of stone. At the same time, modern metal stoves are a winning option, since they are compact in size and allow you to heat the steam room in a short time.

Furnace types

Devices for home heating and cooking were invented by people many centuries ago. Cultural traditions, cuisine and climatic features of the place of residence of this or that nation played a direct role in the evolution of these adaptations, as evidenced by the different types of stoves that exist today.

Stone stoves for houses and dachas, which are most popular today among Russian owners of suburban property, differ in their design and their names, which speak of the place of origin of a particular model, for example, a Russian, Dutch, Swedish stove, etc. In addition, the furnaces are divided according to their functional purpose into:

- heating,

- cooking,

- combined (heating and cooking).

Heating stoves

The main and only function of these stoves is to heat the room. They are not intended for cooking or even heating food. These designs are called Dutch ovens. Their overall dimensions are determined by the area of the heated room. They have a compact rectangular shape and are installed in living rooms or bedrooms.

Cooking ovens

A stone cooking stove is mainly used for cooking and heating a small room. Summer cottages are most often equipped with this type of stove, because serious heating of a large house does not allow for their design features. Such ovens have a hob and often an oven.

Combined ovens

This type of oven is also called "Swedes". This is the most versatile and most convenient option. The device of a stone oven of a combined type assumes the possibility of heating a large area of the room and conditions for cooking. Usually they are installed in the interior wall in such a way that the hob is located in the kitchen, and the main part goes into the residential part of the house.Often, such structures are equipped with a stove bench, turning them into a real Russian stove.

Special purpose ovens

Separate categories include stone sauna stoves and garden stoves used for outdoor cooking.

Sauna stoves

Stone sauna stoves have one purpose - high-quality heating of the sauna room. True fans of sauna relaxation prefer wood-fired stoves, believing that only these structures are capable of creating a unique therapeutic microclimate in the steam room.

According to the principle of operation, these units are divided into two types:

- Batch stoves with a closed heater. In this version, the stones are located in the chimney. You can use such a stove only a few hours after kindling, only after the final combustion of the fuel.

- Continuous sauna stoves with an open heater. The stone bowl is open in them, so constant replenishment of the fire is required. Before starting the bath procedures, the heater will be heated for about 2.5 hours, and then this process is maintained during the steam session.

One of the main requirements for sauna stoves is safety, and in this regard, the option with an open stove is safer, because such a design eliminates the risk of carbon monoxide entering the steam room, while in the first case such a danger exists.

Garden ovens

Garden ovens are designed for outdoor cooking on charcoal or fire. They have a rather simple design, which includes a brazier firebox and a storage for firewood, and in more complex models, a chimney is also provided. Stone barbecue ovens with an open hearth are considered the most convenient for cooking meat and fish kebabs, steaks, poultry dishes, etc.

The most serious functionally are garden ovens with an oven. In such models, you can bake bakery products, cook porridge and even first courses.

Power selection

In terms of power, the sauna stove is chosen so that it can maintain a high temperature in the steam room. For a Russian bath or hammam, you need to warm up the room to 40-600C. For a sauna - up to 80-1100C. It is clear that the higher the required temperature and the larger the volume of the room, the more power is required.

The choice of power is influenced by:

- steam room temperature;

- thermal insulation qualities of walls and outside temperature;

- steam generation requirements;

- steam room volume.

An accurate calculation of the optimal power requires the calculation of the thermal resistance of all enclosing structures, taking into account their location and external temperature. But there is also an easier way to do without complex heat engineering calculations.

To determine the required power, you can focus on the average estimate - 1 kW per 1 m3 of steam room volume. Take, for example, a room with dimensions of 2x3 m and a height of 2 m. The calculation of the volume is simple - it is obtained by multiplying all three dimensions. In our case, the volume of the steam room is 12 m3. 12 kW - this will be the "ideal" design power. If part of the enclosing structures of the steam room does not have thermal insulation, for example, a door, then its area must be multiplied by 1.2 and added to the value obtained earlier. For example, if the door has dimensions of 2x0.7 m, then the additive will be 1.68 kW. We round up and as a result we get the required power of 14 kW.

If the door is made of glass, then to calculate the correction for non-insulated structures, its area is multiplied by 1.5. The same amendment is introduced for the window, if any.

The resulting value is a guideline for choosing a suitable oven. It is better if the real power is slightly higher than the calculated one, but not too much. The high maximum power allows you to quickly warm up the steam room, but then the heating must be reduced in accordance with the operating thermal regime. If the power cannot be reduced to the required level, the steam room will not be able to obtain the desired atmosphere.

Types of stoves for a bath

Currently, there are three types of sauna stoves on the market:

- solid fuel;

- gas;

- electrical;

You can also use liquid fuel - fuel oil or diesel fuel, but this solution is rarely used.

- The wood-fired sauna stove is characterized by high power and simple design. Wood-fired stoves can be great for heating large steam rooms, but adjusting their power is not easy. They are not adapted to work with automatics, and a large mass of stones is used to stabilize the temperature. The combination of an iron furnace and stones, which are placed in special containers or a mesh casing, gives the required power and heating stability.

- In terms of use, the most convenient ovens are electric. They have a wide range of heating settings and are able to stably maintain not only the power level, but also the temperature. For this, they are equipped with a power regulator and a thermostat. Ease of use and automatic temperature maintenance are the main advantages of the electric heater.

Electric heaters have low thermal inertia. To increase it, their design provides for the possibility of stacking stones above the heater. The stones with their heat capacity equalize the heating differences associated with the operation of the thermostat. In addition, the heated stones evaporate the water, which gives the desired steam.

The only drawback of electric ovens is the power limitation due to connectivity. Even 5 kW require special wiring, and 10-15 kW are often unavailable.

- The use of a gas sauna stove removes the power limitation and allows the heating to be regulated within a wide range. Stability of work is also the strong point of such units. Electric and gas heaters do not require a large volume of stones, as they can maintain a stable operation of the heater or burner.

Subtleties of choice

For many years, the question of which stove is better - metal or brick - has been relevant for owners of suburban buildings. When erecting a structure of the second type, it will have to be equipped with heaters. With their help, at the beginning of kindling, the level of heat transfer will be maximum, which will allow you to quickly create a comfortable temperature in the room.

Placement of the stove under the stairs

For home owners who want to choose a stove for a summer residence with the condition that the premises are used only in the summer, you need to give preference to structures with thin walls. In them, the masonry is usually made in a quarter of the brick.

Recently, more and more you can find such a combination of a heating system for a country house, where the stove is equipped with a fireplace. In this case, first, the fireplace is kindled, warming up the rooms, and only then the stove is laid, which for 12 hours can maintain heat in a small house.

Good to know: What varnish to choose for covering a brick oven and how to use it

In order to clearly understand for yourself which oven is ideal for the requirements, it is worth considering a number of design features of all the models under consideration before purchasing.

That is why, in order to decide which stove to choose, you need to know the answers to a number of the following questions:

- Preferred product shape.

- The main material of the product.

- What type of fuel is the cheapest in a particular region.

- Will I have to cook food on the stove?

- Desired wall thickness for the structure.

- The preferred channel system inside the oven.

- How the chimney will be erected.

Stove and fireplace in one design

If you plan to purchase a wood-burning stove for summer cottages, then it must meet the following parameters:

- Lightness and simplicity in operation and maintenance.

- Distinguish in good heat dissipation among competitors.

- The structure must be made of quality materials, which will increase its strength and durability.

- The wood-burning stove should maintain a comfortable room temperature for as long as possible.

- With a high level of quality, the cost of construction should be minimal.

- A wood-burning stove should work not only on logs, but also on wood waste, fuel briquettes.

According to these criteria, you can make a really right choice, which the owner is unlikely to regret in the future.

Furnace design

The choice of a stove for a bath involves the selection of the most suitable design, and there are much more options here than when determining the required power.

Material

Most of the newly built baths are not intended for a large number of people, and their steam rooms have a small area. In such a steam room, the large dimensions of the stove become a hindrance. Therefore, a compact metal oven is a rational choice.

Another advantage of such a furnace is its ease of installation. It does not need a massive foundation, complex work. It is simply placed on a solid platform and connected to the chimney and to the water supply system, if it has a water heater.

Metal furnaces are manufactured from sheet steel. The sheets of the greatest thickness, up to 5 mm, are used for the manufacture of the firebox. The outer casing is painted with high-temperature paint, and in some models stainless steel containing 17% chromium is used as the material for the manufacture.

Heating stability

Steel conducts heat much better than brick, and therefore a metal stove has a high heat transfer. Such stoves heat up quickly and cool down faster than, for example, cast iron stoves, which reduces the risk of fire hazard situations. To accumulate heat and stabilize heating, stone backfill is used. The greater the mass of stones heated from the furnace, the less the intensity of heat transfer changes with temperature differences.

A large supply of heat allows you to get a large amount of steam. At the same time, its high quality is consistently ensured, since the temperature of the stones when sprinkled with water changes little due to their large mass.

Most of these stoves can be fired from a room adjacent to the steam room. The firebox door is located at a considerable distance from the body and is connected to the furnace by a neck - a fuel channel. Thus, it is possible to keep the steam room clean - all waste from the fuel remains in the dressing room.

Safety

The furnace metal is heated to a high temperature, which can be dangerous for people. To avoid burns, this heater is equipped with a protective cover, like this model. In some cases, not a casing, but a stone backfill acts as a protective fence, as in grid furnaces, for example, the Siberian Cliff.

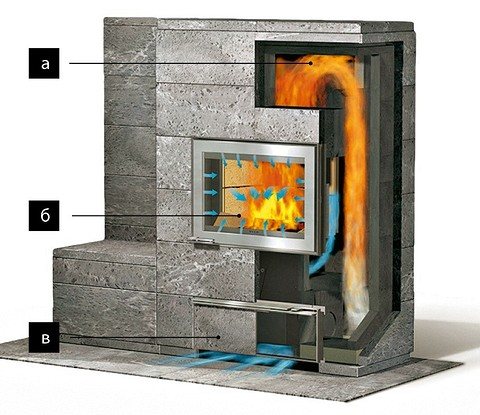

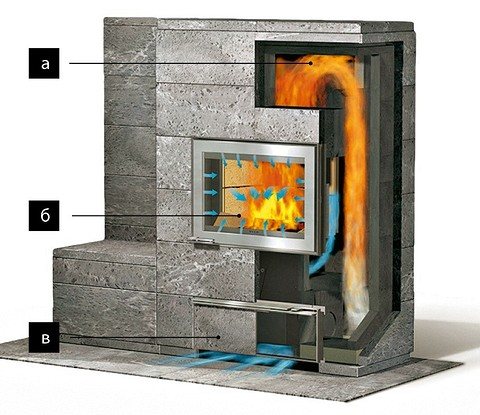

An air gap remains between the firebox and the protective casing, which serves as a heat insulator, which reduces the temperature of the outer casing. A natural draft arises in this gap, which can be used to intensively distribute hot air throughout the entire volume of the steam room. For this, holes are made in the body for air inlet from below and for outlet - from above, as in the models of the Kuzbass series.

The through flow of air through the air gaps of the casing enhances convection, which allows you to very quickly warm up the air in the steam room, and the backfill of stones stabilizes the heating and provides a supply of energy for vaporization. Often a steam generation device is built into the backfill. Using such a furnace design, it is easy to obtain a constant flow of steam.

Which firebox is better?

There are three types of stove inserts: grate, with hearth combustion and combined. In the first type of firebox, the air flow enters through the grate on which the firewood lies - the grate. In the second case, air is supplied through the holes provided in the door, above it or along its perimeter. Combined fireboxes, as you can easily understand, combine a grate and air inlets in the door or above it.

Photo: Tulikivi

Stone furnace design: smoke channel (smoke circulation) (a), vortex-type furnace (the main combustion air is supplied along the perimeter of the door) (b), blower, which is opened during ignition (c)

The grate helps to easily and quickly melt the stove and, if necessary (for example, if raw firewood is caught), accelerate their burning. This is necessary not so much to increase heat transfer as to reduce the amount of soot and carbon deposits in the furnace channels. But when air is supplied through the upper holes, it is easier to transfer the stove to a long burning mode. Thus, the combined option is optimal, in which, at the stage of ignition, the lower grate flap is opened, and when the wood is well heated, air enters through the holes in the door or above it.

Stove stones

When choosing a stove for a bath, you need to take into account the mass of stones in the bookmark and the conditions for their heating. To obtain "light" steam, a high temperature is required. The stones should be heated to at least 150 ° C, and for a Russian bath - at least to 200-250 ° C. In this case, you can expect a good result.

Depending on the design, stones can be laid on top of the firebox or warmed up from all sides. In the latter version, the internal stone filling will serve as an excellent steam generator. It is very important that the stones do not cool down when in contact with water, so that they have a sufficient supply of energy and a strong flow of heat from the firebox.

How many stones do you need?

In order for the stones of the sauna stove to cope with their functions, they must have not only a high temperature, but also a sufficiently large mass.

For a small steam room equipped with an electric oven, if intensive steam generation is not required, 3-5 kg of stones are enough. They are mainly needed only to smooth out fluctuations in heat transfer when turning on and off a thermostatically controlled heater.

If good steam is needed, then the weight of the backfill should be increased. In a small amount, the stones will quickly cool down and stop evaporating water well. If water droplets boil on stones, then they are already cold. Normally heated stones evaporate water almost instantly.

For a solid fuel stove, the mode of which is difficult to maintain constant, you need at least 5 kg of stones for each cubic meter of the steam room. And for a Russian bath, it is better to increase this amount to 8 kg. That is, for the steam room, given as an example at the beginning of the article, the mass of the stones to be laid will be 90 kg or so.

Which stones to choose?

For the bath, stones that are not too small are selected, at least 40 mm in size. Better - from 70 to 150 mm. For heat storage, size is not important, only weight is important. But the coarse fraction is easier to blow through with air, and therefore it gives off heat better in ventilated backfills and warms up better in batch furnaces.

It is important that they withstand temperature fluctuations. If a red-hot stone, when poured with water, begins to crack with the scattering of fragments, it is not suitable for a steam room. Some types of rock, when heated, emit harmful substances.

Recommended breeds for the heater:

- gabbro-diabase,

- talcochlorite,

- jade,

- quartzite,

- quartz,

- porphyrite,

- basalt,

- river pebbles.

The last option on this list is affordable stones, which are easy to find in most regions. Basalt and gabbro-diabase are distinguished by their high heat capacity and resistance to strong heating. Talcochlorite is relatively light and has good thermal conductivity. Raspberry quartzite or jadeite can serve as a decoration for a steam room, as well as white quartz, which is called "hot ice".

Brick ovens

Despite the fact that fireplaces for the home are gaining popularity, conventional brick stoves are not out of service. Today you can choose different types of wood-fired brick stoves for your home, which are not difficult to lay out with your own hands. It will take patience and the ability to own the tool, read the drawings, but a novice master will cope with some models. Let's consider the most popular types of devices.

Oven Baby

This model will replace an air-heated fireplace in a temporary residence or small permanent residence. The modest dimensions of the device do not reduce its quality characteristics - the stove will warm up the rooms, allow you to cook food, and at the same time does not take up much space.

Stoves and boilers for heating a house with a water circuit

Important! After the completion of the calculation, a brick is removed from the bottom row - this is necessary to remove the remnants of the solution and moisture. Then the element is installed in place.

After the arrangement of the structure, next to the firebox, a sheet of metal is lined with an approach to the brick up to the height of the blower door. The areas of joints with the floor are sheathed with a plinth so that sand does not fall from the lower layers when the solution dries. Then a test kindling with paper is performed, the stove is dried for 7 days.

Advice! To detect smoke leaks, the structure must be whitewashed before firing. Smoke marks will be more noticeable on fresh whitewash. And if there is one, clean the seams and seal them up again.

The finishing plastering and finishing is carried out after the start-up and operation of the oven for 3 months. The structure will settle and take on its permanent appearance. The chimney is built into the root pipe, if a stove is already laid out in the house, if not, a new chimney is laid out, leading to the street through the attic ceilings and the roof.

On a note! The Malyshka stove allows the use of a steel pipe with a wall outlet.

Characteristics:

- performance 1210 W;

- one hotplate on the hob;

- chimney tunnel 100x100 mm;

- height to pipe 72.5 mm;

- width 50.5 cm;

- combustion chamber depth 73.7 cm;

- weight up to 370 kg;

- Efficiency up to 75%.

A certain amount of materials will be required for laying out:

- 62 Item (s) red brick;

- 37 pcs. fireclay bricks ША-8.

Depending on the format of the device, a glass door for the furnace, a cast iron door for the blowing chamber, a grate, a stove with a burner, a chimney valve, a sheet of metal are useful.

On a note! The Malyshka stove can be supplemented with an oven or a stove with two burners, a hot water tank.

Tiny oven

These are modern stoves for heating a house, which are useful as the main or backup source of heat for small buildings. Simple design and small size are pluses, and it heats the device at home up to 20 m2, works in an autonomous mode and does not require a connection to the power supply.

The design feature is good heating of the bottom and the placement of the "cap" in the upper part. Such a "cap" slows down the cooling of the device and increases the life of the thermal energy in the house. The system has a summer course for kindling in summer when a lot of heat is not needed. The device differs in three types of options, of which the improved one is most often used with the location of the hob and firebox on one side - the end one.

The fuel chamber is laid out with fireclay bricks, peat, coal, firewood, briquetted fuel are used as an energy carrier. The lower tier is laid out with a protrusion of 30 mm along the entire perimeter of the device - this is a visual division into fuel and air-gas parts. The upper compartment contains channels for heated air circulation. The door is equipped with heat-resistant glass, so it is permissible to use the crumb as a fireplace with air heating.

Specifications:

- productivity with one firebox 1760 W;

- productivity with a three-time firebox 2940 W;

- single-burner panel;

- section of the internal chimney tunnel 100x100 mm;

- height to pipe 203 cm;

- width / length of the base base 640x770 mm;

- the size of the depth of the combustion chamber is 74.6 cm;

- weight up to 1280 kg;

- Efficiency up to 75%.

To lay out the oven you will need:

- 352 pcs. red brick (excluding the chimney);

- Including 124 pcs. figured red brick;

- 21 pcs. fireclay bricks ША-8.

Depending on the format of the device, a glass door for the furnace, a cast iron door for the blower chamber, a grate, a stove with a burner, a chimney valve, steel corners and a sheet of metal are useful.

Stove Shvedka

Construction with hob, oven, capable of heating a house up to 45 m2. The indicators are as follows:

- performance with two-time firebox up to 4600 W;

- chimney tunnel size 100x250 mm;

- height to pipe 201.7 cm;

- width / length of the base base 1280x890 mm;

- the size of the depth of the combustion chamber is 50 cm;

- weight up to 2920 kg;

- Efficiency up to 75%.

Also, the Shvedka stove can be supplemented with a hob for 2 burners; laying fireclay bricks, if there is an oven, is required around the cabinet and the fuel chamber. A different design of the cooking chamber is possible, it all depends on the skills of the master.

Important! The oven requires careful calculations and experience in laying out. It is not recommended to take on manufacturing without skills.

Almost 1000 red bricks are useful for laying out the structure, 63 pcs. fireclay bricks, furnace doors, blower, for an ash pan, grate bars, a stove with burners, an oven, metal corners, summer and winter valves, steel sheet.

conclusions

So, what kind of stove to choose for a bath? This issue is resolved in a few steps.

- Determine the required capacity by the volume of the steam room and its thermal insulation. Study information about different models: the characteristics may indicate not the power, but the recommended volume of the steam room.

- Determine the maximum permissible dimensions of the furnace, taking into account the size of the steam room, its layout and ease of use.

- Specify the amount of space for laying stones. Here you should use the recommendations for calculating the required backfill weight and choose a model that can accommodate no less.

With all the variety of options for sauna stoves, you can make the right choice if you focus on these recommendations. If you still have doubts, you can always contact the qualified managers of the Teplodar online store.

mediagallery.teplodar.ru

About filling in the parameters of the Service.

Indicate the area of the heated room.

In this section, you must indicate what area of the room you want to heat. It should be noted that the heated area means not only the area of a separate room, but also of all adjacent rooms, if it is planned to install a stove for their joint heating.

Our Service performs the calculation based not on the volume of premises, but on their area, since it is often difficult to calculate the volume of a room, and many people know the area of their rooms or it is easy to calculate it. The calculation itself includes a direct relationship between the volume and area of the room with the condition of a ceiling height of 2.5 m. If you have a higher ceiling, you can slightly increase the area of the room for a more accurate calculation

Decide on the type of oven.

In this Service, the calculation is performed only for heating and heating and cooking rectangular stoves, since these are the most common types of stove structures.

It is necessary to select one of the types of furnace structures in order to perform the calculation. If you have not yet decided on the choice, then it's okay, choose any type of oven. At least, you will still know the size of your future furnace and the number of bricks for its construction.

The type of heating stoves includes any rectangular stoves (for example, bath stoves.), Except for stoves with hob surfaces and portal furnaces (for example, Russian stoves).

Select a home insulation category.

Insulation of the house is of great importance for determining the mass of the stove and its dimensions. You understand that even the more the house is insulated, the more stove heat will be kept in it. Heat loss is a very serious indicator of thermal characteristics and therefore, to simplify the calculation, we have divided house insulation into 3 categories: medium, good and weak.

You yourself will decide under which category of insulation your house or summer cottage is suitable. For a more accurate selection of this category, we will draw up a table a little later, but for now we ask you yourself, without hesitation, to determine and indicate how well your house or summer cottage is insulated. For example, in most cases, dachas should be classified as medium or even in the weak category of insulation.Residential buildings with wall thicknesses of more than 63 cm and strong insulation of ceilings have good insulation.

Indicate one of the sides of your future stove.

For the Customer, this calculation position is the most important and interesting. The fact is that the most important and problematic issue for the Customer is the size of his furnace. Knowing this size, you can completely make any plans for the repair and reconstruction of premises, the layout of furniture, the design of rooms, pouring the stove foundation, etc. To calculate it, it is necessary that you approximately know at least the length of one of the sides of the oven. For example, you had an old stove and you knew its size and you want the same size on one side, or you have an opening in the wall of adjacent rooms in which you want to place an array of stoves.

The choice of the size of the side of the furnace is made in increments of 12.5 cm. If you do not know which one of the sides you should have, then enter any one, and by the selection method choose the size of the furnace structure that is optimal for you. The calculation is performed automatically, taking into account the errors of the entered data. If the size is entered incorrectly, then the calculation will be performed to the closest correct side size parameter.

Calculate the size of the oven.

Having filled in all the details and clicking on the "Perform calculation" button, the Service will automatically calculate the size of the furnace and show how many bricks are needed for laying this furnace structure.

Note that the data are relatively accurate and the deviations in accuracy can be no more than 2-3%. Knowing them, you can, while talking with the Stove-maker, set him the task that you need to lay out a stove of a specific size. And since the number of bricks is also known, it is possible to plan the costs of laying the stove and purchasing material.

For example, you need to determine what kind of stove I should have in order to heat a room in a dacha with an area of 20 m2. The dacha is well insulated and I want to put a purely heating stove (as it is also called by the people "group").

Calculation of stones for a bath

Different sources recommend a different amount of stones per 1 m3 of a steam room with 15 people soaring at the same time for 5 hours. Let's take at a minimum: 30kg. Therefore, for our example, you need 30kg * 24.85m3 = 745.5kg.If the steam room is calculated not for 15, but for 5 people, then, accordingly, you need to reduce the volume of stones by 3 times: 745.5 kg / 3 = 248.5 kg ... Something too much for a 25 kW stove and weighing no more than 200 kg (cast iron) ... And what size should a metal stove be to fit so many stones? In another "ancient" book, it is recommended for every 6 liters of supplied water - 8 kg of cobblestone and 1.5 kg - for 1 m3 of steam room volume. In an hour, 5 people pour no more than 4 liters of hot water onto the stones, so during 5 hours of continuous vaping, they will spend at least 20 liters (which is unlikely). Still, let's reduce the amount of water by 30%, taking into account the pauses for airing and rest. It turns out that we need only 18.7 kg. We will also calculate the number of stones for the bath, taking into account the volume of the steam room: 1.5 kg * 24.85 m3 = 37.5 kg. We add everything up and get: 37.5 kg + 18.7 kg = 53.2 kg of cobblestone. This is already an acceptable figure for an ordinary simple bath. You can make a more complex calculation of stones for a bath, determining the required amount of heat by evaporation and heating ... But .., the task of this article is to determine the required power of the stove for the bath. Therefore, let's estimate how many kW is needed to heat 53.2 kg of stones for 15 minutes (the approximate time allotted for a pause between soaring) to a temperature of 500 degrees:

- 1kg of stones from a temperature of 500 degrees, cooling down to 200 degrees (a difference of 350 degrees), will give 294 kJ (0.84 kJ / kg * C x 1 kg x 350C).

- 53.2 kg will give 294 kJ * 53.2 kg = 15640.8 kJ. How much heat will be given off during cooling, the same amount needs to be replenished.

- 1 kW = 3600 kJ / hour

- we convert kJ to kW, we get 4.35 kW per hour

- we recalculate for 15 minutes: 4.35 * 4 = 17.40 kW

Conclusion: a furnace power of 20 kW will provide heating up to 500 degrees 53.2 kg of stones every 15 minutes. Let's add another 5 kW to the calculation of the power of the bath furnace to take into account heat losses through structures and cold surfaces.So, for a steam room with dimensions of 3x2x2.2m, a 25kW oven is needed, based on two different calculations:

- by the volume of the steam room and cold surfaces

- by the number of stones

With a lower consumption of supplied water, for example, when steaming not five people, but two, for not five hours, but only a couple of three, you can choose a stove with a lower power (20 kW).

banjstroi.ru