Dacha is a meeting place for family and friends, an area of rest, peace and unity with nature and your dreams. Whatever the size, scope, style and features of your dacha, it should be comfortable to live in and cozy, which means you need to learn how to insulate the floor in the dacha so that it is pleasant to be inside.

Starting in autumn, cold weather comes to us, at first slowly, appearing only at night, and then more and more distinctly, reminding us of the first frosts. The winter period can completely surround the house with a veil of snow elements, and spring prepares streams of melted snow and temperature drops. All these influences are directly reflected in your home, its surface and internal microclimate. Insulation of the floor in the country will allow you to keep the dampness and cold on the way to your rooms, keeping the temperature inside, preventing the appearance of dampness, mold, condensation. Such work will not only improve your life in this house, as numerous reviews say, but also keep the structure itself - walls, floor, ceiling - in good condition, which will allow you to use the house for a long time without carrying out repairs and restoration work.

Waterproofing layer

The first encounter with low temperatures occurs in the basement - the place where the foundation passes into the subfloor. It is here that it is worth making waterproofing and insulation, if you do not want to then deal with the consequences of floods and dampness. The waterproofing procedure involves laying an impregnating layer or roll film. You can use special mixtures for pouring the floor, which will reliably protect against moisture, it is very convenient. Roll coating is applicable only for perfectly flat walls without cracks, moreover, they must be dry, so it is better to work in the hot season.

The floor in the country is most often concrete, because this material is the most durable and comfortable, therefore it will become your basis. Before carrying out any kind of work, it must be cleaned of dirt and dried. Mold stains or other growths must be removed. If the room goes underground, waterproofing should be done along the perimeter of the walls, since water will rise along their entire height, especially during the period of snow melting.

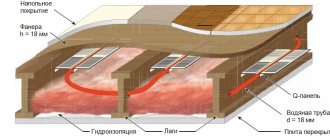

Correct laying of logs under a warm floor

Lags are a kind of "foundation" of the floor, built in the form of rectangular bars. For their manufacture, they use species of hard trees, for example, conifers. The main criterion when choosing a lag is strength. Never use material that has already begun to rot. The number of knots on the bars does not matter. The base must be solid. The larger the room, respectively, the stronger the base is required.

Cottage with warm floors

After laying the logs, a rough floor is laid. It is placed on a special cranial bar, which is attached to the lag. The beam guarantees a support for the board. Do not lay the boards at intervals, because rodents will penetrate through the insignificant gaps.

General work procedure and materials-insulation

To organize the floors in the country with your own hands, you need the correct sequence of actions. First you need to prepare the subfloor - this is the base surface that remained after the work of the builders. A layer of insulation is built on it, which is selected individually, and already on top of it a final floor covering is mounted. At each stage, it is important to follow the technique of performing work so that moisture and dust do not accumulate between the layers.

Sorry, no results were found.

Floor materials for summer cottages have long been tested in practical use and have been selected for construction sales. Polyfoam is a material made from polymer, it has a low density and good thermal insulation properties. This material can be used in sheets, blocks or as loose filler. It is light enough, so it needs to be firmly fixed. Underfloor heating in the country can also be made using expanded polystyrene. This is a more expensive material. There is also its liquid form - penoizol, it can also be used. Mineral wool insulation is used less often, as it can sag over time, forming gaps.

Penoizol.

Basic rules for self-installation of warm floors

If you intend to lay an electric underfloor heating on your own in your country house, then, in addition to preparation, you should also familiarize yourself with the installation instructions (it must be attached to the equipment), which indicates all the necessary information - both directly on installation and on subsequent operation systems.

Important! If you make the smallest mistake during installation, then the system may not function properly because of this. As a result, such problems can be eliminated only after breaking the screed layer. Obviously, after the elimination of defects, the finishing coating will have to be re-equipped.

Here are the basic rules, following which you can avoid these problems.

Range of film products

- The area to be heated is calculated in advance. On the basis of these calculations, one or another system is rationally selected.

- Heating elements must not be placed under pieces of furniture that do not have high legs. Moreover, IR foil floors are installed exclusively in open spaces, where there is no furniture.

- It is important to carefully align the base before installation, and then dry it thoroughly.

- The heating cable must not be lengthened or shortened; it must not be cut or otherwise manipulated by the manufacturer.

- Finally, the system can only be switched on after the screed is completely dry. As a rule, this requires at least 28 days.

Film placement scheme

Cutting material

If a tile will act as a finishing coating, then it is better to use a cable heat-insulated floor - it is the cheapest and best suited for this situation.

In advance, you need to take care of the place where the thermostat will be installed. Make a groove for wiring, temperature sensor tubes. The mounting ends will also be displayed here. Next, the floor needs to be leveled, remove all debris and dust, then apply a layer of primer. In other matters, we have already talked about the main stages of preparation in the previous paragraph of the article.

Here are a few more points to keep in mind.

- It is imperative to check the electrical resistance in the network.

- The cable must be laid with a stretch, but without significant effort.

- The allowable bending must also be taken into account.

- If straight sections of the line come across, then special couplings must be used on them.

- It is also impossible for the turns to touch or intersect.

At the end, a thermostat is installed, the system is connected to the mains. The thermal sensor is laid using a corrugated tube - for the convenience of further repairs, it is laid between the turns.

After completing all the connections, check for damage in the system, measure the resistance in different areas and check the values obtained with the numbers in the manufacturer's instructions. After the screed has dried, perform a test run of the system.

Prices for warm floors "Teplolux"

Warm floors Teplolux

Video - About a film IR warm field in a frame building

Preparation for independent work on thermal insulation

To equip the floor in the country, you will need a basic set of tools. This is a screwdriver and a set of screwdrivers for working with self-tapping screws, a hacksaw for working with wooden beams, an office knife for shortening and trimming material. For measurements, you will need a tape measure and a building level. A furniture stapler is required to fix the insulation. For impregnation, you will need an antiseptic and a primer, as well as a brush to apply it. To organize the lattice for laying the insulation, you will need wooden beams or sheets that you can saw. For the top layer, finishing materials are needed. The calculation of the cost of floor insulation in the country can be done by measuring the footage of the room. Photo and video materials can help in the work, which will consider in detail each stage of the work.

Insulation of wood floor

Wooden floors are often worn out. If you bought a house or inherited it, you need to carefully examine its condition. It happens that a house, which is quite suitable in terms of decoration and layout, turns out to be resting on half-rotten beams. Perhaps the builders did not saturate them with a solution that improves the properties of the wood, and over time it became damp. If the floor is not suitable, you need to disassemble it. All boards must be torn off from the base in the form of an overlap of beams. It is time consuming work, but it has to be done.

It is better to lay the floor in the country from new boards. It is better to fasten them with self-tapping screws, not nails. It is easier to handle and dismantle them. In addition, their fastening will not be a test for wood, since the hole can be shot down with a power tool. The boards should fit snugly together to keep air out of the basement or underground space. By the way, it can be filled with a metal mesh to prevent rodents from moving if they start.

A layer of insulation will provide a warm floor in the country. Install wooden logs around the perimeter of the floor - beams, between which the insulation will be laid. The distance between them can be from 40 cm to a meter. A vapor barrier film is laid on them, which is held together with a furniture stapler. It is better to seal up gaps or breaks. Attach the film to all folds so that it adheres to the joists and the floor. Both polystyrene and expanded polystyrene are suitable for warming floors in the country. Mineral wool is recommended as a joint and joint filler. Insulation blocks are easy to cut, crumble and fill up, so everyone can handle this job. The layer can be from 5 to 20 cm, depending on whether you plan to live indoors in the winter.

The top layer will already become the topcoat; it can be laid from chipboard, wood panels, plywood. It is important here to level the base so that all the boards are, as it were, on the same plane. Between them, gaps are permissible, and even necessary, which will allow the material to expand and contract depending on humidity, in its natural mode. Fastening here should be done carefully so that there are no protruding screw heads or other irregularities on the surface. Such a floor in the country house will retain heat, which will be produced by a fireplace or convector, and will also maintain the temperature inside a little higher than that outside, even during your absence.

What material to choose

The choice of insulation is determined by several criteria:

- the material capabilities of the owners of the dacha;

- the complexity of styling;

- durability;

- resistance to moisture and rodents.

The last point is especially important, because if the owners live in the dacha only periodically, dampness and mice are the main reason for the destruction of floors.

The range of heaters is wide, and along with modern ones, many summer residents willingly use the already familiar, time-tested materials. With a limited budget, you can find several acceptable options.

Expanded clay - lightweight porous granules perfectly retain heat, mice and insects do not start in them, the material does not emit harmful vapors. For effective thermal insulation, it is necessary to provide reliable protection against dampness and to fill in expanded clay with a thick layer - up to 30 cm.

How to easily identify high-quality expanded clay

Wood shavings and sawdust are cheap and environmentally friendly materials that can be purchased at any woodworking enterprise. The shavings retain heat well, but are afraid of moisture, so they also need high-quality protection. In addition, insects and rodents can start in it.

Sawdust and shavings

Slag is an affordable and practical way of warming on the ground. He also needs waterproofing, but he is durable, non-flammable and mice will not start in it.

Slag for floor insulation

Glass wool - affordable, perfectly retains heat and drowns out sounds, is not damaged by insects or rodents. The disadvantages include the tendency to shrinkage and the need to use protective equipment during installation, since thin fibers are very fragile, easily penetrate the respiratory tract, and irritate the skin.

Glass wool

Styrofoam - easy to install, moisture resistant. It has a long service life, but in the absence of mice, since these rodents are very actively destroying it.

Floor insulation with foam

The use of modern materials gives an incomparably better result: installation is carried out with minimal labor costs, the effectiveness of insulation increases significantly, you can forget about repeated repairs for at least 20 years. The only drawback is the high price, but financial investments are fully paid off in several years, thanks to significant savings on heating the home.

| Material | Basic properties |

| Penoplex | EPSP boards are not afraid of moisture, temperature fluctuations, freezing, and due to their high density and special structure, they perfectly retain their shape throughout the entire period of service. The insulation is light, besides, the plates have a convenient connection system, so anyone can cope with the installation. |

| Mineral wool insulation | Produced in various modifications, they have increased wear resistance, less hygroscopicity, and last longer. There are mats and slabs with a foil coating that reflects heat and increases the efficiency of thermal insulation at times. |

| Polyurethane foam | The sprayed insulation forms a dense and seamless insulation layer, resistant to any negative influences. Due to the porous structure, the insulation does not exert large loads on the foundation and floors, and is excellent for thermal insulation of floors on the second floor, attic and attic. True, for spraying, a special installation is required, as well as skills in working with it, so it is problematic to insulate the floor yourself in this way. |

| Ecowool | Cellulose insulation with very low thermal conductivity. Environmentally friendly, has high sound insulation properties. The insulation is blown into the underground space using the installation, since it is quite difficult to evenly distribute and compact the layer manually. |

READ MORE: Underfloor heating from a battery in an apartment

rockwool mineral wool

As a bulk insulation, many use expanded vermiculite - a granular material with a scaly structure. It is lighter than expanded clay and retains heat better, serves as excellent sound insulation. Unlike EPS and mineral wool, vermiculite is completely environmentally friendly, but at the same time it is not affected by fungi, putrefactive bacteria, insects and mice do not live in it. Well, the disadvantages include only the high cost, which is why vermiculite is inferior in popularity to cotton wool insulation and polystyrene.

Expanded vermiculite

Sawdust and shavings

Glass wool

| Penoplex | EPSP boards are not afraid of moisture, temperature fluctuations, freezing, and due to their high density and special structure, they perfectly retain their shape throughout the entire period of service.The insulation is light, besides, the plates have a convenient connection system, so anyone can cope with the installation. |

| Mineral wool insulation | Produced in various modifications, they have increased wear resistance, less hygroscopicity, and last longer. There are mats and slabs with a foil coating that reflects heat and increases the efficiency of thermal insulation at times. |

| Polyurethane foam | The sprayed insulation forms a dense and seamless insulation layer, resistant to any negative influences. Due to the porous structure, the insulation does not exert large loads on the foundation and floors, and is excellent for thermal insulation of floors on the second floor, attic and attic. True, spraying requires a special installation, as well as skills in working with it, so it is problematic to insulate the floor yourself in this way. |

| Ecowool | Cellulose insulation with very low thermal conductivity. Environmentally friendly, has high sound insulation properties. The insulation is blown into the underfloor space using the installation, since it is quite difficult to evenly distribute and compact the layer manually. |

Concrete flooring in the country

The specificity of floor insulation in a country house with a concrete base allows several methods of insulation. The former resembles working with a wooden floor, while the latter is only suitable for a concrete base. So, floor insulation with the help of a film and layers of heat-insulating material in the country can be done by hand. The film is laid in one layer, its footage is easy to calculate. In this case, preliminary work is necessary - sealing cracks and chips with a cement screed and putty.

After the surface dries, a wooden frame is adjusted to it. The distance between the beams is at your discretion, but it is better that it be no more than 80 cm. A film is covered on this base and fixed with a stapler. The space between the beams is filled with heat-insulating material.

Its thickness may vary, but it is worth considering that a small gap is required between this layer and the upper floor covering, that is, the height of the log should exceed the height of the insulation layer by 0.5-1.5 cm.

The second option for the floor in the country is a little more interesting. First, the floor is leveled with a putty or screed. Next, you can lay a layer of roofing material for additional insulation. Insulation is laid on it - always in the form of slabs. They stick together to form a single layer. Filling with a screed holds them together completely. After it has dried, the flooring is laid according to your preference.

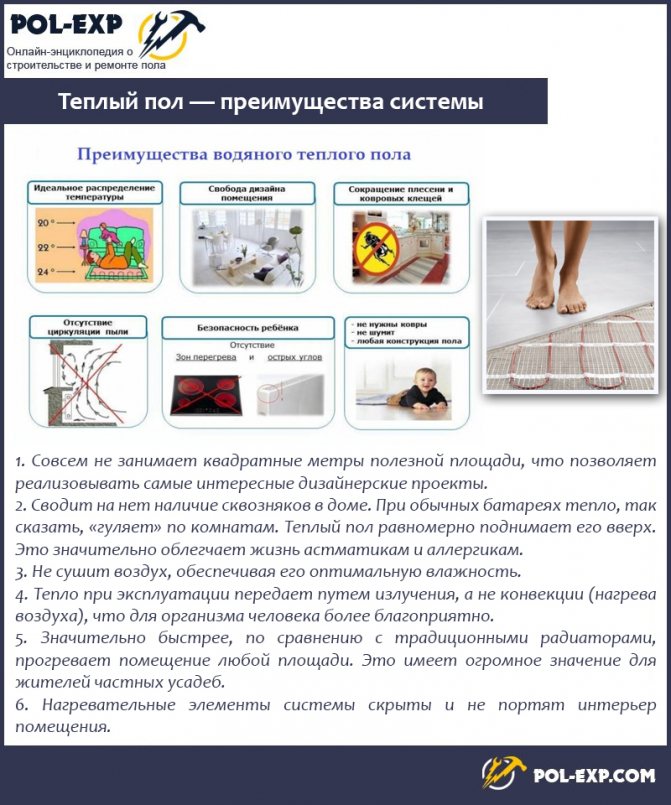

Warm floor using technology

Those who wondered how to insulate the floor in the country have probably heard about "warm floors" more than once. It is carrying the heating system under the surface of your floor. For this purpose, a cable or flexible tubes through which water is driven can be used. The heat source can be any heating boiler - gas or electric. Such a system is laid on top of a layer of insulation, distributed under the entire floor, in the form of a circular or parallel fastening of wires or tubes. Such heating will help you feel comfortable and maintain the air temperature in the room. In this case, experts will better tell you how to make the floor in the country.

The floor in the country house creates the atmosphere. It's one thing when you can safely walk on it in socks, or even barefoot, sit on the carpet in the evenings, allow children to fiddle with toys on the floor, and quite another - when it is icy and any contact with it threatens only with a cold. Not so many materials are needed for the floor in the country, and working with them is simple and straightforward. Having settled in a new house, or deciding to spend the winter outside the city, be sure to remember about the arrangement of the house, because its most vulnerable places are the floor and roof.The insulated floor in the country will save money on heating and subsequent repairs, so be sure to carry out all the necessary work. They can be done year-round, unless your sub-floor is damp.

Low-power underfloor heating

If we talk about electric underfloor heating, which serves only to create a comfortable temperature, then it is impossible to heat a house, albeit a small one, with this type of heaters. The power of the heating device is too small to somehow raise the temperature in the room at negative temperatures outside the walls of the house.

Although these electric floors also have their own areas of application. For example, they are used in bathrooms, laundries, washrooms, ground floor rooms for added comfort. The maximum heating temperature for such electric mats is 45 degrees Celsius. A high temperature will be uncomfortable for your feet, and the design will not allow you to deliver high power for heating.