It is much more difficult to securely attach foam to metal surfaces than to regular walls.

Not sure how to glue Styrofoam to metal? I have repeatedly asked this question, tried several options and now I want to share my own skills and tell you how to choose a high-quality composition, prepare the surface and glue the insulation.

When insulating garage doors, you need to fix the foam especially carefully, since the structure is exposed to temperature extremes

Instrument preparation

If you are concerned about the question of what kind of glue to glue the foam to the metal, then you can first start choosing the composition. Depending on which one is chosen, you may need:

- drill;

- putty knife;

- comb;

- puncher;

- bucket;

- wide brush.

If you prefer a dry mix, you will need a drill with a mixer attachment. To apply such glue, you can use a comb-shaped spatula, but you will need a small spatula as an improvised tool in the work, with its help you can remove excess glue.

We use semi-finished products

Dry adhesives allow you to stick the foam to the brick wall efficiently and quickly enough. Their use has a number of advantages:

- low cost;

- availability;

- low consumption of glue per unit area.

When purchasing dry mixes, it is recommended to pay attention to:

- place of sale (it is advisable to purchase bags that are located and stored indoors);

- the integrity of the package (the surface of the bag should be free of through gaps);

- production date (it is not recommended to buy a mixture made 12 months before purchase);

- no traces of liquid ingress or wetting of the surface on the bag;

- mobility of the contents when carrying (there should be no feeling of a large stone in the bag).

It can be considered that the disadvantages of using these substances for mounting slabs to a brick wall are:

- the need for water to prepare the solution;

- the time spent on preparing it;

- relatively long final fixation on the surface (about 3 days);

- the impossibility of attaching polystyrene foam to concrete and metal surfaces.

The finished mixture can be applied both to the foam and to the wall. The plates are glued from bottom to top.

Preparatory work before installation

If you are thinking about how to glue polystyrene to metal with polyurethane foam, then it is important to know that this material can be strengthened to almost any metal. Among other things, almost any glue or putty can be used. However, you cannot purchase a composition that contains gasoline, acetone or any other solvent among the ingredients. The slabs will collapse.

Another mistake that craftsmen make quite often is the insufficient amount of adhesive used. It is necessary to apply such compositions on the back side of the plates; this must be done in 5 places or more. First, the mixture is applied in the corners, and then in the center. Before you glue the foam to the metal, you need to remember that saving is inappropriate here. To do this, some apply the composition only at three points, this is wrong and violates the technology.

Before gluing metal and polystyrene, the surface should be prepared, it is cleaned of dust, old paintwork, dirt and rust. For this, you can use a vibration or belt sander.After such cleaning, the base is degreased with any convenient means. Adhesion is not a quick process, sometimes it is necessary to secure the material until the glue hardens. At first, the insulation can slide under its own weight, so it must be supported from below with a board or plywood.

Rating and review of the best brands

There are several brands of puzzle glue available from specialized stores. They differ in the quality of the coupling and the appearance of the glued elements.

Step puzzle

Step puzzle glue is odorless, dries after 2 hours, 80 ml is enough to glue 1000 puzzle pieces together. It is poured onto the front surface of the painting in two layers with a break of 1.5 hours. A thin transparent film is formed. If the details were slightly torn, thanks to Step puzzle they are neatly connected and become even. Strengthen the picture on the back side by applying another layer of glue to it.

Ravensburger Puzzle Conserve

The glue is convenient to use because it comes in a can of 4000 elements. The liquid comes from it through the foam nozzle, which does not dry out and remains in working order for a long time. Ravensburger dries in an hour, forming a shiny film on the surface of the puzzles. After application to the front side, the painting does not need to be turned over, since the final quality of the joint is high.

KSK-M

Using a bottle of KSK-M synthetic glue, you can assemble a mosaic with an area of at least 0.4 square meters. After application to the front surface in several layers, the drying time is about 2 hours. Until this happens, it can be washed off with soapy water.

Educa

The glue for fixing the puzzles is released in a balloon, in the upper part of which there is a sponge, the composition is squeezed onto it and applied to the outer surface of the picture. The glue dries up in an hour, does not leave marks and streaks. One can is enough to fix 5000 elements.

"Red Cat"

A bottle of Ginger Cat glue has a dispenser through which the composition is squeezed onto a finished picture or onto a small piece of sponge. With light movements, it is distributed over the surface of the assembled puzzles. Two hours after drying, the painting is placed on the base and in the frame.

Fix Puzzle Conserver Permanent

Using this brand of glue, you do not need a brush, since the bottle is equipped with a sponge spout. A picture made of puzzles is wiped and the composition is applied to the front part so that it hits all the gaps and crevices. Shake the bottle first.

Choosing a foam adhesive

If you are faced with the question of how you can glue the foam to the metal, then you should consider several methods, each of which involves certain material investments. The most budgetary option is considered to be the use of PVA glue. If you have carried out repair work before, then you may have this composition. In this case, you do not have to purchase additional glue, you can use the leftovers. The secret to using PVA is to use burlap, which is impregnated with the mixture, laid on the metal, to which foam plates are glued afterwards. In this case, it will be possible to achieve high adhesion, so that in the future it will be possible to apply a sufficiently impressive layer of plaster in thickness.

An old friend will help

Particular difficulty and confusion is caused by the question: "What glue to glue the insulation to the metal?" The answer is simple.

Being an affordable and inexpensive material, it does an excellent job with the task assigned to it. The glue-impregnated burlap is fixed to the metal. After the glue has dried, the foam is glued to the wall. Plates are abundantly lubricated with PVA.

An increase in the density of the glue is expected (during this time, the next plate can be spread). Press the plate for a short time.As a result, a good result is obtained in terms of fastening strength.

Use of polyurethane foam

If you are thinking about how to glue the foam to the metal, then you can purchase polyurethane foam. It not only seals and insulates, but also has adhesive qualities; it can be used to glue the material in those places where there is no need to achieve heavy-duty adhesion. The foam is sold in convenient containers, in addition, not much of it is required. But it is necessary to work quickly, since the material hardens almost instantly. If you are just the first time faced with the need to stick foam, then this option cannot be considered the most convenient.

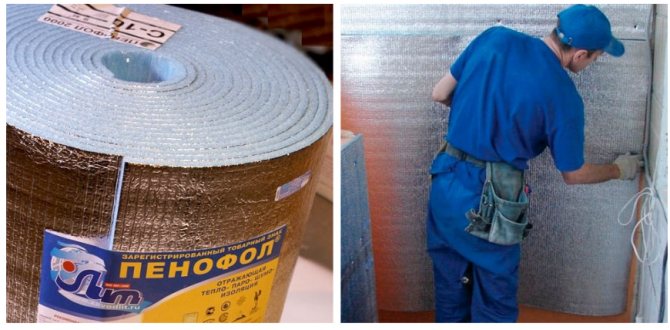

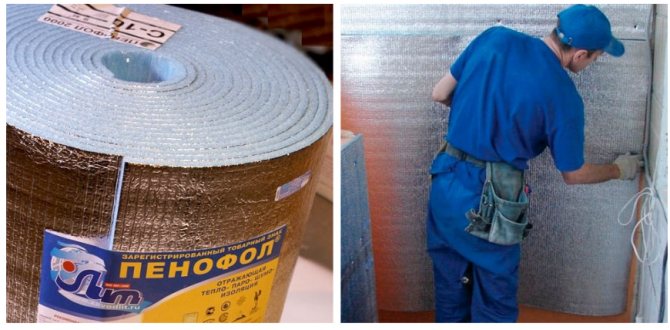

Features of fixing penofol

Penofol (isolon) is produced by a special polyethylene foaming method. The insulation is covered with aluminum foil, which maximizes heat retention. It is used for internal and external work, in the decoration of production mechanisms, heat storage in pipelines or air conditioning systems. It comes in rolls and individual plates. It can have additional characteristics - thickness, color. The bonding of the foil to the plane of the foamed polyethylene can be chemical or physical (stitched).

- small thickness;

- environmentally friendly;

- does not require additional means of protection of the skin and respiratory tract;

- there is no need for special tools;

- ease of fastening.

The glue is used for foam foam with foil on one side.

Double-sided insulation is used for thermal insulation of loggias, garages, pipes. Fastened to the crate or purchase polyethylene foam with a self-adhesive surface.

Due to the lightness of the insulation material, the bearing capacity of the adhesive is not so important.

Using polyurethane glue

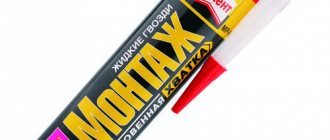

Thinking about how to glue the foam to the metal, the consumer quite often chooses polyurethane glue, it is the most suitable for these works. The mixture is produced in convenient containers, but you will also need an assembly gun. If the work is sporadic, then it is best to purchase a cheap tool, because it will not be constantly used.

If you decide to resort to this technology, then you must adhere to a certain sequence of actions. The adhesive is applied to the surface of the thermal insulation in dots or in stripes, the distance between the individual points should be approximately 7 cm or less. After waiting a few minutes for the points to dry out a little, the plate must be gently pressed against the metal surface. This is just the case when the boards need to be supported with plywood or a board. The support can be removed after only 20 minutes.

What varieties are suitable

In order to reliably connect the puzzles into a single picture, various gluing means are used. Both special glue and intended for other household purposes are used.

Specialized

Together with a set of puzzles, special glue is often put in the box. It has a liquid consistency, is able to penetrate between elements, firmly connect them. Odorless and colorless glue, it can form a glossy layer on the front side, after which the picture does not need to be varnished.

PVA

The properties of special glue and PVA do not differ much. To reliably connect the assembled puzzles, PVA is applied to them on the front side with a brush, filling all joints and gaps. After drying, white stains will become transparent and form a matte film on the surface of the glued picture.

Wallpaper for vinyl flooring

The elastic adhesion of the elements can be obtained after applying the vinyl wallpaper adhesive. The advantage of the composition is the ability to prepare glue of different thicknesses.

Tips for using liquid nails

"How to glue the foam to the metal?" - this question is often asked by home craftsmen.Experts advise them to use liquid nails, with their help you can achieve a high speed of work. The composition will fix metal and plates almost instantly, but the adhesion strength will be slightly less than in the case of a polyurethane mixture. You can combine materials, for this it is recommended to purchase liquid nails and polyurethane glue. The latter allows you to achieve adhesion strength, while liquid nails guarantee the speed of work. In this case, you can refuse to use the props.

Expanded polystyrene - what's what and why?

The correct technical name for the well-known polystyrene is expanded polystyrene. Looking closely at this material from a short distance, you will find that it consists of many small balls that hold each other - these are polystyrene granules that have been foamed under high pressure and temperature and compressed in a press.

Due to this technology, in the structure of the foam there are many microcells invisible to the eye, in which there is air. Thanks to this, the material acquires an airy lightness and the properties of a very good insulation. Consumers loved it for its extremely low cost - in fact, it is the cheapest thermal insulator, and builders appreciated its technical characteristics. We will dwell on this in more detail, because along with the popularity of the material, like mushrooms after rain, numerous myths about its shortcomings grew.

Polyfoam is very durable - polystyrene retains its shape for at least 25 years when used outside and at least half a century when used inside. You will probably be surprised, because many people talk about its fragility. Indeed, ultraviolet light and constant exposure to moisture can shorten the service life. Here are just the same factors that can shorten the life of almost any building material, including all kinds of heaters.

Expanded polystyrene is not afraid of mold and mildew - thanks to this, it can also be used in a humid environment, for example, in a basement. Polystyrene granules practically do not absorb moisture. However, they say that all kinds of rodents easily make holes in the foam. Again, this is only partially true - if rodents have something to eat, they will make holes even in concrete. Deprive them of food or exterminate them with poison, and you do not have to think about their relationship with Styrofoam.

Polyfoam does not support combustion - whatever they say, but this material is many times safer than the same wood... It takes twice as much temperature for it to catch fire as in the case of wood, and when it burns, it emits much less heat. The material is safe for human health and the environment - among the widespread myths, there is also a myth about the alleged harm of the material to human health. But dozens of studies have disproved this myth long ago. Look around, there is a huge amount of much more harmful materials around you.

Of the disadvantages of foam, it should be called a small strength - it breaks easily, and even a small blow can leave a dent on its surface. For this reason, it must be protected from mechanical damage - traditionally, plaster mixtures are used for this. They also protect the material from the effects of ultraviolet radiation.

Adhesive for installing foam at extreme temperatures

Quite often, craftsmen ask themselves how to glue polystyrene to metal in winter. To do this, you can choose the composition WEBER THERM S100, with which it is allowed to work at temperatures ranging from -10 to +20 ° C. The material is waterproof, it can be used in any regions of Russia. The mixture is a dark gray powder, and the average density of the solution is 1.4 kg / m3. You will need 0.26 liters of water per kilogram of the mixture. After mixing, the mixture must be used within one hour, the deformation shrinkage of the solution is 0.03%.If you are deciding what is the best way to glue the foam to the metal, then you can choose this particular composition, the adhesion strength of which is 1.4 MPa. The vapor permeability of the mixture is 12 mg / (h * m * Pa), while the frost resistance, which is expressed in the number of cycles, is equivalent to 75.

How to cook the surface

It doesn't matter which adhesive is used, the preparation process is always the same. If the metal is not properly processed, then no glue will provide a reliable attachment of the foam.

Materials and tools for work:

- Metal brush... It is used for cleaning the surface and removing rust and old paint residues. Instead of a manual device, you can use a power tool - a drill or a grinder with a special metal brush;

A special wire brush will help to quickly remove rust and paint from the metal surface

- Paint remover... It is used if there are several layers of old paint on the surface, which does not hold very well and may peel off later. The composition is easy to apply, but toxic and requires compliance with safety measures;

Spray paint remover is very easy to use

- Solvent. Used for surface degreasing. Personally, I use the composition R-646, it is inexpensive and well suited for preparing metal for further processing;

Solvent R-646 is used for cleaning and degreasing metal in preparation for insulation

- 3-in-1 composition for metal surfaces... A special composition consisting of paint, primer and anti-corrosion treatment. After application, the surface will be reliably protected from rust for many years. If you have metal without foci of corrosion, then you can use ordinary soil for metal, its price is much lower;

Special paints with anti-corrosive additives - the best preparation of metal for insulation

- Brush or roller... Used to apply paint. For large, flat areas, a roller is more suitable. For designs with many curves and angles, it is best to use a brush.

The brush must have a thick bristle to ensure good paint or primer application to the metal

Metal surface preparation:

If in some areas the paint has not come off, the treatment is repeated again.

The paint can also be applied with a spray gun, if available, but a brush can also be dispensed with.

If your metal is rust-free and the paint adheres well to it, you can simply degrease it and apply a fresh coat of primer for reliability.

Application area

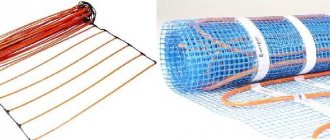

Extruded polystyrene foam is used to insulate walls outside and inside buildings. The material is attached to glue or a frame structure, the second option is rarely used, since the arrangement of the frame increases the cost of thermal insulation. Insulation with a thickness of 2-5 cm is suitable for walls, we note that with an increase in the thickness of thermal insulation, its sound insulation qualities also improve.

When insulating the floor, polystyrene foam boards are placed on a pillow made of expanded clay or other low-density material, and poured with concrete from above. Such insulation protects from cold (first floor) and noise (unlucky with neighbors), but requires raising the floor level, which is not always acceptable in an apartment.

When insulating foundations, the thermal insulation is fixed with glue to the plinth and additionally secured with mounting fasteners. The material protects the basement from the cold and inhibits the release of the concrete basement from the external environment.

On roofs, expanded polystyrene is laid in front of a layer of bitumen on the outside or between the ribs of the rafters inside the roofing cake. This applies to a private house; in apartments, thermal insulation is often used to insulate the outside of the ceiling of the upper floor apartments.In this case, from the side of the attic, insulation is laid (with or without glue) and concreted on top or covered with a layer of fixing material (expanded clay, gravel, crumb).

Video

The process of attaching polystyrene foam to glue in the balcony is shown in the video, it will come in handy if you plan to do the installation of thermal insulation yourself.

The modern construction industry makes extensive use of thermal insulation materials such as extruded polystyrene foam and polystyrene foam. They both have a number of advantages, but there are some differences in their installation, which will be discussed below.

Expanded polystyrene is used for interior and exterior work. It is used for thermal insulation of building facades, basements, plinths and balconies. This foamy material is weakly deformed, has strong hydrophobic properties, is light, lasts a long time and microorganisms grow weakly in it, which prevents the appearance of colonies.

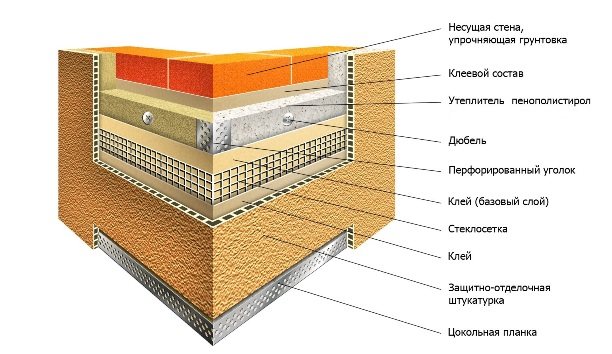

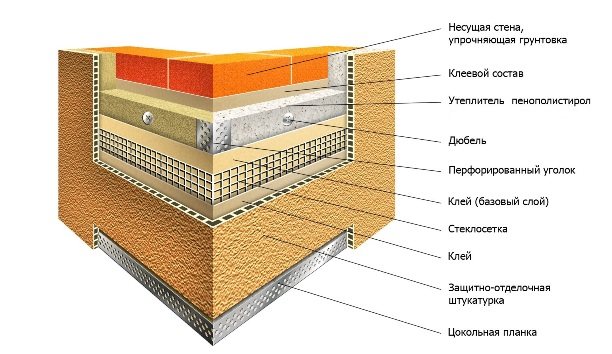

Usually, the installation of expanded polystyrene is carried out using glue or special mastic, as well as mounting dowels. The best result is achieved with a combination of both methods, because then the insulation is first glued to the surface of the building, and then fixed with dowels.