Hello readers of my blog! Today we will talk about How to properly lay a warm electric floor with your own hands. It would seem that this is not a tricky matter, but when faced with this problem, you have to think about how to do it right, what preparation to do, what materials to choose. Thus, I decided that this article would be useful to someone, and I devote my efforts to this subject. In it, I will answer a number of questions that will arise immediately before How to properly lay a warm electric floor with your own hands, and some even after that. This topic is wide enough, because before work, you need thorough preparation, but how to do it? And this is a separate topic. You can find out about all this in great detail in the article below.

What is underfloor heating

How to lay a warm floor, or rather how to properly lay a warm floor with your own hands, so that it will serve me as long as possible? I studied this question from A to Z.

In this article, I will tell you in detail about what is an electric cable floor heating and how to lay a cable floor heating with your own hands.

It's no secret that the most common type of underfloor heating is electric.

Where is it used? Everywhere.

Electric underfloor heating is easy to install and therefore you can find it not only in apartments, in private houses, but also in garages! There is no need to run any pipes, break walls and unnecessarily irritate the neighbors. Laying underfloor heating cable electric is not difficult and not at all noisy. And you will be convinced of this now.

What is underfloor heating cable electric

Since the warm floor is called electric, it is absolutely clear that it is heated with electricity.

Or rather, an electric cable, which, by heating itself, heats the floor. There are two types of such cables: a resistive cable and a self-regulating cable. What is the difference between them?

The first type of cable (resistive) heats up itself due to the electricity that flows through it, and heats the surrounding space, that is, the floor. The cable is single-core and two-core.

Single-core is when there is only one wire along the entire cable - a core. It is braided and insulated. Two-core, respectively, consists of two of the same insulated conductors.

IMPORTANT: When installing, a single core cable must start and end at the same location. That is, it should be closed. This rule does not apply to a two-core cable.

IMPORTANT: Single-core and two-core resistive cables have two drawbacks - they emit an electromagnetic field (however, two-core cables are weaker). Do not place heavy furniture on a heated floor made of a resistive cable, the cable may overheat. The same can happen if the technology of installing a resistive underfloor heating is violated.

The second type of cable (self-regulating) is much more complicated and free from the previous drawbacks. Accordingly, the cost of such a cable is much higher.

So, you figured out the types of cable floor heating. And now I will tell you how you can determine how much cable to buy?

How much to buy cables for electric underfloor heating

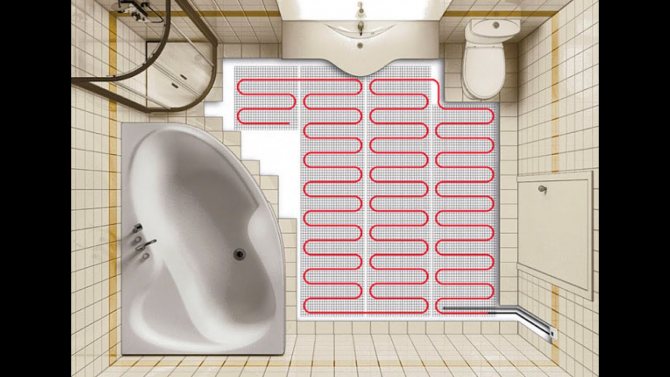

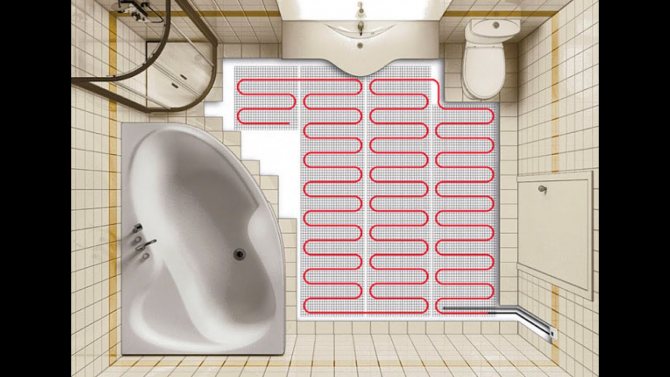

First of all, you need to measure the floor area on which you want to lay the cable underfloor heating.Install an underfloor heating cable electric (as opposed to, for example, water) only on those areas of the floor surface where there is no furniture (cabinets, sofas, beds), plumbing or large household appliances (stove, washing machine, refrigerator).

The cable underneath may overheat. And why heat the surface under the furniture and spend electricity, and hence money, on it? And the warranty period of the floor only decreases from this.

Measured the area? Remember this figure.

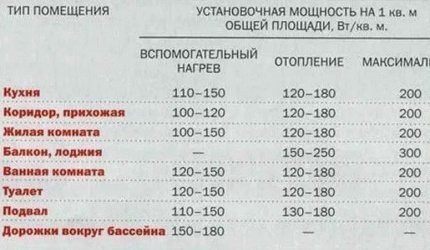

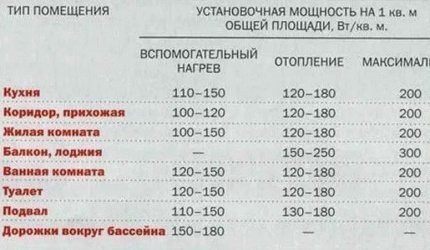

Better yet, write it down (for example, the floor area in my room is 9 m2). Now multiply it by the power of the heating system, which falls on 1 m2 of the room.

Now you have received the system power that you need to heat the entire area of the selected room (I multiply my 9 m2 by 150 W = 1350 W). With this figure, feel free to go to the store, where a smart seller will help you choose the cable of the right parameters. Underfloor heating in the form of a cable is most often sold in ready-made pieces of a certain size.

Necessarily! Ask your dealer for the length of the selected cable.

This is where the fun begins in laying a warm electric floor with your own hands. This is the calculation of the so-called "step". The pitch is the distance between the turns of the cable.

It is measured in centimeters. We calculate how many centimeters should be left between the cables when laying it. To do this, multiply the area on which you decided to lay the warm floor by 100 and divide the result by the length of the cable (in my room: 9 square meters x 100 / cable length = step).

Everything! Now you know how to start laying an underfloor heating cable electric with your own hands.

IMPORTANT! Correctly calculate the required power of the future underfloor heating in order to avoid overheating of the cable.

And now the most important and responsible event is the installation of a warm floor with your own hands or its installation (as you wish).

Varieties of electric underfloor heating

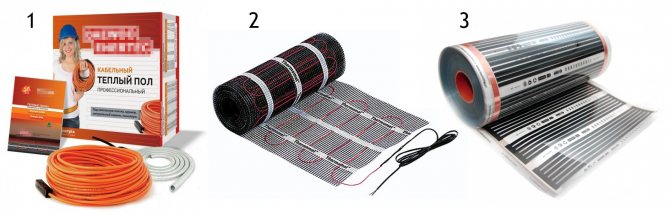

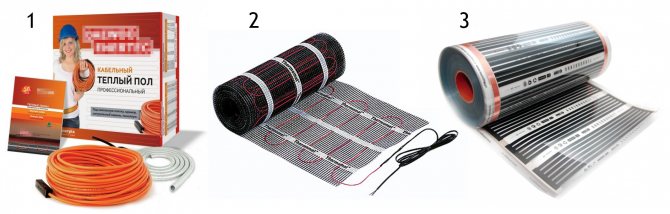

Depending on the heater used, electrically heated floors are divided into 2 categories: with a heating element in the form of a cable and with infrared.

According to the method of production, they are divided into 4 types:

- Heating cable. It can be single or 2-core, including self-regulating.

- Heating mats. It is a cable on a mounting grid.

- Film. Polymer flexible canvases with built-in infrared heating element.

- Rod. Consists of carbon rods connected in series.

A warm electric floor is calculated based on the size of a part of the room free from the situation. It is not recommended to lay heating elements under furniture due to the excess load on the system in the indicated areas. The power of the floor is chosen based on considerations of 0.1 kW / m² on average. This indicator is different for different premises.

Electric floors cannot be called economical to use. You will have to pay for electricity consumption, but in the device they are much simpler than water

There is a wide range of systems for the installation of electric flooring that you just need to install and connect to power and control devices

Unlike water heated floors, the construction of which is allowed only in private houses, electric floors can be arranged in high-rise apartments, in offices and other public places.

The screed over electric underfloor heating is much smaller than over a water floor. The room warms up faster

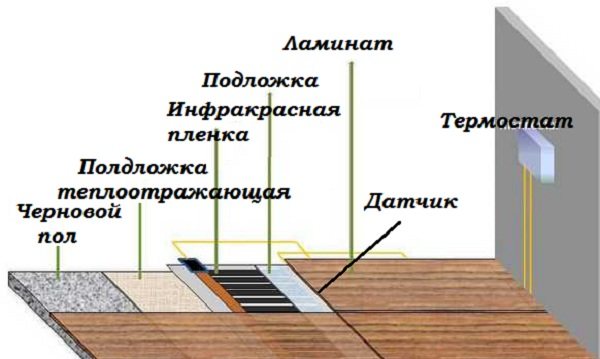

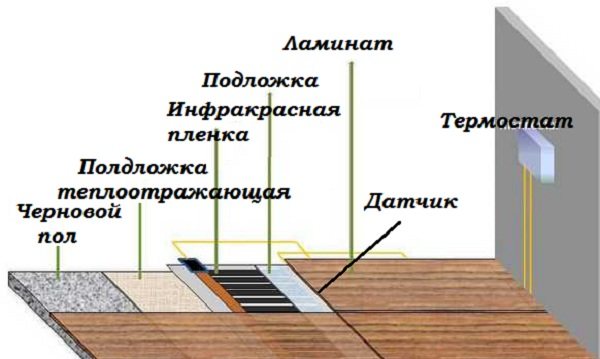

The infrared floor does not require any screed at all. Laminate, for example, can be laid immediately after the organization of the floor system.

The simplest version of an electric floor is a cable system, which is fixed on the base and poured with cement mortar.

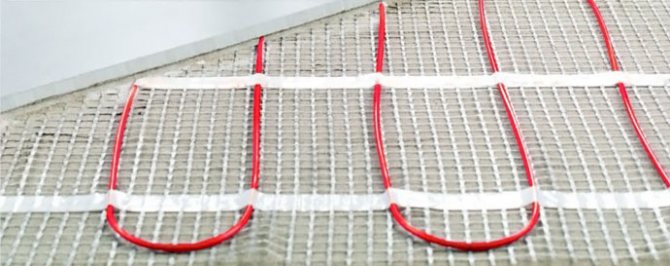

It is much faster and more convenient to lay the cable if it is built into a reinforcing polymer substrate, together with which it forms the so-called mat

An infrared floor device is produced simply and extremely quickly, the construction of which can be undertaken by a performer without experience.

It is important before starting work to calculate the step with which the cable will then be laid out. To do this, find the quotient from dividing the area planned for laying the heating system in m², multiplied by 100 and divided by the length of the section in m, taken from the passport.

If, in addition to the warm floor, there is no alternative source of heat in the house, the area occupied by the system must be at least 70% of the area of the room as a whole.

Do-it-yourself electric cable underfloor heating

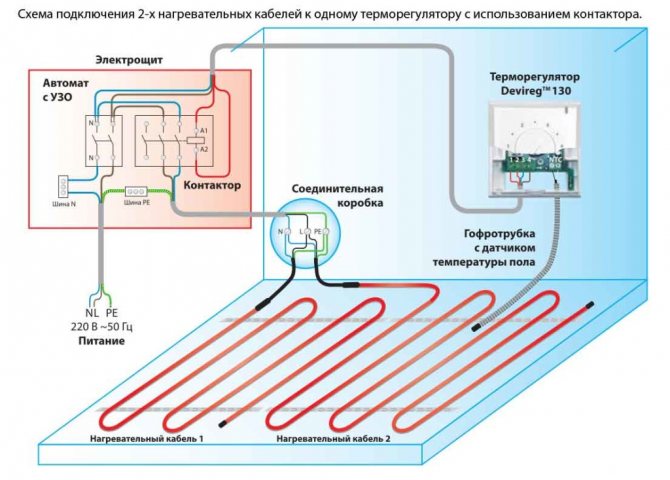

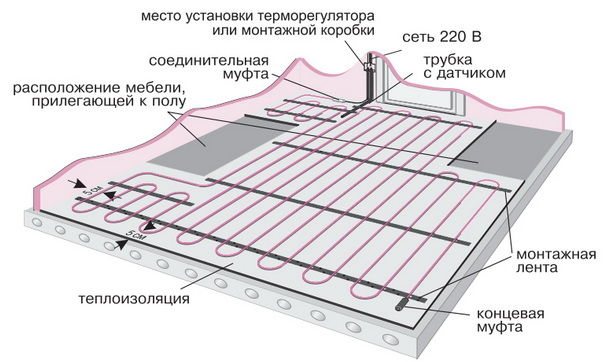

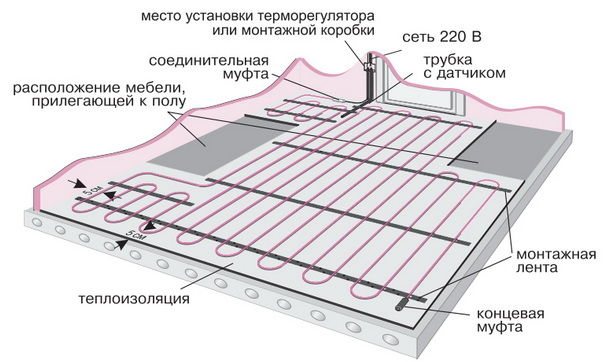

What needs to be done first of all when laying any electric underfloor heating with your own hands? Choose a thermostat and a place for its installation.

A thermostat is a device with which the heated floor is controlled: it keeps the set temperature, regulates the on-off heating. Choose a thermostat based on the power of your underfloor heating.

After you have chosen the thermostat and the place where you will install it, proceed directly to the installation of the thermostat and laying the underfloor heating, having previously leveled the floor surface with a cement screed.

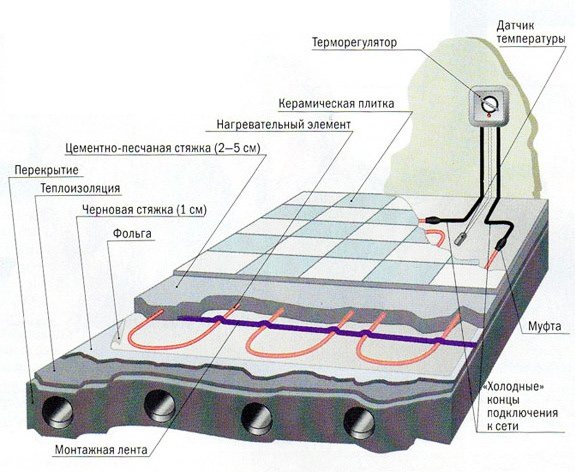

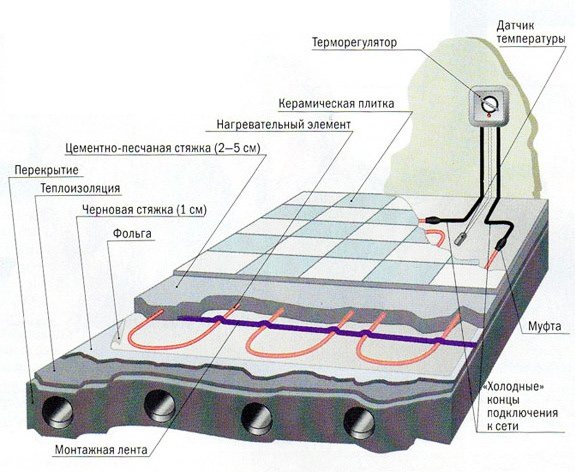

Glue damper tape around the perimeter of the room. Install at least 2 cm thick thermal insulation. It is needed so that the cable heats only your floor, and not someone's bottom ceiling or basement.

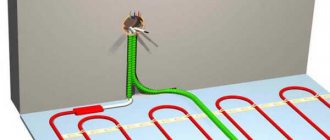

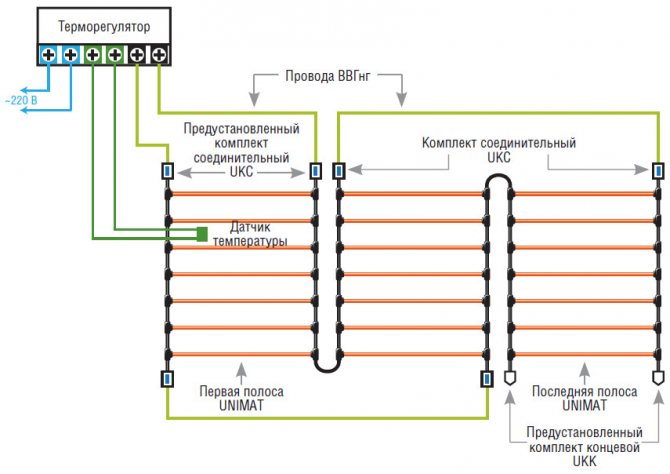

There are two main ways to install underfloor heating - parallel and spiral. The names speak for themselves.

It is more convenient to lay the cable underfloor heating in the second way. You will need: mounting tape, cement screed, the cable itself.

The floor is prepared. It is flat and insulated.

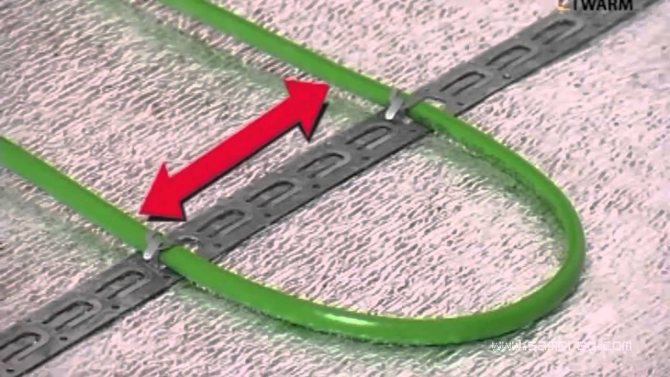

Now lay and secure the mounting tape to the prepared floor surface. And mark the cable laying step on it. Remember, you calculated it before?

IMPORTANT: The cable must not cross itself!

It remains to install the temperature sensor. In the prepared groove on the floor and on the wall (from the underfloor heating cable to the thermostat) we place a cable with a temperature sensor at the end.

Tip 1: To make the temperature sensor serve you faithfully for a longer time, protect it with a plastic corrugated pipe. A plastic corrugated pipe is a special hollow tube into which the temperature sensor wire is placed and the end is closed, for example, with insulating tape so that nothing unnecessary gets inside the tube. Pass the cable with the temperature sensor in the corrugated tube along the floor between the cable turns.

Advice 2: After laying the electric cable of the underfloor heating, check its functionality.

That is, you take a special tester and measure the resistance of the laid cable. The data obtained should not differ from those indicated in the data sheet by more than ten percent. If there is no tester, just connect the cable to electricity and at least check if it heats up or not.

Everything is fine? Now you have come to the finish line. It remains only to fill everything with cement screed.

The thickness of the cement screed should be 3 to 5 cm. Leave the screed to dry. After it has dried (recommended 28 days), you can start connecting the underfloor heating cable to electricity.

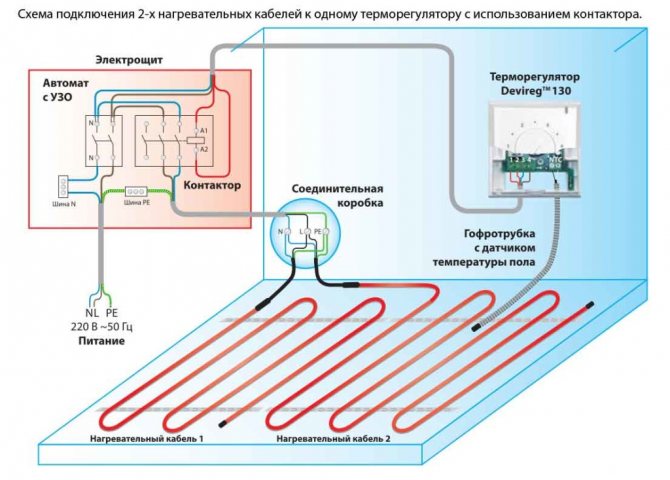

Connect the temperature sensor, floor cable wires, and electrical wires to the back of the thermostat.

Advice 3: If you are not sure that you can independently connect the warm floor to the thermostat, ask professionals to do this (for example, a neighbor - an electrician).

This completes the installation of the underfloor heating cable electric.Floor coverings such as tiles, laminate, carpet, cork flooring and so on can be laid on top of the cement screed with installed electric cable underfloor heating.

Installation of electric underfloor heating

Cable heating systems can be installed in any premises, both in residential and office or industrial buildings. Correct laying and installation of electric underfloor heating will ensure its reliable and safe operation for many years. Installation of electric underfloor heating begins with the work of the preparatory plan.

Preparatory work is carried out for one single purpose - to calculate the required amount of materials and elements. The main task before laying an electric underfloor heating is to calculate the power of the heating cable.

Rod type electric underfloor heating device

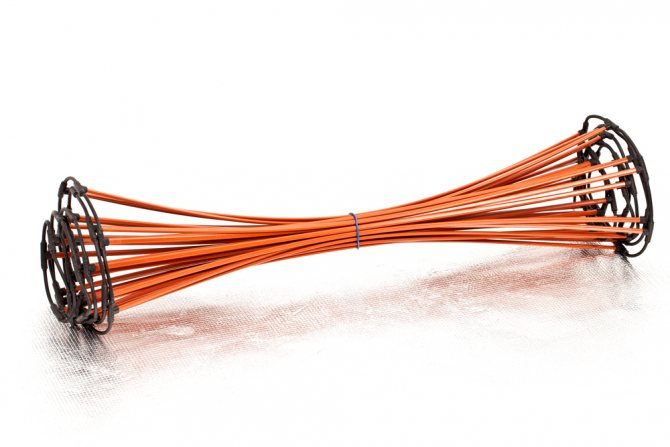

Such a floor heating system uses polymer rods, inside of which there is a carbon mixture. The end part is equipped with contact areas that are connected to the busbars located at the edges of the heating rods.

An electric underfloor heating with your own hands is connected in series, therefore, even if one of the rods fails, the device will continue to function. The technology of the carbon floor heating is based on the generation of infrared radiation, which is close in quality to the sun's rays. Electricity is supplied to the structure, which generates infrared waves with a range of 7-15 microns.

The surface gradually heats up and the heat is released into the room air. The temperature is controlled by the control unit. The core heat-insulated floor can independently adjust its power, this allows you to lay the cores even under furniture. If heavy furniture covers a certain area, then the heating temperature there will become the lowest possible, which will avoid overheating, but will not affect the temperature of open areas in any way.

Differences with other types of underfloor heating:

- Carbon fiber floor heats up much longer than water;

- Installing a core floor is much easier and faster than water-based;

- The screed under the rod heating circuit can be made with a height of 2-3 cm, while the water floor requires more lifting;

- After installation, carbon rods do not require maintenance and additional preventive maintenance;

- The cost of a carbon floor is higher than film and cable;

- Carbon rods are not afraid of strong mechanical loads and can even fit under furniture, while other electric floors require calculation and drawing up a plan of areas where there will be no furniture;

- The core floor warms up the room evenly.

Preparatory work before installation

Before starting work, let's sketch out a small action plan:

At the initial stage of installation, it is necessary to decide on the place where the thermostat will be installed. The thermostat is installed on the wall, like a regular switch, in the most convenient place at a height of at least 30 cm from the floor.

A hole is drilled in the place marked on the wall for installing the thermostat. Perpendicular to the floor, from the installation site of the thermostat, a groove is made in the wall for laying the power wire and the wire of the floor temperature sensor in plastic tubes or corrugation.

First of all, the surface is cleaned of dust and debris, it should initially be flat, without pits and drops. If necessary, the surface is leveled with a screed, the thickness of the screed should be at least 3 cm, if the layer is thinner, the screed will crack. The optimum screed thickness is 3-7 cm.

Before pouring the screed, it is necessary to treat the floor with a primer, this will improve the contact of the surface with the cement-sand screed.After the primer dries, you need to mark the places where the installation of a heated floor is not required (stationary furniture), also the indents from the walls to the heating cable (at least 5 cm) are taken into account.

To make heating the room more economical, it is necessary to reduce heat losses. For this, a layer of thermal insulation is placed between the concrete base of the floor and the heating cable. The insulating layer will make it possible to reduce heat loss by up to 30%.

VERTICAL - along the perimeter of all walls at the base of the floor. For this purpose, thermal insulation in the form of a special damper tape or ordinary polystyrene sheets 15-20 cm wide and about 1 cm thick is suitable. The insulation laid in this way will reduce heat loss through the outer walls of the room;

HORIZONTAL - on the concrete base of the floor, close to the vertical insulation, sheets of heat-insulating material with a thickness of at least 2 cm are laid.

The thermal insulation material must be mechanically strong and resistant to thermal influences. You can use material from such compositions as expanded polystyrene, expanded propylene, cork agglomerate, fiber-mineral boards, etc.

If an electric underfloor heating is installed in rooms with high humidity, a waterproofing layer is laid on top of the thermal insulation. This will prevent moisture from entering the subfloor. It is especially important in apartments so that in the future there will be no problems with neighbors below.

How to install an electric underfloor heating

Installation of an electric underfloor heating in a screed is usually performed in cases when it is necessary to insulate the floor and (or) when repairing and replacing old screeds. When arranging a screed under a warm floor, the old screed is removed completely to the base of the floor. Even in areas where it seems that the old screed is held securely. This is due to the need to exclude the possibility of damage to the cables of the warm floor as much as possible. The ceiling surface is cleaned of dust with a construction vacuum cleaner. Overlap seams and potholes are sealed with cement-sand mortar or repair mixtures. After the repair layer has dried, the surface is primed and dried.

If necessary, waterproofing is done. It can be made using different materials and methods - coating (read: “How to make waterproofing in the bathroom”), welded or waterproofing using two-component cement-polymer mixtures.

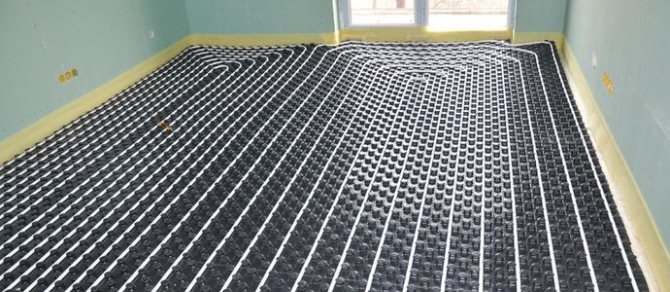

After waterproofing, insulation plates are laid, namely extruded polystyrene foam. The thickness of the insulation is selected depending on whether the floor is heated from below. If the room is heated, 20 - 50 mm thickness is sufficient, if not - up to 100 mm. A damper tape is laid around the perimeter of the room, which should extend to the wall 10-15 cm above the insulation, depending on its thickness and the thickness of the screed.

The next layer is laid with cables or underfloor heating thermomats. To further reduce heat loss, before laying the cable, it is possible to lay a layer of foamed insulation. In rooms with a large area, the screed is reinforced with welded mesh. The mesh, in turn, is settled at a distance from the insulation - 1 - 2 cm and is tied with a knitting wire. The underfloor heating cable can be fixed to the mesh with plastic ties that are not clamped. Alternatively, you can attach the mounting plates to the mesh and run the cable through them. The cable laying step is done in accordance with the technology of the electric underfloor heating manufacturer. In front of the screed device, a place is selected to place the thermostat and connect it to the mains. A groove is made in the wall for laying the cable, as well as the corrugated pipes of the temperature sensor. When installing a thermal sensor, it is necessary to provide for the possibility of replacing it in the event of a malfunction.

Beacons should be installed before pouring the screed. Plaster beacons can be used.Beacons are installed in parallel, at a distance slightly less than the width of the rule. In order to install them, dowels are used, which are placed at the ends of the lighthouse. The horizontal of the lighthouse is set using a level and screwing the screw to the required height into the dowel. Then the lighthouse is attached to the screw with a knitting wire.

When installing a screed for a warm floor, it is recommended to use a plasticizer for a warm floor. The plasticizer increases the mobility and spreading of the screed, which allows, with certain skills, the screed device without beacons. The plasticizer also increases the strength, hardening rate and waterproofing of the screed.

A cement-sand screed is prepared in a container for building mixtures. Then the screed is applied with a spatula or trowel between the beacons, a few millimeters above the upper edge. The excess solution is removed by the rule and at the same time leveled out.

Also, see the “How to make a floor screed” section. After the screed has completely hardened, the finishing floor coverings are laid. You can turn on the warm floor only after a couple of weeks, after the finish coating has hardened.

Preliminary cement-sand screed and fastening of the mounting tape

Before laying the heating cable, a cement-sand screed is poured onto the surface with thermal insulation. The screed layer will help prevent overheating of the heating cable and will also provide a solid base for laying the heating cable.

If for some reason it is not possible to organize a preliminary tie, you can lay the cable on a metal mesh spread over the thermal insulation (with a small cell of 1-2.5 cm). The mesh, in this case, together with the heating cable laid on top of it, is poured with a finishing tie in one step. Due to the metal mesh, the screed is strong and monolithic.

After sufficient hardening of the cement-sand screed, the floor is covered with special foil-clad thermal insulation (mounting foil). The entire surface of the floor is covered with foil, at the joints it is laid with a margin, and the edges are glued with foil tape so that they do not wrap up during the installation of the cable.

Such a foil-shaped heat-leveling shield will contribute to an even distribution of heat over the entire surface of the warm floor.

Mounting tape is used to securely fix the heating cable. An installation tape is laid on the floor surface every 50 cm and fixed with ordinary nails or self-tapping screws.

To fix the cable on the mounting tape, special brackets are provided, located at an equal pitch from each other throughout the entire length (usually 25 mm). With these brackets, it is easy to follow the required cable routing pitch.

Laying the cable floor

This underfloor heating system is the cheapest, but also more laborious to install. It is based on a cable that is laid on a prepared surface, fixed on it, connected to a power source, filled with a solution and covered with a topcoat.

The whole difficulty of laying is that you need not only to calculate in advance the amount of cable, but also its power, and the step between the turns. In order for the electric cable underfloor heating to work effectively, the installation must be carried out according to a pre-selected scheme.

Depending on the area of the room and its location, the heating system is laid in the form:

- zigzag;

- snails;

- loops.

Initially, a single-core cable was used, but since the electromagnetic radiation that was generated during its operation was not suitable for everyone, with the advent of a two-core analog this problem disappeared. It costs a little more, but it is completely safe.

How to lay an electric underfloor heating? Before laying the cable on the prepared floor, you need to spread and secure with self-tapping screws at a distance of 50 cm special mounting tapes. They are provided with latches that will hold the cord in the desired position.

The step of laying the electric underfloor heating should be the same over the entire usable area, and the installation begins from the thermostat.

How to install an electric underfloor heating (cable) correctly?

Installation instructions for electric underfloor heating (cable):

- Fasten the cable to the mounting tape at least 5 cm from walls and intended furniture and 10 cm from heating appliances such as a fireplace.

- Each turn of the cable should be carefully clamped, avoiding kinks when turning it.

- The floor temperature sensor must be placed inside a pre-prepared corrugated pipe, taking into account that their ends must match. To prevent the solution from getting on the sensor, you need to close the tube hole tightly.

- After one end of the tube is laid in the prepared groove in the wall, and the other with the sensor is fixed between the cable turns, you can check the resistance of the system.

- How to connect an electric underfloor heating? A groove with a corrugation must be covered with a solution, then the thermostat must be fixed and connected. If everything is connected correctly, then its indicator will turn green.

- The next step is to grout the entire cable floor system with a screed, and after it has completely dried, laying the floor covering.

This is how the heated cable floor is laid and connected.

Installation of heating sections

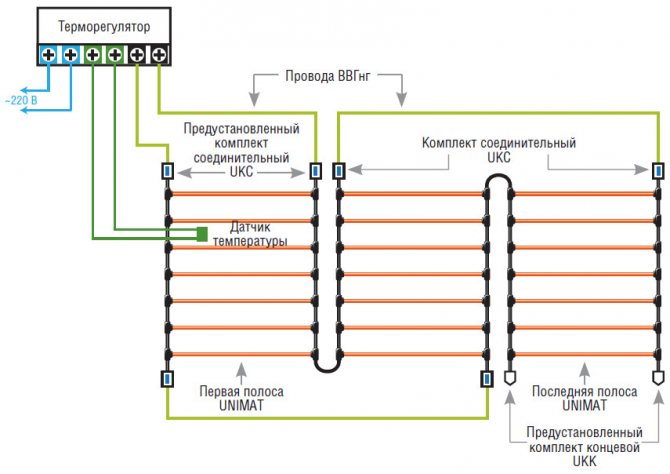

First, you need to return to the previously drawn up plan for laying the heating cable, carefully study such details as the order and step of laying.

Before unwinding the cable, you need to check its resistance.

The value of the measured resistance is recorded in the warranty card. It must match the one indicated on the cable gland label. The permissible discrepancy is ± 10%.

The cold end of the two-core heating cable is pushed into the corrugation and installed in the initially prepared groove. The connecting sleeve and the beginning of the cable are fixed on the floor to the mounting tape, and from this point the laying of the cable begins.

Moreover, the connecting sleeve must be located on the floor in such a way that it is completely filled with concrete screed.

In the process of laying, it is necessary to ensure that the cable lines do not touch or intersect, and also strictly observe a constant laying step throughout the entire heating area. In places where cable bending is required, the bending radius should not be less than 5 cm.

The end sleeve of the two-core heating cable is fixed on the mounting tape with the same condition as the connecting tape - it must be completely covered with a concrete screed. If a single-core heating cable is used for the installation of a cable heating system, then when drawing up a laying scheme, it must be borne in mind that both ends of the cable will be connected to the thermostat.

Installation of electric underfloor heating of cable type

Instructions for installing cable floor heating are performed in the following order:

- Before installing the heating system, you need to mark the place for the thermostat. If you plan to put the cable in a room with high humidity, then the thermostat should be taken out of the room;

- A vapor and waterproofing layer is being laid on top of a concrete base;

- Insulating material is spread, for example, isolon. The foil side should be on top;

- Walls and partitions are pasted over with a damper tape, it will protect them from deformation due to thermal expansion of the floor;

- The heating cable is laid with a pre-calculated pitch of turns;

- The temperature sensor is placed in a corrugated pipe located 40-45 cm from the wall.It is connected to the control unit;

- Power cables are terminated in a tie;

- A screed with a thickness of 4-5 cm is poured, after which the topcoat can be laid.

Features of operation

For the most efficient operation of the cable floor heating system, it is necessary to install software control. It will help to fine-tune the temperature in the room and the general operating mode of the heating circuit.

The required temperature is set manually, after which the system will automatically maintain it at the required level. Thanks to this, you can significantly save on electricity. To avoid accidental electrical shock to occupants, proper grounding and an emergency shutdown device must be connected.

Important! An electric cable floor can deform the topcoat over time if it is continuously exposed to high temperatures. To avoid this, you need to alternate the operating modes of the system.

It is better not to place sofas or cabinets on legs under such a floor, as there is a possibility of furniture drying out.

Installing and fixing the temperature sensor and thermostat.

When the cable is laid completely over the entire surface, you need to install the temperature sensor. It is mounted in a corrugated tube and installed together with the supply end of the heating cable in one strobe. At the end of the tube, where the thermostat will be located, a plug is placed so that the solution does not get into it.

The tube with the sensor is laid on the floor, without crossing them between the heating cable lines.

In order for the temperature sensor to function normally, it is fixed together with the tube in the middle of the cable lines on the mounting tape. The floor sensor with a tube must be located along the cable at least 50-100cm in length.

The thermostat is installed and connected after three wires are connected to the junction box: the floor temperature sensor wire, the heating cable supply wire and the 220 V power cord. The thermostat must not be placed in rooms with high humidity. It is not safe!

At this stage, the installation of the electric underfloor heating is over. You can start filling the cable heating system with a cement-sand screed.

Arrangement of the thermostat and sensor

Following the complete installation of electric underfloor heating, a temperature sensor should be installed. It is installed in a corrugated pipe and placed together with the supply side of the wire in a single strobe. A plug is placed on the edge of the pipe for the thermostatic device to prevent the solution from getting there.

Important! The temperature sensor should be placed in the corrugation so that it is attached to the pipe surface, which is turned towards the upper screed. The smaller the space between the screed and the temperature sensor, the more accurate the readings.

In the event of a breakdown of the temperature sensor, it can be easily changed by pulling it out of the corrugation through the thermostatic box. For this reason, the temperature sensor must be installed in the pipe.

It is placed with the sensor on the floor surface between the outlines of the heating wire without crossing them. For proper functioning of the temperature sensor, together with the pipe, it should be fixed on the tape for installation in the middle of the cable lines. All this must be placed along the cable with a length of at least 500 - 1000 mm.

Connecting the thermostat to the warm floor

The thermostat must be installed and connected after connecting 3 wires to the junction box - mains (220 V), power supply and temperature sensor. Do not place this appliance in a room with significant dampness, as this is dangerous.

The device is a cement-sand screed or self-leveling floor.

Before filling the cable heating system with a screed, it is necessary to make sure that it is working properly. For this, the warm floor is switched on for a short time. The layout of the warm floor with the placement of couplings and end couplings must be sketched, or better photographed and put into the warranty card.

It is better to prepare a screed for an electric warm one from mixtures specially designed for this. It is necessary to pour the liquid cement-sand mixture over the floor surface evenly and accurately, without damaging the cable insulation.

It is necessary to ensure that air pockets do not appear during the pouring of the screed, as they impair the heat transfer from the heating cable.

The thickness of the screed should be approximately 3-5 cm. The time for complete drying of the screed is indicated by the manufacturer of the mixture (approximately 28 days).

After the screed has hardened along the walls, it is necessary to cut off the protruding parts of the insulation (if any). Then you can start laying the flooring (ceramic tiles, etc.).

If during its service life the temperature sensor fails, it can be easily replaced by pulling it out of the corrugation through the thermostat box. That is why the temperature sensor must be installed in the tube.

Underfloor heating with electric and water heating is becoming more and more popular.

The latter often serve as the main heating system for private houses, and electric floors are widely used for additional heating of rooms. This factor, as well as a number of other reasons, made electric heating more in demand.

We propose to consider the design, principle of operation, as well as the possibility of independent arrangement of electric heated floors.

Installation of electric underfloor heating - mistakes

Here are a few typical mistakes that, as evidenced by the reviews of home craftsmen, are very common:

- buying excess material. The error is due to the fact that in the calculations the user is guided by the total area of the room, and not the one that will serve as the basis for the heated floor. The calculations do not take into account the area occupied by furniture and heavy household appliances (refrigerator, washing machine);

- the cable used in the heating mat must not be cut. It is necessary to choose such a laying scheme in order to use the mat completely. It is better to leave part of the floor surface uncovered;

- the underfloor heating system must not be switched on until the screed is completely dry, because this can lead to uneven drying of the layer and the appearance of cracks and voids.

- the cable must not be laid on an unprepared surface. It is better to treat the sub-floor surface with a primer to eliminate dust, which can lead to air pockets around the cable and lead to overheating;

- the temperature sensor is placed in the corrugation, so it can be dismantled and repaired if it fails;

- Resistance measurement is an important step in the pre-operational check of an electric floor and should not be ignored In case of significant deviations, you need to make a decision to correct the situation on your own or involve professionals;

- The cable routing diagram is useful when moving furniture and performing repairs or maintenance. The easiest way is to photograph the assembled floor before the screed is poured.

Electric underfloor heating is unpretentious in operation, reliable (with the choice of good components and correct installation) and will serve for a long time.

Tags:

Underfloor heating Heating

Types and device, as well as features of heating elements

As a heating element for an electric floor, a single-core wire or a two-core cable is often used.

The first option is notable for its low cost, but the increased background EMR imposes restrictions on its use in residential premises.The heating cable has two cores, one of which acts as a conventional conductor, and the other as a heating element. This design allows you to significantly reduce electromagnetic radiation, but increases the cost of the product.

More information about the above heating elements can be found on the pages of our website.

Installation can be greatly simplified by using a heating mat. This design is nothing more than an ordinary thermal cable, laid with a certain step width on a reinforcing mesh.

As a rule, the width of the mats is about 0.45-0.5 m, and the length can vary from 0.5 to 12.0 m (accordingly, the maximum heating area for one segment is limited). There is no standard for the size of the mats, so they may vary slightly from manufacturer to manufacturer. An electromat, like a thermal cable, is a one-piece structure, the footage of which cannot be changed arbitrarily.

Bar structures are considered a subspecies of electric mats. They use special carbon rods with the addition of copper and silver as heating elements. Heating elements are connected in parallel with a certain pitch.

The main advantage of this design is self-regulation. That is, if the temperature on any rod has risen due to poor heat transfer (for example, furniture has been installed), then the heat release decreases. Thanks to this property, the mat can be laid over the entire area of the room.

Infrared film. This heating element is widely available relatively recently, literally at the beginning of the century.

Used in the title, the term "infrared" is a marketing ploy aimed at distinguishing this product from a number of other heating elements.

As you know from the school physics course, infrared emitters are also called thermal, therefore, any heating device can be attributed to this category. The design of a film infrared heating element for a warm floor is shown in the figure below.

Types of flooring

Underfloor heating is a heating system without the usual radiators. The electrical cable in this system or the water flowing through the pipes is a heating element. They are placed over the entire floor area. In this way, the room is evenly warmed up.

The "warm floor" system is enriched with several types of coatings, combined into groups based on installation features:

- sets designed for rooms covered with laminate, carpet, parquet or linoleum;

- selection of heating elements for floor coverings with tiles and porcelain stoneware;

- heating cable for installation in a cement screed.

For the installation of different materials, different methods of installing heating elements are provided.

Underfloor heating has differences in design, but basically all types are similar in multi-layered construction. An insulating layer is placed on the base, and heating devices are installed on top of it.

Then a cement screed is set up (if necessary) and only then the floor covering is laid out.

Hot water floors are heated and controlled by means of a mixing unit. The heat carrier circulates along the closed circuit of the pipes - hot water, which is heated in the boiler and moves into the pipes, passing through the mixing unit.

This option is recommended for private houses, for apartments with separate heating. Most often they are installed in the initial period of construction. The base is isolated from water flows and insulated, and then pipes are installed on it.

We recommend: How is the underfloor heating comb arranged?

By connecting them to the manifold cabinet, the structure is poured with concrete. The finishing coating is laid from above along the screed.

Typical technologies for laying electric underfloor heating

Before giving several laying schemes, it is necessary to explain what affects the design. These factors include:

It should be taken into account that the minimum thickness of the thermal coating is selected based on strength criteria. At the same time, the installation technology does not allow an unreasonable increase in the thickness of the screed, since this affects the inertness (time) of heating (the floor heats up for a long time). Accordingly, the sensor of such a system may not have time to respond to the difference in daily temperature.

On the other hand, a 60-100 mm coating in such a situation can accumulate heat. With this option, you can make a supply of heat, including underfloor heating at night, when a preferential tariff is in effect.

Electric underfloor heating - advantages and disadvantages

Pros:

- the ability to use both as the main and as an additional source of heating for housing;

- uniform heating of the entire area of the room;

- unlimited installation sites. Accessibility for installation, both in living rooms and in offices;

- compatibility with most floor coverings (laminated board, ceramic tiles, linoleum);

- the ability to adjust the temperature regime - both throughout the apartment, and separately for each room. The time to turn on / off the system is also set at the discretion of users;

- no need to install additional equipment (as, for example, in the case of a water heated floor);

- relatively simple installation technology;

- aesthetics. The system is mounted under the finished floor, this eliminates any restrictions in the design of the available space;

- long service life.

Minuses:

- significant cost of using the system. This type of heating can hardly be called economical;

- danger of electric shock. That puts forward special requirements for the calculation and installation of the heating element in all rooms, and in particular in the bathroom;

- the presence of an electromagnetic field created by a heating element (cable);

- the use of natural wood flooring is excluded (installation under parquet, floorboard is not possible), because under the influence of temperature changes, the wood will dry out, as a result, cracks and creaks of the floor appear;

- reducing the height of the room due to the arrangement of a sub-floor with a heating system;

- additional requirements for the capacity of the existing electrical wiring.

Professionals and users who have installed an electric underfloor heating on their own note that compliance with the installation requirements and competent design allow to neutralize most of the listed disadvantages.

What affects energy consumption with cable floor heating

Factors affecting the energy consumption of the "electric floor heating" system

- climatic zone in which the house is built (private or multi-apartment);

- room volume (area);

- type of floor (type of floor covering);

- the level of thermal insulation of the room (degree of fatigue);

- the state of the warm circuit (windows, doors) and the level of heat loss through them;

- the purpose of the premises (living room, industrial facility);

- purpose and period of operation. Whether the electric floor is used as a primary or secondary heating system. Constantly or intermittently;

- the degree of heat perception by people living in the room.

According to the reviews of those who already operate an electric underfloor heating - when using the system as the main source of heat - its power is 170-200 W / m2, as an additional one - 100-150 W / m2.

Instructions for laying an electric floor on an old base

If you make fasteners for concrete, then the heat loss in percentage will be about 30-35%.

Provided that the axis of the thermal cable will be at a distance of 10.0 mm from the base, and the pitch will be 70.0-75.0 mm.In this case, you should opt for a cable with a nominal value of 10.0 watts per meter. The cable is fastened to the base on the mounting tape (first, you need to lay the insulation on the base).

On top, an even layer of tile adhesive is applied. When it dries, you can lay a tile without a screed or other coating in compliance with the technology of its installation, for example, pre-lay a layer under the laminate before installing it.

Laying in grooves

If conditions do not allow raising the floor to the required level, it is allowed to brick the thermal cable into the grooves. It should be noted that this technology is unacceptable for shell rock, foam concrete or other material that has low thermal conductivity.

This method is not acceptable for insulating load-bearing floors, since it violates their strength. As a rule, it is used to warm up open areas.

The technical characteristics of the thermal cable in such cases are selected based on the depth of the strobes. If they are not more than 10.0 mm, then a low-power heating element for a warm floor can be used. When the depth exceeds 20.0 mm, the power consumption can be increased to 17.0-18.0 watts per meter.

Correct laying of the intermediate screed

This method can significantly reduce heat loss. Below is a table of heat loss.

Based on the above table, it can be stated that the maximum screed thickness may not exceed 20.0 mm. If the base is located above an unheated area (for example, a balcony, loggia, etc.), it is advisable to increase the heat-insulating layer to 40.0-50.0 mm.

The best solution is to reinforce the intermediate screed with polypropylene fiber. The further procedure is the same as for point 1 (installation on an old base).

Thermal insulation application

Heating elements of the electric floor are mounted on an insulated surface (GVL, polystyrene or PVC plates, etc.).

It is desirable that the insulator has a foil surface. It should be located in the border area, between the cement base and the self-leveling screed.

It should be noted that this installation option is not durable and reliable, but, nevertheless, its popularity is quite high, since it is easy to install.

Applying a mounting grid

It is most correct to lay a wired underfloor heating element in this way. In this case, you need to fasten the cable to the mesh with plastic clamps, as shown below.

After the term installation has been completed, the assembled structure rises somewhat above the base (you need to put it on some support of the appropriate size), after which it is poured. As a result, we get a thin layer of reinforced concrete, inside which there is a heating wiring.

This method of termo installation allows you to create an economical and reliable warm floor with a minimum inertness of the heating temperature.

Dry screed technology

This option is no less reliable than the one described above. It is called dry, because during the manufacturing process it does not need to be poured with concrete-sand mortar. Below is a short step-by-step instruction for assembling and installing an electric floor in a house or apartment with your own hands:

Concluding the topic of laying an electric floor, it is necessary to refute the false statement about the impossibility of its use in a wooden house (or from a bar). Below is an example of a circuit for such an installation.

Underfloor heating independently under tiles and porcelain stoneware

Rooms with tiled and porcelain stoneware floors are recommended to be insulated with heating mats; a core insulated floor is also used. Heating systems are fairly easy to install.

We recommend: How to install an electric underfloor heating?

The kit contains:

- heating mat roll;

- corrugated tube;

- printed installation instructions;

- warranty card.

For operation, a thermostat is required as a control element.

Taking into account the design features of the heating mats (they are not shortened, they cannot be lengthened), therefore, you need to choose the right set.

This heating system is simply mounted on a place free of furniture. The mesh is cut where the cable is located. Some models are equipped with a self-adhesive base. Installation is a simple process.

Laying infrared thermal film.

Concluding the section on laying an electric floor, it makes sense to describe in detail this process for a film coating due to its popularity. From the materials we need:

When everything is ready, we proceed with the installation, provided that the horizontal of the floor is leveled, the algorithm of actions will be as follows:

This completes the process. Please note that this option of an electric underfloor heating makes it possible to repair it (replacement of heating elements). To do this, it is enough to remove the cover.

Areas of application of the electric floor

Due to its specificity, underfloor heating is used in conjunction with centralized heating in houses and apartments. Here are some examples of its effective use:

Heating of the kitchen and rooms. This type of space heating helps to normalize humidity and temperature. Uniform heating of the floor surface does not allow convection currents to occur, and the electronic thermostat automatically maintains the set parameters.

Application in wet rooms. If you correctly connect the system (via an RCD or a differential machine), as well as ensure reliable grounding of the electric floor and install waterproofing, then you can take a shower without a pallet or rubber mat.

Balconies and loggias. Even on a glazed balcony or loggia, you can get a cold in the winter, you can fix the situation by supplying them with electric floors. It is wiser than making a radiator there.

Mount order

It will be about the installation of a heating cable, which differs from other systems of this kind by the ability to regulate the power in the area.

The best installation time is considered to be a major overhaul of the premises. The screed is being poured with a cement-sand composition of 3-5 cm.

First, a detailed plan is drawn up, which indicates the locations for the heating cable and the location of the “cold” wire. The thermostat is connected to the warm floor through a wire.

It is necessary to indicate on the plan the places for the end sleeve and the connecting piece. In this way, the warm element will be combined with the cold one.

Underfloor heating with a cement screed is usable after about a month.

By measuring the potential heating area and the length of the heating cable, you can determine the laying step, changing which the power is calculated in relation to the heat loss in the room and the expected effect.

We recommend: How to connect a warm floor?

Some important installation details

The type of cable is essential. A single-core cable differs from a two-core cable by the presence of so-called "cold" ends. These ends are connected to the thermostat. The beginning of laying a single-core wire is its end (where they started from, they finished there).

It is recommended to install only a two-core heating cable in the house.

Electric floors cannot be self-regulating, so there is a risk of damage from overheating. The problem can be solved by replacing the expensive "smart" system.

Electric underfloor heating must not be installed under any furniture that does not have legs. Such floors are not suitable for use in damp rooms.

Electric floors are easily damaged during installation.

You can mount the floor yourself, if you take into account all the nuances of the work.

- Similar posts

- What are the advantages of Heat plus underfloor heating?

- How to install a warm floor without a screed?

- How to install a warm floor in the house?

- Do you need an anchor bracket for an underfloor heating?

- How to install underfloor heating Q-Term?

- What are the characteristics of Shtein underfloor heating?

Benefits and features of underfloor heating

If we compare this technology with its water-based counterpart, for example, XL - PIPE, then the first thing that catches the eye is the price level.

Water systems are significantly more expensive than electrical counterparts. This is due to the fact that it is necessary to install expensive equipment, a liquid thermostat for controlling the system, a boiler or boiler, etc., for all this you will have to pay a lot of money.

It is also worth mentioning the setting of the parameters of the thermostats of water systems, you will not be able to use the remote control for this, you will need the help of a specialist. The electrical concept makes it possible to adjust the controller yourself. The termite operating instructions describe in detail how to do this.

On the remote control, you can set the warm-up time, set the maximum temperature, check the health of the main units, etc.

Features.

It is believed that the electric floor is harmful due to the high level of EMI. This is not entirely true, a good European manufacturer will never launch a product on the market that does not meet the accepted standards. Actually, this is the answer to the question of which manufacturers are better.

The system is practically beyond repair, you can check the serviceability, search for a break, but the device of the cable heater is such that it is not supposed to be repaired.

On the other hand, the technology is designed to operate the system for 15-20 years. This is the period that assumes that new renovations will be carried out. Therefore, if the system barely heats up or the heat spreads in places, it is dismantled to the base (tiles, adhesive coating are removed), after which a new installation of the warm floor is done.

It should be noted that this feature is also typical for water systems.

Note that in some options for a dry electric floor heating it is possible to dismantle the coating, therefore, repair (to be precise, replace) the heating element.

Actually, the only serious drawback of underfloor heating is high energy consumption. The operation of the water system is much cheaper.

Well, now it's time to finish the article. All the material that I wanted to share has been reviewed. I hope it will be useful to you, and you will use it if you need to install a warm electric floor with your own hands Improve your own practical skills and gain all the new knowledge, as they say: "It's never too late to learn!" That's all, thanks for your attention, successful and easy repair!

Methods for installing an electric underfloor heating

Installation options for electric underfloor heating can differ significantly:

- Mounting in a screed layer, after which the floor covering is laid;

- Laying underfloor heating on top of the screed under the tiles;

- Installation directly under the flooring (foil floors).

The first option is suitable for heating in living rooms, in the bathroom, in the kitchen, on the loggia. This implies the installation of cable underfloor heating. Waterproofing and a layer of insulation are laid under the system itself. A small layer of screed is formed on top.

If there is an insulated room on the floor below, then you can lay an electric warm floor under the tiles without an additional layer of thermal insulation and mounting in a screed. A layer of tile adhesive and the tile itself provide sufficient protection for the heating elements. However, it should be clarified in the instructions of the purchased product about the possibility of such installation.

If it is necessary to install a warm floor under a laminate or linoleum, and there is no desire to carry out major work related to replacing the screed, then the best warm electric floor for this is film (infrared).In this case, a layer of insulation in the form of foamed polyethylene with a foil surface is laid on top of the existing screed. Next - electrical elements. If necessary, add a layer of waterproofing and directly the floor covering.

Types of electric underfloor heating: 1 - Cable; 2 - Cable with a reinforcing mesh; 3 - Film (infrared).

Important: It is impossible to use a film warm floor under a tile, as well as to mount it in a screed.