10/25/2017 4537 Pechnik (Moscow) The horizontal chimney, in its structure, differs from the classic vertical structures that we are used to seeing. The most commonly used and installed systems are of the coaxial type, since they are distinguished by ease of installation (it is enough just to drill a hole of a suitable diameter in the wall, insert and fix the pipe, seal all gaps). By watching the video in this article and reading the selected information, you will learn more about what such exhaust systems are.

Chimney selection video

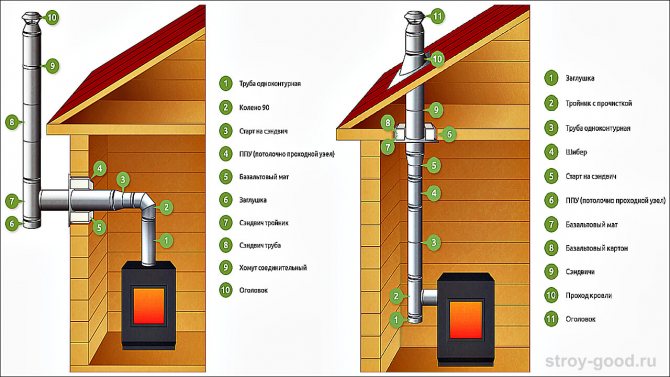

Conventionally, you can divide the chimney passage from the steam room to the street into three options:

- Chimney in the ceiling of the bath

- Chimney in the wall of the bath

- Chimney into the wall of the bathhouse and further through the roof overhang

A chimney running vertically into the ceiling and through the roof of the bathhouse is considered the cheapest and most functional option. And also such chimneys are easiest to clean, if the design of the stove allows soot to fall directly into the firebox and ash pan, then you don't even need to make a sump. But there is one thing, but if you want to buy a chimney for a bath and will install it yourself, there is a high probability that you will not be able to safely and most importantly pass the ceiling and roof tightly.

Making a hole in the wall for the chimney pipe is much easier and faster even for a beginner. For a stone wall, you can simply drill holes along the chimney markings and knock out the middle with a dexterous blow with a sledgehammer. For wooden baths, you need to use a chainsaw or jigsaw and do not forget to use fire-fighting elements of the chimney, such as roof and ceiling cuttings.

And finally, probably the most difficult and most expensive option for a chimney for a bath is passing through the wall and the overhang of the roof. In this case, it would be better to invite more experienced people for installation, they can be advised to you in the store or on the Internet. Alternatively, you can circle small overhangs with additional bends.

If you are going to build or assemble a chimney with your own hands, here are some tips and life hacks:

- A chimney length of 5 meters is optimal, but not more than 7 meters. Do not make long chimneys, because a wood-burning stove never burns evenly and it has periods of maximum burning, attenuation and complete absence of combustion with cooling and freezing of the chimney. Before the next trip to the bathhouse, you start heating and several temperature zones appear in the chimney, in the lower part it is already hot, and above it it is still cold and even frozen at the very top. Due to the temperature difference, the flue gases in the cold part begin to condense on the walls of the chimney and flow, mixing with soot, down to the hot areas, where they turn into very hard carbon deposits. Such carbon deposits cannot be cleaned with the chimney sweep's brushes, and over time, the chimney starts to work poorly, and then completely overgrows and requires a complete replacement. With a long chimney, the stove can stop working properly and your sauna can fill up with smoke and carbon monoxide.

- Do not make horizontal sections of the chimney longer than 1 meter, so as not to impair the draft of the chimney.

- Asbestos-cement pipes cannot be used as a chimney device in a bath. Such pipes are not environmentally friendly and emit toxic substances. Asbestos-cement pipes can ignite already at 300 degrees Celsius, and also tend to explode at the boundaries of the temperature difference, which is a constant component for the chimney.

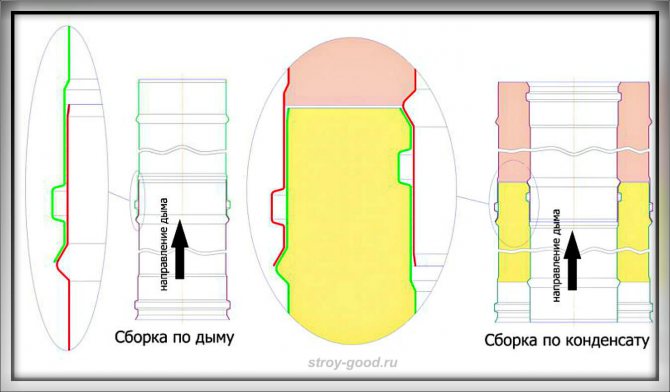

- When choosing a stainless steel chimney sandwich, pay attention to how it is assembled.The upper inner pipe must be inserted into the lower inner pipe so that the condensate, flowing down, does not seep through the joints (assembly by condensation), and the upper outer pipe must be put on the lower outer pipe so that rain does not penetrate into the sandwich insulation (assembly by smoke).

- Single-pipe stainless steel chimneys should be collected only by condensation, do not be afraid that smoke will seep into the room through the joints. The joints need to be coated with a heat-resistant sealant, but even without it, the chimney is more likely to suck in air through the joints, rather than vice versa.

- Avoid kinks in the chimney, the straighter the chimney, the better its draft. Whenever possible, replace right-angle pivots with a pair of 45-degree pivots.

- Single-pipe chimneys for wood-burning stoves 0.8 - 1 mm thick are not crushed by hand, if crumpled, then these are pipes for ventilation.

- Cover the joints of stainless steel chimneys with black sealant 1100 - 1500 degrees.

- The diameter of the chimney should not be less than the diameter of the outlet of the furnace.

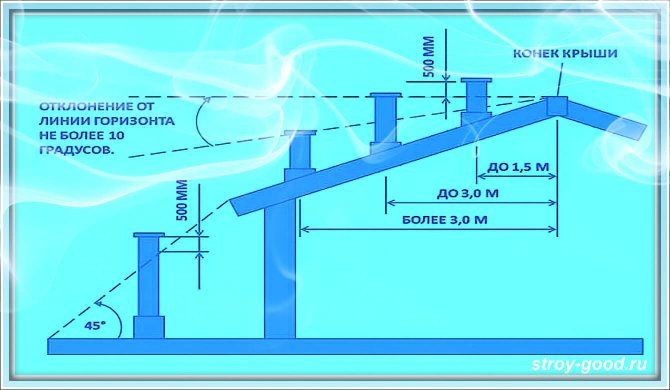

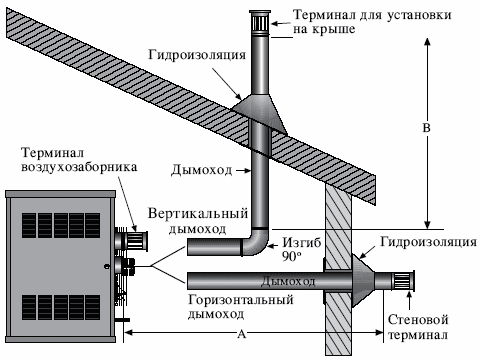

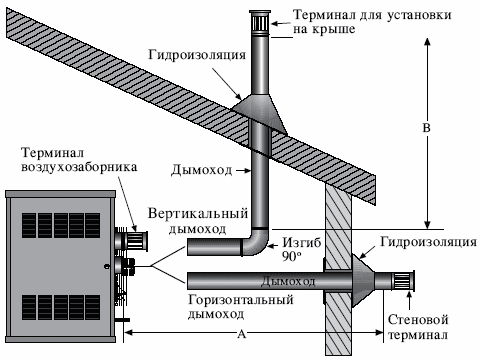

- The height of the chimney on a straight roof is 0.5 meters. How to calculate the height of the chimney on the ridge roof is shown in the diagram:

- If you have a small, one-story, freestanding bathhouse with an iron stove, then take a stainless steel chimney sandwich.

- If you have a large two-story bathhouse or a bathhouse in the basement of the house, buy a ceramic chimney or build a brick chimney with steel pipes.

- A brick chimney is justified only if you have a brick stove or fireplace.

How to properly assemble a chimney for long burning stoves

The chimney is an integral part of any stove. Its correct installation is a guarantee of fire safety and comfortable operation of the heater. Today we will tell you about a few simple rules that will help you avoid problems when assembling this critical structure. By the way, modern chimneys made of steel will last much longer than chimneys of other configurations.

Chimney problems in Russia began after long-burning stoves appeared on the market. In many countries around the world, such as Finland and Canada, stove heating accounts for a significant share of the housing stock. Of course, in cities, apartments are heated by centralized communications, but low-rise housing is still heated by stoves.

This archaism is not devoid of common sense. The capitalists calculated and came to the conclusion that heating small houses with solid fuel (firewood, wood briquettes, saws) is much more profitable than leading a gas pipe to the house and paying for expensive gas. Another plus is environmental friendliness: wood is considered a renewable resource, unlike gas and coal, and the price of such fuel does not grow as fast as gas and electricity.

The popularity of stove heating has attracted the attention of designers, now wood-burning stoves are the height of engineering, and the efficiency of such heat sources tends to 100%. But with the advent of modern technologies, new problems have appeared that have arisen where no one expected them. The chimney turned out to be the weak point.

The root of all evil

Problems with chimneys of long-burning furnaces arose due to their high efficiency. Using an ordinary stove-stove, which is also called a wood-burning stove, eliminates any problems with chimneys. But a stoker must constantly be on duty at such a furnace, who continuously throws fuel into it. Most of the heat escapes into the chimney, and in the literal sense. When the room is heated with a potbelly stove, sparks fly out of the chimney and flames burst out. At the same time, the chimney of such a furnace will always be crystal clear, all carbon deposits and soot in it simply burn out.

In long-burning stoves, other laws apply, the stove gives off all the heat to the room. The chimney at such a heat source is cold. The burnt gases, in contact with cold air, condense on the inner walls of the pipe and flow down.It is this condensate that is the main problem in modern ovens. In appearance, it resembles an oily, fetid liquid of almost black color, which finds the slightest cracks in the joints of pipes, makes its way into them and begins to flow down the outer surface of the pipe. The room is filled with an unpleasant smell of tar, and the shiny stainless pipes take on a disgusting look. In addition, condensate is flammable and sometimes becomes a source of fire. Only the correct installation of the chimney can get rid of this problem.

The monolithic chimney is free from condensate problems. He just has nowhere to break out and ruin our mood. Only now no one builds such chimneys, they were in use 30 years ago.

The manufacturing process for such a chimney is simple. A ferrous metal pipe with a diameter of at least 100 millimeters is taken and welded into a single whole. All joints are sealed and condensate flows calmly down its walls into the furnace and burns out there. But the mass of such a structure will be huge, and you will have to take care of a good foundation for it. Such a chimney is devoid of any aesthetics, and it is fire hazardous. It is especially difficult to bring it out through the ceiling and roof.

Modern chimneys made of stainless steel have an aesthetic appearance, attractive cost and low weight. In fact, they can be installed on the stove without thinking about some kind of special foundation. Very often, manufacturers recommend installing such chimneys "through smoke".

This type of assembly implies that the upper link of the pipe will be put on the lower one, the smoke will not experience resistance from the joints as it moves.

The smoke flue assembly is acceptable only for primitive stoves, where the high temperature of the gases prevents condensation from forming. If you install it on a long burning stove, then problems cannot be avoided. The liquid will drain along the inner surface of the chimney, bump into the joints and seep through the slots in them onto the outer surface of the pipe.

To combat this scourge, sellers advise to lubricate the joints with a special heat-resistant sealant, but the problem cannot be solved that way. Condensate is a very corrosive chemical that will corrode any sealant in a couple of years.

This installation method is acceptable only if there is a special condensate drain in the chimney. Then the section of the pipe from the furnace to the sump is mounted "through the smoke", but the length of such a section should not exceed 1 meter.

Condensate

This type of installation is correct for long burning ovens. When installing "on condensate", the upper part of the chimney is inserted into the lower one. Condensate calmly flows down the pipe without encountering any obstacles in its path. Further, the liquid accumulates in the sump or enters the furnace, where it burns safely.

When installing the chimney "by condensate", the use of a joint sealant is also required, but it is here for other purposes. The joints must be sealed to prevent air from leaking through them. If the joints are not tight, the traction weakens or disappears altogether. The joints must be reinforced with special clamps, which are sold with the pipes.

If you adhere to these simple rules, then problems with the chimney will be excluded.

Materials from which chimneys are made.

- Brick chimney in the bath

- Stainless steel sauna chimney

- Ceramic chimney for a bath

Chimneys for a brick bath are of two types:

- Root - erected next to the furnaces and connected with a pipe.

- Mounted - built directly on the brick oven and being its continuation.

Brick chimneys for a bath are not very justified, since these are very heavy structures, and they require a strong foundation for themselves. Also, if the masonry is not of high quality, excessive accumulation of soot is possible on the excess solution protruding from the seams, which, in turn, also complicate the high-quality cleaning of the chimney.For laying the chimney, use heat-resistant bricks and pay special attention to the tightness of each seam.

We conclude that a brick chimney is the most durable, but not an economical and labor-intensive type of chimney and is not appropriate for a small, freestanding, wooden bath. It is advisable to erect it if you have a brick stove (top-mounted version), or when the chimney goes along the outer wall of the house and the appearance of the building requires this (root version). But in any case, you need to be completely sure - in the strength of your foundation.

Stainless steel chimneys are sold in stores in two versions, these are double-circuit sandwich chimneys (insulated) and single-walled (not insulated).

Single-walled, non-insulated pipes are used mainly for casing brick chimneys and for the first section of the chimney (it can be used to estimate the wear of the entire chimney). They look like and are assembled according to the pipe-socket principle, where the upper pipe is inserted into the socket of the lower pipe. Such chimneys are of high quality mirror stainless steel or galvanized steel.

Insulation thickness on insulated chimneys ranges from 30 to 100 mm. As a rule, basalt wool, which has high fire-fighting properties, is used as a heater.

The thickness of the stainless steel is from 0.5 to 1 mm, the design is lightweight and does not require large silos, powerful fasteners or foundation.

The flare system is a sealed connection. A large selection of fittings and fasteners makes chimney assembly simple and, most importantly, a quick task, even for a person who has never done this.

The passage of wooden floors, roofs and walls near such chimneys is carried out using special elements that isolate the chimney from the tree and prevent fire.

Also, such chimneys are easy to clean and have an aesthetic appearance.

Chimney diameter from 80 to 300 mm. The absence of corrosion, as well as the ability to order (in many cities) individual production, makes the stainless steel sauna chimney the leader of this market.

Chimney supplied with the stove

In most cases, when purchasing a wood-burning stove, a chimney system is supplied, ideally suited to this type of stove. You can install it both independently and with the involvement of third-party specialists. Moreover, the cost of such work is relatively low - it starts from 4-5 thousand rubles.

Structures can be made from a wide variety of materials, ranging from steel with a diameter usually from 9 to 20 mm. and ending with ceramic pipes. Moreover, it is the latter that are considered the safest and most durable. This is followed by chimneys made of stainless steel. The next on the level of quality - pipes "sandwich". Returning to steel pipes, the most preferred steel grade is AISI 310S, which has increased heat resistance.

The complete diagram of the "stove - chimney" design and related systems is as follows.

Particular attention is paid to the node of passage through the roof or through the wall, depending on the type of chimney design.

Wood stoves classification

Wood-burning stoves differ from each other in such parameters as:

- material;

- the principle of functioning;

- design features.

Wood burning stoves in terms of material

Most often, wood stoves are made from cast iron, steel or brick. The surface of these heating devices is smooth and quite attractive in appearance, so they fit well into the interior of any room.

The stove, made of metal, is equipped with a special fire-resistant glass door, which allows you to control the combustion process and put fuel on time.

Cast iron stoves are a kind of rarity, now they are very rare, mainly in villages.Such devices are beautiful, they smell of antiquity and some kind of rural romance.

Brick stoves are "classics of the genre". They are most often built here in the form of high, almost to the ceiling, structures, faced with tiles. Such heating devices heat up for a long time, but they also cool down for a long time, maintaining a comfortable temperature in the room for a long time. Therefore, it is worth finding out what types of bricks are and its features.

Types of stoves according to the principle of operation

- traditional devices operating up to 5 hours;

- long-burning stoves, structurally more complex and capable of heating a room for a long period of time. This is made possible by controlling the intensity of combustion by adjusting the air supply.

Furnace types depending on design features

If you look at wood stoves in terms of their design, the classification will be as follows:

- heating;

- heating and cooking;

- fireplaces;

- stoves with a water circuit.

As the name suggests, wood-fired heating stoves are used exclusively for heating indoor air. The second type, that is, heating and cooking ovens, allow you to heat a room and cook food. Fireplaces are not just a heating device, they are a real decoration of the interior, a kind of "highlight", the central element of the room, where the whole family is so pleasant to gather and share news.

Devices with a water circuit are used for heating the room and for heating water. Such devices are especially popular in places where there is no centralized hot water supply.

Chimney price

The price of a chimney is not less, and often much more expensive than the stove itself.

Let's compare the prices for stainless steel chimneys and ceramic chimneys with the following conditions:

- Chimney height 7 meters

- Internal chimney diameter 160 mm

- Chimney elements Base with condensate drain

- Revision

- T-piece for connecting 90 degrees

- Chimney

- Chimney head cone

Stainless steel chimney from 40 tr. up to 60 tr. chimney weight will be from 40 to 70 kg.

Ceramic chimney from 45 tr. up to 120 tr. chimney weight will be from 500 to 700 kg.

A brick chimney can only be calculated individually according to the project.

How brick ovens with a water tank are laid

When installing a chimney, a furnace refractory brick should be used, laid on a mortar from special heat-resistant mixtures, or using a conventional clay-sand mortar, which is a more economical option that practically does not lose in the quality of the structure.

- An overhead tube installed on the furnace. It is equipped with a damper to regulate the flow of smoke. Masonry is carried out with the obligatory special binding of bricks.

- Fluffing. Starts 5-6 rows of bricks before overlap. The chimney cross-section remains unchanged, but outside it becomes wider by 25-40 cm.

- Riser. Part of a brick chimney running through the attic.

- Otter. Expansion of the chimney after entering the roof, preventing precipitation from entering the junction of the chimney and the roof.

- Neck. The dimensions are the same as for the main chimney. An umbrella is installed on it.

Brick sauna stoves with a water tank can be of different designs. The common thing is that the tank is located either above the firebox, or on the side of it, next to the stove. Usually, under the tank, which has a rectangular shape, a protrusion of appropriate dimensions is made.

For independent work on the construction of a brick oven, experience is needed. The “recipe” may sound simple, but that simplicity is deceiving. Read more about brick ovens here.

It all starts with the choice of design, and there are quite a few of them. When the choice is made and the orders are found (for example, on the Internet), the number of bricks and the weight of the furnace with all components are calculated - the depth of the foundation depends on this parameter.If the weight of the finished oven is more than 700 kg (and it will definitely be more and do not forget to enter the tank filled with water to the top), then the foundation is automatically required. Read about how the foundations for the furnaces are made on our website.

Having prepared the base, you can start laying. But first you need to prepare the correct solution.

IMPORTANT! No cement mortar is used for brickwork. Only clay and sand. There is also a masonry without mortar.

First you need to soak the clay. To do this, take equal amounts of water and clay and mix them. After a couple of days, wipe the solution through a fine grid (3x3 mm is fine). Then take the sand, sift it and add to the mixture so that you get something like thick sour cream. The masonry mortar should be neither too greasy nor too skinny.

Alternatively, you can buy a ready-made clay-sand mixture in bags at a hardware store, it is enough to dilute it with water and you can put the oven (follow the instructions on the bag).

We also recommend useful materials about stoves:

Well, the topic is fully disclosed so that you can decide on the choice of the desired type of tank, its volume and location. Success with installation!

Operating principle

Nothing complicated here. Water is one of the most heat-absorbing substances, so a lot of energy is needed to heat it. We can take this energy either from the furnace body or from the chimney.

Brick stove for a bath with a water tank

It is clear that inside the stove the heat is "working", which goes to heat the steam room, but in the chimney it is already one of the losses, because the gases do not have time to cool down, passing through the pipe, and in this form they go into the atmosphere.

It follows from this that the idea of purchasing a stove for a bath with a water tank can be useful to increase the efficiency of the stove - for this you need to take a model with a tank on the chimney.

Purpose of the chimney

In order to understand what heating devices can do without a chimney, you need to consider the main tasks performed by this unit. Any stove for a home or for a summer residence is technologically aimed at ensuring that processes take place inside it with the release of heat, which can then be used.

In the overwhelming majority of cases, energy is released during the combustion of any fuel. However, this is not the only option, because heat can be obtained by passing an electric current through a conductor or by rubbing surfaces against each other.

Combustion is a chemical process that leaves behind the products of a chemical reaction. In particular, smoke is such a product and must be removed from the room, since the carbon monoxide contained in it is life-threatening.

Popular model Buleryan

For the oxidation reaction, it is necessary to provide an oxygen supply. That is why fresh air is so necessary for combustion. The chimney is capable of solving two problems. On the one hand, it ensures the removal of combustion products into the atmosphere. On the other hand, it promotes air circulation, due to which the furnace is replenished with a new portion of oxygen.

Good to know: A small rating of quality electric mini ovens

Pros and cons of different designs

Individual advantages may outweigh disadvantages, depending on the circumstances. It is clear that if the tank is located on the stove or attached to the side, then three unpleasant things follow from this:

- constant heating of water will lead to the formation of steam, but it will not be the steam heated above 100 degrees, which is called light - it is obtained only from overheated stones. And ordinary heavy steam will pour out of the container, from which it is difficult to be in the steam room.

- using heated water for washing is problematic if the steam room is not combined with the steam room. We'll have to carry hot water to the sink and wash the way our ancestors washed).

- in tanks attached to the side of the stove, heating occurs worst of all, because the walls of the stove do not warm up as much as the top or chimney.Plus, the wall of the tank itself will eventually lose its thermal conductivity due to scale, and the wall of the furnace - due to scale. Therefore, the water warms up poorly, it remains cold below, it must be mixed by hand.

However, there are also advantages to such structures - they are easy to fill with water precisely because the container is not located high. But this is if there is no cold water supply either. Otherwise, the plus is leveled.

By the way! The larger the contact area of the container with water and the stove, the faster the heating. But this is not always worth striving for - why do you need clubs of heavy steam in an unheated bath?

Of course, you still have the opportunity to arrange a shower from any tank. And, although the stove-makers do not advise using the pump, the forced circulation of the liquid in the system will calmly take water from either the instructor or the attached tank. The main thing is not to forget to add.

In fact, we already answered this question in the previous chapter, but the answer referred to the specifics of a particular bath.

How to calculate the required volume of the container? Assume that one washer needs at least 10 liters of water.

How is it supposed to heat adjacent premises? If no other options are available, a remote reservoir can be used for this purpose. It goes without saying that in this case it is not worth insulating it. Alternatively, an oven can be used to heat the antifreeze in a separate heating system.

Are you ready to create forced circulation? If so, then there are no obstacles to choosing any of the described designs. In this case, you will receive not only a shower, but also, if desired, heating through radiators. True, you will have to organize the system according to all the rules.

For example, do not forget about the need to install an expansion tank that receives excess fluid in the system.

Basic withdrawal methods

First of all, you should be aware that a horizontal chimney can be removed in one of two main ways, namely:

- The withdrawal is carried out through the walls of the building. This option is one of the simplest, systems related to this type are steel coaxial pipes with insulation. Mostly gas or parapet equipment is displayed in this way;

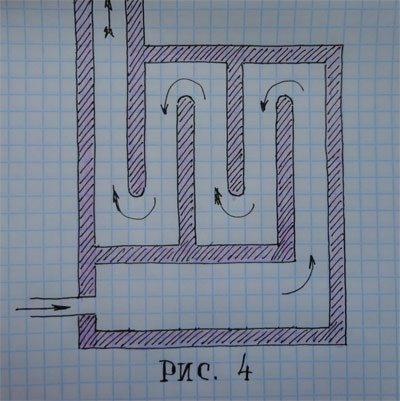

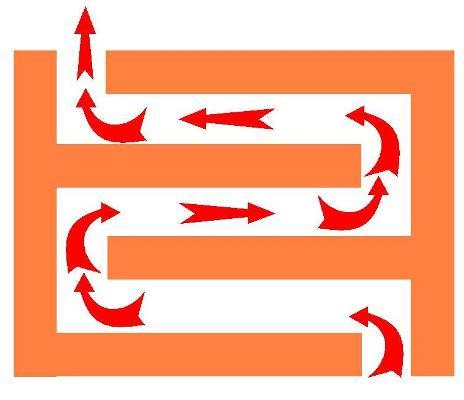

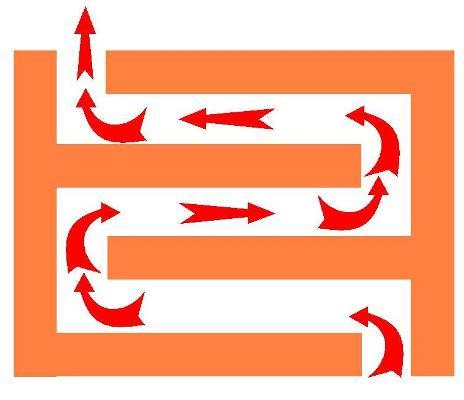

- Pipes are led out through the ceilings and roof of the building. Such designs are more complex in execution and are more suitable for stoves operating on solid fuels. The main assembly material for such chimneys is brick. Popularly, such systems are referred to as "snake".

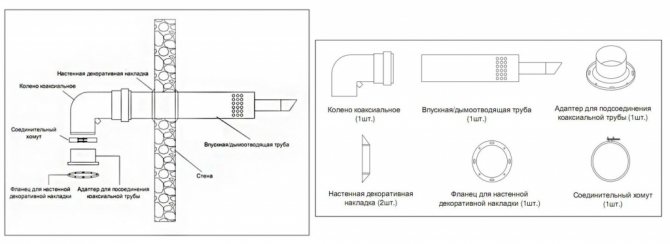

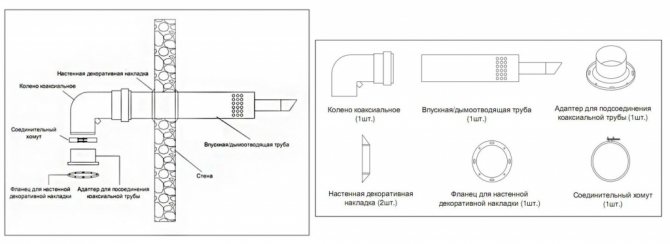

To assemble a coaxial device, you need a minimum of parts and accessories.

The direction of the combustion products allows the pipes to warm up well, quickly and evenly

The difference in the assembly and location of vertical and horizontal chimneys

Lack of vertical sections, allows you to achieve maximum efficiency

Interesting to know:

stove with horizontal chimneyassembled according to the second type, rather difficult to implement, since it is not a simple horizontal section (coaxial chimneys), but a combination of vertical and horizontal ones (repeated at regular intervals).

Basic rules and familiarity with the "Snake" technology

Horizontal chimneys, assembled according to the "snake" principle, have many turns, where longer horizontal sections are connected with shorter vertical sections. Due to the special structure of the device, the thrust in this case always works in full force, and the combustion products are completely removed to the street.

Basic requirements for brick chimneys:

| Requirements | Descriptions |

| Same cross section

| Installation of horizontal chimneys is carried out with strict observance of the cross section and diameter of each of the channels. Moreover, it should always be the same. For assembly, it is preferable to use refractory bricks (ceramics). With its dimensions of 25x12x6.5 centimeters, it can be determined that its half will correspond to the following indicators 12.5x12x6.5 centimeters.This means that blocking the horizontal channel with the vertical one, the width and length parameters will be 12.5 centimeters, with a height of 6.5 centimeters (in total, 2 = 13 cm will be required). It is equally important to add to the obtained indicators a few centimeters, which will be needed to perform insulation and seal the space. In total, add 1 cm to 13 and get 14. The final section size will be 12.5 by 12.5 by 14. |

| Smooth lines

| Both the external and the internal part of the system should be free of sharp corners and outlines as far as possible. Failure to comply with this requirement can lead to a deterioration in the operation of the traction mechanism (what to do if there is no draft in the chimney), as well as excessive accumulation of soot in the corners. |

| Smoothness | The horizontal chimney scheme will allow you to make sure that only pipes with a perfectly smooth inner surface, without roughness and chips, will work at full capacity and will not clog. |

Advice:

horizontal chimneys, schemeswhich you can find in this article may have sharp corners. In order to remove them, use a grinder (for brick structures). However, do not forget that all joints, seams and joints must be completely sealed.

How to install a wood burning stove with a tank

If the stove is not homemade, then the details of its installation are described in the passport. Just in case, we recall that there is a significant difference between preparing for the installation of a metal stove and brickwork.

Stove for a bath with water: heat exchanger on a pipe

In the first case, a relatively light foundation is made, without a separate foundation, which is designed to ensure both stability and fire safety. These are 1-3 rows of bricks, which are laid below the level of the finished floor.

A refractory sheet is placed on top of the base, followed by an iron sheet, significantly protruding in front of the firebox in order to avoid ignition from flying sparks.

If the firebox is remote, then the channel is led through the wall and must be thermally insulated. To do this, a gap is left between the channel and the wall, where a heat insulator is inserted (not any, but only one that can withstand very high temperatures). The wall itself is made of non-combustible material, such as brick. Read more about remote fireboxes here, you may also need material about portals and about fireplace stoves.

After installing the stove (see here and here), the chimney is mounted. This is a separate topic. We are only interested in the case when the tank is on the chimney. There is already a chimney inside it, so it is simply placed on the outlet section of the pipe from the stove, and a regular chimney is mounted on top.

In other cases, the tank is either put / hung on board, or pipes / hoses are attached to the fittings of the built-in heat exchanger, which will connect it to a remote tank fixed in the washing or dressing room.

Installing the tank should not be too difficult, especially when it is not a remote model. Hinged, as the name suggests, is simply hung with hooks on the side of the stove, the instructor is placed on top. Chimney tanks are simply placed on the outlet piece of the pipe from the furnace. For greater reliability, it is worthwhile to provide for a more durable mount, if there is no desire to drop the tank weighing half a centner, or even more.

The remote tank may have wall-mount loops: watch the short video where they are shown.