What are turbocharged gas boilers

Turbocharged gas boiler - the unit responsible for heat supply, which is additionally equipped with a forced air exchange system. Due to this feature, it does not require the arrangement of a full-fledged smoke shaft, since communication with the external environment occurs through a coaxial chimney.

A coaxial chimney is a one-piece construction (usually supplied with the boiler), consisting of pipes of different diameters, nested one inside the other. Oxygen is taken through the outer channel (large pipe), and waste products of combustion are removed through the central (smaller pipe).

Since the high-quality ventilation of the room itself is not important for turbo boilers, they can be installed both in private houses and in city apartments.

The main and, perhaps, the only significant disadvantage is that, due to the presence of a turbine and more complex automation, they are extremely volatile.

Device and principle of operation

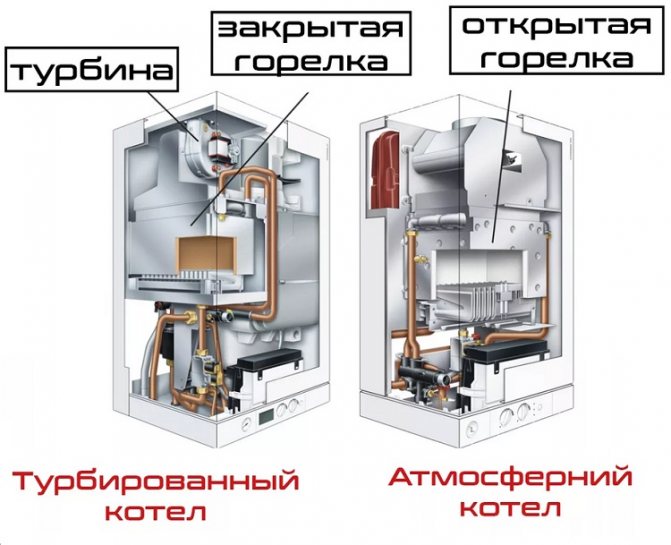

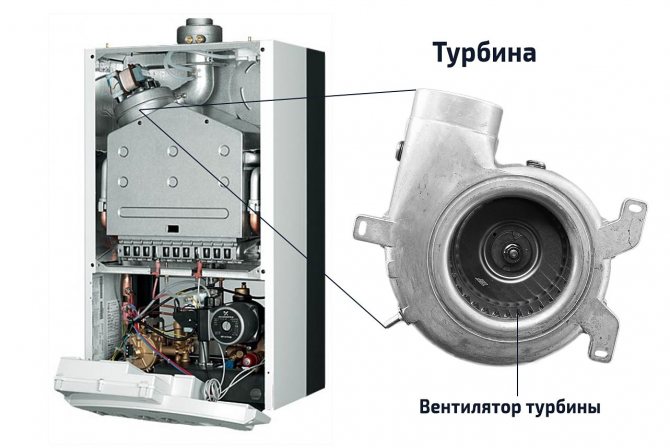

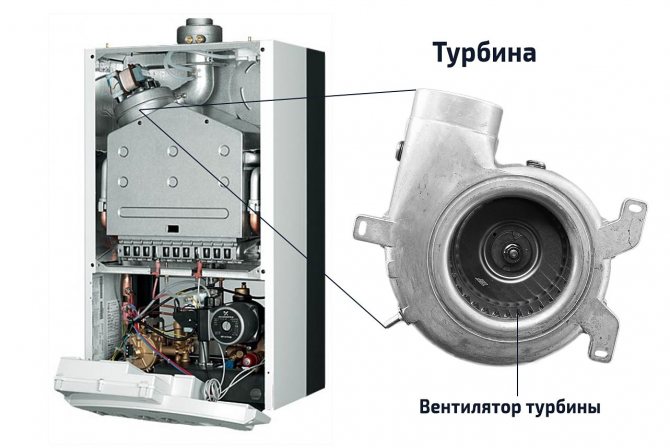

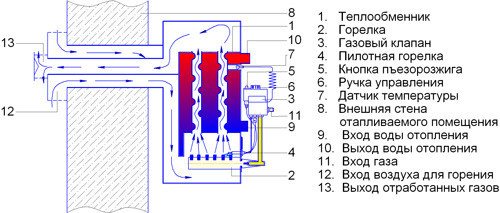

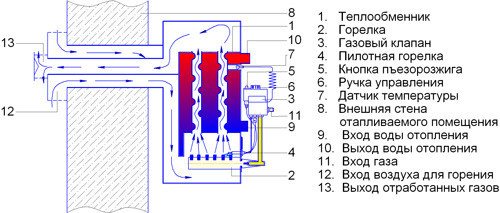

The basic structure of the turbo boiler is not much different from its predecessor, but the presence of auxiliary units introduces some changes in its design.

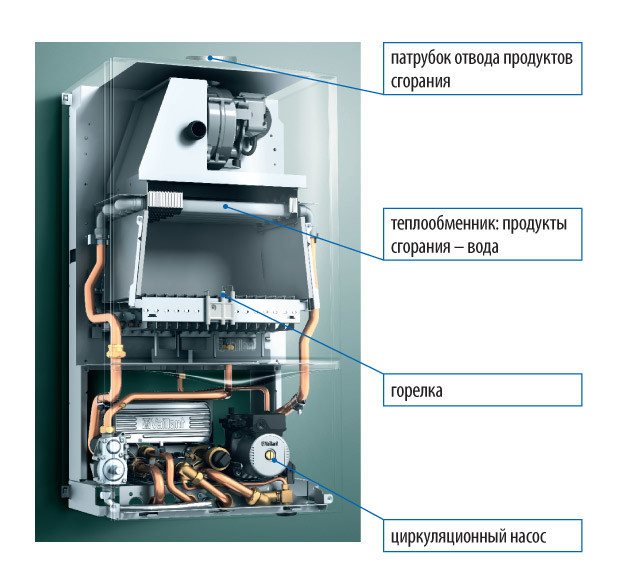

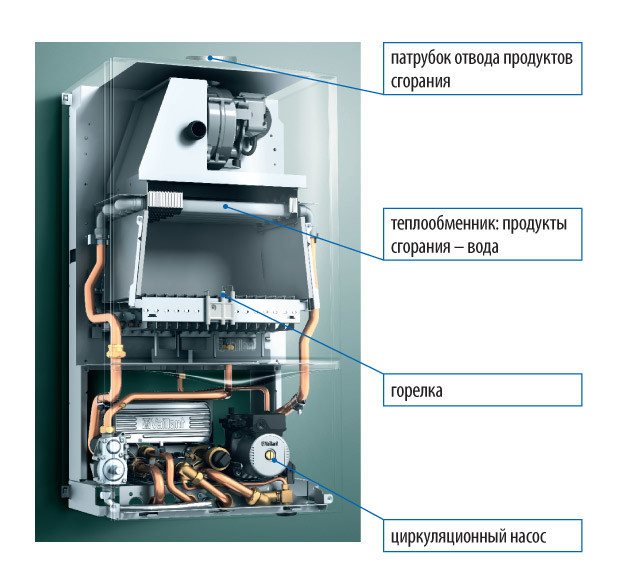

The air necessary to maintain combustion is supplied from the street directly into the closed combustion chamber. Since it is isolated from the living space and is directly connected only to the coaxial chimney, this completely excludes any influence of the exhaust gases on the internal microclimate.

The device is a turbocharged floor model.

The fan (turbine) provides smoke removal outside the house without the use of exhaust fans, creating excess pressure (turbocharging).

The rotation speed of the turbine fan is automatically controlled, therefore, even with a decrease in gas pressure in the main line, the composition of the gas-air mixture remains optimal. When the power changes, the speed is instantly selected, which will provide the required amount of air and proper traction. Thus, the best conditions for the operation of the burner are observed, allowing the greatest amount of energy to be obtained from the fuel.

How to choose a room thermostat and save up to 30% per month on heating

Atmospheric or turbocharged: which is better

A traditional atmospheric boiler has an open combustion chamber: air intake for gas combustion comes from the room. This means that the consumed oxygen must be fully replaced with new one. This requires supply and exhaust ventilation.

Without the organization of good supply and exhaust ventilation, normal operation of an atmospheric gas boiler is impossible. Firstly, the fuel will not be able to completely burn out and, as a result, the coolant will not receive a certain amount of heat, and secondly, life-threatening carbon monoxide (CO) - carbon monoxide - forms in the room.

Therefore, for small buildings, where it is problematic to separate a ventilated boiler room with a vertical chimney separate from the living area, it is better to choose a turbocharged boiler. And for gas heat supply of small retail space, offices and typical high-rise buildings, so it is generally the only option.

Varieties of boilers

Convection gas boiler device.

The heating boiler is the main element of the system in any home. The choice of this equipment on the modern market is incredibly extensive. Each boiler can be categorized according to one of the generally accepted classifications. Heating devices can be classified according to one of the following criteria:

- by the type of fuel used;

- by the method of installation and the space occupied in the heating system;

- by power;

- by price;

- by type of work.

Reviews of household models with forced air exchange: advantages and disadvantages

According to the reviews of the owners of turbocharged gas boilers, the following pros and cons can be distinguished:

| Dignity | disadvantages |

| safety - the tightness of the closed combustion chamber practically eliminates the risk of smoke entering the room | high price - prices for wall models are 20-30% higher, for floor models - 20-50% higher, but you can eliminate the cost of building a full-fledged chimney |

| free placement - air intake from the street allows the boiler to be installed in very small rooms (of course, meeting the requirements) | constant noise - the active operation of all turbo boilers is inevitably accompanied by the monotonous sound of the fan rotation, its volume depends on the model, as well as the presence of a sound insulation layer in the boiler |

| easy chimney installation - for the output of the coaxial pipe, it is enough to make a hole (Ø 110) in the outer wall of the house | volatility - any voltage problems (interruptions, non-compliance) cause the fan to stop |

| low fuel consumption - efficiency is achieved due to automation, which controls the speed of rotation of the turbine |

Difficulties with power supply can be easily avoided by connecting a voltage stabilizer and a backup power source to a turbocharged boiler - an electric generator (gasoline, diesel) and an uninterruptible power supply (UPS). However, it must be borne in mind that this will lead to additional material investments.

How to choose a turbocharged gas boiler for heating a private house

Wall-mounted or floor-mounted

Wall-mounted models fit perfectly into the interior of the kitchen or can be completely hidden in the closet.

- floor - more versatile and durable, since the design is unlimited in weight, they are often equipped with durable cast iron heat exchangers .;

- hinged (wall) - compact and lightweight, medium and low power (10-50 kW) boilers, often having a higher efficiency than floor-standing models. However, due to weight requirements, they use less corrosion-resistant steel and copper heat exchangers.

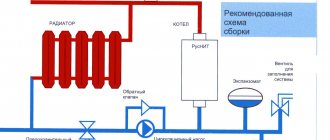

In addition, wall-mounted boilers contain all the necessary modules of the heating system in one housing (expansion tank, circulation pump, safety valve, air vent, etc.), which not only simplifies, but also makes installation cheaper. Floor standing models are rarely equipped with all the necessary modules.

Single-circuit or double-circuit

The functionality of a turbo boiler is determined by the number of circuits:

- single-circuit - its capabilities are limited exclusively by heating;

- double-circuit - along with heating it heats water for domestic needs.

A double-circuit boiler is a combination of a boiler and an instantaneous heater, i.e. the heating of the room is stopped when hot water is supplied. It is worth clarifying that, contrary to popular belief, the coolant does not have time to cool down during the downtime, so the temperature in the dwelling remains the same.

Of course, the cost of the double-circuit version is 10-30% higher, but it is still more profitable than organizing hot water supply in any other way, for example, using a boiler and a single-circuit boiler. And if necessary, one of the circuits can be turned off - for example, in the summer, when there is no need to heat the dwelling.

Heat exchanger type and material

A copper heat exchanger is the most optimal option for a wall-mounted model.

The material of the heat exchanger affects the durability of the boiler:

- cast iron (service life 25-30 years and more) - the most heat- and corrosion-resistant metal, but fragile and heavy, therefore it is used only in floor-standing models;

- copper (service life 12–17 years) - very light and heat-conducting metal (it quickly heats up and cools down), slightly corrosive, but can burn out.

- steel (service life 10-15 years) - the metal tolerates transportation well, since it is not sensitive to physical impact, light and inexpensive to manufacture, but is prone to rust formation, which leads to leakage over the years.

Double-circuit boilers are also divided according to the type of heat exchanger: separate (for each circuit its own) and double - bithermic (the DHW circuit passes through the main heat exchanger). The latter option is cheaper, but it is less reliable, since the scale formed in it is almost impossible to clean, it is the clogging with scale that often causes premature breakdown.

Efficiency

Despite the fact that the atmospheric (90–92%) and turbo boilers (92–95%) have “pure” efficiency practically the same, the latter will have a higher gas consumption efficiency.

The point is to use a coaxial chimney: when cold air from the street enters its outer cavity, it begins to heat up even before entering the combustion chamber from the heat of the smoke (100–130 ° C), which comes out through the inner cavity of the same chimney. Therefore, fewer resources are spent on further heating. To this it is worth adding more efficient control of air flow and traction, which also affects gas consumption.

Minimum required power

You can calculate the required power of a turbo boiler using a simple formula: where 1 * kW of energy goes to 10 m2 of heated area.

* heat loss of an average residential building with ceilings up to 2.7 m from central Russia.

For example, for a standard house in the Moscow region with 2 bricks masonry and a ceiling height of 2.7 m, an area of 120 m2, the minimum suitable power of a turbo boiler will be Q = 120 ÷ 10 × 1 = 12 kW.

We recommend setting a margin of 15–20% of this value in order not to operate the unit at the limit, therefore, for the same object, Q≈14–15 kW.

Also, if we consider a two-circuit model, then the use of hot water supply will have to add at least 15–20%, in total it will already turn out that Q≈16–17 kW. It is also important not to overdo it with power, otherwise the boiler will “clock” too often (turn on and off), which will reduce its resource.

How to accurately calculate the required boiler power Individual calculation, formula and correction factors

Required power of the heating boiler

The choice of the power of the heating boiler is no less important part of the planning of the heating system than the choice of the heat carrier used.

Calculation of the power of a gas boiler.

It depends on the power of the boiler whether it will provide the necessary amount of heat to warm up the house. What equipment power is needed to fully heat your home can be determined taking into account its size. The larger the house, the more power the boiler should be. In addition to the area of the heated room, it is necessary to take into account heat loss, which is inevitable even in a well-insulated house. The main places for heat leakage are open windows and the front door. In any case, you need to choose equipment with a power reserve.

As a rule, the calculation of the optimal power is based on the fact that 1 kW can heat a room with an area of 10 m². For example, if the area of your house is 150 m², then 15 kW of boiler power will be required to heat it. The power reserve for heat loss must be at least 15%. In this example, after adding the margin, you get 17.25 kW. Thus, for efficient heating of a house with an area of 150 m², a boiler with a capacity of at least 18 kW is required.

If you choose a boiler with a capacity not less than the optimal one, then the service life of the heating equipment will be much longer, since it will not work at the limit of its capacity. In addition, even in maximum frosts, your home will be warm enough.

The best known manufacturers and models: characteristics and prices

BAXI ECO-4s 24F

The Italian double-circuit turbo boiler with a capacity of 24.0 kW was developed taking into account the specifics of Russian conditions, therefore it is adapted to work with low gas pressure, power outages and other unstable indicators. It also has one of the best efficiency in its price segment - 92.9%, while gas consumption is 2.54 m3 / h. The primary heat exchanger is made of copper.

The owners note the almost silent operation, for more than 5 years of operating practice, there were no serious service complaints.

Cost: 33 110 - 36 850 rubles.

Manufacturer: BAXI (BAXI), Italy.

Vaillant turboTEC pro VUW 242 / 5-3

Dual-circuit model from the reference German brand with a capacity of 24 kW. Differs in particular reliability and durability due to excellent build quality, use of high-tech alloys and the best materials. Efficiency 91%, maximum gas flow 2.80 m3 / h. It also features a copper primary heat exchanger, modulating burner, functional automation with many protective systems and a pleasant, stylish design.

Cost: RUB 53,920 - RUB 57,860.

Manufacturer: Vaillant (Vailant), Germany (assembled in Slovakia).

Viessmann Vitopend 100-W A1HB001

One of the best gas turbocharged boilers for heating a private house and another reference German model with a capacity of 24 kW. Like the previous Vaillant turboTEC, it is distinguished by its high reliability and durability, while the boiler is absolutely not picky about the quality of the coolant and the pressure in the gas main. Efficiency - 91%, maximum gas consumption - no more than 2.77 m3 / h.

A serious advantage is the presence of a programmer that allows you to set the boiler operation settings for the next day or week, for example, setting the temperature to 15 ° C during working hours when the owners are not at home, which will significantly reduce operating costs.

The only common problem is that the boiler shuts down due to icing in the chimney at temperatures below -17-18 ° C. The solution is to monitor the condition of the chimney and promptly knock down ice, insulate its outer part or install an anti-icing structure.

Cost: 36,010 - 43,550 rubles.

Manufacturer: Viessmann (Wiesman), Germany.

Buderus Logamax U072-24

Wall mounted turbocharged gas boiler with a capacity of 24.0 kW. In fact, this is another reference German model, but with Russian localization, which made it possible to significantly reduce its cost and distinguish it from its analogues. The efficiency is 92%, the maximum fuel consumption is 2.8 m3 / h. The boiler is also equipped with a copper primary heat exchanger, modulated by a burner.

The only drawback is the lower Russian build quality, which is not typical for other German and Italian models.

Cost: 27 950 - 34 820 rubles.

Manufacturer: Buderus (Buderus), Germany-Russia.

Navien GA 23KN

The 23.0 kW floor-standing double-circuit turbo boiler has a modest gas consumption of 2.24 m3 / h. It is equipped with a unique protection against voltage surges: with a difference of ± 30%, the SMPS chip is triggered on the microprocessor, which allows you to continue working without the risk of damaging the electronics. At the same time, the boiler is equipped with a modulating burner, a programmer, a room thermostat and a remote control are already in the factory complete set.

Perceptible disadvantages are the steel heat exchanger, mediocre build quality, noisy, relative to the above models, work.

Cost: 32 980 - 36 140 rubles.

Manufacturer: NAVIEN, South Korea (often assembled in Russia).

Energy sources for heating boilers

You can use one of the following fuels to heat your home:

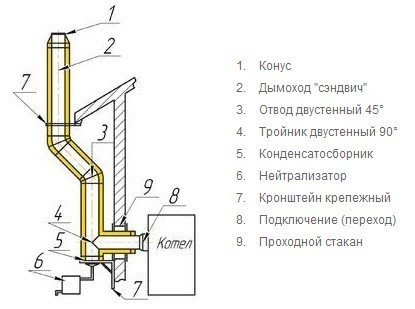

Chimney diagram for a gas boiler.

- Gas. In domestic practice, this energy carrier is the most popular, its use is more common. This is due primarily to the lowest cost of this type of fuel.If you have access to gas in your home, then you should not even consider other types of energy. When accessing the gas main, the choice of the boiler according to the type of fuel is obvious. A gas boiler is able to provide convenient and inexpensive heating for your home. Any gas boiler can also be connected to gas cylinders, but this option has some drawbacks, for example, the price of gas in a cylinder is slightly higher. All gas appliances of this type work automatically, which simplifies their operation.

- Solid fuel. The use of wood or coal is still widespread. Especially such boilers are relevant for areas where gas mains are not laid. The arguments in their favor are the availability of fuel and the relatively low price for it. The disadvantage of such equipment is the need for constant attention to it. The operation of a solid fuel boiler must be constantly monitored and fuel must be periodically added.

- Electricity. Electric boilers are by far the cheapest, but using electricity to heat your home is the most uneconomical option possible. But even if the high costs of electricity do not scare you, then it may not be possible to install an electric heater due to insufficient power supplied to the house. It is advisable and very convenient to install a simultaneous electric and solid fuel boiler. Such a system will be cheaper than operating only an electric boiler, while the need to constantly monitor the operation of a solid fuel boiler and add coal or firewood to it will disappear.

- Liquid fuel. Diesel is used as a liquid fuel. Its cost is lower than the cost of electricity and higher than the cost of other types of energy. Such equipment works automatically. If the gas pipeline near your house is temporarily absent and it is planned to supply it in the near future, then you should definitely opt for a diesel boiler, since it can easily be converted into a gas boiler. A common misconception about diesel is its unpleasant smell when the boiler is running. Diesel really has an unpleasant odor, but you can only feel it when refueling a container with a diesel engine. The only inconvenience associated with the operation of a liquid fuel device is the need to create certain conditions for storing a diesel engine. However, at the same time, such equipment also has advantages, the main of which are automatic operation and less cost than using electricity.

Gas boiler installation diagram.

You can choose the type of heating for your home according to your preferences and capabilities. Consider the efficiency of this or that type of energy carrier, as the cost of heating can be impressive.

Prices: summary table

Comparative rating of popular turbocharged gas boilers:

| Unit model | Efficiency,% | power, kWt | DHW, l / min. | Consumption, m3 / h | price, rub. |

| BAXI ECO-4s 24F | 92,9 | 24 | 13,7 | 2,54 | 34 500 |

| Vaillant turboTEC pro VUW 242 / 5-3 | 91 | 24 | 11,5 | 2,80 | 56 000 |

| Viessmann Vitopend 100-WA1HB001 | 91 | 24 | — | 2,77 | 40 000 |

| Buderus Logamax U072-24 | 92 | 24 | — | 2,80 | 29 500 |

| Navien GA 23KN | 91,5 | 23 | 13 | 2,24 | 34 500 |