In the "Window Factory" we care about the comfort of our customers, therefore we are always ready to offer new developments that help to make the house more comfortable, safer and warmer. One of these technologies is the use of special double-glazed windows, which are much stronger than others, perform heat and sun protection functions, can be integrated with the “Smart Home” system, and much more.

Are you already intrigued? Let's tell you more about this unique material.

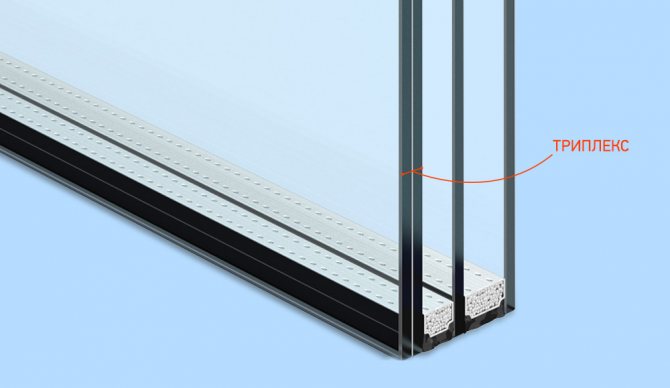

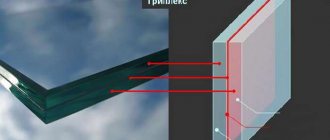

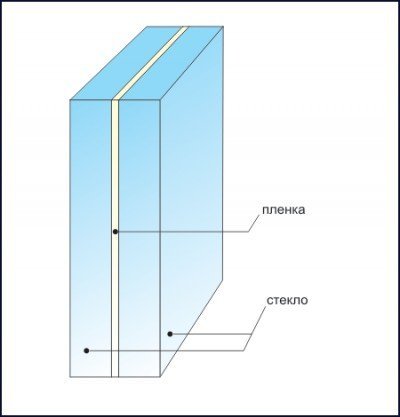

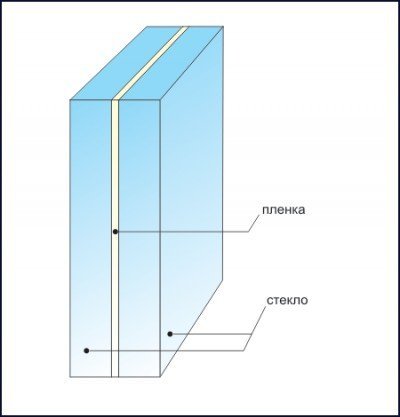

It's about triplex. It consists of two or more layers (heat treated glass sheets + special bonding layer). The special structure increases the strength, flexibility and safety of the glass surface.

Upon impact, the glass sheet does not break into small fragments. Fragments of glass remain on the surface of the adhesive film.

The thickness is up to 40 millimeters - this value does not affect the light transmittance of the surface.

The advantages of this material:

- Safety - safety glass.

- High impact resistance - withstands increased loads, shocks, pressure.

- Heat resistance - not afraid of sudden temperature changes.

- Light transmission - the material transmits daylight well.

- Sound insulation - a single-chamber double-glazed window increases the sound insulation inside the room by 4 dB.

In laminated glass, it is possible to use an additional decorative layer: inserts made of fabric, natural rattan, bamboo, multi-colored film in the form of drawings, patterns. This solution is used in the design of shop windows, partitions in office and retail premises.

Content

- 1. Differences between triplex and tempered glass

- 2. How laminated glass and tempered glass are made. Key features of materials 2.1. Strained glass

- 2.2. Triplex

- 3.1. Durability and safety

Advantages of using triplex doors

The high aesthetics of triplex allows it to be used in luxurious interiors, in combination with expensive furniture and appliances. Budget options are available to all buyers with good taste.

If glass is not usually installed in the interior doors, but triplex, they can be safely installed in the children's room. The child will be able to play freely with the ball, hitting it against the door and not causing any harm to them. If a strong directional blow with a hammer is inflicted on the triplex, you do not have to collect sharp fragments scattered throughout the rooms. They will remain on the adhesive.

Changes in temperature and humidity will not in any way affect the properties of the triplex and will not lead to premature wear, so this is an excellent option for use in a bathroom or sauna. Glass surfaces are not difficult to clean from grease, tea, coffee, juice stains, so they serve to delimit the kitchen and living area.

Possessing increased soundproofing capabilities, interior doors with triplex glass will become reliable protection against the penetration of extraneous sounds into the personal space of the bedroom.

Due to the strength of the materials and the ability to withstand significant static and dynamic loads, the triplex door structure demonstrates high reliability and long service life even under conditions of daily intensive use.

How laminated glass and tempered glass are made. Key material features

Tempered glass and triplex are made using different technologies.

Strained glass

Tempered glasses are made from ordinary sheets. They are placed in an oven and heated to a temperature of 650–680 ° C. After that, the sheets are evenly and quickly cooled with air on both sides.Sudden changes in temperature lead to mechanical compressive stress. As a result, the sheets acquire increased strength and heat resistance.

The main features of tempered glass are:

- perfectly straight edges of the sheets;

- excellent light transmission;

- the possibility of decoration (using ceramic printing and sandblasting drawings).

Note! Hole drilling and other types of machining are performed prior to hardening. If you do this later, the material will collapse.

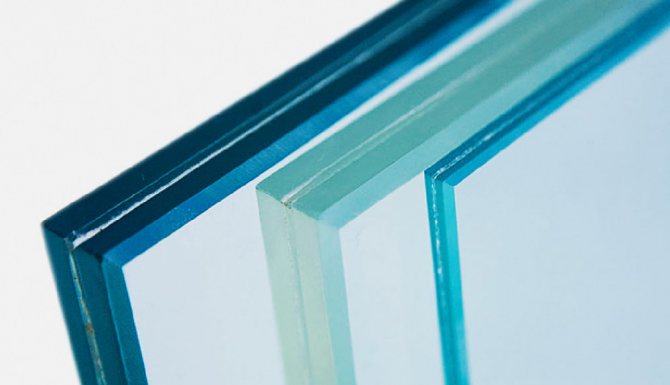

Photo # 1: tempered glass

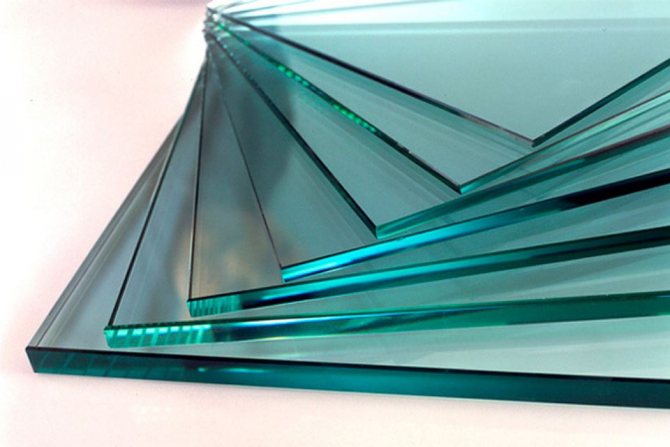

Triplex

Triplex glass is made by gluing several sheets. Moreover, they can be both raw and seasoned. When using the latter, technical and operational characteristics are increased to the maximum level.

Image # 1: triplex structure

Specifically, triplex is made by gluing two sheets. For the connection, a polyvinyl butyral film or a polyvinyl butyral composition is used. The technology is different.

- In the first case, the polyvinyl butyral film is placed between the sheets and sent under the press. Then the glasses are placed in an oven. There, at a temperature of 150 ° C, the film melts and reliably glues the sheets.

- In the second case, the surfaces to be joined are treated with a polyvinyl butyral compound and applied to each other. Bonding takes place under the influence of ultraviolet radiation. The composition polymerizes and reliably holds the glass together.

Let's list the main features of the triplex.

- During production, various materials can be inserted between the glasses (fabric, lace mesh, colored film, etc.). Triplex is ideal for decoration.

- There are production technologies in which material with variable transparency is obtained.

- Triplex can be processed mechanically after manufacture.

The only negative is the uneven edges. To eliminate this disadvantage, polishing is used.

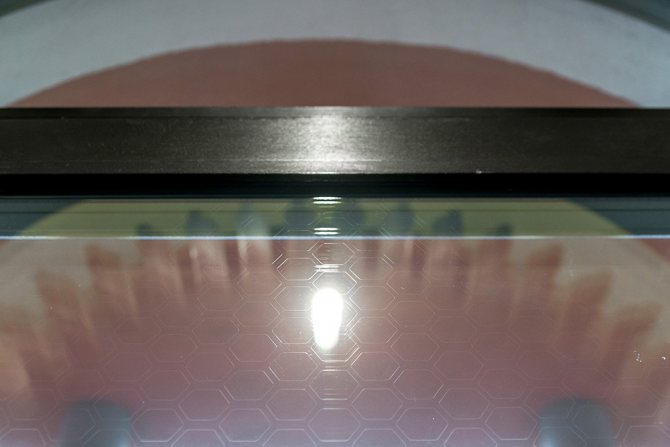

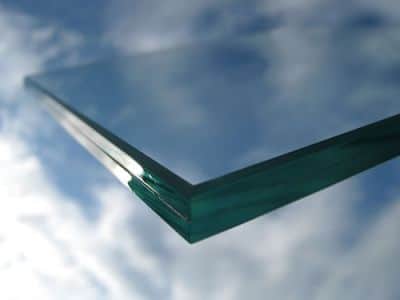

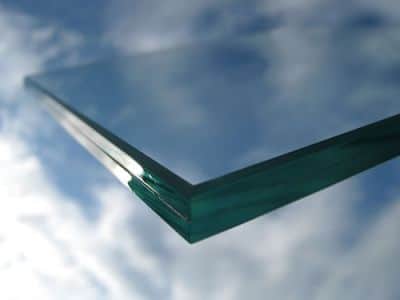

Photo # 2: triplex

As you can see, laminated glass from tempered glass is easy to distinguish visually.

The history of the emergence of technology

Even at the dawn of the automotive era, at the very beginning of the 20th century, chemist Benedictus conducted his experiments and accidentally dropped a flask filled with reagents. Despite the fact that the vessel was glass, it did not break, but only became covered with small cracks.

Having understood the reasons, the scientist came to the conclusion that safety glass is the best option for the automotive industry. After a series of additional experiments, a technology for the production of laminated glass for installation in cars was created and patented.

If earlier drivers and passengers were injured by fragments of windshield and side windows at the slightest accidents, then with the advent of triplex this problem has practically disappeared.

Differences between triplex and tempered glass in terms of operational and technical characteristics

Let's compare triplex and tempered glass in terms of strength, safety, heat resistance, sound insulation and light transmission.

Durability and safety

Tempered glasses are 5-6 times stronger than their raw counterparts. With very strong blows, the hardened sheets break. In this case, a crumb is formed with non-sharp edges on which it is impossible to cut. At the same time, there are about 180 non-hazardous fragments per 1 m2 of glass. This is in line with safety standards.

Photo # 3: Broken Tempered Glass

The strength of the triplex depends on the type of glued sheets. The material, consisting of raw glass, withstands impacts much better than conventional counterparts.

When using hardened sheets, the strength increases many times over. Shockproof and armored double-glazed windows are made from such a triplex. Material with a thickness of 13 mm or more is considered bulletproof.A bullet from a Makarov pistol (9 mm) will not pass through such glass.

In this case, the triplex, if damaged, does not crumble into fragments. They are securely held by means of a film or a special compound.

Photo # 4: damaged triplex

Heat resistance

Good tempered glass can withstand high temperatures better. Sheets do not deform when heated up to 300 ° C.

Triplex is less resistant to high temperatures. It will withstand temperatures up to 180 ° C. This is due to the fact that as the temperature rises, the interlayer deforms.

Soundproofing

Triplex is the undisputed leader. If the choice of material is mainly influenced by this characteristic, then it is worth buying triplex, and not tempered glass. The multi-layer package will guarantee maximum sound insulation.

Light transmission

The light transmission is higher for simple tempered glass. Triplex transmits the sun's rays worse due to the presence of an intermediate polyvinyl butyral layer.

Solutions from designers

In the interior design of a private house, office, administrative or public building, you can use the design triplex. Such glass transmits light well, provides thermal insulation and sound insulation, has high aesthetic properties, and is safe.

Types of designer glass:

- One of the surfaces has a decorative layer. The decor is textured fabrics, metal nets (chrome, silver, gold and brass, painted), leaves of plants, flowers, wicker rattan.

- With drawing. Geometric ornaments, drawings, logos are applied to the glass surface using sandblasting, film.

- With a textured surface. Not only glass with a perfectly smooth surface is available to order. Designers offer products with a wavy surface, embossed patterns.

On our website you can find triplex glass partitions of various types: all-glass, sliding, with images, colored or matte, which are suitable for zoning any premises.

Areas of application of tempered glass and laminated glass

Tempered glass is best suited for residential or standard applications. Showers, office partitions, stairs, windows, interior items, etc. are made of hot-tempered sheets.

The main field of application of the triplex is industry. This material is used to make glass for cars, trains, aircraft and equipment for special services. In these cases, the use of multi-layer impact-resistant glass units fully justifies itself.

Another specialized area of application of the triplex is the manufacture of bulletproof windows, partitions, doors, etc. The installation of such structures is relevant for objects with increased safety requirements.

Triplex is also used in everyday life and under standard conditions, but much less often. If there is free money, no one forbids spending it on making more beautiful and durable products.

Why you can be sure of the safety of triplex doors

Requirements for laminated glass are established by GOST 30826-2014. The technological process of triplex production includes a stage-by-stage quality control, including the use of special devices. The finished material undergoes a series of tests, during which it is checked for its ability to withstand mechanical and thermal shocks, transmit light, be resistant to a humid environment, etc.

Such a strict approach is explained by the need to protect human life and health, to ensure the safety of material assets. The state standard regulates the properties of all types of multilayer glasses that are used for installation in translucent building structures with increased operational properties, including door and window blocks, trade showcases, and the like.

Self-production

It is possible to create laminated triplex glass at home

... This does not require a lot of time and effort, but there are conditions that must be met.

Note!

It is required to make a binder component only after the glasses are fully prepared.

To do this, the required amount of substance is calculated based on the fact that to create a layer with a thickness of 1 mm on an area of 1 m2 is required 1 liter of liquid.

The process itself, how to make a multi-layer product at home, is as follows:

- First, the sheets of glass need to be cut into the desired uniform size.

- The surfaces of the material should be thoroughly cleaned chemical reagents

, rinse with water and dry with napkins. In this case, not even lint should remain. - Mounting tape is glued over the entire surface, and a slight gap is created in the corners so that air escapes when pouring liquid.

- Further, the protective film is removed from the installed polyurethane foam, except for the future place of installation of the watering can, where the edges are pulled behind the glass.

- The next sheet of glass is stacked on top and gently nestles

to the previous one along the perimeter. - A watering can is inserted with a thin spout in the established place, where the protective film is removed.

- A wooden block is placed on the work surface, on which glass must be placed at an angle. Using a watering can, a liquid adhesive is poured into the cavity. Important exclude breaks

to prevent the formation of air bubbles. - Upon completion of filling, all corners are sealed with plastic, which will prevent the solution from flowing out, and the watering can is removed and the last hole is closed.

- Further along the entire perimeter, the upper glass must be pressed, especially for the corners. It is important that the products are on a horizontal surface so that the solution evenly distributed

on the inner space. So it is left until it hardens completely. - The process is repeated until the required number of layers is created.

Triplex is a laminated glass with increased strength. There are several types of such products, differing in the type of the bonding layer of the component. But its negative side is the high cost and difficulty of maintenance.

Characteristics

All technical characteristics are defined in the current GOST 30826-2001. Triplex has increased flexibility,

in comparison with classical glasses, due to its layered structure.

The thickness of the products starts from 6 mm, moreover, that already 13 mm is a class of bulletproof glasses that are installed on armored vehicles.

Another feature is the high soundproofing characteristics, which determines the technology for the manufacture of triplex.

But there are also negative sides that this material possesses - it is high cost and complexity of processing

, for which it is necessary to attract professionals.

Summing up

Triplex is a modern impact-resistant glass, which is simply unmatched today. Resistance to shock, penetration of ultraviolet rays - what has expanded the scope of its use. Today, triplex has ceased to be a luxury; you can buy it in almost any hardware store at an affordable cost. Pay special attention to this material, for sure its numerous advantages and relatively low cost will make a special impression.