Varieties of solid fuel boilers

As you know, one of the main properties of a heating boiler for a summer residence, which must be taken into account when choosing a particular model, is the efficiency of work (in more detail: "How and which solid fuel boiler to choose: selection and comparison"). This parameter directly depends on what type of solid fuel boiler is planned to be operated, since the fuel burns out in completely different ways in different designs. Therefore, it is necessary to dwell in more detail on the types of TTK.

Wood-fired boiler

A wood-fired summer cottage boiler is the best option for installing a heating system in your country house.

When choosing a boiler for a summer residence, the following aspects should be considered:

- At what speed the boiler consumes fuel material;

- Is it possible in the future to connect a DHW system to this boiler;

- At what speed the selected model heats up a separate room and the entire area of the house;

- Is it convenient to operate this equipment in a country residence?

Solid fuel boilers for long and direct combustion

- In mechanisms operating by means of direct combustion, the process of heat transfer occurs during the combustion of the consumable, which explains the need to constantly maintain combustion. In these devices, fuel consumption is high, while the performance ratio is far from ideal. Moreover, these boilers are not automated.

- Direct fired boilers transfer heat while the fuel is smoldering and not directly from the flame. Thanks to the top burning method, this equipment is able to provide a room with constant heat. The method of supplying material for combustion is manual, and the time for warming up such devices is long.

Boilers for summer cottages

Usually, country houses do not have access to centralized communications, and in most cases, there is not even access to the gas main. That is why boilers for summer cottages are ideal for the heating system of your country house. Indeed, in most cases, not only firewood, but also coal, peat briquettes, and so on are suitable as fuel for such a boiler. Such a boiler saves more than ninety percent of the heat energy and gives it away for heating the whole house, rather than sending them into the “pipe” and at the same time consumes much less fuel.

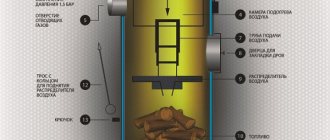

Depending on the design, the combustion system in it is arranged in such a way that you will have to put the next portion of firewood or peat briquettes into the bunker after a fairly long period of time. Thanks to this, a long period of time is freed up for a permanent lining of fuel material, as it would be in a “Russian stove” or fireplace. There is practically no need to follow such a design. It is only required to observe the portioning of the supply of combustible material into the bunker and not to overload it, trying to push as much as possible there.

Boilers of pyrolysis and pellet type

- The efficiency coefficient of the TTK pyrolysis combustion is very high. It functions by releasing a combustible gas produced when heated at high temperatures. These gases enter a special part of the boiler, where they are burned. It should be noted that such solid fuel boilers for heating summer cottages and other residential premises work in such a way that the fuel burns out almost without residue, while it is not necessary to equip a complex chimney system, since the combustion products are removed by means of a blower fan. Among the disadvantages of pyrolysis equipment is the high cost, as well as the need to use extremely well-dried fuel. In this case, the moisture content for wood should not exceed 20%, otherwise the boiler performance will significantly decrease.

- The most functional is the pellet boiler system, where the heat source is special fuel pellets (pellets). There is practically no need to control the operation of this mechanism, since the fuel supply and ignition to them are automatic. Only the fuel material needs to be added periodically. Moreover, the efficiency of such boilers is very high, which is explained by the afterburning of gases in the system and the use of additional heat.

Types of combined boilers

The thing is that it is very difficult to find an equivalent replacement for gas. All available alternatives for one reason or another are noticeably inferior to gas heating:

- Solid fuel boilers require regular filling of the furnace, in addition, fuel for them must be stored somewhere and regularly replenished;

- Heating units operating on electricity are completely devoid of these disadvantages, but they can not be considered economical in any way. In addition, power outages are not uncommon, especially in rural areas;

- Diesel fuel is at least not cheaper than electricity, and for safety reasons is perhaps not the best choice;

- Other exotic sources: waste oil, fuel oil, solar panels are usually not available in the required quantities for the average user.

Combined boilers have become a rather successful solution to the problem of creating an optimal heating unit for objects that do not have a central gas supply. Depending on the situation and current needs, they can operate on different grades of fuel and switch from one type to another without any problems. One of the most popular types of such devices is a solid fuel boiler with a heating element.

Steel boilers

Steel TTK, as a rule, have obvious advantages, such as an affordable price and low weight. But at the same time, long-burning solid fuel boilers have one big drawback - a short service life. In addition, if such units are installed in open heating systems, this also contributes to faster wear of the equipment.

This is explained by the fact that the coolant contains oxygen, which, as you know, is one of the reasons for the appearance of corrosion on the mechanism. All these factors, negatively affecting the operation process, reduce the service life of the boilers to 10 years.

But in those devices in which the circulation is forced, active oxygen does not appear. Thanks to this, their service life is increased and is approximately 20 years.

Alternative ways to avoid system freeze

The long operation of solid fuel boilers equipped with electric heaters requires little details in their maintenance. It becomes insufficient only to clean the boiler from the build-up of gaseous, liquid and solid substances (soot) and check the smoke exhaust ducts. It is also required to systematically watch tubular heaters, which are inherent in the long use to build up with scale and become unusable (burn out).

Neglecting to check the condition of TENOV, you can incur the danger of a malfunction that will deal a devastating blow to the heating system: it will rupture heating devices with ice, deform the lines from the pipes and also violate the impermeability of the boiler tank.

Advantages of solid fuel units with electric heaters and disadvantages

An ordinary wood-fired or coal-fired boiler installed in your home or in the country is good for everyone. There is only one drawback that the owners have to keep silent about. The problem lies in the constant need to feed the heating unit with fuel. Electric heaters installed in the boiler are able to radically improve the current situation, taking on part of the work in an endless process.With such devices, you do not have to regularly visit the boiler room and monitor the fuel combustion process.

Important! It is not worth counting on full-fledged heating of a residential building and provision of hot water with operating electric heating elements. Electricity in this case is a temporary source of heat energy. Allowing long interruptions in the operation of the main part of the boiler means putting yourself in front of the fact of high costs for the consumed electricity.

What advantages do you get by installing a combined solid fuel boiler at home:

- autonomous operation of the entire home heating system;

- increased time interval between fuel loads into the combustion chamber;

- protection of the water heating system from defrosting at low temperatures.

With regard to technological advantages, solid fuel units equipped with electric heating devices have the following capabilities:

- absence of condensation formation on the inner walls of the combustion chamber due to constant heating of the heat exchanger by electric heaters;

- with constant maintenance of the required temperature of the coolant, there is no need to mount a spare circuit and install a thermo-mixing valve;

- due to the operation of electrical appliances, the efficiency of a solid fuel heating boiler increases to 95%.

Versatility is the main advantage of this technique, but such advantages have a downside. The combination of both types of heating elements in one device leads to a significant increase in the cost of the model. In comparison with traditional solid fuel units, such boilers are much more expensive. However, if you want peace of mind and comfort, price won't be a deterrent.

The second aspect that can scare the consumer away from such boiler equipment is the manufacturability of the device. A large inertia of a heating boiler is characteristic both for a solid fuel unit and for its electrical part. The low power of electric heaters is the main factor that hinders your choice. As a rule, with a main power of 50 kW or more, electric heaters produce only 6-24 kW. As a rule, the total power of electric thermal heaters is not more than 1/3 of the maximum power of a solid fuel boiler.

On a note: Boilers equipped with more powerful electric heating devices are more expensive, and in this case the power consumption will be significant. Such combined boilers are convenient to operate, but not at all cost-effective as a heat source for the heating system.