Any owner of a private house dreams of a large fireplace, which in itself creates an atmosphere of warmth and comfort. The whole family will gather near an open fire on dark, winter evenings, exchanging events for the day. However, modern fireplaces are not just a decorative part of the interior. A well-done modernization turns the fireplace with a water heating circuit into a full-fledged source of heat for the whole house, along with the generally recognized factory-made heating equipment.

As practice shows, fireplaces for air heating at home and equipped with a water circuit also help to significantly save on energy consumption. After all, solid fuel costs somewhat less than the price of electricity and gas.

What is a fireplace with a water heating circuit?

A fireplace is a type of heating equipment where heat is generated by burning primary fuel. It can be wood, coal, pellets. There are gas fireplaces for heating.

Fireplace equipment can be:

- with open and closed fireboxes;

- water and air heating circuits;

- natural and forced air flow;

- built-in and free-standing.

The main distinguishing feature of the heater is an open combustion chamber.

The heat generation area and the fuel oxidation zone (process zone) are combined here, which reduces the percentage of heating of the environment as a result of natural air convection. Most of the room temperature rises due to radiant energy (IR waves).

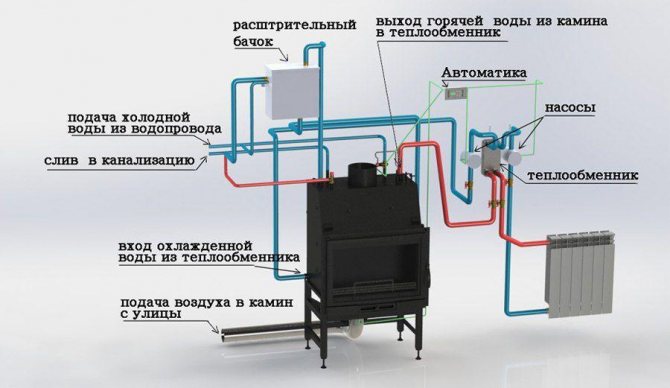

The main disadvantage of the above-described scheme of heat exchange between the fireplace and the environment is significant heat losses from the combustion products of the energy carrier leaving the combustion chamber through a brick chimney. The built-in water circuit, which is integrated into the wiring of the house heating system, allowed to increase the efficiency of the heating equipment. That is, a fireplace with a water heating circuit heats the room both through the formation of IR waves, and according to the principle of a conventional boiler, heating the coolant in the radiators.

Equipment device

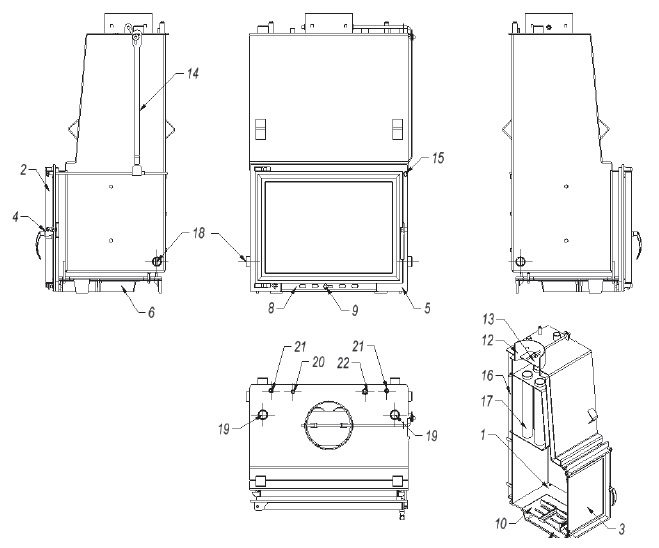

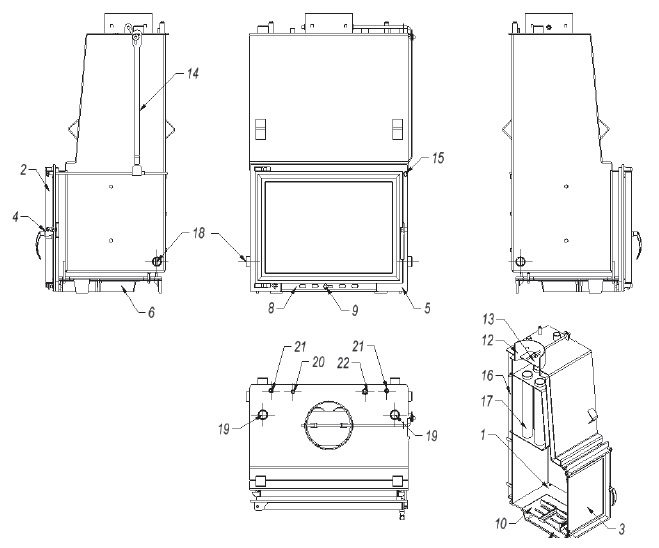

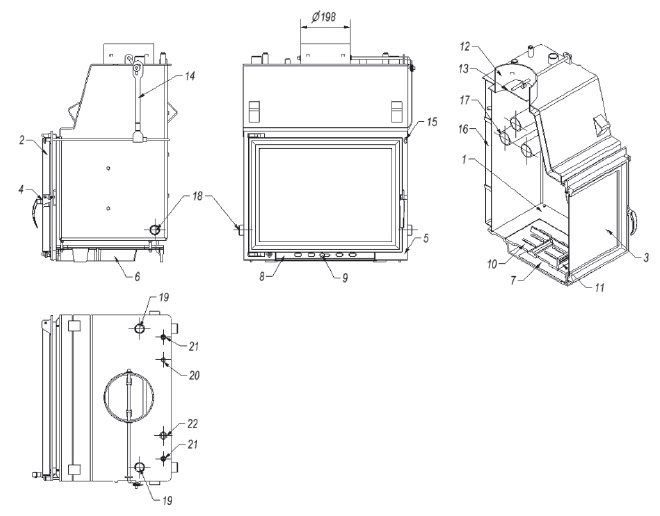

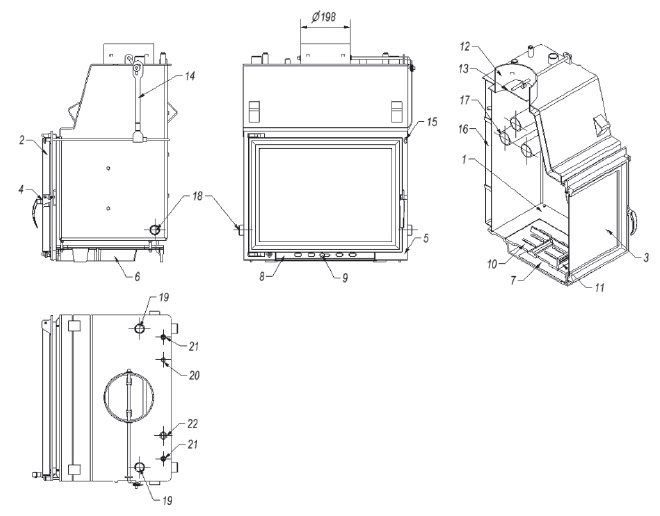

The heart of the fireplace is a steel casing (16). The combustion chamber (1) is mounted in it. The cast iron door (2) prevents heat from escaping from the combustion chamber. For this, it is equipped with a tempered glass (3) and a bolt (4). The combustion chamber casing (5) is connected to the frame using cast iron axles. The bottom of the furnace is made of heavy-plate cast iron (6). The grates are laid on top of it (10).

Fireplace complete set.

Today, a fireplace heating element can be bought on the market for similar equipment. However, some people want to make a DIY fireplace with water heating. To do this, you need to familiarize yourself with its device in more detail.

They also have an impressive thickness, since there is a direct oxidation reaction of the energy carrier. Gas fireplaces for heating do not have a grate, since ash does not form here, which should accumulate in the ash pan. The combustion chamber has a cast iron fence (11). It also serves as a decorative function, and acts as an additional protection against the fallout of burning fuel. The ash pan (7) at the bottom of the device is necessary to collect solid combustion products. It must be retractable without fail.

Components for a fireplace with a water heating circuit.

The regulation of the intensity of combustion of the energy carrier occurs due to the supply of primary air. The regulating function is performed by a window (8) in the ash pan and a manual choke (9). Secondary air necessary for the afterburning of gaseous combustion products of wood and solid particles, which rise along with the gas streams, enters through an opening in the tempered glass of the door.

A fireplace with a water heating circuit with their own hands is equipped with smoke tubes through which the smoke passes into the chimney (12). The obligatory attribute of the chimney is a regulating damper (13). The angle of its inclination is determined by a special mechanism (14). The supply of cold heat carrier from the heating circuit occurs through the lower branch pipes (18). The heated coolant leaves the fireplace through the upper nozzles (19). Branch pipes 20-22 are intended for installation of a coil, thermostat.

How to increase the efficiency of an open fireplace

When installing a fireplace with an open hearth, they strive to create a cozy atmosphere for communication and relaxation in the house. An open fireplace helps well with air exchange in the room and allows you to watch the fire in a comfortable environment. Subject to building codes, such a fireplace is quite safe in terms of fire safety.

However, it cannot be regarded as a heating device. The thermal efficiency of an open firebox does not exceed 15-20%. In addition, the absence of convective heating allows you to heat objects and parts of the interior directly adjacent to the fireplace - floor, walls, ceiling. A person can feel comfortable only in the immediate vicinity of the fireplace. If, over time, it becomes necessary to use a fireplace with an open firebox as a heating device, then it is necessary to carry out certain measures for its reconstruction.

In order to understand and accept the need to reconstruct an existing fireplace into an efficient heating device, you need to understand what an open firebox is and what processes occur inside the firebox when wood is burning.

An open firebox is a hearth consisting of a hearth on which the fuel is burning, walls framing the bottom from one, two or three sides and a smoke collector that catches the products of fuel combustion - flue gases and unburned fuel particles. Flue gases are discharged into the atmosphere through the chimney.

All elements of an open firebox are made of non-combustible materials - chamotte, cast iron or steel. Air from a room with a temperature of about 20 degrees Celsius enters the furnace without restriction. The amount of thermal energy that is released when burning wood in the firebox depends on how completely the logs decompose into the hydrocarbons that make up the wood and how completely the hydrocarbons react with oxygen - they are oxidized to carbon dioxide and water vapor.

Combustion is a chemical reaction that releases heat energy. The combustion process can be broken down into two main phases: pyrolysis and oxidation.

During pyrolysis, initial heating, wood decomposes into volatile compounds, consisting of hydrocarbon compounds, up to 99% of the original volume of wood, and into unreacted particles - coal and ash. The reaction takes place with the release of heat. In the combustion zone, the temperature rises to 600-650 degrees C. During pyrolysis, 10-15% of the theoretically contained thermal energy is released, 85-90% of the thermal energy contained in the wood is contained in the volatile hydrocarbon compounds released during pyrolysis. In order to obtain this energy, it is necessary that the molecules of hydrocarbon compounds (containing carbon, hydrogen, oxygen) decompose into simple compounds - carbon dioxide - CO2 and water vapor - H2O. For this, preheated air must be supplied to the upper zone of the furnace.

To start the oxidation reaction (combustion of gases), the temperature in the combustion zone must rise to 700-750 degrees.

The oxidation reaction takes place with the release of a large amount of heat. The temperature in the combustion zone rises to 1000 degrees. C.

It is impossible to achieve efficient combustion of wood in an open firebox.

.

Relatively cold air, which flows into the firebox from the room without restriction, greatly lowers the combustion temperature. As a result, all wood does not decompose during pyrolysis - except for ash, coals remain.

Due to the insufficiently high temperature in the upper part of the furnace, complete oxidation of volatile hydrocarbons in the upper part of the furnace does not occur.

Incomplete oxidation produces poisonous carbon monoxide CO and low-temperature water vapor H2O. Flue gases entering the chimney contain unburned wood particles - soot, ash, and have a low temperature of about 100 degrees. FROM,

Condensation is a consequence of the low flue gas temperature.

In the absence of proper insulation, the upper part of the chimney gradually

collapses. The efficiency of open fireboxes does not exceed 15-20% of the theoretically possible amount of thermal energy contained in the wood.

To convert an existing open firebox into an efficient heater, the following is required:

1. Achieve an increase in the temperature in the furnace, dosed and distribute heated air into the furnace: 25% of air in the lower part of the furnace for pyrolysis, 75% of air in the upper part of the furnace for oxidation of hydrocarbon compounds (secondary afterburning of gases).

2. Create convective flows in the room, transferring heated air from the firebox and directing cold air from the room to the firebox.

Since during combustion an open firebox consumes a huge amount of air, in order to prevent drafts in the room, it is advisable to supply air to the firebox from the outside.

These tasks can be optimally solved only by installing a convection cassette into an existing open firebox.

To prevent air from entering the room directly into the chimney, the space between the cassette and the open firebox must be insulated. When burning in a closed cassette, the temperature in the upper part of the furnace will rise to 700-750 degrees C. The secondary air passing between the walls of the furnace is heated, enters the upper part of the furnace and effectively oxidizes the hydrocarbon compounds released during pyrolysis. Through the pipes arranged in the structure of the cassette, the air in the room with the help of convective flows is efficiently and quickly warmed up.

When burning wood in a closed cassette, the temperature of the flue gases entering the chimney is 250-300 degrees. C, which prevents the formation of condensation.

Installing a closed cassette with convection channels in an open firebox allows you to increase the efficiency of the fireplace up to 60-70% and turn it into a fairly efficient heating device.

Back to the list Our current promotions

Sale. Fireplace stove Cotopaxi. (Romotop, Czech Republic)

Finnish stove installation

Fireplace project for free

How are fireplaces with air ducts arranged?

A fireplace with air heating is simpler in comparison with similar equipment, but with a water circuit. That is why making the first option in artisanal conditions is much easier than making a do-it-yourself fireplace with water heating. This explains the popularity of the air circuit in private houses. Such wiring acts as an excellent alternative way to heat a room when the main (gas or electric boiler) has ceased to function for some reason.

Air heating method.

Fireplaces for air heating of a house are similar in structure to their counterparts with a water circuit. The process of removing combustion products from the system is of interest.

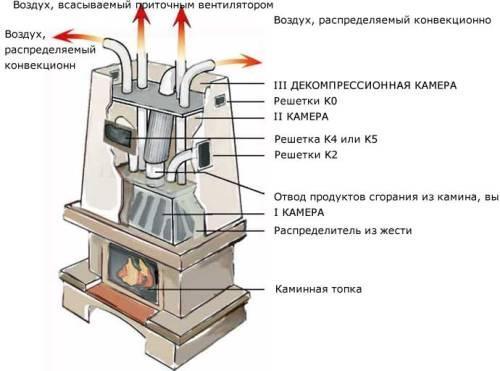

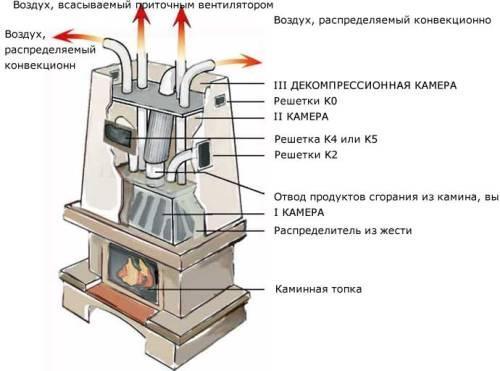

Chamber I. It is located under a metal convector.It is equipped with a fan that supplies hot air. The latter comes from the combustion zone. Chamber I is equipped with a series of pipes. They are mounted to the side walls of the fireplace chimney. These tubes end with valves. Such a device is necessary if the electricity is cut off and the supply ventilation stops working.

Camera II. Through it, cold air is drawn through the side grilles-fans of the outer shell of the fireplace. Cold air is heated by the metal body of the heating element and pipes through which the combustion products are removed. The chimney can be heated up to 700 ° C. It is in it that the final afterburning of the gas formed as a result of fuel combustion and solid particles occurs.

In order to significantly increase the heat exchange between the chimney and the cold air entering chamber II, the surface of the former is increased by means of ribbed hoops. Also, the chimney is equipped with a damper. With its help, it is possible to mechanically regulate the draft in the fireplace, and, consequently, the intensity of combustion. From chamber II, warm air is either evenly distributed in the space near the fireplace through special openings, or enters the air ducts, which diverge from the heating element throughout the house.

Any home-made device is inferior to factory equipment in terms of efficiency and efficiency. That is why you need to trust the manufacture of fireplaces to specialists who have the appropriate education and experience in this field.

Camera III. Decompression chamber. It is necessary so that heating by a fireplace with an air duct is safe. It plays the role of an insulating space between the ceiling of the house and the hot chimney.

Air-heated fireplace piping.

How does a fireplace work?

The principle of operation of a fireplace with air ducts is based on the correct supply of fresh air from the outside and the timely removal of combustion products.

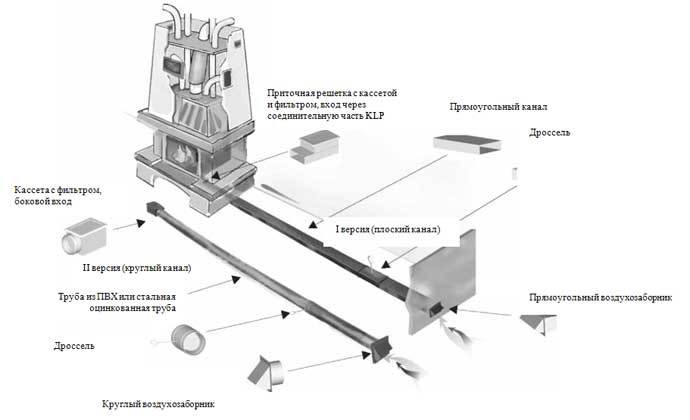

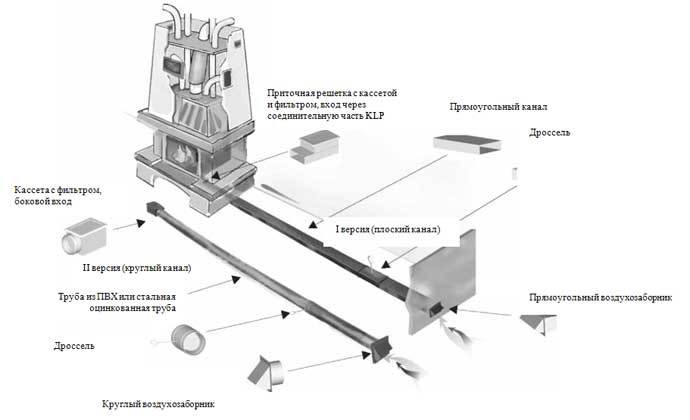

The air supply to the fireplace can be done in two ways:

- directly from the living quarters;

- using an air duct from outside the house.

The first method is easy to install. To do this, it is necessary to correctly calculate the area of the room where the fireplace is mounted, according to the power of its combustion chamber. So, for the combustion of 1 kg of wood, 8 cubic meters of air is needed. Based on this, it is easy to calculate that a heating element with an average power should be installed in a room with a cubic capacity of at least 30 cubic meters. Otherwise, unfavorable conditions for human life and even an emergency situation are created in the house.

The advantage of the second method is that there is no relationship between the power of the equipment and the cubic capacity of the room where it is installed. In this case, combustion air is taken from the street. For this, round or rectangular air ducts made of galvanized steel or PVC material are laid under the floor in the house to the fireplace. At the end of the pipe facing the street, there should be a grill. It protects the air duct from rodents and insects. Filters are also important in this case. They are designed to clean the supplied air from dust. They are installed in the valve directly in front of the fireplace.

Which is better: a fireplace with a water circuit or with air ducts?

This question cannot be answered unequivocally. The advantages and disadvantages of both systems come from the characteristics of the heated room, the desired temperature regime in the rooms.

Heating fireplaces with a water circuit have the following advantages:

- efficiency;

- low cost;

- the contour of the fireplace can be easily integrated into the existing heating system of the house;

- the possibility of preparing hot water;

- low cost of equipment;

- low price of energy carrier.

A heating fireplace with a water circuit has disadvantages:

- low efficiency;

- the need for constant loading of the energy carrier;

- manual mechanism for adjusting the intensity of work.

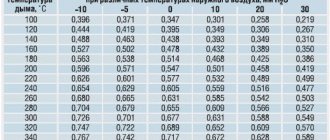

If we compare fireplaces with open and closed combustion chambers, then the efficiency of the first is 20%, and the second is 70%.

A fireplace with air heating with your own hands is the easiest to make, because the equipment is not distinguished by a complex device. The very layout of the air ducts is also easy to organize. The room temperature is reached within a few minutes.

Disadvantages of a fireplace heating system with air ducts:

- constant circulation of dust in the house due to the operation of fans (in the case of forced air circulation);

- increased noise level due to air movement along the air ducts;

- the temperature in the room drops as quickly as it rose after the extinction of the fireplace;

- low efficiency;

- the need for manual control of the combustion reaction;

- the need for constant loading of the energy carrier into the furnace.

Heating a house with a fireplace with a water circuit and air ducts can be an excellent alternative source of heat, but not the main one. Such heating elements run on an inexpensive energy source. But fireplaces can be afforded by those people who are not too lazy to constantly throw firewood into the firebox, control the intensity of their combustion and periodically clean the chimneys.

Efficiency of fireplace stoves

Some introductory information about the efficiency of fireplace stoves:

- The efficiency, even under ideal conditions in a testing laboratory, is variable and depends on the intensity of combustion.

- The highest efficiency (up to 90%) is for long-burning fireplaces with secondary afterburning. In such models, the fuel burns out completely, forming a minimum of ash, plus heat is released during the combustion of pyrolysis gases, which in other fireplaces literally fly into the chimney.

- The efficiency decreases if the fireplace stove is more powerful or, on the contrary, weaker than necessary for heating rooms of a given volume. In the first case, the house will be stuffy, you will have to ventilate, i.e. energy is wasted. In the second, the warm air generated by the stove will cool down quickly, and more wood will be needed to reach a comfortable temperature.

Speaking of increasing efficiency, it is correct to consider not a single fireplace stove, but the entire heating system, which also includes chimneys and heat pipes.

The conditions for the efficient operation of heating equipment are laid down at the installation stage. In particular, it is important to correctly design the chimney in order to achieve optimal draft (with excess fuel consumption increases, with insufficient smoke goes into the room), and insulate the channels.

In addition, the efficiency will be higher if:

- choose a place for a fireplace stove, taking into account the direction of air circulation;

- reduce heat loss in the room - close up cracks, insulate floors and walls;

- make air ducts for forced heat distribution;

- use special heat storage inserts for the combustion chamber or external blocks (popular brands Hoxter, Romotop).

You can also influence the efficiency during the operation of the equipment.

Typical diagrams for connecting a fireplace to a heating system

Gravitational convection.

To maximize the efficiency of the fireplace and efficiently distribute the heat generated in its combustion chamber throughout the house, it is necessary to integrate the fireplace into the heating circuit of the house (in the case of a fireplace in a water shirt). Fireplaces with air ducts require a special development of the heating elements.

The scheme of air heating by a fireplace depends on the area of the served area. So, gravitational wiring is suitable if the area of the room that needs heating is very small. The length of the air ducts should not exceed 3 m in length. In this case, the air heated by the fireplace will rise through the channels, displacing cold air at the ends of the pipes.

Forced convection.

This circuit is completely non-volatile, easy to design, install and use. Requirements for its installation: the length of the air ducts should not exceed 5 m, the pipe itself should be flat with a minimum number of turns. The material of construction for the pipes should be refractory aluminum capable of withstanding a temperature of 250 ° C. Thermal insulation of the duct body is required.

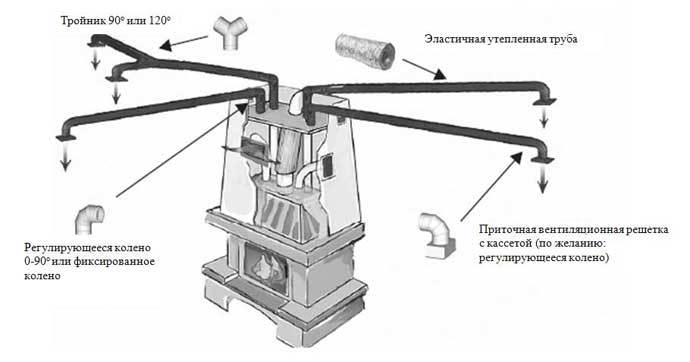

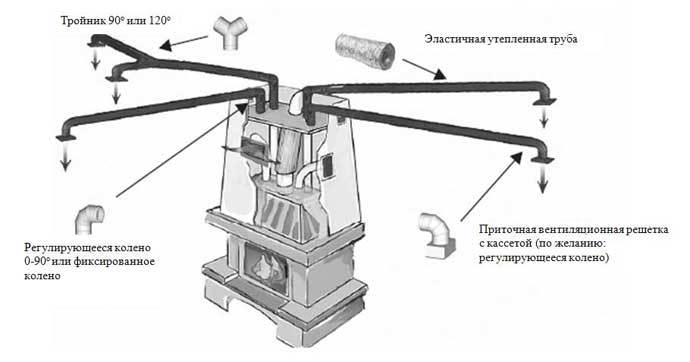

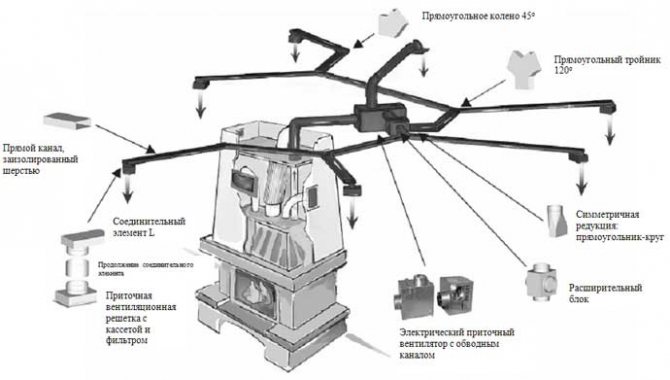

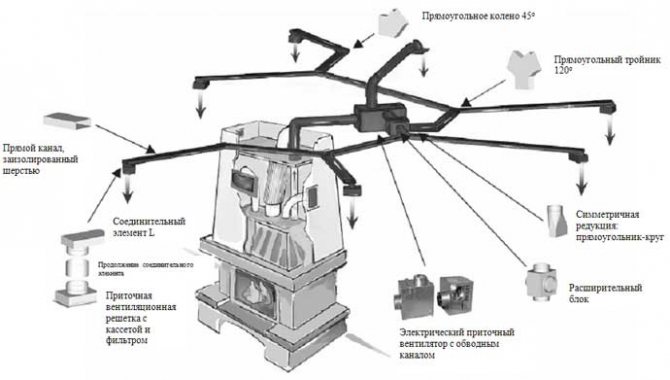

The contour with forced air movement, although it is more expensive in execution, compared to the gravitational analogue, it allows you to heat a large area of the room. At the same time, the complex layout of the house will not affect the efficiency of the system. In addition to air ducts, this circuit is completed with elements of supply ventilation (as the main driving mechanism of warm air), connecting nodes and corners, all kinds of elements for controlling directed air flows.

Application in the interior

The most interesting ideas are presented below:

Living room.

You can decorate the radiator with a decorative false fireplace, a special plasterboard box. It all depends on the imagination, style direction of the interior.

Kitchen.

You can cover the heating element with a special screen, which is consistent with the overall concept of the interior. If desired, it can simply be painted in a contrasting color.

Bedroom.

A decorative grille, screen or false fireplace will fit here. You can paint the batteries with an interesting ornament or use the decoupage technique.

Children's.

An interesting option would be decoupage decoration. The child really likes to look at beautiful modular pictures.

If you liked the video - share with your friends:

It will also come in handy for repairs:

- Houseplant smells like mint

- Lighting in the living room dining room

- What does smartphone firmware mean?

Is the use of fireplaces in the home effective?

Any fireplace is, first of all, a decorative element of the interior, which, thanks to modern developments, is able to effectively participate in heating the premises. So, heating a house with a fireplace with an air duct has a simple structure and an equally simple principle of operation, and therefore it is inexpensive. However, the low efficiency of the circuit sometimes casts doubt on the entire expediency of erecting such a structure.

The principle of operation of a fireplace with a water circuit, as well as the structure of the heating element itself, is more complicated than the previous version, which explains the high cost of both equipment and installation work. However, the efficiency of 70% of fireplaces with a water circuit makes this equipment an excellent alternative source of heat in the house when the main heating element (boiler) is turned off. How to properly install a fireplace with a water circuit will help you understand the video:

P.S. And remember, just by changing your consumption - together we are changing the world! © econet

Diy heat-storing fireplace - video

The process of making a heat storage fireplace

© Author: Vladimir Grigoriev

TOOL FOR MASTERS AND MASTERS, AND HOUSEHOLD GOODS VERY CHEAP. FREE SHIPPING. THERE ARE REVIEWS.

Below are other entries on the topic "How to do it yourself - a householder!"

- How to make an inexpensive fireplace with your own hands Building a small fireplace with your own hands Ok ...

- Classic "British" style fireplace - photos and masonry orders Classic style fireplace with ...

- Do-it-yourself fan heater for a stove - photo and diagram How to equip a brick stove with a fan heater ...

- Choosing a place for a fireplace Where is it better to build a fireplace About the fireplace ...

- Do-it-yourself biofireplace How to make a biofireplace (fireplace on ...

- What kind of fireplace to build architect's advice and drawings Building a fireplace in the house: drawings ...

- Combined stove - both fireplace and heating: DIY masonry Double-circuit heating stove and fireplace ...

Subscribe to updates in our groups and share.

Let's be friends!

With your own hands ›Stoves, fireplaces, barbecue› To keep the fireplace warm and stay warm longer ...