The main purpose of the element is to drain water from window panes, prevent moisture from entering the window sill and window frame. If moisture gets into these places, then the processes of accelerated destruction of building materials begin: the plaster of the facade walls falls off, the window structures become unusable. If the walls are sheathed, then the problems are even greater. In addition to the protective function, ebbs serve as an additional element for decorating the facades, they acquire a finished look, the designs of window openings look organic.

Ebb for windows

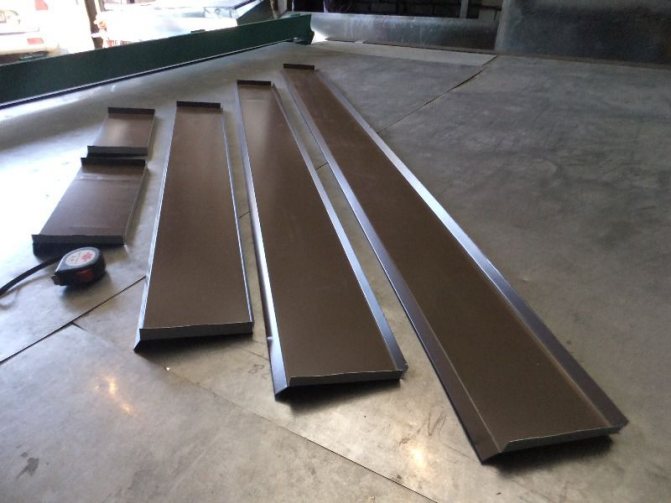

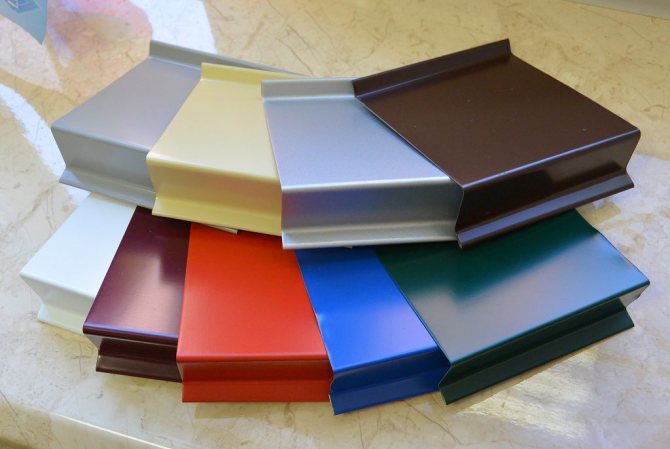

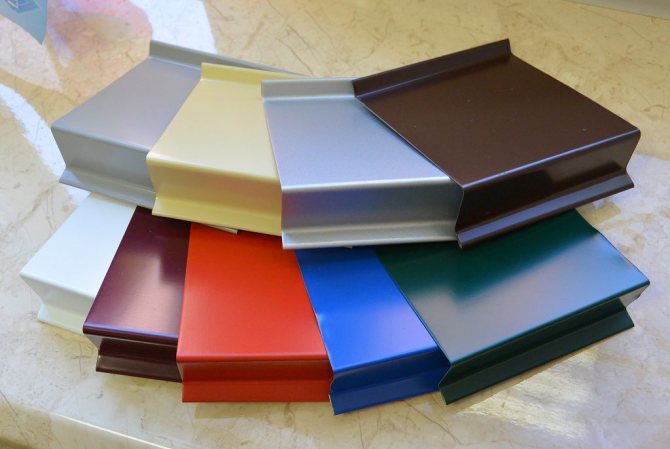

Polymer coated drips

Window with ebb

It is possible to install ebb tides both during the construction of buildings before the completion of the facade walls, and after the start of operation. The first option is better - it is possible to use a full range of special measures to seal all joints and seams and do it with minimal loss of money and time. In the second case, the technology becomes somewhat more complicated, but this does not have a noticeable effect on the quality and cost of work.

Ebb as a decorative element of the window

Materials for the manufacture of ebbs

Today, ebb tides are made of two materials, each of which has its own pros and cons.

| Materials (edit) | Description |

Sheet steel | Most often used. The cheapest option is galvanized steel, the more expensive one is the zinc coating is additionally painted with multi-colored polymer paints. A wide range of paints makes it possible to solve design problems. Metal sills have no restrictions on their use, they are installed on plastic and wooden windows. Houses can be timber, brick or block houses. The service life of high-quality metal castings is at least fifty years. Metal ebbs are technologically advanced; during installation, there is no need to use complex tools. If you wish, you can make them yourself. |

Plastic | Modern ebbs are most often used in conjunction with plastic windows. Made of modified, sun-resistant plastic. Modern plastics grades increase their resistance to the negative effects of hard UV radiation. Although resilience is increasing, destruction is still happening slowly. Intermolecular bonds are broken, the material loses its plasticity and becomes brittle, under dynamic loads, through cracks may appear. In addition, the formation of microcracks is inevitable, dust accumulates in them over time, mosses and lichens begin to grow. Despite the promises of manufacturers, the real life rarely exceeds thirty years. |

The advantages of metal shims are durability, versatility and a wide selection of colors. The disadvantage is low mechanical strength, it is undesirable to walk on them, especially if the base is not prepared correctly.

Steel ebb

Plastic sills can withstand relatively large static loads, but they are used only in combination with reinforced-plastic windows. At a cost, metal is slightly cheaper.

Plastic drip - photo

Functions, types

Ebb tides perform not only the function of drainage of water, but also complement the decoration of the facade of the building. They are distinguished by types depending on the material from which they are made.

They are lightweight made of aluminum and resist external influences.Made of galvanized steel, they do not corrode, as they are coated with a special compound.

General requirements for the installation of ebbs

Structures have one unpleasant feature - the consequences of improper installation are discovered late, and it will take quite a long time to eliminate them. Sometimes it is necessary to repair the finishing coat of the facade walls. To prevent this from happening, you should adhere to a few simple rules.

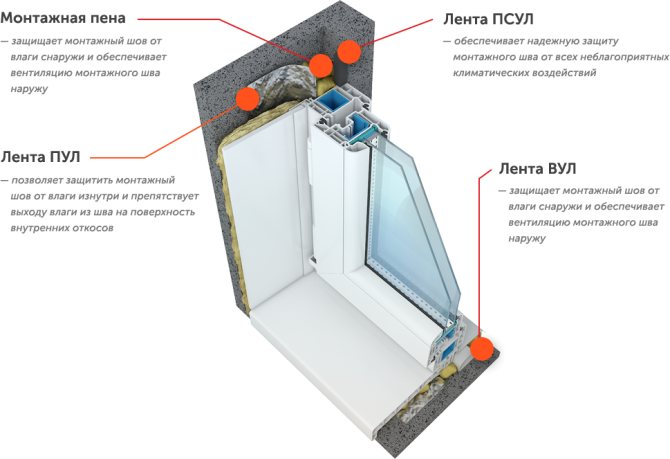

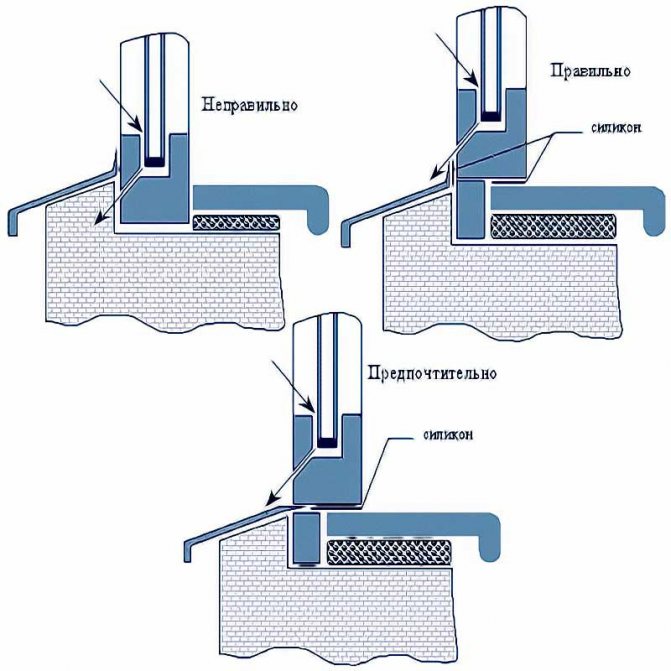

Take the maximum possible measures to seal all joints, special attention should be paid to the places of abutment to the window frame and side slopes.

All joints must be insulated

Important. Sealants should be used as an additional method of sealing, and not as the main one; their service life is limited to several years. In the future, the sealants peel off, water penetrates into the cracks. Flaking occurs due to unfavorable operating conditions. The main measures to eliminate leaks are construction technologies. Which ones - we will indicate in the step-by-step installation instructions.

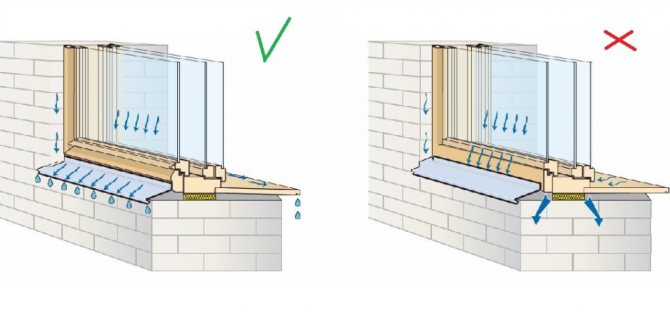

The low tide should be at least two centimeters wider than the slope. The water from the glass should not immediately fall on the wall.

Low tides are wider than slopes

Strive for the most even position of the ebb tide horizontally. If it is installed at an angle or has an uneven surface, then water streaks accumulate in one place and traces form on the wall. When it rains, drops of water should drip evenly along the entire length of the low tide. This will reduce the degree of wetting, the wall will dry out much faster.

The ebb must be installed strictly horizontally

Make a solid and even cement-sand base at low tide. Now it is fashionable to use polyurethane foam: the ebb is exposed in several places with wedges, the free space is foamed. It's fast, cheap, but wrong. Windows in any building should be periodically cleaned from the outside. Often they become feet at low tide, and no foam can withstand such loads. If you see that hired craftsmen are doing hack-work, make the work redo.

There must be a solid foundation under the tide

The side faces of the ebb must necessarily be located under the trim of the slopes. If the slopes are made of plaster, you need to cut into it about a centimeter. Do not rely on the use of sealant to avoid leaks. We have already mentioned that the term of its use in such difficult conditions is very short. We will tell you how to make a tie-in later in the installation instructions.

The side faces of the ebb are under the slopes

It is difficult to install ebb tides on the windows of the second and higher floors; it is necessary to assemble scaffolding or completely remove the window sashes. Do the work so that later you do not have to eliminate the marriage, do not rush, carry out all construction operations.

Prices for metal ebb

Metallic ebb

What are they needed for

A drainage sill or simply an ebb is a structure whose purpose is to divert precipitation from the window. It has a functional configuration and a smooth surface, so it does not impede the downward movement of water droplets. The manufacturer provides today for the presence of low side edges so that the jets do not flow into the side seams of the building and window openings. Installing software rules will allow avoiding not only runoff of liquid, but also the collection of snow, autumn foliage, particles of dirt suspended in the air. There are other effects from installing drainage systems. This is an improvement in sound insulation, protection against wetting of joints in the area of the window and adjoining walls, thermal insulation. Window, having low tide, looks aesthetic and complete. Its service life is lengthened, it is easier to care for it. It is a reliable addition to properly designed slopes and sealed windows.

Step-by-step instructions for installing a metal ebb

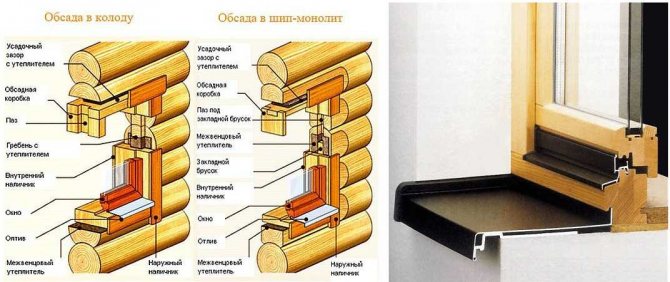

The metal ebb can be ordered or made by yourself.We will describe below how to make the structure ourselves, and for example we will use a custom-made element. For the initial data, we will take the following indicators: an outflow from sheet steel, a brick house with cement-sand plaster. The ebb is installed on the plastered slopes.

For work, you will need scissors for metal, if they are not there, then the use of a grinder is allowed. In addition, you need to have a square, a marker (a pencil on metal draws very badly), a tape measure, a screwdriver and self-tapping screws. If you need to prepare a cement-sand base, then prepare construction tools.

Step 1. Check the condition of the lower outer slope. If it does not meet the above conditions, then you will have to plaster. Use ordinary cement-sand mortar or ceramic tile adhesive. With glue, you can only level out small irregularities, and plastering mortar is used if the place is not prepared at all. During operation, keep the slope within 10 °.

How to make a slope?

- Throw in a layer of mortar, about 1 cm thicker than necessary. Remember to wet the surfaces of the bricks before plastering.

- Using a spirit level on the fresh plaster, make indentations at the desired angle. Press it into the mass, watch the scale readings. Grooves should be made along the edges and in the middle of the slope.

- As an equal rule, gradually remove the excess mass, control the position of the tool along the grooves made.

- Smooth the surfaces completely with a trowel. Continue installing the ebb after the mass has hardened.

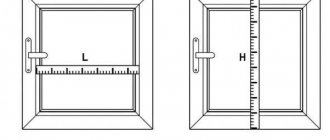

Step 2. Take off the dimensions of the ebb for ordering. It should be several centimeters longer and wider than the slope.

Taking measurements

Measurement of width

Step 3. Measure the slope parameters and transfer them to low tide.

Slope measurement

Further, there are two options for the production of work.

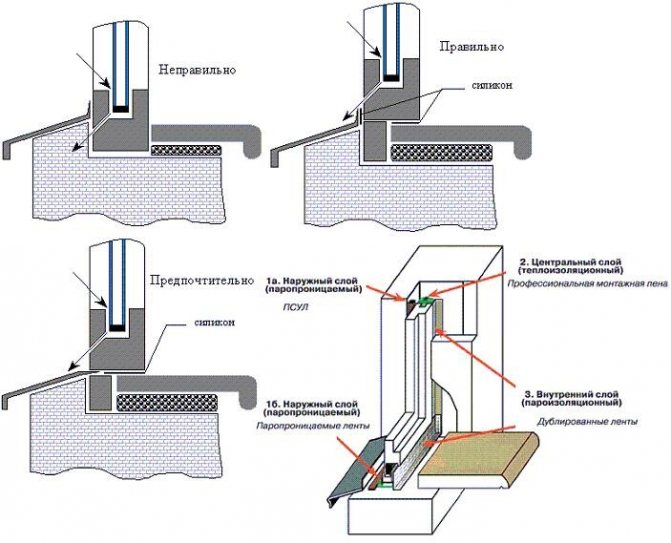

- Bend the ebb according to the marks. Cut off the folds a little with metal scissors or a grinder. The height of the side folds is about a centimeter. Make sure the edges are even and fit as tightly as possible to the side slopes. We have already mentioned that we do not recommend installing ebb tides by this method, the risks of leaks at the junction are too great. There is a more reliable option.

Undercutting low tide

Ebb edge bend

Prices for construction scissors for metal

Metal scissors

Edge bending

- Using a grinder with a diamond disc, cut straight grooves up to a centimeter deep in the plaster at the bottom of the slopes. The cut should be flat and level with the low tide. The groove in the corner between the window frame and the slope will have to be grooved manually, the disk will not be enough in this place.

- Make the low tide length about two centimeters wider than the width of the lower outer slope. You don't need to fold anything on the sides.

- Insert the molding into one groove until it stops, bend it slightly and carefully insert the other end into the opposite groove. Move horizontally so that both ends of the drip plate are in the groove.

- Fill the groove with a small spatula with mortar. Fill the mass tightly. Smooth the edges with a slightly damp sponge, make the transition smooth and invisible.

Unfortunately, plastic drips cannot be installed in such a reliable way. They are mounted end-to-end, the place of contact is sealed with a sealant. The ends are muffled with special inserts.

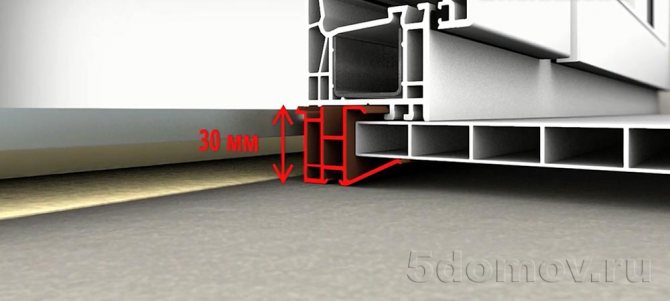

Step 4. Fix the bend of the ebb to the window frame with self-tapping screws. There are special grooves on the frames, make sure that the edges of the bend do not go beyond them, the bend of the ebb should be located in the groove.

Peel off the tape from the ebb

Installing an ebb tide. Last fit and fit

Foam application

Putting the ebb in place

If the metal ebbs are more than one and a half meters long, then you can use liquid nails during installation, lubricate the surface of the base and then put the ebb in place.

Ebb on the windows

Selection Tips

We advise clients who have contacted us to place an order, guided by the following principles:

- width external drainage is calculated based on the distance from the window to the outer edge of the window opening plus 3-4 cm;

- coating should be selected taking into account the climatic characteristics of the area. So, severe frosts polymeric the composition will not stand;

- the necessary part is plug for the side part. It protects the structure from kinking, provides maximum protection against the ingress of liquid under the ebb and soaking into the assembly seams. The plug adds completeness and accuracy to the ebb;

- at montage outside window sill to multi-colored transoms, their color should be half a tone darker. Light windows are recommended white plastic drainage or natural metal - aluminum.

Our specialists, performing installation, will never leave gaps on the sides of the windowsill. The drain is installed over the entire width of the opening, providing reliable insulation of the materials adjacent to the bottom. For clinker designers offer their design around the perimeter of the house, walls, including swivel options. And we will handle such an ebb and flow quickly and professionally.

Making a metal ebb with your own hands

Metal ebb tides can be made by yourself, they do not have much design complexity.

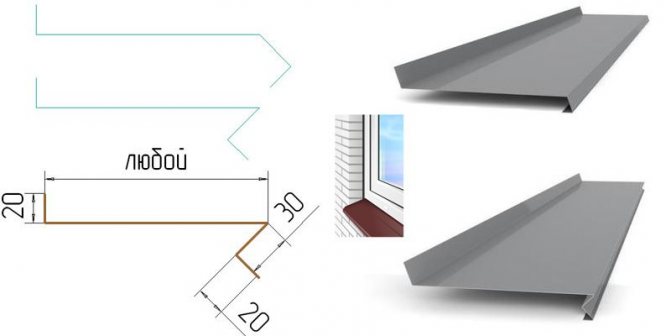

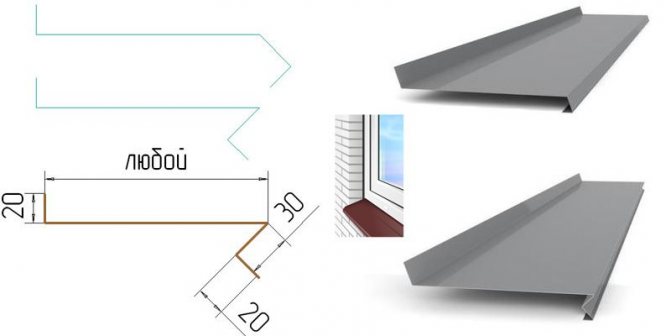

Window ebb diagrams

How to make them?

Step 1. Buy a galvanized steel sheet with a thickness within 0.5 mm. Pay attention to the quality of galvanizing, the layer thickness must be at least 40 microns, the surface is uniform in appearance, sagging and gaps are prohibited.

Galvanized sheet (galvanized)

Prices for galvanized steel sheets

Galvanized steel sheet

Step 2. Measure the length and width of the workpiece, taking into account the folds. Leave about two centimeters on the hem along the entire perimeter. Take the length with a margin, it is better to cut off the excess later than to throw out the ebb.

Step 3. Transfer the measurements taken to an iron sheet. For drawing, it is better to use an ordinary felt-tip pen, the lines from the pencil are poorly visible. Use ordinary markers, do not use waterproof ones. The visible marking lines then need to be removed, there will be problems with waterproof dyes. The sheet should have a bend line for installation under the window frame and a bend line of the protruding part of the ebb. It is better to cut with scissors for metal, in extreme cases with a grinder. After the grinder, the burrs must be removed from the cut line.

Step 4. Lay the sheet on a flat edge of the table, press on it with one hand, do not allow vibration. With your other hand, gently bend it, tapping on the sheet with any piece of the board. There is a mallet - great, it is easier to work with it.

Galvanized sheet

Method of sheet fixation

Steel sheet bending

Practical advice. To increase the rigidity, you can make a drip. It not only improves the ebb but also drains water further away from the wall. Dripper - additional Z-shaped bend along the lower edge of the low tide.

Bend the metal slowly, start at one edge and gradually work towards the opposite. The sheet should bend in a wave. Do not try to bend right away from the middle, irregularities will appear. Apply blows from top to bottom, part of the plane of the mallet should bend the metal, and the second part at the same time hit the edge of the table. From the first time, bend about 30 °, to a right angle, you need to make several passes along the line back and forth. The more passes, the smoother the bend of the sheet.

Making an ebb

Learning to bend sheet metal is not difficult, after a few centimeters, experience appears.If you have any concerns, practice on unnecessary pieces of galvanized steel. You will be able to control the strength, direction and frequency of impacts, the bend will turn out to be even. In terms of quality, it, of course, is somewhat inferior to a sheet bending machine, but you have the opportunity not only to save on cost, but also to make ebbs of your own sizes separately for each window.

Video - Installing window tides

Production

Basically, manufacturers offer designs of standard sizes, which can then be selected for your opening.

They are made in production using a sheet bending machine. First, the workpiece is cut to the required length, then it is fixed with a clamping traverse and the ebb piece is bent with a rotary beam. Then the corners are still bent, where the drops of moisture flow down. That's the whole cycle of work.

In large production, the machines are serviced by operators. The production is carried out on a large scale.

Packing tips

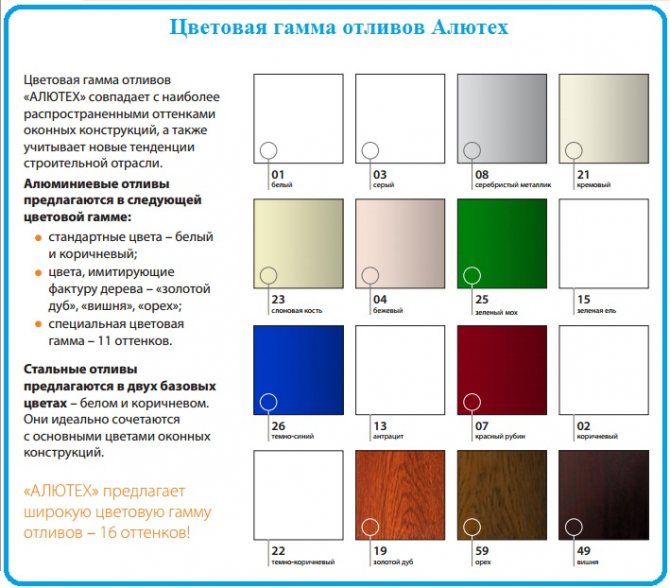

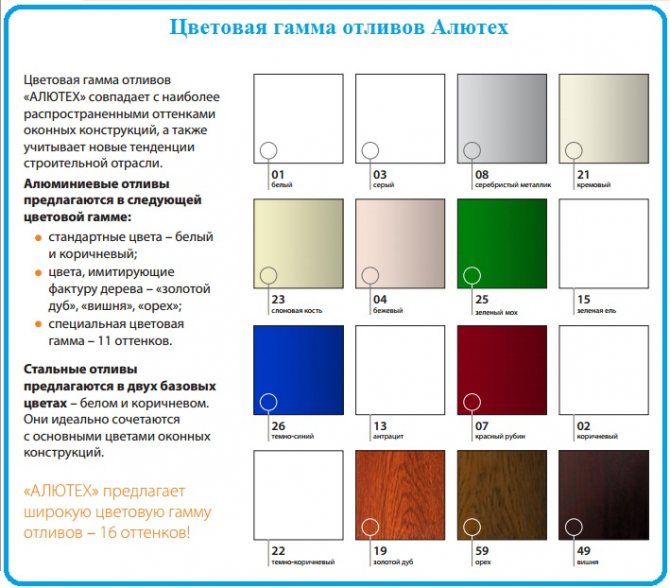

For those who want to make the most functional drainage design on budget rates, you need to contact us. We offer to complete steel and aluminum structures with support brackets and molding plates. Quality products are manufactured by the company Alutech.

For cases where the length of the drainage exceeds 1300 mm, the use of brackets will increase its rigidity and impart sound-absorbing properties. They are also used in the case of a console installation. Casting pads made of ABC plastic retain their color for a long time, are resistant to changes in outside temperature, and improve the performance of drainage. Regarding Alutech products, our customers often ask the question: “Doebb installation: price? ". From work experience, we can say that the price of such drainage is price list will be 1.5-2 times higher than steel. However, the costs will pay off with a long service life and impeccable appearance. Our experts own the most modern ways their settings and guarantee maximum functionality.