What if there is nowhere to throw the trash out? Take, for example, a summer cottage or a house in a village. There are no waste bins within a radius of several or even tens of kilometers. How to be? Leave it in place or throw it in a ditch on the way home? Observing a similar picture in the suburbs, we are indignant in our souls.

There is a way out: some of the waste can be burned. But it is dangerous to do this on an open fire. It is better to use a dedicated garbage oven. Various models of Russian and foreign production are sold on the market. It is easy to make a stove, having the materials at hand and skill.

Installation and operation of a waste incinerator

The waste incinerator is installed according to the rules or its own calculated drawings. If the item is from a store, it is better to entrust the installation and adjustment to the service department.

Additional permission for the installation of a household structure at a summer cottage is not required, but no one cancels the instructions and operating rules.

Working with a flame requires caution, because the safety of life, home and the prevention of harm to the environment is more important than the benefits that household incinerators provide.

Correct use and cleaning of the oven

Fire up the unit for the first time with the slide gate open: put a rapidly burning solid fuel on the grate and set it on fire. After burning out, add more logs, close the door and flap, and use the blower to adjust the power. It is worth remembering that the gate has a cut that does not allow blocking the chimney.

It is not necessary to clean long burning stoves often: the fuel burns out completely, and soot in the chimney is formed in small quantities.

Do-it-yourself regular repair of a pyrolysis oven presupposes timely troubleshooting. If the firebox door is deformed, this element should be corrected or replaced. If the structure diverges along the seam, then it is important to stop operation and urgently eliminate the cracks.

A stove of this type is easy to do with your own hands, but the design must be created with great accuracy, using ready-made drawings or developing them yourself. The heating system requires the use of quality materials and care in manufacturing and assembly. Only in this case will the pyrolysis oven be safe to use and effective.

legkovmeste.ru

General advantages and disadvantages

Let's take a look at the advantages and disadvantages of self-incineration in the country.

| Benefits | disadvantages |

| Disposal of solid waste where collection is not organized. | Not all household waste is safe and incinerable. |

| Recycling in an environmentally friendly way. | Strict adherence to fire safety requirements and standards is sometimes difficult. |

| The resulting ash is useful for fertilizing the backyard. | The price for purchased installations starts from fifteen thousand. |

| Receiving additional heat sources for heating water, heating, cooking. | Impossibility of incineration of liquid waste. |

| Extending the life of old things: pipes, barrels, fuel boilers, etc. | The damage caused by the incinerated waste to the atmosphere will have to be reduced by filtering the smoke. |

| Profitability in handicraft production. | Low efficiency. |

The plasma waste incinerator is fast and environmentally friendly. At the same time, at the output, electricity is obtained in an amount sufficient to supply energy to enterprises, recycled products - slags, which are used, for example, in construction.

We advise you to read: Waste shredder in the kitchen sink: the choice of a disposer

Unlike standard incinerators, plasma processing does not emit carbon dioxide or toxic substances into the atmosphere.

Advantages and disadvantages of this design

Any oven, regardless of whether it is pyrolysis or a potbelly stove, has a number of advantages and disadvantages.

Advantages of a pyrolysis oven:

- there is almost complete combustion of fuel, which burns for a long time, due to which high efficiency is achieved;

- very few harmful substances are released into the air after combustion: it is mainly steam and a little CO, therefore it is environmentally friendly;

- high efficiency, which reaches 85%, and if the Lachinyan pyrolysis oven is installed, then up to 95%;

- it is possible to regulate the combustion process, while the furnace can operate from 5 to 100% of its power;

- it is possible to connect a heating circuit, which can be both natural and forced circulation; in this case, Lachinyan's pyrolysis stove will be able to heat not one room, but the whole house, and you can also take water for household needs;

- it is possible to use various types of fuel: a pyrolysis stove can operate on both solid and liquid fuels;

- It works in automatic mode, the presence of a person is only necessary for loading fuel, which, depending on the model, is carried out approximately once a day, and the unloading of ash once every 5-7 days.

But do not think that such a design has only advantages. She also has her drawbacks:

- large enough sizes, especially if you want to make such a brick oven;

- it is necessary to provide a place for storing firewood, it must be protected from precipitation, since only dry firewood is needed;

- there is still a slight odor during incineration of garbage, therefore, a high-quality and efficient ventilation system must be installed in the room;

- to increase the efficiency of the pyrolysis stove, it is necessary to install a fan, and if there is a water circuit, then a pump, and this requires an electrical network;

- as the temperature of the smoke is low enough, condensate accumulates in the chimney. To collect it in the chimney, it is necessary to make a storage device. The chimney cross-section must be large, and it must be insulated.

Safety regulations

When working with an incinerator, adhere to safety rules, as this is a fire hazardous facility. It should not be located near flammable objects. Do not store flammable materials, dry grass, wood or planks, trees nearby. An accidental spark has dire consequences.

The waste-incineration boiler is not placed closer than 50 meters from residential, utility, and other buildings. The proximity of power lines, gas pipelines, other networks and communications is taken into account. For violation of this requirement, there is even an administrative fine of thousands of rubles.

Children, animals must not be allowed near the burning fire, and they must not be left unattended. Place extinguishing media in the immediate vicinity: water, sand, fire extinguisher.

What can't be burned?

Only organic waste is subject to incineration. This is garden waste - branches, grass, leaves, etc. It is allowed to burn paper, cardboard, and unusable wooden objects.

When burning, materials made of plastic, polymers, synthetics emit toxic substances that are harmful to human health and the ecology of the environment.

Cannot be burned:

- Painted parts.

- Full-color glossy printing with ink content.

- Chipboards, fibrous boards, which used glue and phenols.

Not every oven is suitable for burning paper. It is dangerous to throw aerosol cans, glass, metal objects into fire. Even empty, but under pressure, can explode in fire.

Ready-made incinerators

Waste incinerators in their simplest design are similar to an ordinary metal barrel. The upgraded structures are equipped with a chimney, a blower, a tank for fuel intake, filters and other useful functions. Up to water heating or heating. Many parameters of a purchased oven depend on the capabilities of the owner's wallet.

A garbage incinerator is an incinerator with a chimney. The larger the combustion chamber, the faster disposal will take place, and a reliable chimney will save the owners and neighbors from unpleasant annoying smoke.

Waste incinerator - a complex for the destruction of solid waste

An incinerator, or incinerator, helps to quickly, easily get rid of household waste. Such ovens are in demand among summer residents and villagers.

It is more difficult in the design and operation of an installation for the incineration of hazardous and hazardous waste: medical preparations and used equipment, animal corpses, chemical products.

We advise you to read: The procedure for classifying products as primary processing products

The difference between pyrolysis furnaces for burning garbage is that the combustion takes a long time. The principle is based on reducing the oxygen content required to maintain a flame. Therefore, the fuel does not burn, but smolders slowly, releasing pyrolysis gas. Hence their second name is a smokeless waste incinerator.

In the second cycle of operation of such a smokeless furnace, oxygen is already added to completely burn out the fuel.

Long burning stoves: why do they heat better and longer?

There is a well-known phrase - "fly into the pipe." It is often used figuratively, denoting a deplorable financial situation, but in the case of fireplaces and stoves, this phrase is used in the most literal sense. Indeed, with a relatively simple design of the device and an open valve, heat really flies out very quickly into the pipe. Therefore, many manufacturers are trying to reduce heat losses and add an exhaust gas afterburner to the design, which turns a conventional device into a long-burning furnace.

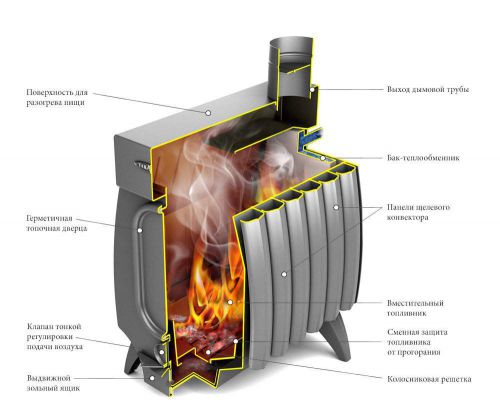

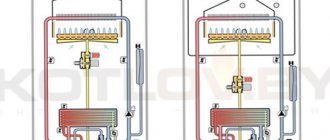

Long-burning stoves - efficient, compact and relatively inexpensive - have enjoyed well-deserved popularity for many years. Unlike conventional devices, such devices have two chambers. One of them, the lower one, works like a firebox in an ordinary fireplace. After the wood burns in it for 10-20 minutes, the air flow is reduced to a minimum by closing special technological openings, and the flue gases enter the second, upper chamber. There they are burned out, having received an additional portion of oxygen from the outside, which is supplied through special injectors.

In fact, firewood does not burn, but smolders. But, oddly enough, the efficiency of long-burning furnaces is much higher than that of conventional ones. The fact is that with a lack of oxygen, the fuel is almost completely converted into flue gas (a mixture of methane, hydrogen, carbon monoxide, etc.), and when burned, it gives a lot of thermal energy.

The efficiency of a long-burning furnace is on average 70-80%. For fireplaces with an open firebox, this indicator does not exceed 10-15%

Bullerjan furnace design with afterburner

As you might guess, the described devices smoke weakly, and ash accumulates in them slowly. But in fairness, it should be noted that economical combustion has its drawbacks. Completely exhausted and almost cooled smoke enters the chimney. And if the pipe is not properly insulated, condensation will accumulate on its walls, flowing into the afterburner. In addition, it is fraught with a weakening of traction.

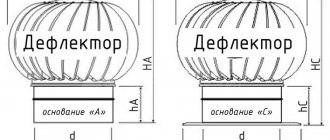

However, it is worth talking about the chimney device in more detail. A long burning stove can be connected to both a traditional brick and modular ceramic chimney. But it will be easier and cheaper to mount the so-called "sandwich" - steel pipes nested into each other with a heat-insulating layer of stone wool.In any case, the pipe must have a height of at least 6 m. This is important for good traction. It is desirable that the chimney is perfectly straight. Doing knees is not recommended. But if you cannot do without them, it is important to ensure that the bending angle does not exceed 45º.

Long burning ovens must not be operated with fully open dampers. They are not designed for such an operating mode.

But back to the furnace design. To increase the heating effect, manufacturers supply their devices with various heat exchangers (air heaters). There are many options. For example, it can be a system of convective pipes in contact with the firebox. From below, cold air enters them through special holes, and well-heated air comes out from above.

Oven design with slotted convector

In some models, an additional metal casing plays the role of a heat exchanger. A layer of warm air forms under this "jacket", which increases the efficiency of the furnace. There are also devices with a water circuit.

Depending on the efficiency of the heat exchanger in furnaces with the same combustion chambers, the heating rate of the room can vary by 1.5-2 times. Determining how good a particular design is is quite simple. The larger the area of the heater, the higher the heating effect.

Of course, the air heater is not the only thing that you need to pay attention to when choosing a stove. The models differ in power (from 4 to 50 kW), on which the volume of the heated room directly depends. This point should be checked with the manufacturer or seller. However, even the "weakest" model is able to heat a room with an area of about 20 m².

The burning time from one firewood bookmark also matters. For different devices, this indicator fluctuates, depending on the size and design of the furnace, from 5 to 15 hours. But the double-digit numbers should be treated with a reasonable degree of skepticism. Achieving such high performance is extremely difficult, and sometimes impossible. A bookmark in a medium-sized oven burns out in 5-7 hours. In any case, before buying a specific model, it is worth reading consumer reviews. Their testimony will be much closer to the truth.

Prices for long-burning furnaces of domestic production vary within 7,000-15,000 rubles, the cost of imported cast-iron furnaces with an afterburner is 120,000-200,000 rubles.

As for the operation, it is extremely important to use only the type of fuel for which the specific model is designed. There are ovens that use wood, pellets and coal. And if the description says "to heat with brown coal", black coal cannot be laid. It gives too much heat, and the walls of the chamber, which are not designed for such a load, will burn through and through.

At the end of the topic, we will answer a logical question that the reader may have. If the high efficiency of the described stoves is ensured by the fact that the wood does not burn, but smolders, what prevents the fire from “shutting off oxygen” in a simple fireplace with a closed firebox? Unfortunately, this technique will not work, since a conventional fireplace does not have an afterburner. Flue gas that could be used will at best "fly into the chimney", and at worst - seep into the room.

Homemade constructions

The zealous owners make a garden oven for burning garbage with their own hands in their personal plots. A metal barrel or a large diameter piece of iron pipe will do.

For the base according to the size of the bottom of the future furnace, a recess is dug in the ground, approximately on the bayonet of a shovel. It is lined with bricks around the perimeter, a firebox is installed on them. Holes are drilled at the bottom for blowing. It is good if the homemade stove is equipped with a door for adding fuel and collecting the remaining ash.

A lid with a built-in chimney will come in handy. Features, appearance, practicality of such a homemade design depend on the skills of the master, materials and tools.

Metal barrel

It is easier to make a garden waste stove from a two-hundred-liter metal barrel. The thicker its walls, the longer it will serve. For the same reason, it is important that it does not rust.

Old heater

An old sauna stove will serve as a garbage stove in the country. If you love giving things a second life rather than throwing them away, this option is fine.

Criterias of choice

If desired, it will be easy to choose a ready-made model, the parameters of which meet the requirements, but often home craftsmen, carried away by the ideas of the inventors, make pyrolysis ovens with their own hands. When choosing an option for a gas generator set, a number of points are taken into account:

- the purpose of the pyrolysis unit. For heating a barn, chicken coop, garage or other technical premises, a relatively compact metal or brick structure is chosen. To heat a house, the priority is to build a long-burning brick oven. For tourism purposes, choose a portable type camping pyrolysis oven,

- device power. Depending on the parameters of the heated object, the required power of the gas generator is determined,

- design mobility. The brick pyrolysis oven is stationary, the device is erected at a permanent place of operation. Almost all types of metal gas generators are mobile.

For tourism purposes, choose a portable type camping pyrolysis oven.

For the high-quality operation of a pyrolysis oven, solid fuel of a certain moisture content is required, the reserves of which are stored in a utility room.