The service life of cast-iron heating radiators is so long that residents take their work for granted, therefore, in the event of a leak or fistula in the wall of the device, they do not know what to do. It is especially unpleasant if the breakdown occurred in the midst of cold weather, but even in the off-season, you cannot leave the heating elements unattended. As a rule, preventive work carried out by heating network workers can reveal the presence of dirt or leaks in the device.

In this case, there are simple ways to eliminate a leak in a cast-iron radiator.

The device of cast iron radiators

This type of heating device consists of sections. Models of the old type even today are produced in the form of "accordions", while the new generation has a flat outer panel that provides better heating of its entire area.

During operation, these devices use two types of heat transfer:

- Radiation, or as professionals call it, radiation makes up 25-30% of the heat. It not only heats the air, but is transmitted to nearby objects, providing better heating of the room.

- The convection produced by the heating battery ensures the constant movement of air masses around the room, and accounts for about 75% of the heat transfer.

The device of the cast-iron battery, despite all the external changes, remained the same. It consists of sections equipped with:

- plugs;

- locking devices;

- traffic jams;

- shank and thermostat;

- locknuts;

- nipples and gaskets.

As strong as cast iron is, even it has its limits. As a rule, the service life of cast iron radiators is 25-30 years, and with proper care and optimal working conditions, they can work without interruption from 50 to 100 years.

The same cannot be said for the parts that hold the sections together, such as the gaskets. With frequent water hammer, they can "wobble" or crack from time to time. In this case, a leak appears between the sections of the cast-iron battery, which, if not eliminated in time, can cause a serious accident and a threat to human health and life.

To avoid this, you need to check the condition of the cast iron radiators after the end of the heating season. In this case, you can find completely different malfunctions in the heating system.

The most common problems and their symptoms

Although cast iron perfectly tolerates the imperfection of the central heating coolant, and the batteries from it have channels wide enough so that debris does not accumulate in them, even they may have problems. And this despite the fact that this metal has no wear. The culprit for the fact that the cast-iron battery burst or a fistula appeared in its walls may be the following factors:

- Everyone knows the large weight of radiators made of this metal. If, during the installation of the structure, not strong enough brackets were used, or there were few of them, over time it can sag under its own weight and bend over. Even a slight deviation of just a couple of millimeters will reduce the efficiency of the device, and if the misalignment is not corrected, then after a few years, corrosion will appear in the place where the coolant is absent. At first, it will look like a small brown speck that will grow with each heating season until a fistula forms in its place.

- The reputation of "long-livers" is characteristic of both old and new models of cast-iron radiators, but provided that they are mounted in the circuit of an apartment building no higher than six floors. If the heating system is reliable and does not "sin" with strong water hammer, then they can be installed in nine-storey buildings. Otherwise, under a strong pressure of water, a cast-iron battery can leak at the joints of the sections. In the event that a cast-iron battery leaks during the heating season, you need to know how to repair it in advance. Today there are a lot of sealants that will help the device "hold out" until warm days.

- The internal structure of domestic batteries is such that the cast iron from which they are smelted has roughness that is completely absent in imported counterparts. That is why, over time, a lot of garbage is deposited on the walls, which is filled with water in the heating system. Suspensions, particles of rust and metals, all this settles and makes the wide channel narrow so that it is no longer able to pass the coolant unhindered under high pressure. In this case, the structure can burst anywhere, and then you will have to urgently decide how to eliminate the leak in the cast-iron battery.

- Gaskets and nipple threads are the weak "link" of heating devices... If cast iron does not have a limitation period, then this cannot be said about the parts that make up the battery. In order not to bring the situation to the point that the repair of the cast-iron battery is required, the joints must be checked after each heating season and the gaskets must be periodically changed on them.

As practice shows, most often it becomes known that something is wrong with the heating system when the repair of cast-iron radiators is already required. To know about a problem in advance, you need to listen for "help signals" that indicate the presence of defects.

How to repair a cast iron radiator

Repair begins with preparatory steps. A film is covered under the radiator, since water and dirt are indispensable here. It is important to know that if a method of gluing with epoxy resin or cold welding is chosen, then the radiator must be disconnected from the heating system, otherwise the coolant flow will prevent the bandage from sticking to the cast-iron surface. However, this can be done when the battery is equipped with shut-off valves.

Suppose there are taps on the piping to the radiator. They must be closed before starting repairs. The next step is to drain the coolant from the battery to eliminate the leak. The problem area is cleaned of paint, dirt, rust. Degrease with acetone or alcohol. Epoxy is applied to a strip of bandage or cotton fabric. If the crack is on a flat section, then the patch is simply glued in several layers, giving time for each of them to harden. On the section of the supply pipe or the collector, the tarred bandage is wound in the form of a bandage. After hardening, the area is painted over to match the color of the radiator.

The problem area is cleaned of paint and degreased before repair

Similar actions are performed when the repair of a cast-iron battery by cold welding is provided, but a bandage or a strip of cloth will be needed for other actions. The tool resembles plasticine. Before use, cut off the required amount of mass and knead it with your hands. At this time, the mixing of the components responsible for the curing of the cold welding takes place. The softened mass is glued to the area requiring repair. Try to wind a bandage over the top with a strip of fabric. The harder the cold weld is pressed against the cast iron surface, the stronger the patch will be.

Advice! Instead of cloth, tape or strips of other material can be used to press down on the cold weld.

The clamp will help to eliminate the leak if it is impossible to disconnect the radiator from the heating system

In apartments with an old renovation, cast-iron radiators are installed without shut-off valves. Repair with epoxy resin or cold welding is not possible, as the coolant constantly leaks.If the problem area is on the pipe or the connection of the section manifolds, the clamp will help out. The product for the bandage consists of one split ring or two half rings. Bolts are provided for the screed. The rubber strip acts as a seal. The clamp is installed on the problem area, the bolts are tightened until the leak stops.

Overhaul requires complete disassembly of the radiator

If there is more than one leak, it is better to disassemble such a radiator immediately. Before that, it is disconnected from the heating system, the coolant is drained. Repairs are carried out in the following sequence:

- When a cast-iron battery is connected to the heating system with metal pipes that have served for more than a dozen years, it makes no sense to unwind the drives. They will end anyway. The threads are cut with a grinder. In their place, new squeegees will have to be welded.

- The radiator is removed from the brackets and placed on the floor. They try to unscrew the plugs from the manifolds and the nuts with cut-off beads with a wrench. It is important to remember that one manifold will have a right hand thread and the other a left hand thread. If the nuts do not go, they are heated with a blowtorch. After unscrewing on the plugs, the threads are cleaned with a metal brush. It is better to throw out nuts with cut off grips and buy new ones. It is difficult to unscrew the threaded tube pieces.

- To disconnect the sections, a special key is introduced into the collector. One end of it resembles a shoulder blade. It is with this flat part that they are looking for a hook on the antennae of a cast-iron nipple. It similarly has a right-hand and left-hand thread. They try to rip off the nipple with a key and turn it a couple of turns. If it does not give in, the collector section is heated with a blowtorch. A similar operation is performed on the opposite manifold. Each nipple is alternately turned a couple of turns until the section is completely disconnected.

Likewise, you can disassemble the entire radiator or separate damaged sections. If there is a lot of dirt inside, caustic soda is used for rinsing. A solution of 9% vinegar and water in a 1: 1 ratio is suitable. In extreme cases, a 5% sulfuric acid solution is used. For flushing, the liquid is poured into the radiator for a day, then washed with clean water. After these actions, the battery is disconnected into separate sections, the O-rings are changed, and the reassembly is performed.

The video shows more details about the repair of heating radiators:

The first signs of a problem

There are a number of factors that indicate that something is wrong with the heating circuit or batteries. These include:

- Feeling cool in the room. In this case, it is worth asking the neighbors how warm they are in the apartment. If everything is in order, then you can start looking for problems in yourself. The reason may be elementary contamination of the channels, the skew of the device or the presence of fistulas. In the first case, it is enough to rinse the batteries, in the second - to fix or change the brackets and check the correctness of installation with a building level, and in the third - to help the "sick" radiator.

- If an incomprehensible plaque appears on the battery, visible to the naked eye, then the reason for this is worn out gaskets. We'll have to turn off the system, dismantle the batteries and install new ones, for example, made of paronite.

- The leak is immediately noticeable. If it is small, then you can do with a clamp or cold welding, otherwise you will have to completely change the device.

It should be remembered that even small defects can develop into a big problem if they are not eliminated in time. Do not rely on temporary clamps and patches. Only heating specialists can determine the reliability and tightness of the heating circuit and its elements.

Fistula elimination

For any breakdown, there are a number of reasons accompanying it. Fistulas on the pipes of the heating system or on the radiator are no exception. If a small brown speck appears on the elements of the heating network, you should not think that this is the paint coming off. In fact, this is the beginning of an often irreversible process, but knowing how to close a fistula in a cast-iron battery, you can stop the destruction and extend its service life. Reasons for the appearance of corrosion:

- Taking into account the frequent increases in the cost of utilities, some craftsmen are cunning and, for the sake of saving electricity, connect a zero cable to the heating circuit. The currents that begin their "journey" through the pipes by means of the coolant exactly cause the formation of corrosion. It is possible to identify a dishonest neighbor if there are several fistulas, and they appear with a certain regularity. A call to the appropriate service will help to save the situation in order to identify the offender, and do-it-yourself repair of cast-iron batteries.

- Too high acidity of water can harm even corrosion-tolerant cast iron.

- The batteries have expired or deposits on the sides have damaged the metal. In this case, even a small fistula or crack under the influence of water pressure can cause the battery to burst and a stream of hot water will flow out of it.

Any of the options requires urgent intervention. If the cast-iron battery only leaks slightly, then you can do without disconnecting the circuit and dismantling it. The clamp can save the situation. If the water only drips, then a one-sided pad will do, but if it runs in a thin line, then it is better not to risk it and use a double-sided clip.

In the event that the coolant tore apart the place where the fistula was located, the question immediately arises whether it is possible to brew a cast-iron battery... As a rule, cold welding becomes an emergency aid, but even if it has restored its tightness, it is necessary to call the masters from the heating network to check the condition of the heating system.

Elimination of the fistula

Any breakdown occurs for a reason. Fistulas on the pipes of the heating system or on the radiator are no exception. If a small brown spot has appeared on the parts of the heating system, then do not think that it is just paint peeling off. This is the beginning of an irreversible process. But if you know how to remove a fistula in a cast iron battery, you can prevent destruction and extend its useful life.

Causes of corrosion:

- Given the constant increase in the cost of utilities, some, in order to save electricity, connect a zero cable to the heating circuit. The currents move through the pipes by the coolant method and provoke the occurrence of corrosion. This situation can only be saved by the appropriate service, which will find the violator and make repairs;

- the high level of acidity of the water damages even corrosion-resistant cast iron;

- the batteries have reached the end of their useful life, or deposits on the walls have damaged the metal. Even a small fistula or crack under the influence of water pressure will cause the battery to burst and hot water will flow from it. If the battery is dripping a little, you can use the clamp. If it runs in a given stream, it is better to use a double-sided clamp.

Recommended: How to install heating on a balcony from central heating?

If the coolant has torn the place where the fistula is present, then the question arises, is it possible to weld the battery? Cold welding is usually an urgent help. But even if it restored the tightness, it is necessary to call the masters from the heating network so that they check the condition of the heating equipment.

Repair of cast iron batteries can be done independently with the help of tools and the necessary materials, but subject to the detection of non-critical breakdowns. Cold welding is an easy and quick way to restore a heater, but even it will not guarantee that nothing terrible will happen in the future.In order to make sure that the heating device and all its parts will serve for a long time and do not harm people, it is necessary either to completely replace the repaired device after the end of the cold season, or to call the technicians to check its stable and reliable operation.

YouTube responded with an error: Access Not Configured. YouTube Data API has not been used in project 268921522881 before or it is disabled. Enable it by visiting https://console.developers.google.com/apis/api/youtube.googleapis.com/overview?project=268921522881 then retry. If you enabled this API recently, wait a few minutes for the action to propagate to our systems and retry.

- Similar posts

- What are the best radiators for central heating?

- Which radiators are best suited for autonomous heating?

- How to repair bimetallic heating radiators with your own hands?

- What is the pressure in the central heating batteries?

- What is the norm for the water temperature in the central heating batteries?

- Can bimetallic radiators be installed on central heating?

Methods for repairing cast iron radiators

There are several methods that allow the batteries to hold out not only until the end of the heating season, but also for a couple of years. These include:

- If a leak occurs at the junction of the sections, then it can be quickly eliminated with a bandage and epoxy glue. The material is impregnated with glue and wound around the leak. After it grabs, you can paint over this place in the tone of the battery, but the main thing to remember is that such an "operation" is considered temporary, and it is better to buy and install a new section after the end of the cold weather.

- If a fistula or crack is found, a clamp will be required. You can buy it at a building materials store, or you can make it yourself from rubber or tin.

- Cold welding for cast iron batteries is the best way to quickly fix a defect. This is a special sealant that looks like children's plasticine. It must be thoroughly kneaded and applied to the damaged area. The tool sets quickly, is resistant to temperature extremes and is quite suitable for quick and temporary repair of a cast-iron battery.

Knowing how to weld a cast-iron battery using a welding machine with an inverter circuit, you can save the device from leaks for a long time.

Sequence of work

Depending on how serious the breakdown is, the actions to eliminate it depend. So, if the leak is small, then you can do without disconnecting the battery from the circuit, and repair will require:

- Place a container under the place of breakage in case of a breakthrough or an oilcloth with a rag to collect water.

- The place of the gap or crack must be cleaned to the base with a cable or emery. It is necessary not only to remove the paint layer, but to expose the metal itself.

- Degrease the prepared area with some kind of solvent.

- If special glue or epoxy is used to eliminate the breakage, then strips of thick cloth or bandages will be required. Apply the product to them and wrap them in several layers over the gap.

- In the case of cold welding, no fabric is needed.

- A clamp is put on and screwed onto the place seized by the sealant, but it is important to make sure that its clamps are on the opposite side of the leak. For example, a crack has formed on the inside of the radiator, which means that the clamps will be on the outside, and vice versa.

- If the breakdown is serious and hot water gushes from the battery, then you need to call the emergency team, and not try to stop the leak yourself without the necessary tools.

Even the highest quality repair does not guarantee a long service life of the device. The restored cast-iron radiators will still have to be changed, and the sooner this is done, the safer it will be in the apartment.

The main causes of malfunctions of cast iron heating radiators

Cast iron is characterized by high strength, the service life of heating products - 25-30 years old, under optimal conditions - 50 years and more.

But thick-walled cast-iron batteries have vulnerabilities: most often radiators leak between sections, at the joints with pipes, sometimes fistulas and cracks appear on the cast iron itself.

Main reasonsfor which repairs have to be performed:

- Great weight. Depending on the type and manufacturer, the weight of one cast iron section 4.5-7.1 kg, filling volume 1-4 liters, the standard set consists of 4-10 elements. In case of improper installation and incorrect calculation of the number of brackets, the radiator is skewed. As a result, the connecting elements suffer, and metal fatigue occurs. In places where there is no coolant, corrosion appears, then a fistula.

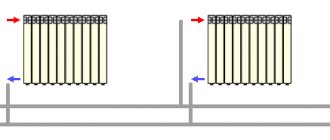

- Instability to water hammer, high pressure. With a sharp elimination of the obstacle, the liquid acquires tremendous speed and rushes to the area of least pressure. The power of the water hammer in the heating circuit exceeds the force of a hammer blow. A sudden change in pressure or its high values threaten a depressurization of the heating system - more often leaks occur at the joints of the radiator parts.

- Dirt and debris. The elements of domestic cast-iron batteries are produced by casting. The technology is such that the surface remains rough, which is excluded in imported counterparts.

Due to the granularity, rust particles and suspensions, which are filled with the coolant, settle on the walls. Gradually, the channels become clogged, do not withstand the pressure of water - the battery can burst from pressure or water hammer. To prevent repairs, regular flushing of the system is required.

Photo 1. Cast-iron battery elements clogged with rust and debris, because of this, the radiator cannot cope with the water pressure.

- Wear of intersection gaskets. The strength of collapsible joints is always inferior to monolithic structures. Cross-section gaskets and battery threaded nipples wear out faster than cast iron, and are more exposed to temperature and pressure. To avoid leaks and emergency repairs, do not forget about prevention: after the heating season, check the joints and change the gaskets.

DIY tools and materials for eliminating defects

Minor repairs to cast iron radiators are possible without the involvement of plumbers, do it yourself. Depending on the method of restoration work, you will need:

- metal rope or sandpaper - for cleaning the defect site;

- for repairing the joints of sections: clamp - a fastener consisting of two rubberized plates from the inside, connected by bolts;

- to eliminate fistulas: cold welding for radiators - a plastic mass intended for fixing metal parts without thermal heating;

- degreasing solvent: gasoline, acetone, white spirit and others;

- one of the sealants: powder iron, polymer, cold welding, epoxy resin;

- bandage or strips of fabric;

- wrench under the size of the clamp fasteners, pliers;

- rags, oilcloth, a container for collecting water.

Attention! For emergency repairs, instead of a clamp, a a piece of thin rubbercut from a car tube or elastic rubber bandage and a wire for fixing.

To flush cast-iron batteries, an adjustable pipe wrench is prepared, solutions of caustic soda 10%, citric acid (50-60 g per liter) or a special liquid for heat exchangers.

Photo 2. Preparation of a solution for flushing a cast-iron radiator, soda and citric acid are added to it.

Battery Leak Repair and Cleaning

Actions to eliminate the defect depend on its location and the severity of the breakdown. In all cases, the repair begins with the preparation of the workplace.

Attention! If the leak is significant, call the emergency team. Attempts to tighten the crack under pressure with a clamp are hazardous to health, as they can rupture the radiator.

Sequence of work when repairing section joints:

In order not to flood the neighbors, cover the floor with oilcloth, prepare a container and rags to collect water.- Use a thin rope or emery to clean the leaking area - peel off paint to metal. Degrease the cast iron surface thoroughly.

- Cover the leak. Apply epoxy or putty to fabric strips or bandage. Wrap the defect in 2-5 turns, do not smear the top layer.

- Knead cold welding with your hands until smooth, pressing firmly, apply without fabric.

- Put on the clamppositioning the clamps on the side of the battery opposite the leak. Tighten the nuts.

If rubber is used instead of a clamp to repair the joint of cast-iron radiators, wind it over the leakage area and pull it off with a wire using pliers.

Reference! The clamp, without prior application of sealant, is used to quickly repair minor leaks. Rubberized base ensures tightness of connections.

If a fistula has formed on a cast-iron surface, for repair to a cleaned and degreased place cold weld by indentation method. A non-standard solution to the problem - drive a wooden cork into the hole or screw in a self-tapping screw, coat with sealant on top.

How and with what to flush the radiator?

Before flushing the battery, disconnect from the system using pipe wrench # 3 (gas) and remove all plugs. It is most convenient to perform the washing procedure in a cast iron bath. To prevent damage to enamel, the bottom is covered with rags.

When disconnecting the battery from the heating network, substitute the container, as liquid may remain in the system.

Work order:

- Filling in hot water. Use a flexible shower hose to clean the structure. Supply water under pressure, direct it to all sections, shake and turn the radiator regularly. Remove large blockages with stiff wire. Follow the procedure until the flowing out water becomes clear.

- Pouring solution. To rinse, plug all openings, fill with hot (90ºC) 10% caustic soda or concentrated dishwashing detergent, leave for 40-60 minutes. The mixture will remove the remnants of organic contamination, open access to mineral deposits. Shake the product, then drain the liquid.

- Removal of limescale. Pour in the warmed up to 60–70ºC acid solution, leave for a period from 3-6 hours to 2 days. Tap the battery periodically with a wooden mallet. Citric acid can be used at this stage of rinsing, vinegar 9% in proportion to water 1:5. And also a special liquid is used for flushing heating systems, a product for car radiators, but in these cases the exposure period is determined according to the instructions.

- Re-rinsing with water. To better wash away the softened limescale, tap on the battery housing while rinsing it with a strong stream of water. Repeat the procedure until all particles of layers come out.

Important! For effective heat dissipation, flush cast iron radiators once at 3-4 years old... Thoroughly flush out residual chemical solutions as they cause oxidation, metal breakdown and the formation of a layer of rust.

How to clean the structure without removing it?

To flush cast iron batteries without dismantling, without removing them, use hydropneumatic and electrohydropulse devices.

First devices create an air shockwave with high kinetic energy that tears away solid deposits.

Apparatus of the second type with the help of an electrical impulse, they destroy the mineral salts that have settled on the walls.

Both techniques are safe for cast iron, they are highly effective, they remove blockages that cannot be washed normally, but in order to clean this way, special equipment is needed.