Specifics

The main aspect that should be taken into account is this: the hood of the hood necessarily surpasses the area of the equipment above which it is located. This way the smoke is collected much more efficiently. The chimney should have a constriction and bend. This improves the dynamics of the extraction of combustion products and does not produce reverse thrust. The top side of the pipe is usually positioned at least 3 m from the ground. This provides the necessary exhaust conditions. If the calculation is incorrect, the chimney cross-section results in an ineffective discharge of the combustion results.

Each owner is especially proud when, by his efforts, he creates both a brazier and an extractor hood for him.

Thanks to additional components, the extraction efficiency is developed. But this requires additional costs. These components are:

Spark extinguisher. The position is the top of the chimney. This is a tubular metal sieve. Smoke easily flows through it, and sparks are extinguished. Fat trap. This frame with an inserted special cassette (cassette - replaceable) for capturing fat. When this device becomes dirty, it needs to be rinsed well or replaced altogether.

It is important here how the model is delivered, what filtering substance is involved. Fan

It seriously develops pulling power. When installing it, it is necessary to make competent calculations with the parameter of the required equipment.

Do-it-yourself metal version

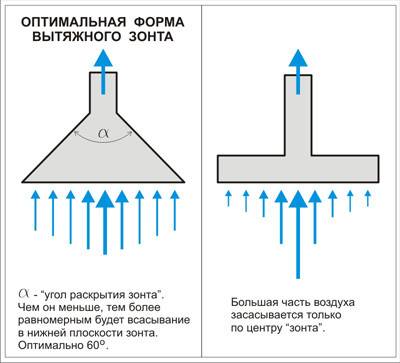

The metal structure is an exhaust hood, the operating principle of which is extremely simple. It collects combustion products and removes them through a pipe from the room. Such an umbrella must be very smooth, as any roughness will reduce its effectiveness. If you prefer a metal umbrella, you must also provide a wide opening.

To make it, you will need a sheet of steel, corners (made of metal), a riveter, rivets, screws, a welding machine, a grinder and a drill.

Now as for how to do it:

- The first step is to create a drawing and apply all the dimensions on which the hood will be designed.

- Now we make the frame. First, blanks of the required length are cut from metal corners. We alternately weld the lower and upper parts of the frame, and then we connect them into one structure.

- The frame of the chimney itself is assembled from the corners.

- Treat the seams left after welding. They are sanded with a disc, and on top are coated with a special varnish against metal corrosion.

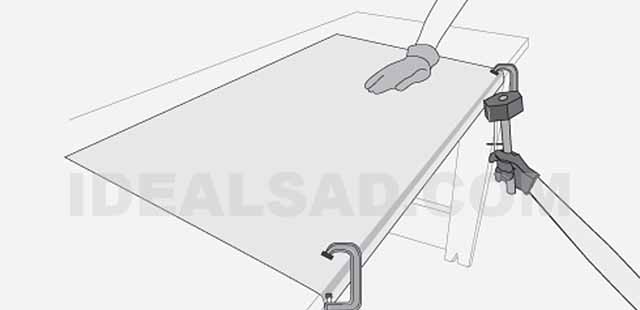

- Let's start covering the finished frame. We cut out metal sheets and make folds, having previously laid the sheets on the workbench.

- We use a drill and make mounting holes to securely fix the skin.

- Finally, a riveter will help sheathe the frame with sheets of metal.

- The final touch is the application of an anti-corrosion coating to extend the life of your structure.

Many are interested in how such a hood is attached. This can be done either with racks or with suspensions. The former are made of brick or iron. You can also add an interesting iron element - massive chains on which the hood will be mounted.

How to make a cooker hood for a barbecue with your own hands.

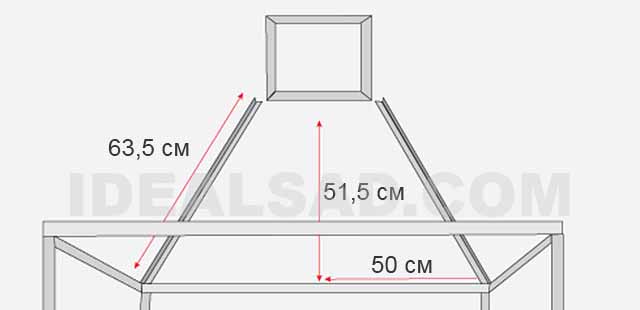

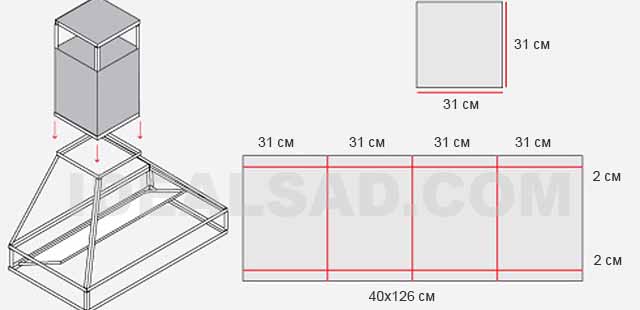

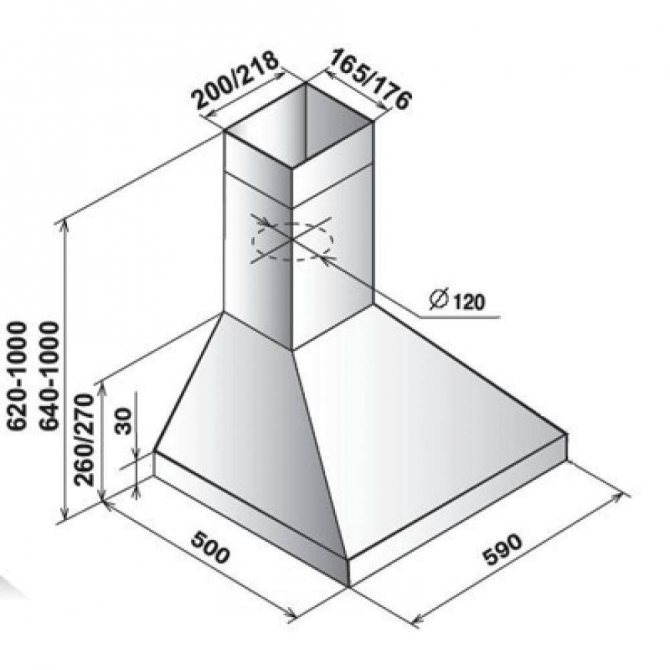

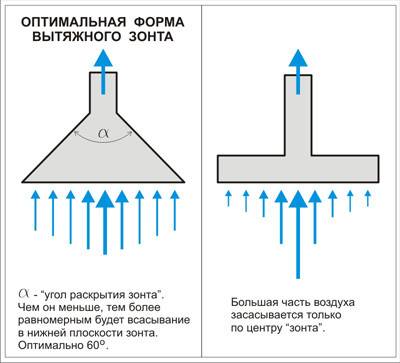

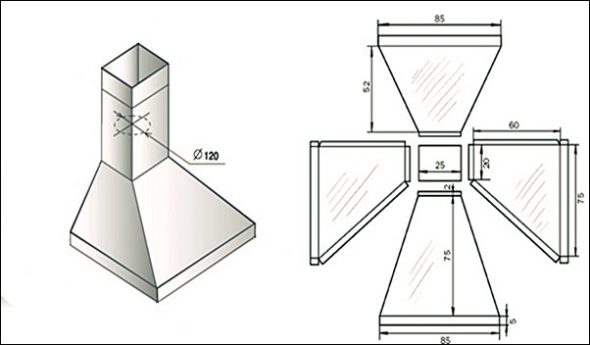

Before starting work, measure your grill, if your dimensions are different, then you need to adjust the dimensions of the hood.

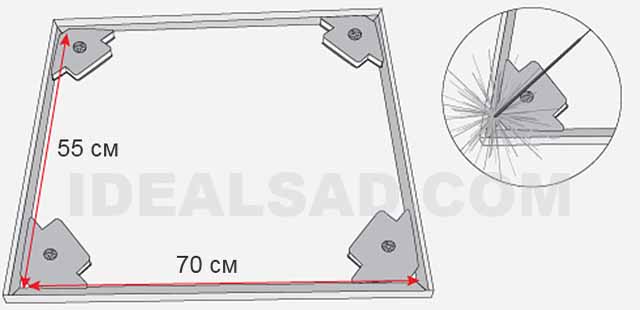

Before work, new metal corners must be cleaned from factory grease with a clean rag. We cut metal corners with a grinder (dimensions for each part of the barbecue in the drawings below).In order to avoid the ingress of metal shavings when cutting metal, be sure to work in safety glasses.

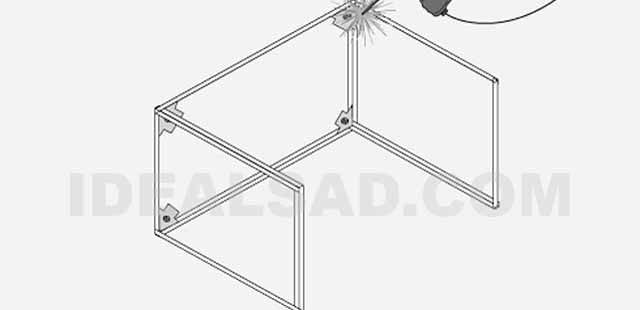

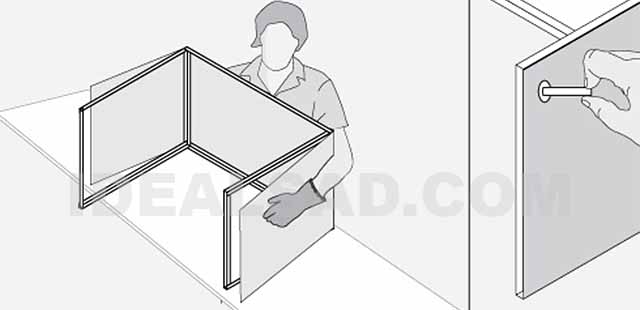

- We weld 2 sides of the hood base from metal corners:

- Then we weld the corners to them for the back surface of the brazier base:

- We collect the lower part of the dome of the exhaust hood for the barbecue:

- We weld the corners of the back of the brazier dome onto it:

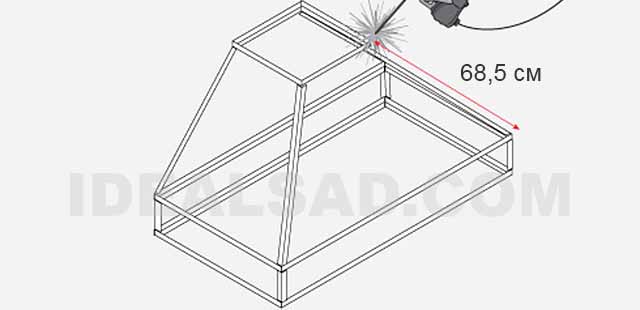

- We collect the side parts of the hood for the barbecue:

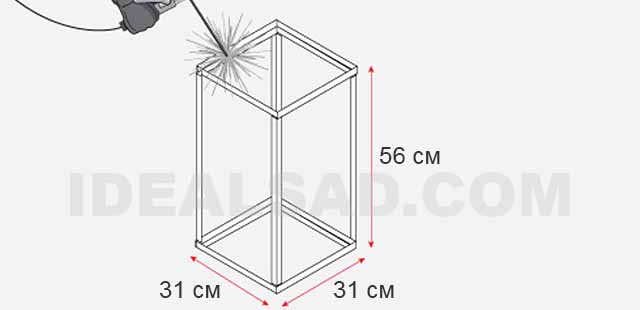

- We collect the pipe:

- After welding, we process the seams of the hood with a grinding disc. In order to protect the metal, we process the frame with heat-resistant paint.

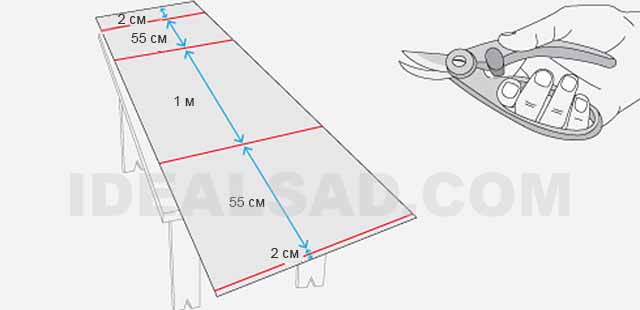

- We mark the metal for sheathing the exhaust hood:

- We bend the edges and fold lines, securing the sheet to the edge of the workbench:

- We sheathe the base of the hood with metal using rivets and an installation tool (rivet):

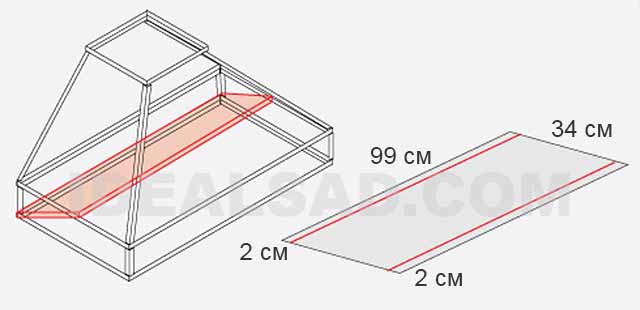

- Before covering the hood of the hood, add a metal plate diagonally inward, which will improve traction. This plate is a metal sheet measuring 99x34 cm with 2 cm edges along the edges, for which it is attached in the lower part of the dome.

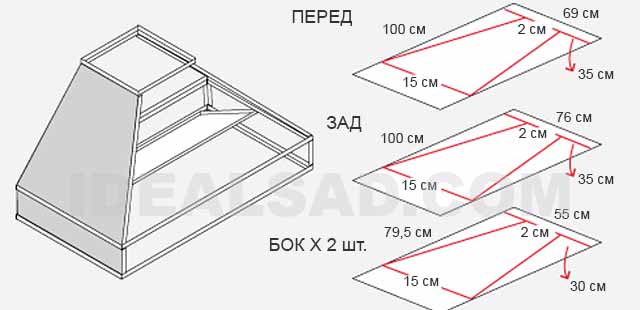

- We mark and cut out the metal for covering the hood dome:

- We sheathe the pipe of the exhaust hood for the barbecue:

- We paint the grill hood with thermal paint.

- We install the base on the brazier, fixing it to the brick with self-tapping screws for concrete (brick).

- We install the dome, fastening it with rivets to the edge of the base.

- We install the pipe, putting it on the dome, we use rivets for fasteners.

Hood for barbecue in the gazebo

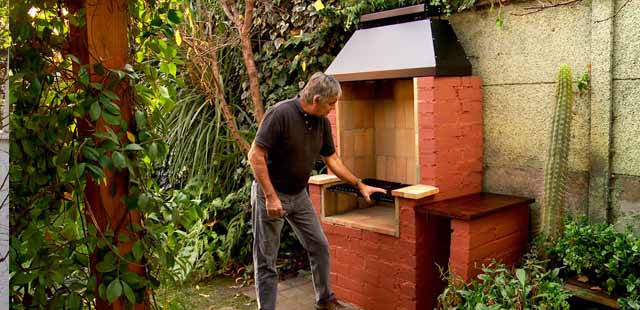

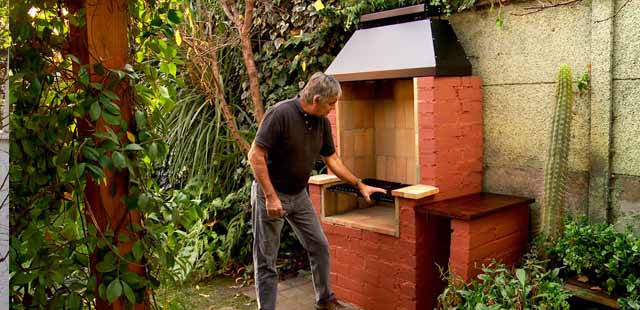

This attribute of outdoor picnics can be portable and stationary. Portable barbecues, very simple designs, do not need hoods. The owners can easily place them anywhere, so that the smoke does not go towards the recreation area, and does not interfere with the guests. But stationary barbecues need a smoke extractor, especially if they are located inside the gazebo or in the summer kitchen.

There are two main types of brazier hoods: metal and brick. The first are the most widespread. They are easy to make with your own hands, you can hang or install them on supports above a brick oven, the choice of shapes and sizes is very large. Brick hoods, in fact, are an integral part of the barbecue oven, on which you can cook not only barbecue and grilled vegetables, but literally anything. Laying out a brick hood, which will become the beginning of the chimney, is already a matter for the master, the stove-maker.

Therefore, we will focus on metal exhaust hoods, which can be in the form of a hemisphere, parallelepiped, or a cut pyramid. Such domes for barbecues are made most often from stainless steel sheet with a thickness of 2 millimeters. Factory products are covered with a protective polymer layer; at home, the metal can be simply painted to give the hood a more attractive look and extend the service life.

The design of the simplest metal hood is not complicated:

- Smooth rectangular base;

- The dome is on it;

- Chimney pipe.

The size of the dome will depend on how large your grill is. In order for the umbrella to remove all combustion products, soot and sparks, it must be 30 percent larger than the size of the barbecue. And the pipe should be located exactly in the center, above the hearth!

We give you the standard parameters of an exhaust hood:

- The width of the smoke box, dome - from 65 to 95 centimeters;

- The length of the smoke box is from 85 to 155 centimeters;

- The height of the pipe is not less than 300 centimeters, which will ensure normal traction in any weather;

- The pipe section is at least 25 centimeters, also for good traction.

You can increase or decrease these standard sizes of the smoke collector-umbrella depending on the features of your barbecue. But we do not recommend reducing the height and diameter of the chimney pipe!

The manufacture of a metal barbecue is associated with welding and flexible steel, but in general it does not represent anything complicated, a home craftsman can do it quite well. You can supplement the exhaust hoods with a fan so that the draft appears immediately after the firewood or coal is ignited, without waiting for the smoke to heat up and begin to go into the chimney in a natural way.

A spark arrester, which is installed on top of the pipe under the chimney hood, will also not interfere. Some people put a removable grease trap inside the hood, which will have to be cleaned regularly. However, this process is familiar to all owners of conventional kitchen hoods. All of these additions will increase the cost of the hood, but make the cooking process safer and more convenient. published by econet.ru

If you have any questions on this topic, ask the specialists and readers of our project here.

Cooker hood: design options

You can modify the base hood by making other hoods. Often the base is laid out of bricks, and then a dome with a pipe is installed on it.

The pipe can be either finished metal or brick.

In addition, instead of a U-shaped base, you can make an angular one:

Exhaust hoods made of bricks are made according to the same principle - a metal frame is cooked, which is lined with refractory bricks.

In addition to bricks, the hood is often decorated with wild stone.

The cooker hood can also be decorated with wood - a metal hood is sheathed with wood using thermal insulation gaskets.

A do-it-yourself barbecue hood will create more comfort for you, eliminating annoying smoke in your eyes when cooking and leaving the aroma of open fire for ready-made dishes.

If you are just starting to think about how to make a brazier yourself, you will be interested in our article Want to make a brazier with your own hands: 25 photos and drawings

Features and Benefits

A gazebo with barbecue will make cooking in the fresh air a truly relaxing, comfortable and relaxed experience. Its huge advantage is that an unexpected change in weather, insects will not spoil it. The gazebo will be able to protect a large number of people from bad weather. And if the interior, for example, provides for a resting place with a rocking chair, a hammock, then many guests are definitely provided for the owner of this miracle.

Gazebos can be temporary or permanent.

Temporary gazebos are installed directly in the warm season, by the onset of cold weather they are dismantled and put away for storage. As a rule, they are used by summer residents whose stay on the site is seasonal. The advantage of this option is the ability to move them, the ease of construction.

Permanent gazebos are installed on asphalt pavement, piles or strip foundations, depending on the type of soil and the severity of the structure. Even in winter, such a gazebo can be used for its intended purpose. The size of permanent gazebos can be quite large, it all depends on the desires of the owners. Often full-fledged kitchen and dining areas, a resting place are arranged there.

The most important attribute in such a gazebo is a barbecue, on which any dish turns out to be tasty and aromatic. The chimney is the key design element here. The presence of this design is necessary even if the gazebo is open. The chimney removes smoke and soot from the gazebo space and brings them out.

The smoke collector for the barbecue in the gazebo can be made of brick or metal. It is better to make metal hoods from stainless steel; there is practically no need to care for it.

Brick chimneys are more difficult to assemble, heavier and more expensive, therefore they are rarely used. They are used mainly for brick arbors, in case there is a desire to withstand the entire building in a single style.In small buildings, due to their heavy weight, their use is highly undesirable.

A fairly common option for a gazebo is a folding brazier. During the cold season, gazebos are usually open, and the coatings inside are exposed to the weather. The brazier suffers from them quite strongly.

When organizing a hood in a gazebo, the following difficulties most often arise:

- The smoke does not leave the gazebo. This is usually due to the low combustion temperature. This problem can be corrected by raising the temperature in the hearth - the smoke heats up, its density changes and it begins to rise and go into the chimney.

- Combustion products accumulate in the gazebo. This is due to the insufficient length of the smoke collector pipe. The top of the pipe must be at least 3 meters above the ground. In other cases, the draft is not enough, smoke and soot remain in the room.

- After heating the wood to a sufficient temperature, the smoke does not go away. In this case, we can already talk about the wrong size calculation. The diameter of the outlet pipe must be at least 15 cm, and the section of the chimney itself must be a square with a side of at least 26 cm.

It is desirable that the gazebo is warm and protected from the weather as much as possible. Such structures can be open and closed.

At the open gazebo, the walls are low, the roof rests on racks of various types. In case of worsening weather, they can be provided with PVC curtains or film, reinforced as roll-curtains on the openings. In the event of a cold snap, they can be lowered and the space inside from the wind and rain can be closed. A closed gazebo is a small house with a door and walls. The walls can be movable and fold in good weather.

There are times when the means or the size of the gazebo do not allow organizing the hood for the barbecue. This issue can be solved by placing the hearth outdoors.

In addition to a barbecue or barbecue, an open hearth can be equipped in the gazebo. It can be used for cooking, boiling, or braising in refractory cookware.

It is good if a comfortable firebox is equipped next to the gazebo. It is better to close it with a canopy or make it in the form of a special box with a lid.

Fire safety must be provided in full. The distance from wooden residential buildings to a gazebo with a barbecue should be at least 8 meters. Electrical appliances must be grounded, only a special outdoor cable can be used. If there are elements made of wood in the gazebo, they must be treated with fire retardant compounds against fire.

Types of ventilation hoods

round ventilation hoods of different diameters

Depending on the shape and purpose, exhaust ventilation hoods are:

- round;

- rectangular;

- exhaust;

- sewer.

Round ventilation hoods

Round umbrellas are installed on the tops of ventilation pipes of the corresponding section. They are suitable for systems with any type of draft, protecting pipes from precipitation. The umbrellas are fastened with a bandage, flange or nipple connection.

Round umbrellas for ventilation systems are produced from:

- galvanized sheet steel;

- copper;

- PVC;

- of stainless steel.

Plastic is used mainly for the production of ventilation hoods.

Some models are supplemented with a net covering the outlet from small rodents, birds, dry foliage.

Rectangular ventilation hoods

rectangular ventilation hood

Rectangular and square ventilation hoods are usually installed on insulated exhaust shafts. Fastened with a nipple connection.

Rectangular umbrellas for ventilation are produced from sheet steel with a thickness of 0.55 - 1 mm according to TU. The aspect ratio can be selected depending on the mine project, but taking into account the GOST for ventilation system umbrellas.The outlet of the rectangular hood can also be covered with a mesh.

Sewer ventilation hoods

PVC umbrellas for ventilation of internal sewerage have the same protective function, but they also regulate the pressure in the pipes. The ventilation umbrella is installed on the head of a non-pressure sewer pipe, it can withstand up to +60 degrees. For fastening PVC ventilation hoods, a socket joint is used, which is sealed with a rubber ring that does not allow leakage.

GOST requirements for PVC umbrellas for ventilation systems:

| Diameter in mm | Weight, gr |

| 50 | 890 |

| 110 | 1230 |

The diameters of PVC ventilation hoods coincide with the standard size range of sewer pipes and can be 50 or 110 mm. Umbrellas for ventilation made of PVC are produced only for a circular cross-section.

Exhaust ventilation hoods

classic hood

Exhaust hoods are installed in the kitchens of cafes and restaurants above the hobs and ovens. Hot air and steam rise up and immediately fall into the canopy. To increase efficiency, a fan is often built into the umbrella. There are also supply and exhaust models of kitchen umbrellas.

Exhaust ventilation hoods can be:

- Wall mounted. They are hung on the wall above the heat and moisture source. Small-diameter umbrellas are attached only to the wall, larger ones in addition to the ceiling with chains;

- Central. Such umbrellas are installed with the "island" arrangement of the plates. The optimal effect is achieved by arranging two umbrellas, which are attached to each other with their back surfaces, and to the ceiling with chains.

At catering establishments, wall-mounted ventilation umbrellas are often installed.

Any umbrella model consists of a body and labyrinth filters, which are periodically dismantled for washing. All parts are made of food grade stainless steel, resistant to heat, moisture, grease and detergents.

Central and wall-mounted ventilation hoods are equipped with a drain channel and storage tanks, into which grease flows from the filters.

The principle of operation of central and wall umbrellas for ventilation is quite simple: hot air with oil particles hits the walls of the labyrinth filter, condensation of oils occurs, which, as they accumulate, drain into storage tanks through sealed drain pipes. A small amount of detergent is poured into the storage containers to facilitate cleaning. Glasses are cleaned 1 time in 7 days.

Main characteristics

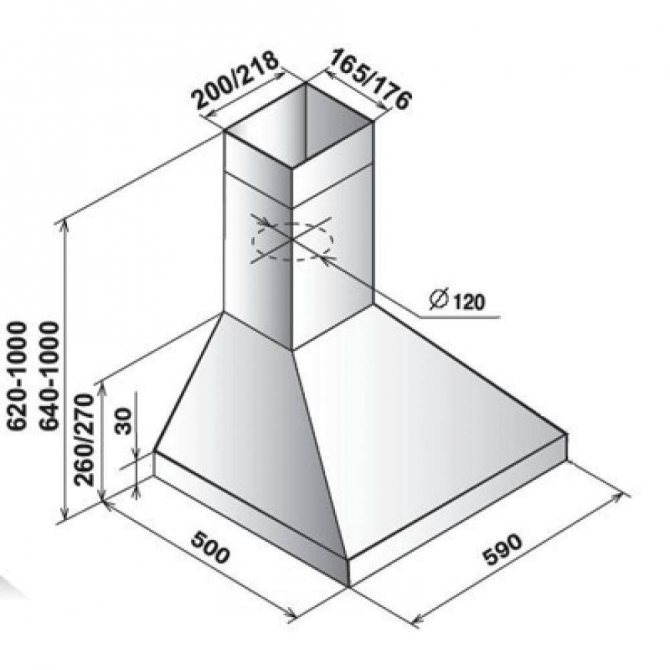

As a rule, do-it-yourself exhaust ventilation umbrellas are not made. Therefore, when choosing, the main parameters that determine the work will come in handy:

- Dimensions. The width of the dome should be 10 cm wider than the surface of the slab. For example, if the hob is 450 mm wide, the umbrella is 550 mm or more. Otherwise, it will not be able to efficiently capture steam and fats;

- Air speed and drag. Air resistance and air velocity depend on the design of the labyrinth filter. In order for all the oil to settle on its walls, the air speed must be within 0.8 - 1.5 meters per second. Otherwise, the quality of the umbrella will noticeably decrease;

- Inside temperature. If the temperature in the umbrella is above +100 degrees, the fat will evaporate and settle in the air duct;

- Air consumption. This is one of the most important indicators, which is calculated depending on the volume of the room, the power and number of stoves and ovens, and the intensity of the workshop.

As you can see, it is not easy to make a ventilation umbrella with your own hands. There are GOSTs for umbrellas of ventilation systems, regulating the dimensions, characteristics and materials for their manufacture.

Interior decoration

The design of gazebos with barbecue is a matter of taste and capabilities of each owner. There are several recommendations, following which your barbecue corner will become a favorite place for the whole family and will decorate the site.

You need to start arranging the design of the gazebo with the idea of the structure itself, it should be harmoniously placed on the site.

The gazebo must be positioned correctly. To do this, they choose the most beautiful and quietest corner in the garden, far from prying eyes. This will allow its visitors to relax and unwind. The landscape and the summer kitchen should be compatible with each other.

If we talk about the interior, then everything is more complicated here. The space inside must be beautiful, safe and functional at the same time.

When decorating a gazebo, the scope of imagination is unlimited. This is a great way to apply things that may have lodged somewhere in the attic. For example, a horn on the walls or an old samovar can become interesting interior elements. Anything can become a beautiful element: curtains, forks hung on the wall near the barbecue, shovels and grabs for meat, jars with spices, flowers on the table.

Lighting is an important element of any interior. The cooking area should be lit most brightly, and soft dim light is suitable for the relaxation area. It's good if the light level is regulated.

Design of the cooking area. The key element of this area is the oven. Depending on the size of the gazebo itself, the content of this zone will be different. For a small gazebo, it is possible to install a small table with a hand basin. The worktop material should be easy to clean and durable. It is convenient if there is a small shelf next to the barbecue where you can put seasonings, put the most necessary appliances.

If space permits, you can make a lounger in the gazebo or hang a hammock in a secluded corner. The space next to the gazebo is equipped as much as possible. For example, you can pave the area under an additional canopy in case of an increase in the planned number of guests. You can install a large garden swing with a roof, which will become a favorite place for children and adults. For children, you can also arrange a sandbox or soft playground for active games. Here, the master's imagination can be unlimited.

The very material of the gazebo can contribute to the creation of coziness. Here the tree will be the undisputed leader. Mats made of straw or other natural materials can be used to complement it. In a closed gazebo, you can use any kind of textiles: large interior pillow-chairs, soft bedspreads. It should be noted that the size of the gazebo affects the coziness - the smaller it is, the more comfortable a person is in it, as a rule.

All materials must be suitable for outdoor use or handled appropriately. Also, they should all be easily cleaned, since staying in the gazebo is associated with eating.

The most common and pleasing to the eye is the use of natural colors of the natural range. The gazebo should not be striking with its brightness or pretentiousness - it will quickly get bored.

The style of the gazebo is often chosen based on the preferences of the owners or from what is at hand. The Asian style involves intricate flattened roofs with multiple levels of flooring inside. Country style works well for wooden buildings. The English style with forged elements will appeal to lovers of elegance and sophistication.

When deciding on the idea of \ u200b \ u200bdesigning the entire gazebo and its interior in particular, one must not forget that this is an auxiliary structure, and unnecessary costs and difficulties in its construction are not necessary in all cases. And often they may turn out to be unnecessary and unnecessary and only make it difficult to stay inside and the process of cooking itself, which is the main one.

A few words about folding barbecue

The folding brazier is a lightweight brazier that can be easily moved and installed in the right place, including in the gazebo.The best material for its manufacture is stainless steel, the optimal wall thickness is two millimeters.

Thinner sheets will quickly burn out, thicker ones will significantly increase the weight of the structure. To improve the combustion process, through holes are made around the perimeter of the lower part of the brazier. Through them, coals can fall onto the floor of the gazebo and ignite it.

In addition, the folding brazier is easy to tip over, so you need to use it very carefully.

Benefits

However, a folding brazier has certain advantages. These include:

- small weight for easy transportation;

- when disassembled, the brazier easily fits into the trunk of a car;

- low cost.

A big plus of a folding barbecue is the ability to use it without arranging a hood.

A small brazier does not generate much smoke when cooking meat. As a rule, a folding brazier is installed in gazebos, which are a canopy without walls. In closed gazebos, it must be equipped with an extractor hood.

Why build a chimney

Many lazy inhabitants do not see the point in arranging a chimney for a barbecue in a summer gazebo. They rely on the wind to blow smoke out from under the canopy, but in reality this is not happening. One has only to start frying the meat - the whole gazebo is covered with clouds of smoke, and if there is a hood, it is removed outside.

If you do not do it, then after using the barbecue, a layer of soot and soot will settle on the ceiling, which is extremely difficult to clean. If you often fry meat on such a grill, the kebab will be seasoned with soot crumbling from above.

In addition, a fireplace with an open flame that is not equipped with a hood poses a fire hazard.

What is a chimney umbrella and why is it needed

A pipe umbrella is a device that is located at the top of a house pipe and carries several functions. In appearance, the following main types are distinguished: in the form of a cone, pyramid and semicircle, there are also umbrellas of more complex designs. It is installed both on the chimney and on the ventilation pipe.

It has several main functions:

- Prevents precipitation from entering the chimney or ventilation system. When moisture accumulates inside the chimney, the functions of the draft of the air system are reduced by an order of magnitude.

- Prevents destruction of the chimney. It significantly increases the service life of the pipe, and with proper arrangement, it is possible to drain the accumulated condensate through special grooves.

- Debris protection. Protects from the entry of leaves, insects and other foreign objects into the system.

- Increase in traction properties. Increases traction by almost a third.

Despite the ease of installation and low cost, the umbrella has many advantages. When choosing an umbrella, you should also pay attention to the fact that your friends and neighbors will see it, so if possible, do not forget about the design.

Some notes and recommendations

Any hood, including hand-made devices, has certain disadvantages that should be borne in mind in advance, so that later you do not have to re-install the installation.

The barbecue fan is mounted after masonry using special bricks and clay mortar. The bricks should be laid flat on top of each other. The chimney must be fitted with a shutter and the rear wall must have a bend to provide improved draft.

If you need to light the brazier, then the smoke will not go straight into the smoke box. At first, the device smokes in different directions. The smoke generated during ignition can have a fairly low temperature level. The moment the flame flares up, the thrust will become stable.

After the flame has ignited, the smoke collector may not be able to cope with the elimination of smoke, that is, the barbecue woman smokes at the same time.This sign indicates that the chimney has a small cross section. Since it must cope with its functions without any problems, the dimensions of its square section must be at least 26x26 cm.

The best aerodynamics of a vertical metal pipe is ensured only with its narrower cross-section, the diameter of which is about 15-20 cm. Since the smoke coming out of the pipe begins to interfere with the cooking process, the upper part of the chimney should be at least 3 m above the ground. Then there will be enough thrust, and the smoke will be removed to the required height, and then dispersed in the air.

Exhaust hood design

A metal hood can be thought of as a smoke collector or a domed smoke hood. The fixture has a hole in the center and a barbecue pipe. The dome design is a smoke hood or exhaust hood. Its diameter should be 1.5 m. A popular material for creating a dome-shaped device is a metal sheet, which is 2 mm thick.

Copper hoods have a rather impressive look. The center of the dome of the device is equipped with a hole with the edges connected to a vertical pipe, the height of which is 2-3 m. Do not use asbestos-cement pipes to create a hood with your own hands. Although asbestos is a flame retardant material that has excellent thermal insulation properties, it is hazardous to health.

Rack-mounted metal hoods are suitable for barbecues and are becoming more and more popular. If the brazier, grill or barbecue is installed in the gazebo, then the hood is suspended from its ceiling on chains. In this case, the pipe usually passes through the center of the gazebo roof.

The material that is adjacent to the chimney must be fireproof. To create a hood, you will need experience with a sheet of metal. The device does not have to be domed. You can order the manufacture of hoods from professionals.

A do-it-yourself smoke collector from metal can have not only a cone-shaped shape, the cross-section is rectangular or square. The device is functional, but requires constant maintenance. Its smooth surface makes it easy to care for. It should be good at removing smoke, having aerodynamics.

Owners of gazebos, which are lined with brick smoke collectors, claim that a rusted metal hood can contaminate food. When the stove smokes, soot and rust can drip onto the food being cooked. Brick hoods are durable.

How to make an exhaust hood out of metal sheets

How to make a cooker hood for a barbecue without spending a lot of time and money on it? A lightweight and durable hood over the barbecue in the gazebo will be obtained from the following materials:

- Iron. Sheet thickness 3 mm.

- Several metal corners.

- A welding machine is indispensable. A mask is required to protect your eyes and face.

- Drill equipped with concrete mixing attachments.

- Screws.

- Riveter and grinder with discs suitable for cutting sheet metal.

- Heat resistant paint.

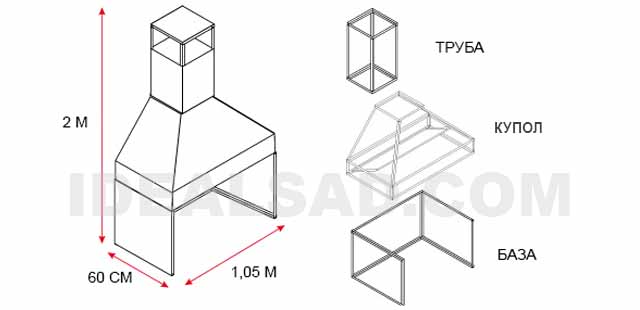

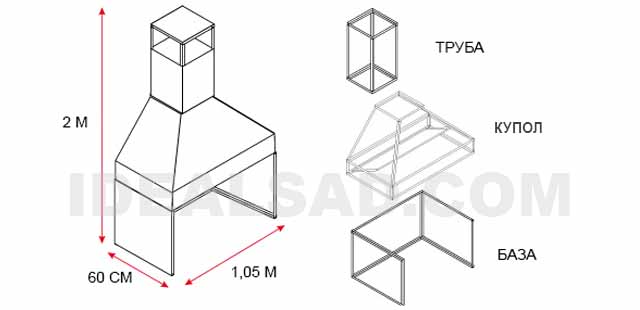

Exhaust hoods for the barbecue are built from metal corners. First, the skeleton is welded, and then sheathed with a metal sheet. For a medium-sized gazebo, it is enough to make a hood with a height of 1.5-2 m. It is suitable for a barbecue with a size of 105x60 cm. An apparatus is required for welding. In addition, electrodes must be prepared for this equipment.

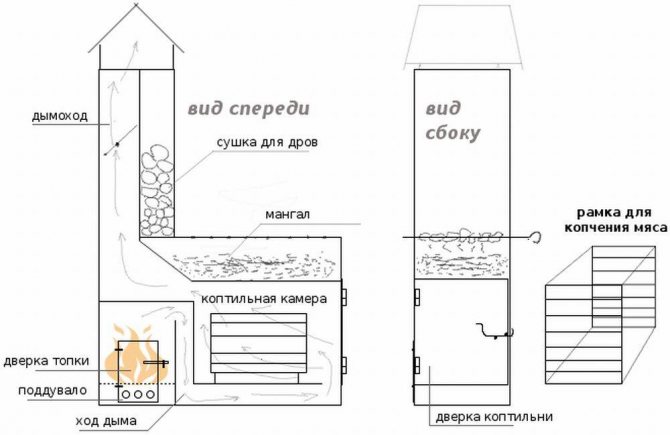

If we talk about the design, then the exhaust hood consists of 3 parts, including:

- Smoke exhaust pipe.

- Grill hood with internal crosspiece. It is needed to improve traction.

- Base. It is mounted on a grill.

The hood for the hood, which is made of sheet copper, looks very nice.But it must be borne in mind that the manufacture of a copper dome will be difficult if a beginner takes it up. But you can make a do-it-yourself hood from simple sheet iron without an assistant, but this will take more time.

It is forbidden to use asbestos-cement pipes in construction. The material from which they are made is heat-resistant, but it is hazardous to health. A vertical metal exhaust pipe can be installed on the site.

Even before starting construction, it is necessary to determine how the metal exhaust hood will be installed. It can be suspended from the ceiling of the gazebo, in which case chains will be used to fix it. Another option would be to install the hood on racks above the hearth. In this case, the chimney will pass through the center of the gazebo roof. In addition, the hood can be installed on the grill. It is better to call an assistant, then the work will be done faster.

When installing a flue hood, you should pay attention to the material of the roof. In those places where it is adjacent to the pipe, refractory materials must be used. For example, a galvanized roof would be a good option.

The metal smoke collector can have a square or rectangular cross-section. It is functional, has excellent aerodynamics, so it catches smoke well.

To make a hood from a metal sheet, you need to do the following:

- Clean the metal corners, for this you need to remove the factory grease from them with a rag.

- Based on the drawings, mark the material.

- Using a grinder, cut the corners into pieces. You need to work in safety glasses.

- Assemble all elements and weld parts of the structure.

A homemade hood can be made of stainless steel or other material. Before use, the iron must be covered with a heat-resistant anti-corrosion coating. It is recommended to make a cap over the pipe.

Brick umbrellas

Brick umbrellas are built over static barbecues, since they are much more durable than metal ones. In addition, they have an attractive appearance that will look great on any landscape design.

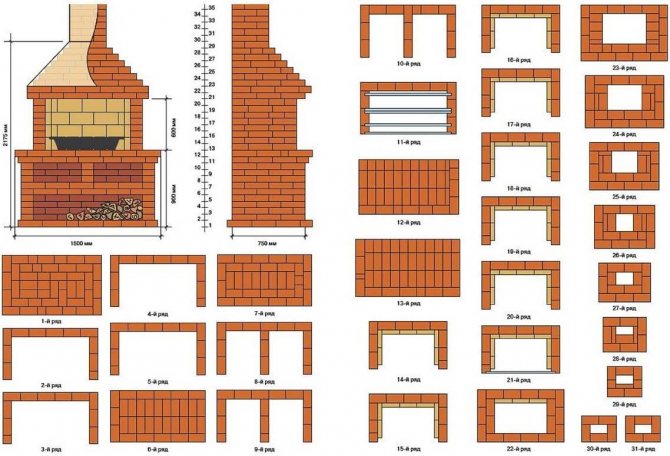

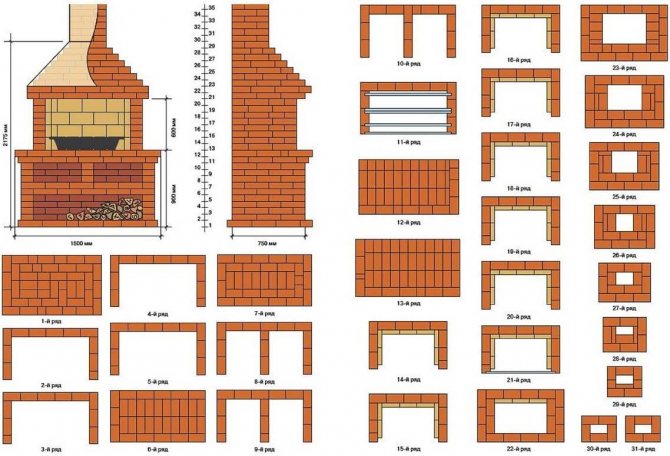

Diagram of a brick umbrella.

To build such an umbrella, you can use either oven brick or fireclay. Moreover, the area that is laid out strictly above the brazier is made only of refractory (chamotte) bricks, and the chimney itself can be made with a stove. Seams should be sealed with clay mortar. For this, it is advisable to use clean clay diluted with water to the consistency of sour cream. Less often, sand is added to the solution, but it should not exceed 50% of the clay mass. Before starting work, the brick must be soaked in water so that the water completely covers it. After pouring the bricks, they are left to "get wet" for 2-3 hours. This is done so that the bricks do not absorb water from the solution, otherwise the structure will collapse after a while.

Before starting work, you should assemble the frame, which will be the base for the dome. It is welded from a wide steel angle, which must be primed and painted after welding.

After welding, it is necessary to wipe the welded seams with sandpaper or a file in order not to trim the brick in the future. The welded frame is installed above the brazier on the supporting walls (there should be a minimum of 2, a maximum of 3). For its installation, reinforcement tabs should be provided - to ensure the strength of the structure, a frame is welded to them. Laying bricks begins to do along the perimeter of the frame. Moreover, such a hood should not have a large area - the frame may not withstand. Most often, the hood is made in a stepped shape, while the outgoing chimney can be metal. Sometimes after laying the hood, the edges are rounded to improve the appearance.

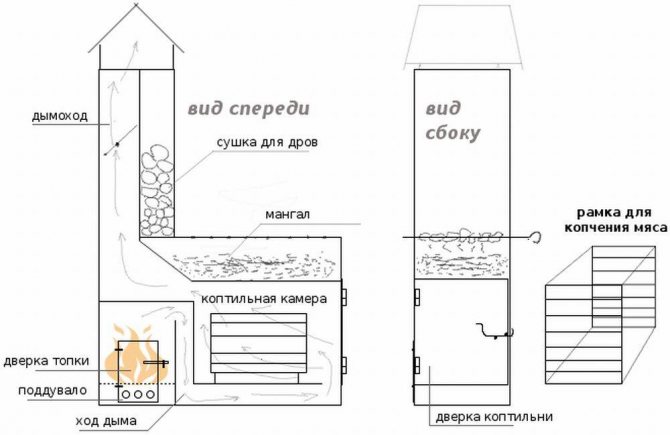

Barbecue device diagram.

After the hood is folded, it is given several weeks to dry, otherwise the wet mortar will collapse and destroy the structure.After 2 weeks, the structure is inspected and the seams are checked for moisture (one of the options for checking is to attach tissue paper to the seam and leave for a while). After the solution has dried, a test run (short-term) is carried out.

A brick cooker hood provides a comfortable stay at the grill when barbecuing. Such umbrellas have the following advantages:

- Good draft resulting in no smoke from the brazier.

- Stronger construction (compared to metal umbrellas).

- Longer service life.

- Maintainability.

The disadvantages include:

- Large weight of the structure, which requires the creation of a full-fledged foundation under the barbecue.

- The complexity of the construction of such a dome.

- Much higher cost of work and materials compared to metal umbrellas.

Nuances of operation

I would like to pay special attention to firewood, which is recommended to be used in the process of cooking various products. So:

- seafood and poultry - oak, grapevine;

- lamb, pork, beef - apple tree;

- turkey or salmon - alder;

- pork, poultry, seafood - maple;

- chicken, beef - birch;

- lamb, poultry - cherry.

Video: tips on how to properly stack firewood in the grill

Each type of wood will add a special taste and unique aroma to the prepared dish. Experts do not recommend using conifers for kindling, since resins can be released during combustion. If it is not possible to prepare firewood on your own, then you can buy briquettes with ready-made charcoal in almost any supermarket, which, moreover, perfectly keep the heat necessary for cooking barbecue.

Metal hood

The easiest and cheapest way to make an umbrella is from metal. To do this, you can use the following materials:

Stainless steel. The best option for such structures, especially if the grill will be constantly outdoors. You can buy stainless steel sheets at almost any hardware store. Large diameter stainless steel pipes are suitable, which are cut to length and unbend. The main drawback of such material is the price.

Stainless steel can attract the attention of "metal hunters", so it is recommended to paint it. Galvanized. It is less durable than stainless steel, but cheaper

The disadvantages of galvanizing include the fragility of the coating, which over time will lead to the destruction (rusting) of the entire structure. Steel. The cheapest material. However, before starting the installation (after making the hood), it is necessary to apply a protective coating - a primer and paint. In this case, the condition of the protective coating should be constantly monitored, and in case of damage it will have to be primed and painted again.

Diagram of an umbrella for a barbecue made of metal.

Regardless of what kind of metal was chosen, it will not affect the shape of the structure. As standard, all hoods are domed with a chimney opening in the center of the dome.

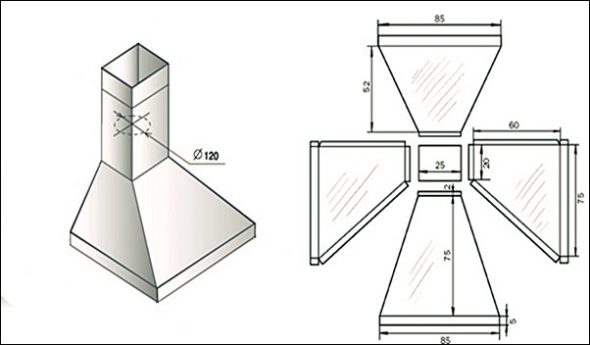

At home, to make such a hood with your own hands, you need a welding machine. The easiest way to make a trapezoidal umbrella. For this, 4 identical trapezoidal parts are cut out. They are welded to each other with side faces, after which the upper, narrower hole is closed with a cut-out square element, in which a hole is made in the center for a chimney. The pipe itself is bought ready-made, it is welded to the exhaust hole, after which the lower part of the dome is strengthened by welding thin reinforcement around the perimeter. The size of the trapezoidal parts to be cut depends on the extrusion parameters. In this case, the length of the base of the trapezoid should be such as to ensure the flow of smoke from the barbecue. Installation is carried out strictly above the brazier.

The metal hood is installed on stone / brick supports (if a brazier is made of them) and fixed (cemented).Another way is to lay the fittings of the required length when building a brazier and weld an exhaust hood to it. Such a hood can be installed over a portable metal brazier: for this, fittings are welded to the brazier in the corners, onto which the hood is welded. However, this is not advisable as it will reduce (or even negate) portability; in addition, the effect of such a hood will be negligible.

Optimal hood shape.

After the first launch, patterns may form on the metal, they will be especially noticeable on stainless steel. You should not be afraid of them - they do not affect the life of the hood and do not spoil the quality of the metal.

Such hoods have the following advantages:

- Material availability.

- Ease of manufacture.

- Fast and easy installation.

- Low cost (compared to the rest).

- Renovation and easy maintenance.

- Attractive design.

Metal hood for the hearth

The metal hood has a very simple design. It can be installed over any kind of barbecue. You can buy such a model in a store or make it yourself.

Advantages of a metal fume hood:

- Compact dimensions.

- Can be installed in any gazebo or outdoors.

- Simple technology for leading the chimney to the roof and connecting to other household communications.

In stores, exhaust umbrellas are often presented with built-in additional functions - a fan for a barbecue, air purification, etc. It is advisable to buy such models for regular use in closed rooms (for example, when installing a barbecue in a restaurant or at home). For summer cottages, an extractor hood with the simplest configuration is also quite suitable.

The disadvantages of a metal hood consist of several points:

- Regular cleaning.

- Heat may occur during use.

Do-it-yourself iron exhaust umbrella

If you have the skills to work with metal and have the necessary tools, you can make a simple version of the hood for the barbecue with your own hands. Here we will give the most simple instructions for its construction.

The grill smoke collector consists of three parts: a base, a dome with an internal lintel and a pipe. To make this design with your own hands, you will need:

- metal sheets 2-3 mm thick;

- iron corners 20x20, of the same thickness;

- screws;

- rivets;

- heat-resistant paint;

- grinder with nozzles for cutting metal;

- welding machine;

- drill with concrete nozzles;

- riveter.

First, you need to make the corners and make a frame out of them, which will later be sheathed with iron sheets.

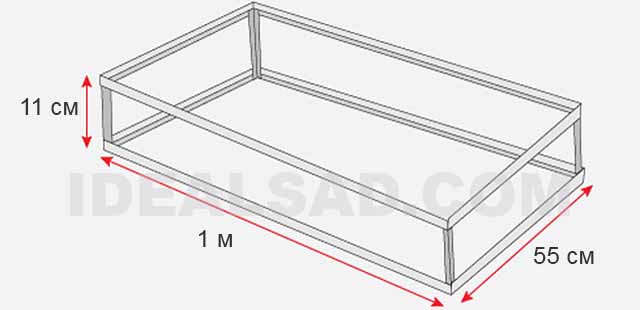

- The frame must be started from the bottom, which will serve as a support for the hood and close the brazier on three sides. Its size must be determined in accordance with the dimensions of the barbecue. As a rule, this part consists of a back and two side walls. The optimum base height is 50-60 cm.

- The next element is the dome, which is a truncated pyramid. Its dimensions must be calculated in such a way that the lower part completely hangs over the hearth, and the volume of the dome is several times the volume of the barbecue.

- Inside the canopy, a metal plate should be welded to the back at an angle, which will provide better traction.

- The chimney pipe can be simple rectangular or round. It should be of sufficient height so that smoke does not enter the room, but is discharged upstairs.

- After creating the frame, you need to sheathe it with metal sheets. Then it is necessary to cover the parts of the structure with fireproof paint.

- All elements are sequentially installed on the base and fixed with rivets.

With the start of using a homemade barbecue with a pipe, summer residents can find problems caused by insufficient elaboration of the product model:

- The smoke is discharged too low and interferes with being near the hearth.To avoid this, you need to calculate the height of the hood so that the top of the pipe is at a height of three meters from the ground.

- The hood does not draw in smoke from the barbecue, it hovers around the room. For the chimney to work properly, it is necessary that the smoke temperature is higher than the air temperature (initially they are almost equal). You just have to wait until the coals are hot enough.

Brick hood

Brick barbecues are becoming more and more popular. They have their own merits. It is a monumental, durable structure. With the right device and the skill of the master, such a grill will delight and decorate the territory for many years.

Advantages of a brick hood:

- Durability;

- Low heating of the brick surface;

- Aesthetic appearance, with the help of a brick grill with an exhaust hood, you can create a practical architectural miniature on your site;

- Combines the functions of a brazier and a cooker hood.

Making a brick hood

If you wish and have good experience in construction, you can build a brazier with a brick hood with your own hands. For this you will need:

- Brick;

- A mixture for laying bricks, or a mortar of clay and sand, in a ratio of 7 parts of clay to 3 parts of sand;

- Metal corners, to simplify the installation of the hood;

- Masonry tools, for cutting and welding metal corners.

Important: for the construction of a hood and a barbecue bowl, use only refractory bricks (chamotte) and mixtures. Otherwise, under the influence of high temperatures, the entire structure will collapse.

Instead of a heat-resistant mixture, it is permissible to use a solution of clay and sand.

Installation sequence:

- Mark the position of the hood, not forgetting that it should be larger in size and volume of the barbecue itself;

- First, the supporting walls are laid out on which the smoke collector will lie. Back and two side;

- A metal frame from the corners is installed on the brick supports. By analogy with a metal hood, it also has the shape of a truncated pyramid. First of all, the lower part is welded, then the upper narrowed part of the frame, and they are connected by corners, also by welding. For the convenience of masonry, you can assemble the chimney frame from the corners by welding it to the hood frame;

- The finished frame is lined with bricks. The first row is exposed with a brick perpendicular to the rear support wall, the second and subsequent rows are placed in parallel, with an offset of 17 mm, creating the necessary pyramidal shape;

- The chimney is laid out on the frame or without it, subject to the minimum internal diameter of 120 mm;

- Install an umbrella cover to protect from precipitation.

What material to choose

For the construction of hoods in gazebos, two main types of material are used:

- metal;

- brick.

Brick is most often used in stationary barbecue structures, which are also made of bricks. Such hoods have a pleasant appearance, but they have a number of disadvantages, which include a certain difficulty in cleaning. In some cases, it is not possible to achieve ideal cleanliness of such a chimney. The design of such a hood turns out to be quite cumbersome and requires certain skills for the correct construction. In addition, the cost of such a project is several times higher than that of a metal hood. Due to these disadvantages, the choice often falls on metal hoods. The latter have the following advantages:

- the possibility of self-assembly;

- comparative ease of installation;

- light weight;

- availability of materials;

- smooth inner walls;

- ease of cleaning;

- the ability to choose a shape.

A hood made of sheet metal can be assembled by anyone who has certain skills in working with a power tool and a welding machine. At the same time, there are no restrictions on the choice of form or method of design. Installation of a metal structure is easier than a brick one. Moreover, the total cost of the project is several times cheaper.The most interesting thing is that you can use material that the user may have idle. The metal hood does not load the base of the gazebo. Cleaning such an umbrella is easier than cleaning a brick one. This is due to the possibility of using various agents that would leave efflorescence on the brickwork.

In addition, the metal walls have a smooth surface. This reduces the likelihood of soot sticking to them, which cannot be said about the brick design. It is easy to paint a metal hood in any desired color. In this case, it is necessary to use a special dye composition that is resistant to high temperatures. The metal hood can be removable and installed only in season.

Problems that may arise in the process

There are no products that are completely perfect - everything has flaws. Several problems emerge from this, which we will consider below:

The biggest problem is if the smoke does not go into the hood, but diverges to the sides. This only happens if you have not taken care that the ventilation is equipped with a fan. They are usually electric and can be turned on as soon as you start working with the barbecue. Although, as a rule, smoke can remain in the room also because it simply did not have time to heat up and its density is the same as the density of air. Therefore, as soon as the smoke heats up, it can independently go up and go out through the ventilation pipe. The chimney cross-section is about 25-27 cm. What if this is not the case? Nothing special, just smoke cannot be absorbed in full.

By the way, it is also very important that the pipe is about 16 cm in diameter. Also, do not forget that the height of the pipe must be at least 3 meters from the ground. Only in this way the smoke will completely come out and disperse.

The rest is simple. Assemble the exhaust hood as shown in the drawing above and weld it to the pipe. After - just attach the product in the right place.

Of course, you can also build a brick hood, but, firstly, it is only suitable for brick barbecues, and, secondly, this design is much more complicated.

Types of smoke exhaust structures

The types of smoke exhaust structures and materials for their manufacture are not very diverse. In gazebos of any type, chimneys for the barbecue are made of metal or brick. Brick structures are mainly used in stationary barbecues made of the same material.

They look very attractive, but it is rather difficult to clean them properly, and sometimes it is simply impossible. To build a brick chimney, you must have the skills of a bricklayer, in addition, the cost of such a structure is much higher than that of a metal product. Therefore, zealous owners most often prefer to build a metal hood over the barbecue.

Metallic

Chimneys made of metal have the following advantages:

- do-it-yourself assembly availability;

- ease of installation;

- low weight;

- smoothness of the inner surface;

- ease of cleaning;

- the ability to give the product any shape.

Almost any home craftsman with the skills to work with power tools and welding equipment can assemble a metal chimney.

In the absence of a welding machine, the structural elements can be bolted. The metal hood does not create a serious load on the base of the gazebo, its walls have a smooth surface, on which, unlike brickwork, soot contamination does not stick. If you need seasonal use or transfer to another place, the structure can be easily disassembled. It can be painted in any color with heat-resistant paint.

Types of protection for the chimney and ventilation pipe

The classification of types of umbrellas is due to the shape, purpose, as well as the materials used in the manufacture.

Depending on the shape, the most common are standard designs that repeat the appearance of a hipped roof, as well as varieties in the form of a mushroom head.

Varieties can be represented by droppers and drainage systems, designed to collect and further drain all flowing moisture, as well as prevent it from getting inside.

Various non-ferrous or ferrous metals can be used to make a fungus or an umbrella, but galvanized durable steel is most often used.

Deflectors also belong to the varieties of the smoke umbrella, which serve as a very effective spark extinguisher.

The appearance of the structure and the materials for the manufacture of the chimney "fungus" do not have a significant effect on the performance indicators, therefore, when choosing, consumers should focus on finances and personal preferences in decor.