How the expanded polystyrene is attached to the walls, what are the features of its installation, how this material is extruded, we will tell all this in this article. You will also see photos and videos on the topic of wall mounting with extruded polystyrene foam.

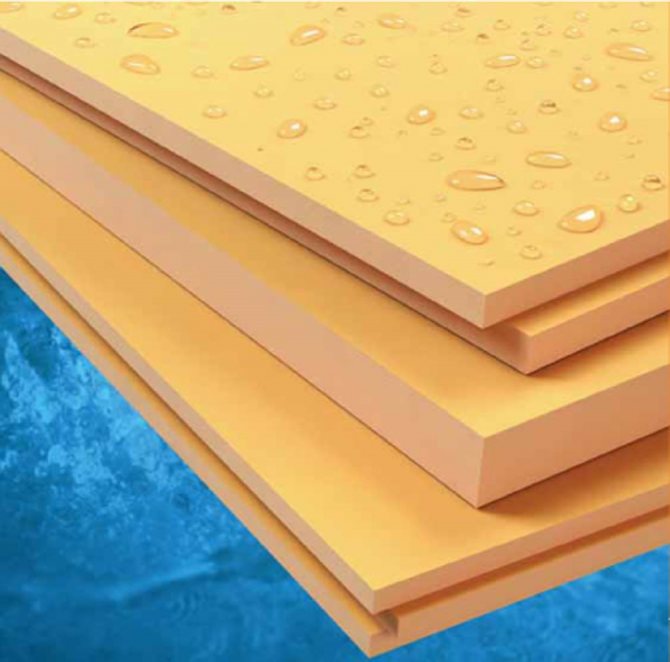

Extruded polystyrene foam what is it? - nothing more than a kind of special dense foam. In our century, this synthetic thermal insulation material, most often orange in color, has rapidly gained universal popularity.

The American extruded polystyrene foam, developed in the distant 50s of the last century, has found wide application as thermal insulation of foundations, plinths, and there is probably not enough paper to list all the places where this bright modern material can be laid.

The material is manufactured according to the perfect method of foaming polymer compositions in the process of extrusion. That is why we can hear the name of the material as extruded polystyrene foam. After pushing the material through a special high-strength mold, a very strong reliable material with practically unique thermal insulation properties is obtained.

Before it was found that freon gas has a destructive effect on the ozone layer of the planet, it was used as a blowing agent.

Since the current 21st century, the so-called “CFC-free” method of manufacturing heat-insulating material has been used all over the world.

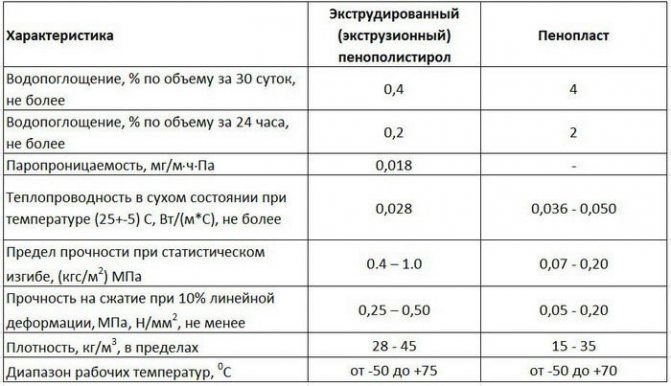

Extruded polystyrene foam, or rather the technical characteristics that it possesses, are not the same and differ depending on the manufacturers. Brands with the largest sales in the Russian market are well-known:

Extruded polystyrene foam

- water absorption by volume does not exceed 0.2%, which indicates almost complete waterproofness;

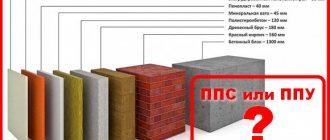

- thermal conductivity at (25 ± 5) ⁰C, no more than 0.032 W / m • K indicates the minimum values. So, for example, a three centimeter thick corresponds to a 56 centimeter red brick laying;

- high resistance to deformation, suitable for blind areas, for the foundation;

- resistance to inorganic chemical compounds and solvents;

- able to withstand extreme temperatures from minus 50⁰С to plus 75⁰С;

- long service life, the manufacturer assures that the service life has been exceeded 50 years;

- environmental friendliness of the material;

- light weight;

- small thicknesses.

A few words about the environmental component. Note that, apart from being used for construction purposes, extruded polystyrene foam can often be found in the nearest supermarket in the form of light disposable plates and other cheap dishes. You can even find this material in children's toys. As we know, in such products, ecology is or at least should be at the highest level.

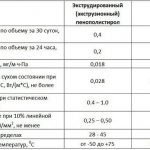

Technical characteristics of expanded polystyrene

Among the technical characteristics of the material, its low thermal conductivity is of particular importance - 0.032 - 0.050 W / m * C, these indicators are significantly lower than that of brick or concrete.

The second most important characteristic is good moisture resistance. For the absorbency to be 3%, it takes about a day of water contact with the material. The vapor permeability is also very low - 0.06 mg / m * h * Pa. The extrusion variety is even lower - 0.013 mg / (m * h * Pa).

The advantages of expanded polystyrene include its inability to become an acceptable medium for biological environments.He is not afraid of fungi and mold.

User reviews indicate that this material also has drawbacks. This is primarily mechanical and chemical instability. A way out of the situation can be the purchase of plates, the density of which is not less than 16.2 kg / m3.

Disadvantages of extruded polystyrene foam

We would not be completely objective if we kept silent about the significant shortcomings of the material. Despite the listed advantages, a number of negative points make one think about the prudent use of extruded polystyrene foam. You shouldn't apply it everywhere and everywhere. To begin with, let's note the cost of the material, which becomes a stumbling block for people with little income.

More financially, there are concerns and serious technical shortcomings:

- expanded polystyrene burns and burns strongly;

- when the temperature reaches over 75 ° C, it releases substances harmful to humans;

- ultraviolet rays destroy the structure and deprive it of thermal insulation properties;

- contrary to the assurances of the manufacturers, insects, ants and mice are introduced into the material.

Like conventional polymer, extruded polystyrene foam loses its properties when exposed to inorganic solvents. It becomes problematic to carry out work using waterproofing. Bituminous mastics contain solvents in quantities capable of destroying thermal insulation.

Often, during construction work, adhesives are used, you need to understand whether it will harm the polymer. The rules for using EPP must be strictly followed, since the use of an inorganic solvent based adhesive is likely to cause the boards to shrink or even soften.

It is strictly forbidden to use when working with extruded polystyrene foam:

- thinners for oil paint;

- plasticizers which contain coal tar (glue, putty compounds);

- acetone;

- petroleum oils, toluene, widely used in the petroleum, chemical and paint and varnish industries;

- ethyl acetate: ethyl acetate used to remove paint;

- wood protection compounds.

What is extruded polystyrene. Differences between EPP and conventional polystyrene and foam

EPP, Styrofoam and Styrofoam belong to the category of synthetic polymers. Their production technology provides high quality characteristics. Polyfoam is made from a polymer composition. The resulting granules reach 3-5 mm in diameter. After that, they are pressed using an adhesive.

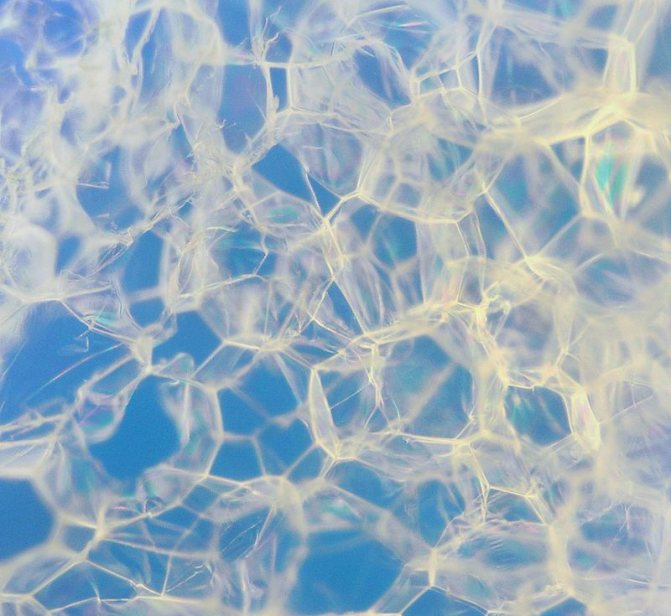

Considering what expanded polystyrene is, it should be borne in mind that it is a material that has a uniform structure, including granular cells of no more than 0.1-0.2 mm. To obtain the material, polystyrene granules are mixed with special foaming agents (they can be carbon dioxide or a mixture of freons). After that, sheets are formed under pressure. After drying, they can be used in construction.

Styrofoam and polystyrene have a lot in common with extruded polystyrene foam, but the latter has a more complex production technology. In the manufacture of the material, the granules are first melted to a homogeneous state. After that, special additives and additional components are introduced into the composition, due to which the substance acquires a viscous-fluid state. Due to this, a material is obtained that has inseparable intermolecular bonds.

There are no pores in the finished slabs, and the cells present in this material are filled with gas. Due to this structure, the vapor permeability of the material is extremely low. The density of extruded polystyrene foam is much higher than that of foam and polystyrene, so it has better performance characteristics.

Advantages and disadvantages

EPSP boards have a lot of advantages, but this material also has some disadvantages. The pluses include:

- low thermal conductivity;

- waterproofness;

- the ability to withstand deformation loads;

- increased rigidity;

- resistance to temperature changes;

- long term of use;

- light weight;

- environmental friendliness.

The thickness of the extruded polystyrene foam is small, which simplifies the formation of insulating pies. This insulation also has a number of disadvantages. It should be borne in mind that EPP is much more expensive than many other materials intended for surface insulation. In addition, the combustion temperature of this material is extremely high. Plates need to be covered with plaster, since EPP can be destroyed by direct sunlight. It should also be borne in mind that boards can collapse under the influence of some solvents.

This insulation is quite tough, so rodents rarely damage it. At the same time, mice can make moves in the slabs. In some cases, the water resistance of EPP plates can be a big disadvantage. When using material for insulating the walls of a wooden house, mold can form under the formed cake.

Trapping vapors near walls can contribute to dampness and musty odors. In addition, when heated to temperatures above 75 ° C, stoves can release substances that can adversely affect human health.

Extruded polystyrene foam technical characteristics

I would like to draw special attention to the fact that often manufacturers are cunning in advertising a product about its fire-fighting properties. Of course, the material does not ignite from a carelessly discarded cigarette or a smoldering butt, but from a sparking electric welding or a match, quite even nothing flares up like that. Many people have seen EPG burning more than once. Everyone notes that during the burning of the material, black clouds of acrid smoke with a pungent odor are formed.

Taking into account the experience of the residents of the European Union, who have successfully used extruded polystyrene foam in residential buildings for many years, it can be noted that our domestic homeowner will always choose a thicker sheet for insulation. The European, as a rule, considers 3-4 mm sufficient. Of course, their winter is not so fierce, you say, and you will be partly right.

But on the other hand, in the event of a fire, a thin layer of thermal insulation releases much less toxic substances into the room. Households will be able to leave the building without having time to cause significant harm to health. Why don't people completely abandon hazardous material? The point here is not even the arrogance of EU citizens, but the fact that the positive properties of EPP are so numerous that fastidious foreigners forget to pay attention to minor "shortcomings".

Do not use EPP as thermal insulation for structures where higher temperature conditions are expected, such as baths or saunas. As we mentioned, the sun's rays, more specifically ultraviolet radiation, has a devastating effect on the EPC.

Evgeny Filimonov

Ask a Question

Cover the insulation with a coat of paint or a durable cement mortar. Avoid direct sunlight on the material even for a short period of time!

As for the large thickness, it should be noted that extruded polystyrene foam does not "like" too much sudden changes in temperature conditions. Under the influence of this kind of extreme change, EPI has been seen to acquire cracks. There is a danger that over time, frosty air will penetrate through the cracks. On the other hand, the statement that the thicker polystyrene foam we use, the warmer our room is, is absolutely indisputable.

Technical characteristics of extruded polystyrene foam

Before purchasing a material such as extruded polystyrene foam, the technical characteristics should be studied carefully. This will allow you to purchase the highest quality material. The building material made in compliance with the technology has universal characteristics, which expands the scope of its application.

Marking. Manufacturer brands

When buying plates, be sure to pay attention to the marking. The technical characteristics, dimensions and dimensions of the plates, as well as special information concerning the operation, must be indicated. In addition, information about the manufacturer must be provided. The following grades of extruded polystyrene foam are most often found on the market:

- Krauf.

- Europlex.

- Styrex.

- Penoplex.

- Technoplex.

- URSA.

- TechnoNIKOL.

- Primaplex.

Many manufacturers produce not only standard panels, but also EPPs with specific characteristics that allow the material to be used in certain extreme conditions.

Release form. Dimensions (edit)

This building material is produced in the form of sheets. Standard sheet sizes are 600x1200 mm, 600x1250mm, 600x2400mm. The thickness can be from 20 to 150 mm. Some manufacturers produce EPP plates with non-standard dimensions.

Thermal conductivity

The thermal conductivity coefficient of extruded polystyrene foam is from 0.03 to 0.032 W / mS. These figures indicate that this material has a low ability to conduct heat. Thanks to this, all the heat in the room is retained, which reduces heating costs in winter.

Low thermal conductivity reduces the degree of heating of surfaces in the heat. The low thermal conductivity of extruded polystyrene allows it to be effectively used for arranging heat-insulating pies.

Water vapor permeability and moisture absorption

The less the ability of a material to absorb moisture and vapors, the higher its durability and lower thermal conductivity. The water absorption coefficient of this material ranges from 0.2 to 0.5%. These indicators mean that no moisture is absorbed in contact with vapors and liquids.

Strength

Expanded polystyrene plates can have a strength index from 0.15 to 0.45 MPa. This is a sufficiently high indicator that allows the use of plates to form an insulating cake on the roof, floors and facades of houses, where great pressure and mechanical stress will be exerted on the material. The use of EPP boards increases the strength of the surfaces. Tough insulation cake reduces the risk of severe wall shrinkage.

The ability to absorb sounds

Expanded polystyrene boards have a high ability to absorb sound pollutants. With the correct arrangement of the insulation cake, the noise level in the room is reduced by an average of 30-45%.

Biological resistance

There are almost no pores in this material through which oxygen and water can penetrate, therefore, its defeat by fungus and pathogenic bacteria is impossible. In addition, these plates cannot serve as a breeding ground for microorganisms.

Environmental friendliness

When used outdoors, this building material cannot cause any harm to people (except in cases of fire). When using expanded polystyrene as a heater inside the house, people are in direct contact with the material, the question immediately arises whether health can be harmed in this case.

It is not easy to fully understand this issue, since there have been no long-term studies that allow us to say for sure that in 5-10 years harmful fumes will begin to be released from the plates. The insulation can come into contact with some household chemicals.

There is also evidence that when exposed to temperatures above 75 ° C, the material may begin to emit harmful vapors. Chemicals released into the air from expanded polystyrene are fat-soluble.

Fire resistance

The melting point of this insulation is about 80 ° C. Most varieties of this insulation are extremely fire hazardous. The combustion temperature of this substance exceeds 1100 ° C. Among other things, you need to take into account the duration of combustion of polystyrene foam. The surface trimmed with this insulation can burn for more than 40 minutes.

During the burning of stoves, a lot of poisonous gases are emitted, incl. methanol, ammonia, carbon monoxide, nitrogen oxide, formaldehyde, styrene, carbon monoxide, etc.

The high flammability and the release of a mixture of poisonous gases emitted when this insulation is ignited does not leave a chance for salvation for people in the immediate vicinity of the fire site.

How to choose the right styrofoam

We have talked enough about the pros and cons, about the strong and weak properties of EPP. The time has come to decide what to devote our time to when buying material and what to look for. A good salesperson praises his product, tempted to sell it soon. Our task is to buy the best quality extruded polystyrene foam.

The best solution would be to purchase goods from well-known, reputable suppliers offering equally well-known manufacturers' brands. Such foreign brands as "Basf" or "Novakhimikals" will meet all your expectations. Of the Russian firms, in fairness, it is worth noting that produce products of the same quality as imported, we recommend paying attention to the brands "Penoplex" URSA, Knauf and "Technonikol".

If the above mentioned brands are not available on the market, carefully study the technical instructions. EPG designation begins with two digits. Refuse to buy if the marking value is less than the index 28, such a polymer is not suitable for construction and insulation work. It is not profitable for the seller to mention this, and most likely he will modestly keep silent about it. For facade work on thermal insulation, the PSB-S-40 brand is perfect, in addition, it is a self-extinguishing material.

A quick quality check can be done by breaking a small piece of styrofoam. A smooth rift indicates that you have an EPG in front of you. Otherwise, if the fracture line is uneven, there are many small balls, then most likely you are holding ordinary foam plastic, which is suitable only as packaging for household utensils.

It should be understood that the manufacture of EPP is a complex process, and different manufacturers do it using different technologies. Some of them are completely safe for health, while others are irreparably harmful to humans.

Choosing extruded polystyrene foam look at large firms that have long established themselves as decent manufacturers. In this case, we can confidently talk about an undoubtedly high-quality product. Unknown brands with loud names may be initially more profitable, but the risks associated with the subsequent alteration will cost you much more!

Remember that the poor quality of expanded polystyrene not only will not serve as a good heat insulator, but will also affect the health of your loved ones not for the better.

Types of foam

The raw material for the manufacture of the material is polystyrene and its derivatives. There are the following types of non-pressed foam:

- PSB - ordinary;

- PSB-S - self-extinguishing.

A distinctive feature of PSB S 25F is a surface with a high adhesiveness property. The smooth and even structure makes painting and plastering work easier. This variety is made from smaller granules, in comparison with the PSB-S 15 and PSB-S 25 brands.

The production method of the material is different, which is why the products are divided into two large classes. For the production of the first (non-pressing), a high temperature is used, leading to sintering of the granules. For the second (press) granules are kneaded at an elevated temperature, adding a special blowing agent to the composition. The final stage of production is removal from the extruder.

Two letters are used as marking - PS. Pressless varieties are designated as PSB. The most common brands:

- PSB-S-15. Due to its low density, it is more suitable for insulating those places that do not need high mechanical strength. It is in demand when insulating: attics, attic roofs, containers, wagons. Among the advantages: high moisture resistance, environmentally friendly and not "afraid" of the effects of microorganisms;

- PSB-S-25. The most popular and versatile brand. They insulate it: walls, floors, loggias, facades. The advantages are the same as for the first type;

- PSB-S-35. Foundations and underground utilities are insulated with this expanded polystyrene. Good because it is suitable for regions with an unfavorable climate;

- PSB-S-50. The difference is the highest density. It is used in situations where high mechanical strength is required. Fields of application: road construction in wetlands, construction and insulation of floors of interfloor ceilings, garages, industrial zones.

There are even more types of foam, each with its own properties and characteristics.

Thermal insulation boards made of extruded polystyrene foam

During the construction and repair of a building, the question of its insulation necessarily arises. A warm house is a guarantee of your family's health, as well as an opportunity to save on utility bills. As soon as you asked yourself this question, there is a need for a solution: what material is better to choose as a heater?

Currently, the market offers several options for insulation:

- glass wool;

- stone wool;

- extruded polystyrene foam;

- Styrofoam.

You need to choose one of these materials depending on the characteristics of your home and the specific work area: floor, balcony, walls, etc. There are certain rules to follow when choosing a heater.

Extruded polystyrene foam boards are almost universal materials for insulating a room and a building from the outside. It has the following positive qualities: moisture resistance, strength, high thermal protection, durability and safety for the health of the residents of the house. Why these properties of the material are important, we will understand in more detail.

Scope of application

It is the non-pressed polystyrene foam that is called polystyrene. The main area of application of this material is thermal insulation, sound insulation. They insulate walls, floors, windows, balconies, etc. The popularity of this method of insulation is economically justified. If you need to access a closed area, you can simply delete the fragment, and then reinstall it in its original place. Its low cost allows it to be massively used in other areas. It is often used to protect sports grounds and other objects from freezing. The specific scope of application depends on the brand.

The extrusion type is needed for thermal insulation and sound insulation of walls, facades, roofs, partitions, foundations. This type is more durable than the pressless version. This is due to the production technology. The extrusion method involves melting the original granules and then pouring the resulting mass into a mold.

Pressed polystyrene foam is taken in the manufacture of refrigerators, thermoses, vehicle bodies. It is irreplaceable in shipbuilding. Its electrical insulating properties make it popular in the electrical industry.

Packaging for products (disposable dishes, containers for fruits and meat products) and technical packaging are made of expanded polystyrene. The photo shows an example of numerous options for similar products. It has become an irreplaceable material for creating decorative elements.

Moisture resistance

The material for insulating the building must be resistant to moisture from the environment, and also prevent the accumulation of condensate inside the insulated surface. If, during operation, the insulation accumulates water, it will lose its heat-shielding properties, and your house will be cold in winter and hot in summer.

In addition, mold will begin to accumulate in the damp insulation; it will gradually destroy it and harm the health of the residents, who will have to inhale mold spores. Expanded polystyrene is resistant to moisture and is ideal for insulating walls, foundations, roofs, floors.

Heat protection

Heat protection is the main property that we wanted to get when choosing a material. Thermal protection is determined by the coefficient of thermal conductivity. This component is always indicated by the manufacturing plant in the accompanying documents for the product. The lower the coefficient of thermal conductivity, the higher the thermal insulation properties of the insulation. The thermal conductivity coefficient of expanded polystyrene ranges from 0.030. This is a good indicator that will allow you to save on the amount of material when calculating the thickness of the insulating layer.

Health safety

Extruded polystyrene foam for thermal insulation boards is used mainly of the same brands as children's toys, disposable tableware, and medical supplies. When the temperature drops, this insulation does not emit any substances hazardous to health into the external environment.

But polystyrene foam boards also have their drawbacks. Some consider low vapor permeability to be such a disadvantage, since the walls do not breathe. But the same "drawback" is a great advantage when insulating the foundation and floor, as it provides reliable waterproofing. But the flammability of extruded polystyrene foam really somewhat limits its scope.

And although some manufacturers have learned to add special substances that increase the resistance of the material to fire, this is still a rarity. More often on sale there are extruded polystyrene foam in the form of a plate of the G3-G4 flammability group. In any case, you will not use such plates without a protective coating, they will be inside the structure. With high requirements for fire safety, it is allowed to use a heat-insulating material of a flammability group of at least G3.

Evgeny Filimonov

Ask a Question

The largest producer of extruded polystyrene foam boards in Russia is PENOPLEX. The factories of the company are equipped with modern European equipment and produce high quality materials. The choice of goods for their intended purpose is also great. You can choose slabs: for the roof, for the walls, for the foundation, etc.

When choosing a heater, pay attention to its purpose, technical characteristics, appearance. If the insulation is of high quality, then it will have a uniform structure, an even and smooth edge and resistance to mechanical pressure.

Expanded polystyrene foam

Styrofoam expanded polystyrene is a modern heat-insulating material of white color, 98% consisting of air, enclosed in billions of microscopic thin-walled cells made of expanded polystyrene. The basis of the foam is polystyrene foam - one of the forms of polystyrene, which in turn is obtained from styrene by the method of radical polymerization. After synthesis and cooling, polystyrene is foamed using special installations and then shaped into the desired shape.

Expanded polystyrene is a modern, environmentally friendly heat-insulating material that allows not only to provide high thermal insulation, fire safety, but also to bring a decent economic benefit. Polyfoam is almost weightless, convenient for transportation and installation. Styrofoam expanded polystyrene is durable and reliable. The guaranteed service life of expanded polystyrene foam in the Far North is at least 50 years!

Basic properties of expanded polystyrene foam

- has a thermal conductivity in the range of 0.037-0.041 W / (m * K), which allows several times to reduce heat loss during insulation in construction, since in terms of thermal conductivity, 12 cm of expanded polystyrene foam is equivalent to 2 m of a brick wall and 4 m of a reinforced concrete wall.

- is highly resistant to various substances, including sea water, salt solutions, lime, cement, gypsum, alkalis, dilute and weak acids, soaps, salts, fertilizers, alcohols, adhesives, etc.

- has a very low water absorption, so the expanded polystyrene foam does not dissolve and does not swell in water, practically does not absorb moisture, and is resistant to aging. Styrofoam expanded polystyrene is not susceptible to microorganisms and decay. The operating temperature of expanded polystyrene foam is from -200 to + 85 ° C.

- due to its structural properties, it has decent compressive and flexural strength. Foam plastics, high density polystyrene foam, imply the replacement of some types of plastics with foam. Polyfoam expanded polystyrene does not sag in the wall after warming after a while, since it has some bearing properties, and accordingly does not form so-called "cold bridges", which sharply reduce the degree of thermal protection and sound insulation of the constructed building.

- consists of 98% air, which is inside a huge number of microscopic cells, forming white foam balls. In view of this, expanded polystyrene foam is widely used as an active noise absorber and sound insulator.

- environmentally friendly thermal insulation material. Using expanded polystyrene foam in the work, it is not required to use protective equipment, the foam is not poisonous, the foam is odorless, the foam does not emit dust during processing, the foam does not cause skin irritation. Polyfoam expanded polystyrene does not contain chemical compounds of the freon series that destroy the ozone layer of the atmosphere. Utilization of expanded polystyrene foam occurs without damage to the environment and human health.

- easy to handle with a hand saw or knife, has a low volumetric weight. Styrofoam expanded polystyrene is glued to various building materials and is easy to mechanically fasten.

- the shape is sheet, facade and profile.

Plates made of expanded polystyrene differ in thickness, density and, as a result, in purpose. There are the following main types of foam sheets:

- Polyfoam PSB-S-50 (density 40-42 kg / m3)

- Polyfoam PSB-S-35 (density 20-27 kg / m3)

- Styrofoam PSB-S-25 (density 15-16 kg / cubic meter)

- Styrofoam PSB-S-15 (density 10-13 kg / m3)

more details

The main areas of application of expanded polystyrene foam:

- Thermal insulation and sound insulation of walls, facades

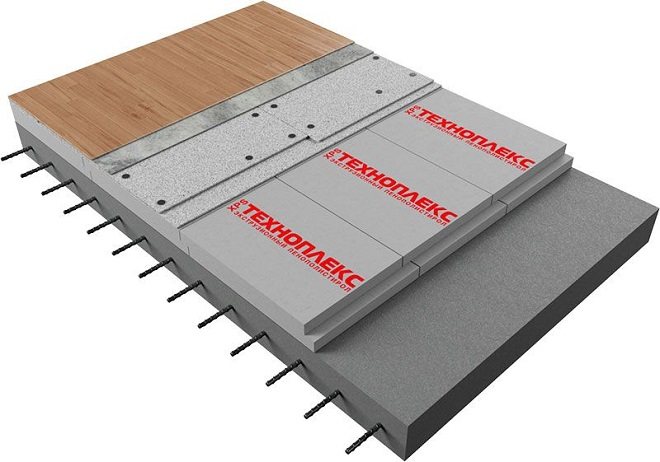

- Thermal insulation and sound insulation of floors and foundations

- Thermal insulation and sound insulation of roofs and attics

- Thermal insulation and sound insulation of attic ceilings

- Thermal insulation and waterproofing of underground utilities

- Thermal insulation of pipelines

- Thermal insulation and sound insulation of loggias and balconies

- Heat insulation and sound insulation of apartments, houses.

- Thermal insulation and sound insulation of structures that are not exposed to strong mechanical stress

- in the manufacture of multilayer panels, incl. reinforced concrete

- devices for heated paths, driveways, car parks

- to prevent freezing and swelling of soils

- for drainage, strengthening slopes in the construction of swimming pools, laying out lawns, sports grounds

more details

Currently, expanded polystyrene foam is one of the cheapest heaters on the market for thermal insulation materials. The most popular today is expanded polystyrene foam of the PSB-S brand. sells and supplies PSB-S polystyrene plates.

- Technical characteristics of expanded polystyrene foam

- The cost of polystyrene foam

How polystyrene foam is extruded

Extruded polystyrene foam is the most common type of gas-filled polymers. It is extruded using a technology that was developed more than 50 years ago and continues to be successfully used today.

The material is extruded in the following way:

polystyrene granules are mixed with a blowing agent at high temperature;

- then, using an extruder, the resulting mass is squeezed out.

Previously, the material was extruded using hard freons, then they began to use first a mixture of soft with hard ones, and then switched to CFC-free systems. In this way, polystyrene foam was extruded at the end of the last century, when freon-containing materials for insulation were banned in most European countries.

Where is expanded polystyrene used

Basically, extruded polystyrene foam is used to insulate such building elements:

- ceilings;

- floors;

- foundation;

- walls;

- doorways;

- window openings.

For example, when fastening this material to the floor, it does not reduce the height of the room and is suitable for floors with different heating systems, as well as for those floor coverings that are located under basements or run on the ground.

The advantages of installing this material on the floor are as follows:

- high compressive strength;

- maximum application period;

- minimum deformation;

- minimum thermal conductivity.

The floors should be insulated with expanded polystyrene in rooms that are operated at low temperatures, where there is a need to withstand heavy mechanical loads or high levels of humidity.

Expanded polystyrene boards can be attached directly to concrete, for this you just need to prevent the insulation boards from intersecting with concrete joints.

Wall insulation

Expanded polystyrene is actively used for thermal insulation of walls, both external and internal. Moreover, it is worth noting that the internal thermal insulation of the walls is relevant mainly with the rapid insulation of the room.

External walls are equipped with polystyrene foam in the following ways:

- fastening the material to the adhesive;

- installation of expanded polystyrene on the wall on a cement mortar based on fiberglass reinforcement;

- mounting on mastic;

- wall mounting using special tools.

When the walls are externally equipped with expanded polystyrene, it should be treated with a non-combustible substance:

- bricks;

- plaster;

- ceramic tiles;

- steel profile;

- aluminum profile.

Also, expanded polystyrene is used in the construction and insulation of the foundation. In particular, if you use it as a permanent formwork, then you will significantly reduce the consumption of concrete and reinforcement. Thanks to extruded polystyrene foam, you will significantly extend the life of the foundation of the reinforced concrete and basement walls.

Below you can watch a video tutorial on the installation of extruded polystyrene foam. And then we will talk about this in more detail.

Preparatory work

To prepare polystyrene sheets for installation, they need to be processed, that is, cut to one size or another. You should also select an adhesive composition and elements for attaching the material to walls or other surfaces.

The glue should be applied to the insulation sheet about an hour before it joins the surface.

If we plan to insulate the walls, then their entire surface must be cleaned of dirt and all unnecessary in advance:

- old cladding;

- old fasteners;

- irregularities;

- protrusions;

- gaps;

- cracks.

Using a putty mixture, gaps and crevices should be closed so that they do not interfere. If there is a very noticeable curvature, the surface must be equipped with a leveling layer of the mixture. And if you cannot remove the convex places before installation, then the sheets of insulation must be slightly trimmed inside.

Also, do not forget to treat the walls with deep penetration soil.

Installation

Install facade thermal insulation in dry and calm weather. Permissible temperatures are from +5 to +25 degrees Celsius. First of all, carefully prepare the work surface. Stages of work:

- All elements are removed from the wall (gutters, lamps, etc.). The protrusions in the form of stucco or masonry above the surface level are dismantled. If you want to leave them, you will have to use more insulation (fits on the sides and on top). Old plaster, dust, dirt are removed from the wall. Using a level or a long rule, check the flatness of the plane. The wall is then covered with a deep penetration primer and left to dry.

- Set the starting profile required to hold the sheets. Plastic elements are suitable for connecting their joints.

- Insulation is glued. To begin with, prepare the glue, focusing on the instructions. Next, the glue is applied both to the work surface and to the foam board. Work is carried out from the bottom up. The adhesive is removed from the seams. The next row should be mounted with an offset of at least 20 cm (preferably on the floor of the slab). When installed near window openings, the following rule is followed - the vertical joint of the insulation should not coincide with the border of the opening. It takes three days for the glue to dry completely.

- The 25F foam is fixed with dowel-umbrellas (the thickness is selected depending on the wall material).

- A reinforcing layer is created.

- Finish the work with finishing.

If you follow all the rules during the installation of facade polystyrene foam, the thermal insulation will remain effective and durable.

How to install extruded polystyrene foam under siding

To install this material under siding, you need to put a vertical crate made on the basis of pine needles and treated with an antiseptic, or from galvanized metal profiles. You need to fix it to the facade of the building, observing a step within 40 cm.Use dowels and control the level of the plane of the frame.

Evgeny Filimonov

Ask a Question

Expanded polystyrene must be placed between its guides, then it is fastened with disc dowels. Next, the layer of insulation must be covered with a membrane that protects from the wind, which will remove the moisture from their layer of thermal insulation to the outside.

Between the layer of thermal insulation and the cladding, you need to consider the presence of a ventilation gap. To do this, install another lathing with a step of 30 cm guides. The height of the gap should be approximately 1.5 cm. Then, the siding panels should be attached to the frame guides.

How to install the material under the facade plaster

So that the thermal insulation layer does not lose its integrity, the expanded polystyrene sheets must be joined with cut pieces. If too large gaps appear between them, they are sealed with liquid polystyrene foam or wedge-shaped pieces of insulation.

In this case, polyurethane foam cannot be used, since it can spread the insulation layer and thereby violate its integrity. The joints between the thermal insulation must be sanded with a float.

For attaching expanded polystyrene sheets, disc dowels are used, equipped with hats in the form of umbrellas, which help to press the heat-insulating material to the wall surface.If you take other elements for fastening, such as nails or self-tapping screws, there will be a high risk that the thermal insulation layer will be deformed under the influence of atmospheric phenomena. After the installation process is over, the dowel heads must be carefully putty.

Features of the use of disc dowels when fastening

When installing insulation by means of disc dowels, you can use special adhesives. This is especially advisable in the presence of irregularities on the surface, as well as all kinds of pits and defects.

The sheet of extruded polystyrene foam must be soaked in the adhesive and pressed against the wall. The glue mixture should be applied using special combs, which are usually used when laying tiles from tiles.

Evgeny Filimonov

Ask a Question

It is necessary to alternate layers of glue so that the sheets fit better to each other, regardless of the unevenness at the base of the wall.

After the glue has dried, you need to make holes for the disc dowels using a hammer drill or hammer drill. They are not recommended to be installed until the glue is completely dry, since during installation the sheets may shift or press in too much, and this will require additional costs of putty and plaster. Dowels should be placed along the edges of the sheets and in their center.

Features of a two-layer installation of insulation

To increase the thermal insulation properties of the material to be installed, it can be placed in two layers. In this case, it is not necessary to putty the first layer of material. The thermal insulator must be directly attached to the wall surface. For fastening, the same disc dowels are used, the length of which should be selected depending on the thickness of the thermal insulation layer.

Thermal insulation of walls and other surfaces using extruded polystyrene foam has both disadvantages and advantages, of which there are much more in this case. This material is versatile and environmentally friendly, in addition, installing it as a heater, you do not have to change it to a new one after a few years, because with proper operation it can serve for decades.

Based on materials from the site: teplogalaxy.ru, kotel.guru

Application in housing construction and reconstruction of buildings of extruded polystyrene foam

External insulation scheme.

It is not difficult to insulate the walls of the building with expanded polystyrene with your own hands, since the installation technology is quite simple. The load-bearing walls of the house can be insulated outside and inside the building. External thermal insulation of the structure is more preferable, since this method does not reduce the useful area of the room due to the laying of an insulating layer. But if for some reason it is not possible to perform external thermal insulation, you can lay sheets of expanded polystyrene and indoors. Do-it-yourself insulation of bearing walls with expanded polystyrene can be carried out at the construction stage or during the reconstruction of a building.

Now in house building technologies are used for the construction of hollow walls, which provide significant savings in building materials. Hollow walls are filled with insulation, most often extruded polystyrene foam is used as a heat-insulating material. Thermal insulation of walls in this way allows you to apply finishing to the surface of the walls, both inside and outside the building. Insulation is placed directly into the wall cavity. Such thermal insulation of the structure is more durable, since the thermal insulation material does not have contact with the external environment and is protected from external factors.

Back to the table of contents