Material selection and glazing

Take into account the weight of the materials: they should be extremely light. If we talk about glazing, it is better to give preference to wooden windows. If your budget is tight, order an aluminum window system: it is not only lightweight, but also relatively cheap.

Today, outside glazing services are in great demand. It helps to increase the free space around the balcony perimeter by several tens of centimeters.

Erection of a new frame

Independent insulation and improvement of the Khrushchev balcony must be started with the process of erecting a new parapet. First of all, dismantle all the elements of the old frame. Only the concrete base of the balcony should remain intact.

Outrigger beams

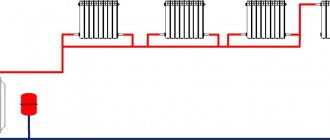

If you want to expand the balcony, then this is done using outrigger beams. As such, as a rule, ultra-strong metal channels are used. The frame is welded from metal corners and securely fastened with dowels to the base of the balcony and the wall of the building. This approach allows you to increase the perimeter of the balcony by 40 cm on each of the three protruding sides.

Balcony with outrigger beams.

However, please note that an extension exceeding 30 cm is already considered a redevelopment, which means that it will require approval from the relevant government agencies. And if you wish to move the central heating batteries along with the glazing and insulation of the balcony, you will need to obtain additional permits.

Roof

For a new frame, a new roof is also needed. It is usually erected from metal or corrugated board, which are attached to a metal frame. The frame, in turn, is mounted with reinforced dowels to the wall of the house. Raindrops falling on metal can generate a lot of noise, so make sure your roof is soundproofed.

Glazing

The choice of window systems plays an important role in how effective the insulation of the Khrushchev balcony will be. They can be "warm" and "cold". Before installing new windows, make sure that the top of the parapet is level and strictly in a horizontal plane. The old metal fence can be leveled by welding, and concrete or brick - with a suitable layer of mortar.

Another important point is the collapse of the walls of the building. If it does not exceed 20 mm, then the frames adjacent to the walls are deepened into the groove. If the deviation of the walls from the vertical plane is more than 20 mm, it makes sense to revise the building: perhaps it is in an emergency condition, and then it is generally dangerous to carry out any work on the balcony.

If the balcony is hanging and does not have an upper overlap, then the glazing must be reinforced with pipe supports. They will also be required when the length of the balcony exceeds 4 meters. Pay attention to the correspondence of the horizontal plane of the balcony ceiling. If there are deviations, then a corner is welded to the ceiling, taking into account the level, and the resulting wedge is sewn up with the same finishing materials that are used inside and outside.

We insulate and sheathe a glazed balcony in Khrushchev

Yes, I'm sorry ... I misled you. The line "in the garage was lying around a piece of foliage beam 100 * 150 mm treated with an antiseptic" read differently. "Behind the garage, 6 years ago, I put a piece of the remaining timber 100 * 150 mm treated with an antiseptic." Six years ago I was building / insulating / finishing a garage on the lake shore.High humidity and constant temperature drops (stupid condensation behind the crate is a common situevina) prompted me to study antiseptics. During the construction, I first bought antiseptics of the Senezh type. It took a lot. The price of 490 rubles for 5 liters turned out to be unacceptable ... Having studied the composition of all available wood antiseptics ofigel ... 95% of each of them were sodium fluoride ...

Sodium fluoride is used as a component of compositions for cleaning and aluminizing metals, fluxes for welding, soldering and remelting metals, glasses, enamels, ceramics, refractories, as a component of acid-resistant cement, heat-resistant lubricants, compositions for etching glasses, solid electrolytes, as a wood preservative, insecticide , a sorbent for absorption of UF6 from gas streams, a reagent for the production of fluorocarbons, as a component of special grades of paper, as a fermentation inhibitor, as a component of fire retardants and fire extinguishing agents.

A 20-kilogram bag in the central factory laboratory cost me a smile to a laboratory assistant. Since then, I don’t recognize any other antiseptics. Just look at the photo. The bar lay in the open air for 6 years. It didn't even darken. At the same time, the timber became relatively fireproof. Of course, for reinforced concrete confidence, it was possible, as I did for the pier, to saturate it with boiling linseed oil with working off (1 to 1 ratio) and then the balcony floor would survive the house itself, but I considered it superfluous. This antiseptic is harmless to humans and animals, poorly diluted with water ... therefore, boldly pour a liter and a half of white powder into a bucket of warm water and stir by hand for 5-7 minutes. How much will stir. Well, then a simple sponge and go ahead - wipe the wood. Antiseptics is a different topic, so here I touched the edge. Let's continue. I did not waterproof the floor at the lag level due to a drop of 150 mm. There the wind blows so much that no waterproofing is needed. Condensation does not form a priori. We are considering a specific option.If it were a loggia / balcony in a new panel house and we would simply beat a bar (for example 40 * 45) on a flat concrete floor, then yes, the same foil-clad isolon would have been initially laid on concrete.

Materials and tools required for work

There are several approaches to how to insulate a balcony in Khrushchev faster, more efficiently and cheaper with your own hands. Here is a set of tools and materials we propose to use:

- mineral wool for floor insulation;

- penofol for finishing the ceiling;

- foam plastic with a thickness of 75-100 mm for walls;

- wooden beams or metal profiles for lathing;

- wooden logs for the floor;

- plywood with a thickness of 10 mm or more or OSB boards for arranging the subfloor;

- material for finishing walls and ceilings (of your choice);

- puncher;

- screwdriver;

- hacksaw;

- gun for applying polyurethane foam;

- foam knife;

- roulette;

- building level;

- construction stapler;

- fastening accessories.

The choice of insulation for the balcony and loggia

When choosing a material for thermal insulation, many parameters and the ultimate goals of insulation must be taken into account. If in the cold season it is required to maintain a positive temperature on the balcony (for example, for storing pickles, vegetables and fruits), you can opt for a thin insulation. With the option of maximum insulation, then in order to achieve the result, it is imperative to use two types of insulation. We work with several materials at once for various options for insulating a loggia:

STYROFOAM.

This material has long been successfully used to insulate apartments and houses. It is distinguished by its relatively low cost, minimum weight, and long service life.However, the thermal insulation characteristics of foam are inferior to more modern materials, therefore, when decorating balconies, plates with a thickness of at least 3 cm should be used.

PENOPLEKS.

This type of thermal insulation materials appeared on the market relatively recently, but quickly became popular, if not the main one. No balcony insulation is complete without this "armor" from the cold. Its demand is explained by many advantages, including resistance to moisture, simple installation, and a wide range of operating temperatures. And most importantly, penoplex has a high heat-insulating ability.

PENOFOL.

This is a modern multi-layer insulation. Most often it is produced in the form of rolls. Low thermal conductivity allows the use of a material with a small thickness (from 3 mm), thereby saving usable space.

Thermal insulation

The quality of the thermal insulation of the balcony depends not only on the air temperature and comfort in the apartment, but also on the ability to effectively use its area in the winter season.

Floor

The first stage is laying a waterproofing layer on the concrete base of the balcony. If the balcony is already glazed, plastic wrap is fine.

We mount the lags on top of the film. They must be leveled with support bars. Control the process with a building level. Further, insulation is laid between the lags. It should be cut in such a way that there are no gaps between the pieces of the material itself, as well as between it and the lags.

The insulation is covered with a vapor barrier membrane, and then a sub-floor is erected from OSB panels or plywood. The rough cover is attached to the logs with self-tapping screws.

Before you start laying the finishing flooring, finish all the insulation and finishing work on the walls and ceiling of the balcony, otherwise you risk severely staining or even damaging the finished floor.

Ceiling

The ceiling of the balcony must be pre-cleaned of old paint, plaster and other finishing materials, primed with an antifungal agent and thoroughly dried. Only after that, you can begin to glue foil penofol on it. This is done with PVA glue or polyurethane foam. Sometimes they do without glue at all: they attach penofol to self-tapping screws with large caps.

On top of the penofol, a sheathing bar is mounted. Before laying the finishing finishing material, take care of installing electrical wiring for lamps and other communications that will run along the ceiling.

Walls

Warming the walls of the balcony is the most laborious process. First, we attach a lathing of 40x40 mm or 50x50 mm timber to the walls. If the thickness of the insulation is greater than that of the timber, installation along the crate of the support blocks is allowed. The step between the vertical elements of the crate is no more than a meter, and between the horizontal ones - about 50 cm. When choosing the level of installation of horizontal bars, you can focus on your own knee, belt and shoulder. It is at these levels, according to statistics, that the internal sheathing of the balcony is most often pushed through.

Further, in the niches of the lathing, we glue the foam plastic, tightly adjusting it to size. We use glue for expanded polystyrene or glue-foam in cans.

Polyfoam must be covered with a vapor barrier film, which will protect the insulation from waterlogging with condensate.

Ceiling insulation

Ceiling insulation is carried out using the following technology:

- First of all, the ceiling is cleaned of dust and dirt. After that, it is covered with an antiseptic.

- Penofol, which is sold in rolls, is glued to the prepared surface. For fastening, PVA joiner's glue is used. After gluing, the material is rolled out with a roller to prevent the formation of bubbles. Also, mounting foam or self-tapping screws with wide heads are widely used as fasteners.

- A crate is mounted on top of the penofol. For its manufacture, a metal profile or wooden beams of a small section are used, which will allow maintaining the height of the ceiling on the balcony.

- The installation of the wiring is carried out according to the developed scheme, which indicates the location of the lighting fixtures.

Finishing plating

It all depends only on your imagination and, of course, financial capabilities. If you use lining, then it should be mounted on nails or using a construction stapler. If you prefer plastic panels, attach them with liquid nails. MDF panels are also a good choice, but keep in mind: they absorb moisture very much! MDF panels are mounted to the crate with the help of special clearing plates.

And only at the very end, the installation of window sills, platbands and other decorative elements is carried out. As a result, we get a spacious, beautiful, cozy, and most importantly, a warm balcony!