Solid fuel boilers are an excellent solution for an autonomous heating system. Especially in those areas where there are problems with electricity and there is no gas main. But when choosing equipment, many questions arise. We will tell you which solid fuel boiler is better to choose in our article.

Types of solid fuel boilers

A solid fuel boiler is one of the most economical options for heating a private house. Heating a room with gas or electricity is not always cheap. And also in the absence of the possibility of connecting gas, the acquisition of a solid fuel boiler remains practically the only profitable option. This heating equipment is divided into several types:

- Heating boilers, into which you need to load fuel yourself. They are divided into 3 types: top-burning pyrolysis boilers, classic boilers and long-burning boilers.

- Pellet boilers. They are also called boilers with automatic fuel supply. In such equipment, fuel is supplied automatically. The boiler operates on solid granular fuel.

Choose solid fuel heating boilers according to the main parameters:

- The type of fuel on which the equipment will work efficiently;

- The time during which the fuel will burn with one load.

And also when buying a heating boiler, you should pay attention to the following nuances:

Unfortunately, solid fuel heating boilers are only of floor type. Wall-mounted boilers of this type are not produced. Perhaps this factor is a disadvantage of such equipment, since it will take up a lot of free space in the room.

How to choose

First of all, you should decide on the type of fuel that you plan to use.

If the boiler is needed to work in a remote area from the city, a coal-fired unit would be an ideal choice for heating a private house. It is versatile, completely autonomous and inexpensive.

For burning wood and agricultural materials, pyrolysis and wood-fired boilers are suitable.

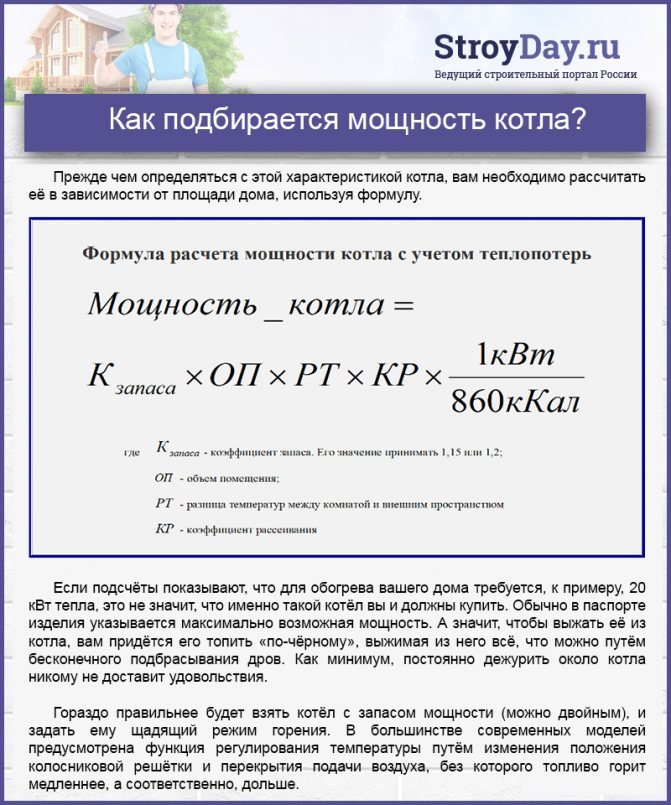

Calculate the area of the heated room. These calculations will help determine the required equipment power. This takes into account the height of the ceilings, the level of heat loss, the average temperature in the region in winter. It is better to entrust the calculations to professionals.

To visit the boiler less often, pay attention to the models with automatic fuel supply.

The system, equipped with a special tank, eliminates the need for regular manual fuel loading. Depending on the volume of the tank, one bookmark is enough for up to 5 days of continuous operation. Thus, fuel consumption is saved, and stable power is provided.

Boiler performance and fuel loading frequency also depend on the volume of the combustion chamber.

Be sure to pay attention to the material from which the heat exchanger is made. The most effective are cast iron and steel. The maximum efficiency of a cast iron boiler is achieved with coal fired, a steel boiler works better on wood fuel.

The presence of an automation system will not be superfluous. If it is not available, check the possibility of its installation in the unit. This will avoid unnecessary costs and boiler modifications in the future.

The selected model of the unit must comply with safety standards. It is important that the system is equipped with an automatic shutdown, a device for sounding an alarm in case of unforeseen situations.

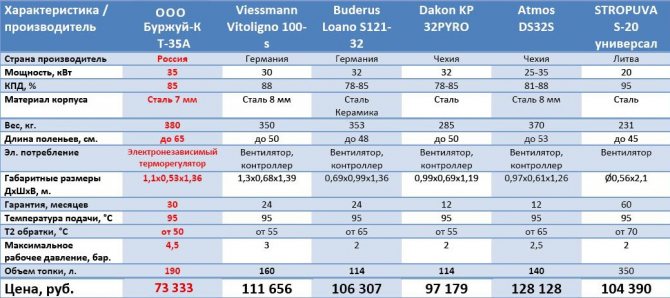

It is not recommended to purchase cheap models: often their characteristics are not enough for heating a room. Better to opt for a device from a well-known manufacturer.

Pyrolysis boilers

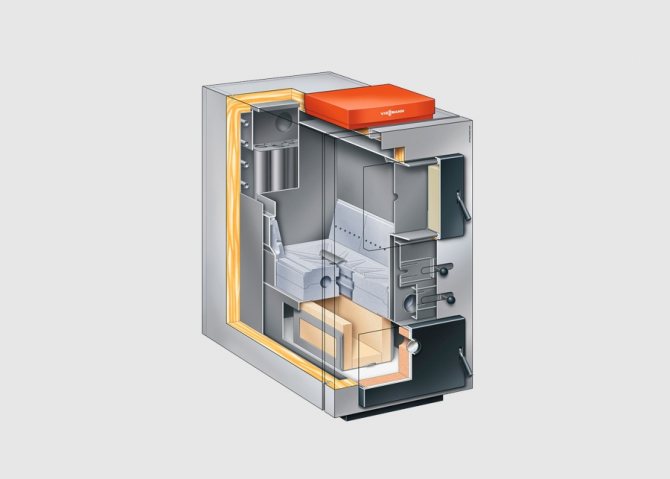

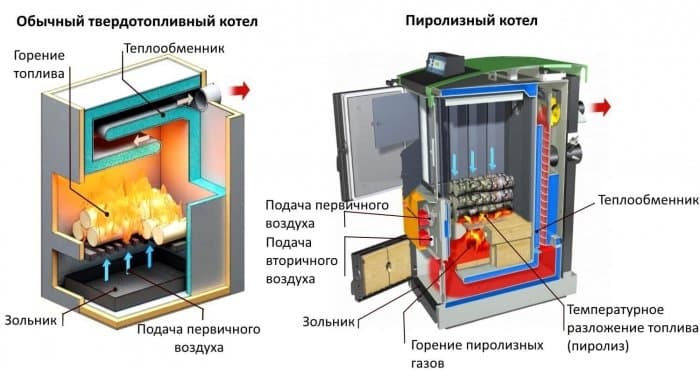

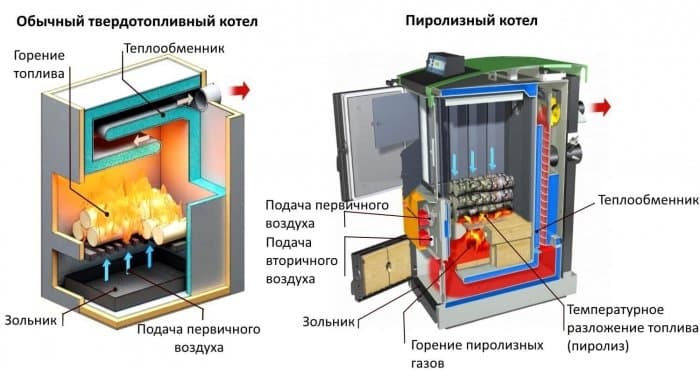

This type of solid fuel boiler runs on gas, which is obtained by burning fuel and lack of oxygen. The device is equipped with two chambers, which are separated by grates. An upper combustion chamber and a lower chamber in which gas is burned. The upper chamber is used to load fuel. After it ignites, and then the fan automatically starts to work.

Under the influence of high temperature, the tree begins to burn and release gas. It, in turn, moves down through the nozzles, and then mixes with air. As a result, the mixture once again heats up the fuel in the upper chamber. Due to the lack of air, the fuel is gasified and decomposed.

Pyrolysis solid fuel boilers are complex devices. To increase the burning time, a tree with a thickness of less than 10 cm is used. In order not to disrupt the operation of the device, it is necessary to load it with a power of 50 to 100%. It is recommended to use other heating devices during the off-season.

In pyrolysis boilers, some features are distinguished:

- The burning time of the fuel of one load is equal to 10 hours.

- Full boiler load is required.

- The wood must be dry.

- High price.

- High efficiency. It can be as high as 90%.

- Environmental friendliness of the equipment.

The pyrolysis boiler includes: controller, smoke exhauster and electronic control.

With a heated area up to 100 sq. m.

Stropuva Mini S8 8 kW

pros

- economical

- compact

- long burning

- reliable handles at the door

Minuses

- heavy

- pebbled cladding

From 53000 ₽

The first in the top rating of long-burning solid fuel boilers is the Stropuva Mini S8. The model with manual fuel loading is intended for the heating system of a small house, summer cottage, etc., with an area of up to 80m2. Design features: upper combustion of fuel, air is supplied to the combustion zone through a telescopic pipe, cyclic operation, automatic adjustment of air supply, large fuel loading chamber.

Teplodar Kupper Practician 8 8 kW

pros

- airing is excluded

- small-sized

- comfortable deep inclined firebox

- protective cover-converter

- convection openings for additional heating of the room

- manual and automatic control

- capacious ash pan

- cast iron grate distributes air throughout the entire combustion zone

- equipped with a shurovka, a poker, a rotary gate and a thermometer

Minuses

- not identified

From 15 300 ₽

Teplodar KUPPER PRACTIC - 8 is designed for an area of up to 80 sq.m. With the help of the thermometer, which is included in the kit, it is possible to easily control the temperature of the coolant. Compact, suitable for garage and summer cottages.

EVAN WARMOS TK-12 12 kW

pros

- price

- end chimney

- long firewood

- well painted

- scoop and poker included

Minuses

- not identified

From 20,000 ₽

Hot water boiler WARMOS-TK-12 is an option for heating small rooms. The cylindrical shape is the guarantor of the greatest structural strength, and the wide door is convenient for loading coal, logs and subsequent ash removal. In order for the solid fuel boiler to work at maximum, it is recommended to install a heat accumulator.

Classic boilers

The most popular type of solid fuel boilers is considered to be classic. Heat is spread by burning solid fuels. Such boilers are made of steel or cast iron. Moreover, heat-resistant steel is used. Classic boilers can heat the house and heat the water.This boiler can operate on wood, coal, pellets or peat. The most profitable option is coal heating. Since when using firewood as fuel, the combustion process will be much faster. The boiler with one load can work from 2 to 6 hours.

Using a temperature sensor, you can maintain a certain temperature regime and adjust the air damper. If the temperature drops, the damper will open with the help of the sensor. On the contrary, if the price rises, an opening will occur. Classic boilers are independent of gas and electricity.

For more efficient heating, some models have a built-in fan, control panel and an electronic temperature control sensor.

The advantages of this solid fuel boiler include:

- Large selection of manufacturers, models.

- Low cost of equipment.

- High-quality manufacturing technology.

- Easy to operate.

- Low fuel costs.

- Large selection of fuels.

- No electrical connection required.

But there are also several disadvantages:

- Self-loading fuel.

- Fuel delivery and preparation.

- Frequent loading of fuel.

- Availability of a place where fuel will be stored.

- The inertia of fuel combustion.

Despite some shortcomings of this model, it is the most demanded due to its high efficiency and low cost.

Wood and pellet boilers

Due to the high content of resins and moisture in biomass (mainly in wood), the problem of reducing the boiler output is more acute. The lower the boiler temperature, the higher the risk of condensation formation and the greater the likelihood of corrosion of the boiler parts.

In the case of using biofuels, top-combustion boilers become completely ineffective, since practically no combustible gases (and much more of them are formed when burning wood than when burning coal) in such a boiler will not burn. Consequently, the efficiency of such boilers will hardly reach 30%, which means that the fuel consumption will be too high.

So if you are choosing wood as fuel for your home, you need a bottom combustion boiler. Such devices still have a very high price, since they are made from high quality heat-resistant materials, because the gas burns at very high temperatures. The efficiency of such boilers reaches 80%, which is very, very good.

Unfortunately, this again brings us back to the problem of overpowering such a boiler when it comes to a small, well-insulated house. The high efficiency of the boiler becomes a double-edged sword - after all, you have to reduce the power of the device and again think about the problems with corrosion. Is there a way out of this situation?

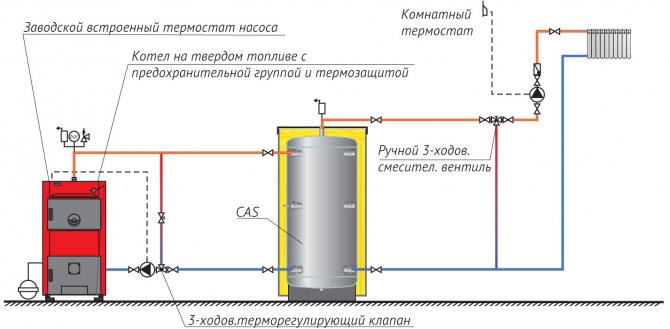

Of course there is. Part of the energy generated during combustion can be easily redirected to the heat accumulator. This could be a large water tank, masonry, or even a tank of sand - if you're brave enough to make the decision. The efficient combustion of wood in a heating boiler, in particular in a house with good thermal insulation, requires the rapid release of a large amount of energy generated during the optimal operation of the boiler. The best solution would be to use an additional water tank called a heat accumulator. Thanks to him, a fully loaded boiler can work for several hours at a nominal power, which can significantly exceed the current required in the premises. This does not lead to overheating of the house, since excess energy accumulates in the heat accumulator, due to the high heat capacity of the water. The coolant is supplied to the radiators of the heating system not directly from the boiler, but from a heat accumulator with a mixture of waste coolant from the return line using a three-way valve.

Automatic control and management of heating power is carried out by a controller with a temperature sensor, which, using a three-way valve, changes the ratio of the coolant.

In a well-insulated tank, the water cools slowly, therefore, it can feed the heating system for several hours after all the fuel in the boiler has burned out. In addition, if you use a large-capacity tank (up to 1000 liters), there will be enough water in the system to prevent it from boiling.

The problem with such a system, first of all, is its cost. After all, installing a heat accumulator and laying heating pipes, in addition to a solid fuel boiler, adds a significant amount to the price of heat in the house. In addition, not every house has a place for such a large-scale structure. In fact, such expenses of money and space must be calculated even at the stage of designing the building, and the homeowner must be mentally and financially prepared for such difficulties. It is worth noting, though, that installing a complete heating system is the smartest approach possible. It makes no sense to buy an expensive boiler, and force it to heat your house alone - the operation of the boiler below the rated power, as has been said more than once, leads to its breakdown.

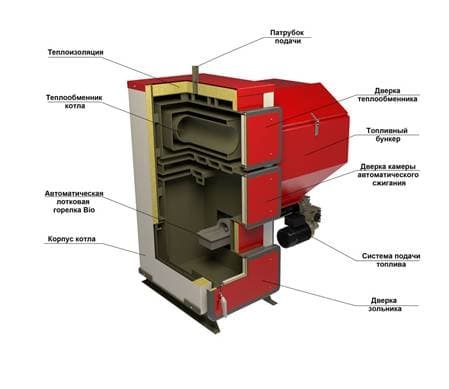

However, in this case, there is an alternative. The best solution is a pellet boiler - it costs more than a wood-fired boiler, and raw materials for it are also more expensive, but, in the end, such a heating system does not require additional investments in installing a heat accumulator with all the ensuing consequences.

The efficiency of a pellet boiler is higher, working with it is much less laborious. As in the case of automated coal-fired boilers, the fuel is supplied in small portions, which can be adjusted to achieve a balance between the required heating level and the technical requirements for the boiler output. In addition, such a boiler allows you to save fuel without spending part of it on re-ignition, as is the case with a coal boiler, because the pellets ignite almost instantly. Then, when the temperature in the system has reached the desired level, the controller in the boiler stops its operation, the next portion of the fuel burns out completely, and does not smolder as in the case of coal, that is, such a scheme of operation practically eliminates fuel loss. In order to ignite granular fuel in such a boiler, an electric heater, which is controlled by the controller, is sufficient. Therefore, the boiler can be operated intermittently without user intervention.

The operation of the pellet boiler is cyclical, and therefore, the efficiency reaches 80%. Indicators for coal-fired boilers are lower on average.

Wood burning boilers are generally designed not only for burning solid fuel, but also for burning its gaseous component. So, they work very effectively, provided that the heating system of the home can receive a large amount of heat from them in a short period of time.

Long burning boilers

Long-burning boilers can operate on different types of fuel: wood, sawdust, drill, coal, etc. But there are models that are designed to work on wood. They differ from other boilers in the material from which the combustion chamber is made, as well as in the air supply system.

One load can be 50 kg of fuel, and the burning time of firewood varies from 12 to 48 hours. If coal is used as fuel, then it will burn from 4 to 7 days. If you decrease the fuel combustion rate, the boiler output will decrease. This option is suitable for light frosts.

The fuel burns from top to bottom. Therefore, these boilers work for a long time with one load.

Long burning boilers have the following advantages:

- Low cost of the boiler in comparison with pyrolysis ones.

- Long fuel combustion.

- They do not depend on the power supply.

- Ash does not need to be removed more often 2-3 times a month.

- The power regulation is deep, in contrast to the classic boiler.

The disadvantages include:

- Low efficiency.

- Installation of a circulation pump.

- The boiler operates in a full cycle. This means that it is impossible to add fuel to the equipment.

When changing the burner, you can easily switch to another type of fuel. To do this, it is necessary to change the burner, and then reconfigure the automation.

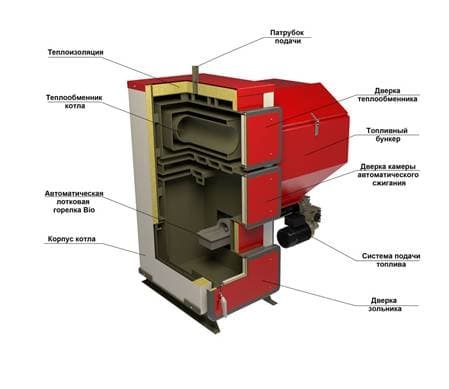

Boilers with automatic fuel supply

Such boilers are quite popular for heating private houses. With the help of a screw or transport bunker, the fuel is automatically fed. Fuel burns with one load from 3 to 10 days. Boilers with automatic fuel supply are highly efficient. It can be 85%.

For safe operation, it is necessary to install the boiler in a separate room and install a fireproof ash collector. This boiler has a high cost, and is also dependent on the power grid. The fuel can be used: wood or other pellets of combustible materials and granular coal. Such fuel is more expensive than others.

In order to prevent overheating of the boiler, it is necessary to fill the firebox with firewood gradually. Since they quickly ignite, and this leads to the release of a large amount of heat. If you use coal as a heat carrier, then it burns slowly and gradually. Therefore, the temperature in the furnace will be the same throughout the entire combustion.

Benefits

The main advantage of a solid fuel boiler is a noticeable savings in money spent on heating a private house. Such indicators are achieved due to the high efficiency of the unit.

The solid fuel system is quite simple in terms of technology, so the installation of equipment can be carried out on their own, without the involvement of a team of installers.

Environmentally friendly non-toxic materials of natural origin are used as fuel: coal, wood, pellets, etc. The availability and relatively low cost of fuel materials can significantly reduce the financial costs of heating.

The operation of a solid fuel boiler is completely autonomous and does not depend on the availability of gas or electricity. The installation of such equipment would be ideal in places where there are regular interruptions in gas and electricity supplies.