A metal garage is the easiest way to hide a car from bad weather and intruders. Naturally, it is necessary to make it warm in order to make it comfortable to stay in the "stall" of your favorite vehicle. How to insulate an ordinary metal unheated garage? Now it is customary to carry out insulation with classical materials. Although the construction market is ready to offer a lot of new products that have excellent characteristics in terms of thermal insulation. Therefore, the problem of insulating a metal garage is easy to solve. But how to do it correctly, how to carry out insulation - we will analyze in more detail.

Materials (edit)

Advanced motorists who decide to insulate the garage with their own hands prefer to use the following insulator options as material:

- Polyurethane foam. Special equipment is required to apply polyurethane foam to the surface. However, only such material allows for a really high-quality insulation, and for many decades. This is the best way to get things done.

- Penoizol. This is the name of liquid foam. It is also durable, it is not afraid of moisture, high temperature.

- Astratek. Another liquid heat insulator applied by a brush. A millimeter layer of Astratek retains as much heat as thick mineral wool. Disadvantage: high consumption (about half a liter per square meter of metal).

Each of the listed materials for garage insulation is quite effective, but usually the owner of the car is forced to abandon it due to its high cost. Therefore, much more often a metal garage is insulated using the most affordable material, namely, foam.

Insulation of the walls of a metal garage

Consider how to insulate a metal garage from the inside, and completely with your own hands. All work is required to be performed according to a certain scheme. First, it is necessary to make a frame, inside which the insulator slabs will then be laid.

To begin with, you should take care of the availability of a certain tool. It is impossible to do in such a matter as insulating your own garage, without a drill, screwdriver, hacksaw, grinder. When everything is collected that is necessary, you can start the process of warming.

First, you need to mount the frame from the guides and profile, using the material that is taken for the manufacture of plasterboard partitions. The guides are fastened with dowels, and the profile is fixed to them with special hangers.

After the garage insulation, it is not necessary to use drywall for cladding thermal insulation; asbestos fiber is also suitable for this purpose. The material perfectly resists fire, but is fragile. Because of this, the distance between the posts is required to be slightly less.

After completing the installation of the frame, insulation should be placed between the racks. We recommend using a classic heat insulator - glass wool or mineral wool slabs. This material retains heat well, it is non-flammable. But the cheaper option - polystyrene, refers to flammable substances that release toxic components when ignited. If the step between the posts is made across the width of the mineral slabs, their installation will be simple and will not require additional adjustment. The final stage of insulation is the fixing of the vapor barrier material with tape and the installation of the cladding.

The cheapest material that allows you to insulate the walls of a metal garage from the inside is foam. Before using glue to fix this material, it is necessary to thoroughly clean the inner surfaces of the building from rust and the slightest dirt, then by all means degrease the metal. So the mount will be of better quality. When the foam sheets are already glued, it is advisable to blow out the gaps between them from a can of polyurethane foam. Then you can close the insulation layer with any finishing material.

Construction insulation options (garages, shells)

How to insulate a metal garage with your own hands? With liquid insulation, everything is very simple, a brush is taken, a roller is applied to the surface.

Do-it-yourself insulation of a metal garage has several options, from the inside or outside of the structure. Insulation from the outside in this case is not a suitable way. Consider the methods of internal thermal insulation:

- Before carrying out work, you should prepare the base. This stage is important, and it cannot be ignored, in order to avoid rust and detachment of the insulation. Corrosion is the main enemy of metal products. First of all, the metal is protected from rust;

- An unpainted base is treated with a metal cord-brush. Or a special attachment is placed on the grinder (drill). Thus, the process of work will be accelerated. A sheet with old peeling paint is also processed;

- If the surface has a good finish, it should not be removed. Under the insulation, the paint will remain unharmed for many, many years;

- If the garage is made of galvanized profiled sheet, with a frame made of profiled pipes and a corner, then this material already has reliable protection that cannot be violated;

- After cleaning the base, the surface is degreased (with acetone, etc.);

- If you cover the metal, wake up with foam (penoizol), then the preparatory measures taken are sufficient. If the foam is used as insulation, it is necessary to paint the iron. You can cover it with Kuzbasslak, it is economical and reliable.

Insulation of the gate of a metal garage

Having decided to make the insulation of a metal garage of high quality, you should make sure that the gates do not let cold into the room either. Experienced motorists recommend making an entrance door in the gate leaf, then you do not have to open them completely at the entrance. In addition, a special curtain should be arranged from the inside in front of the gate to prevent heat leakage from the room.

An excellent material for organizing the task at hand is transparent plastic or plastic wrap (always thick). Having cut the selected version of the protective curtain into long strips, they are attached with a stapler to a wooden rail fixed above the gate from the inside. Each fixed strip must find one and a half centimeters on its neighbor, then when the car leaves, they will deflect and then return back, preventing heat from escaping.

However, the curtain alone is not enough; the door leaf itself must also be insulated with protective material. Typically, foam is used for this purpose, which can be fixed to the metal using glue.

You can sheathe polystyrene outside with anything:

- clapboard;

- plywood;

- Fiberboard;

- plastic.

To prevent the penetration of cold through the gaps around the perimeter of the gate, use a rubber seal. So that condensation does not appear subsequently, it is advisable to treat the metal at the place where the rubber is glued with any anti-corrosion compound.

Insulation of walls and ceilings

Installation of slab insulation

So, you can't do without insulating a metal garage, but how can you do it? And there are actually quite a few options. Some are more suitable, some are less, but some are the most universal in most cases.

It should be immediately noted that there are three ways of insulation, by and large.

- Insulation from the inside.

- Insulation outside.

- Combined option.

Each of the methods can be considered separately.

Foam insulation

Installing Styrofoam on Walls

Insulating a garage made of metal is not so difficult. For example, one of the best options for performing the work would be to glue the foam slabs to the walls and ceiling.

Note! It is better to carry out work in the warm season or preheat the room with a heat gun.

Walls must be washed, dried and degreased before pasting. The boards are glued tightly to each other, and the joints are blown out with polyurethane foam and glued with construction tape. It should be added that this option will solve the problem of insulation, but it will be extremely unstable to external influences, which means that after insulation, the walls need to be additionally finished with some more durable material.

Foamed polyurethane

And for the ceiling

Polyurethane foam is used for walls

Another option for insulating a garage is to apply a special insulating composition. For example, such a composition is polyurethane foam. There are a lot of options on the market, so there will be no shortage. The compositions are applied with a paint gun (spray gun).

Mineral wool

Mineral insulation in a roll

You can do a little differently, and first equip the surfaces of the garage with a special crate, and put insulation, for example, mineral wool, in the resulting cells. After that, all this is sheathed with the same metal profile. The result is something like a sandwich panel, which is a very effective option.

Note! This insulation method is also suitable for insulating a garage outside. However, it should be borne in mind that usually the "shells" are located quite tightly, and therefore insulation from the outside may be impossible.

External insulation with basalt wool

Note! One of the options for insulation is a combination of internal and external insulation, but it is not always possible to implement, although it is the most optimal.

Insulation of the ceiling in a metal garage

Solving the problem of how to insulate an iron garage, you should definitely take care of the thermal insulation of the ceiling. It needs to be insulated not only from the inside, but also from the outside. Only then will it be possible to obtain the desired effect. If the outside of a metal garage is traditionally insulated with paint, then there are several ways to work from the inside:

- multi-layer painting of the ceiling with a heat-insulating agent;

- spraying a liquid heat insulator;

- the use of mineral wool or expanded polystyrene plates.

Having chosen the latter option, as the cheapest, the slabs should be fixed with bitumen mastic. When using expanded polystyrene, you will additionally have to treat the seams with some kind of sealant. When using mineral wool, remember that it absorbs moisture, so you need to protect its layer with waterproofing.

With a roof rafter system, its insulation depends entirely on the design. When there is sufficient clearance between the rafters, the insulator plates should be mounted between them and the waterproofing secured from above. It is advisable to perform such work at the construction stage - it is easier and better to insulate the room this way.

If the step between the rafters is small, you should lay insulation under them. When there is an attic, it is most practical to fill it with expanded clay, and then lay a waterproofing material on top. The final stage of such insulation is the filling of a cement screed. However, high-quality thermal insulation of the interior will not be achieved by this - it is also necessary to carry out internal work. It all depends only on the material that will be used:

- Foil-clad polyethylene should be fixed with slats directly to the ceiling.Such material perfectly repels moisture. To get the maximum effect, plywood or fiberboard must be nailed over the slats.

- Mineral wool. First, it is necessary to glue the waterproofing to the ceiling, then mount the lathing. In its intervals, lay mineral wool slabs, protect them with a vapor barrier film and sheathe them with cladding.

- Expanded polystyrene. Glue the tiles to the ceiling using tile adhesive. To improve thermal insulation, it is recommended to pre-glue a waterproofing sheet to the ceiling.

Insulation materials for metal garages

Warming of a metal garage occurs after the choice of material. How to insulate an iron garage from the inside? This is a responsible process. How to insulate? What material to choose so that it serves the most efficiently, and is optimal for insulating the garage from the inside with your own hands? Additionally, you will need material for finishing, as well as fasteners for a particular material.

The most popular thermal insulation is foam, but there are many different options:

- liquid insulation;

- foamy insulation;

- plates for insulation of different strengths (polystyrene, polystyrene foam);

- fibrous soft boards.

Floor insulation

Basically, we have sorted out the question of how to insulate a metal garage. It remains to consider additional options for protection from the cold. It will help to improve thermal insulation floor insulation. Since its surface is usually made of metal or concrete, we will consider options for warming these materials.

The most affordable now is to insulate the floor with foam:

- First, you need to carefully level the surface, then clean it up, removing all cavities or cracks with a putty.

- For concrete covering, it must first be primed twice.

- If there is a pit or cellar in the garage, waterproofing is required.

- Apply adhesive directly to the floor and foam plastic with a notched trowel, lay the board and press it down carefully.

- It is allowed to use special dowels, but then you will have to drill the floor.

- The floor insulation is completed with a screed. Additional strength will be provided by the addition of extruded granules to the solution.

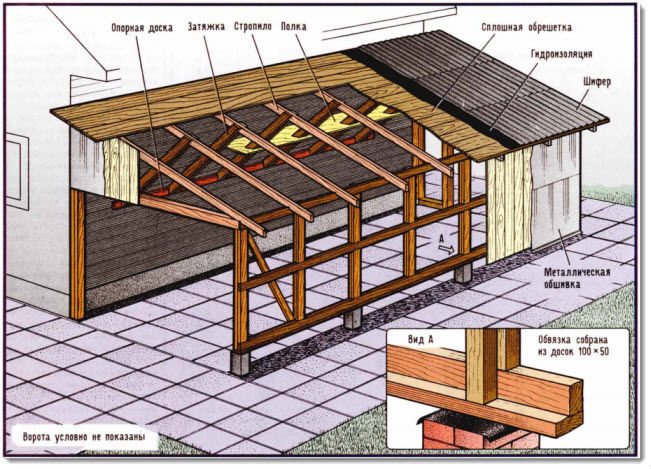

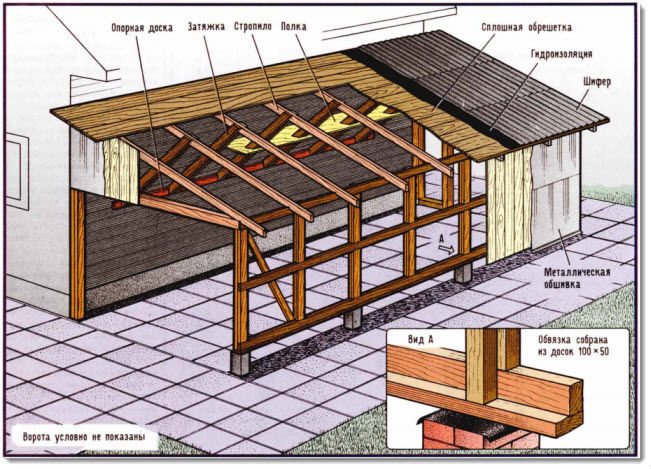

Insulation of the roof of a metal garage

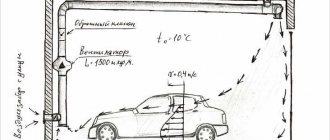

Most metal garages have a pitched roof, which is the most economical and simplest. The basis of such a roof is made up of rafters, which are supported by Mauerlat beams, laid on top of the walls of the structure and firmly connected to them with anchor bolts. The easiest way is to insulate the garage roof simultaneously with its construction. This kind of work will take much less time.

Garage roof device.

A beam should be used as rafters, one of the sides of which (located vertically) is 150 mm. The rafters must be placed at a distance of 59-60 cm from each other. This requirement is dictated by the fact that the standard width of the insulation material is 61 cm. A certain margin in width allows the insulation to occupy the space between the rafters tightly and without gaps.

Next, you need to fix the vapor barrier on the rafters from the inside of the garage. Fastening should be done with construction brackets or buttons. Try to achieve complete tightness of the vapor barrier layer by gluing the joints of the vapor barrier with adhesive tape.

On top of the vapor barrier (inside the garage), the rafters should be sheathed with fiberboard, clapboard or any other suitable material. In the process of cladding, it is important to carefully monitor so that the vapor barrier is not damaged. If there are breakouts, then the torn places must be sealed with tape.

General scheme of roof insulation.

Glass wool with a thickness of 150 mm is laid from above between the rafters. The edge of the insulating material (from the side of the lower and upper edges of the roof) must coincide with the vertical outer surface of the walls.It must be limited to a 15 cm wide board nailed between the rafters. Make sure the top edge of the board is flush with the rafters. As a result, the thermal insulation will be framed by wood on all sides.

Further work is carried out using the standard method for roofing. A crate is nailed to the rafters, the material and installation method of which depends on the type of roofing material used. A waterproofing layer and roofing material are laid on top of the lathing.

If the insulation is carried out after the roof has already been made, the principle of insulation remains the same, only the working conditions change. The insulation must be laid between the rafters from the inside of the garage, a vapor barrier is laid over the insulation and the ceiling is lined. It is not very convenient to lay the insulation from below, most likely, it will be necessary to fix the insulation mats so that they do not fall down until the sheathing is installed. This can be done using strips of steam and waterproofing, nailed to the rafters and keeping the thermal insulation material from falling.

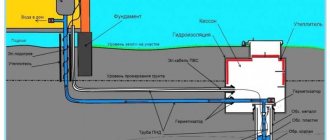

Insulation of the garage cellar

If there is a cellar or a viewing hole, they also need to be carefully insulated.

Cellar ceiling

Before insulating the cellar ceiling, mount a waterproofing layer on it. Then you can already glue the foam to the ceiling. Liquid filler is ideal for insulation, although it is much more expensive to use.

Cellar walls

The material for wall insulation must be mold-resistant and moisture-proof. The best option is expanded polystyrene. Its slabs should be fixed to the lathing or directly to the walls. When performing insulation work, do not forget about wiring. It is required to lay it in a metal sleeve or fasten the box.

Cellar floor

Since the floor in the garage cellar is usually unpaved, it is better to fill it with bitumen. First, crushed stone should be poured, then sand, everything should be tamped and poured with bitumen on top. If the floor is reinforced concrete, it is better to cover it with roofing material over the sawdust, and then fill it with a cement screed on top.