Structural differences and appearance

Cast iron

Let's start with cast iron radiators, which today have changed their design, but, as before, have wide water channels and are made up of several cast sections. Heat-resistant gaskets made of rubber or paronite, which are placed between the sections, provide the required tightness. The length of the finished radiator is determined by the number of sections, the height varies from 0.35 to 1.5 meters, and the depth can be 0.5 meters or several centimeters. In accordance with the volume of the room, you can select the desired size of the radiator, while there is a possibility of its modification (for example, remove an extra section or add several new ones)

Varieties of cast iron heating radiators.

It is worth mentioning the models of radiators, artistically cast from cast iron. They will not only perfectly heat the room, but are also able to give it charm and charm. Such radiators with molding patterns skillfully executed on their surface are produced mainly by foreign manufacturers. Like any piece of art, such devices cost a lot of money.

Several types of artistic cast iron heating radiators.

Bimetal

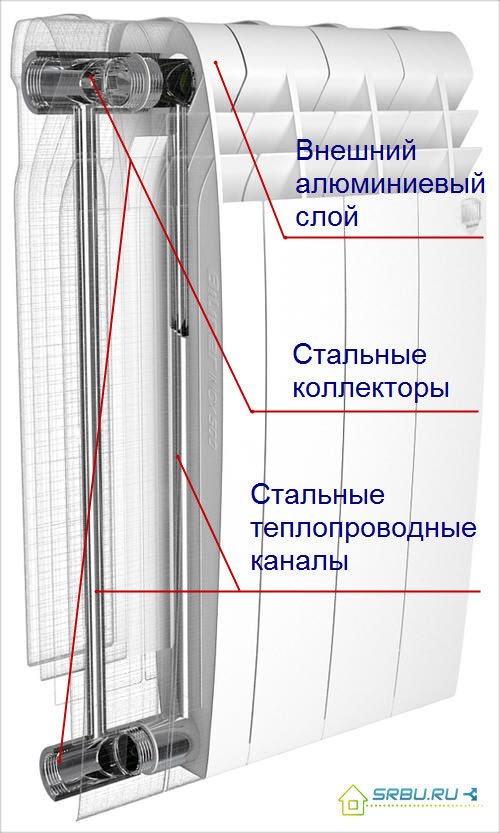

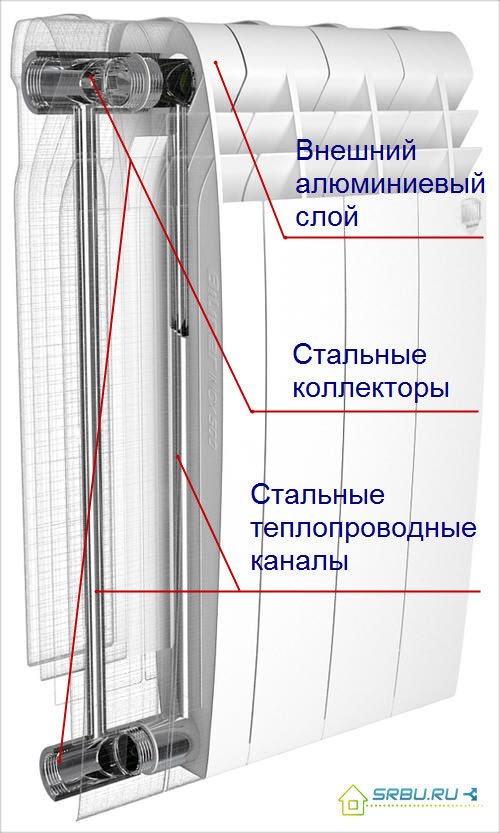

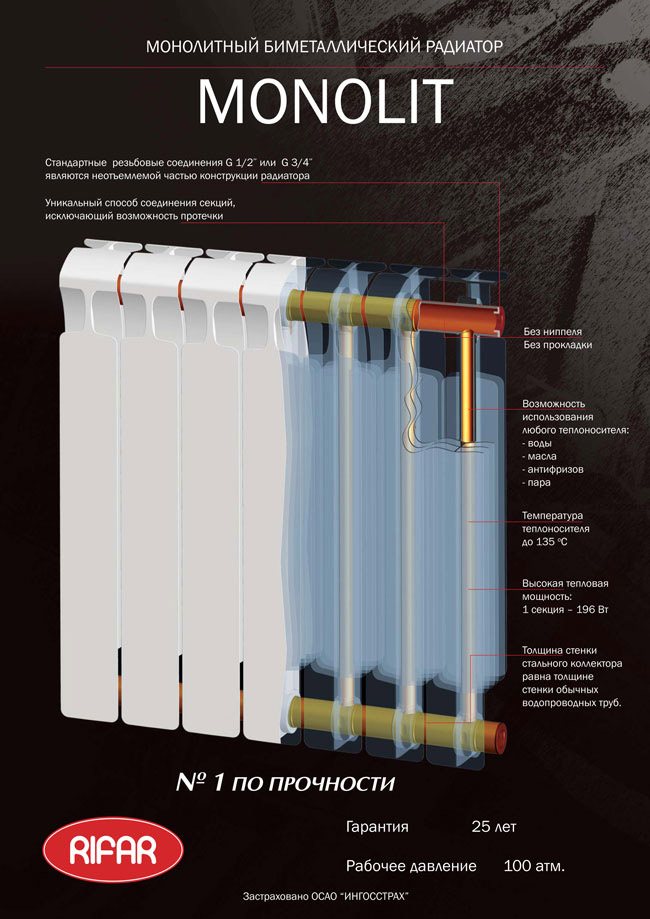

The case of bimetallic radiators is aluminum, its shape is ribbed-shaped. This is how it is designed for better heat dissipation. A strong steel core is hidden under the body - this refers to "real" bimetallic radiators. However, there are also semi-bimetallic (or pseudo-bimetallic) radiators - their difference is that only the vertical radiator channels are reinforced with steel.

The rest of it is made of aluminum. Such a device costs 20 percent less than a completely bimetallic one, and gives more heat. But it is less reliable and durable, and it is highly undesirable to use it in a centralized network.

The device of a bimetallic heating radiator.

Like cast iron radiators, their bimetallic counterparts are usually sectional, which allows them to be modified. Models are usually sold with an even number of sections. A small segment of the market is occupied by monolithic models, which cannot be disassembled, assembled and improved. The design of all bimetal radiators is very attractive.

Appearance: Cast iron + — | Bimetallic +

Conclusions and recommendations of experts

After comparing cast iron and bimetallic radiators, you will still have to make a choice directly. When purchasing a radiator, you need to take into account the characteristics of the device, the assessment of the room and other aspects. The correctness of the choice made will determine how well and for a long time the heating system will work.

Cast iron heating radiators

By many criteria, bimetallic radiators win. But if you want to save money, make sure that there is no water hammer in the house and feel free to buy cast-iron devices. They can be installed in apartment buildings with no more than five floors. If the number of floors exceeds 5, then it is not recommended to take risks. Devices made of bimetal should be installed.

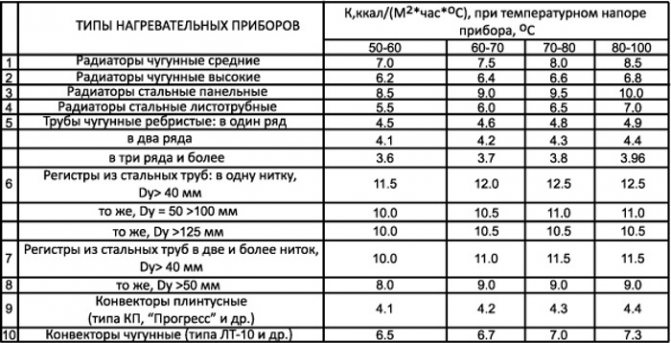

Let's compare the heat dissipation of radiators

Cast iron. Let's start again with traditional cast iron radiators. They are so slow that you can sometimes freeze while waiting for a cold room to warm up. But on the other hand, such radiators cool down for a long time - and this is a completely different matter. After all, it is not uncommon for the heating to be turned off once. Because of an accident or repair, for example. And near the cast-iron battery you can still warm up for a long time.

A great advantage of cast iron products is that they heat the room not only by convection, but also by radiation. That is, when they are turned on, in addition to air, objects close to the batteries also become warm. As for the thermal power, it is usually given for one section and ranges from 100 to 160 watts. These are average values and may vary from model to model.

Bimetal. The good thing about these radiators is that they just heat up instantly. However, they cool down just as quickly, alas. Heating in them is carried out mainly according to the principle of convection - the radial component is much smaller. This is some disadvantage. The thermal power of sectional models is comparable to cast iron products. This figure ranges from 150 to 180 watts (on average). If we compare the heating rate of the room, then they certainly outperform cast iron.

Heat dissipation: Cast iron + — | Bimetallic +

Advantages and disadvantages of cast iron models

Advantages of cast iron batteries:

- unpretentious maintenance and long service life;

- excellent inertia or ability to retain heat;

- chemical neutrality, thanks to which cast iron batteries can be washed;

- excellent resistance to pressure, hydraulic action;

- resistance to high temperatures;

- resistance to mechanical impact.

Disadvantages of cast iron radiators:

- outdated technology. Cast iron models cannot be connected to a system with automatic thermostats;

- slow warm-up;

- the need to use a significant amount of water;

- large weight and dimensions.

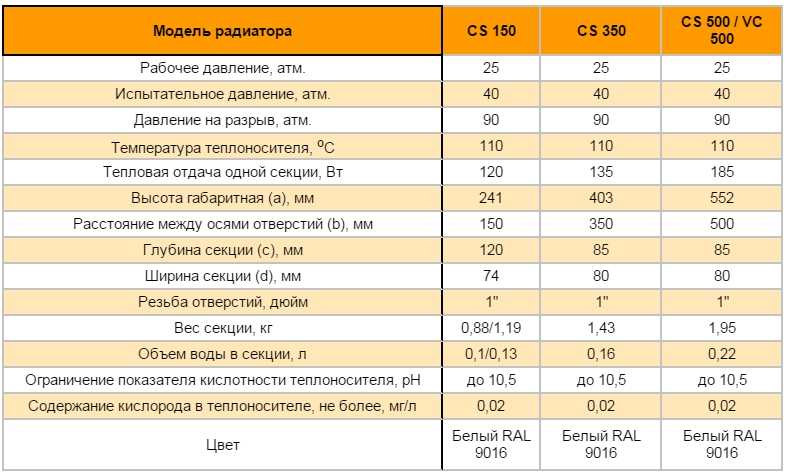

Ability to hold pressure

In a traditional central heating system, typical of multi-storey buildings, the pressure is by no means stable. Sometimes even water hammer occurs. After all, the cranes of circulation pumps, according to the rules, should turn on smoothly, but often workers do not follow these rules. And with a sharp shutdown of hot water, its pressure in the entire system jumps so that many batteries burst. Therefore, apartment residents should definitely choose radiators with a good pressure margin.

Cast iron radiators can withstand 9-12 atmospheres of pressure. This may be enough until a strong water hammer occurs. If it does happen, then brittle cast iron, unfortunately, can burst. Therefore, if you look from this point of view, that it is better to cast iron or bimetallic radiators, then it is better, of course, to insure yourself and take bimetal.

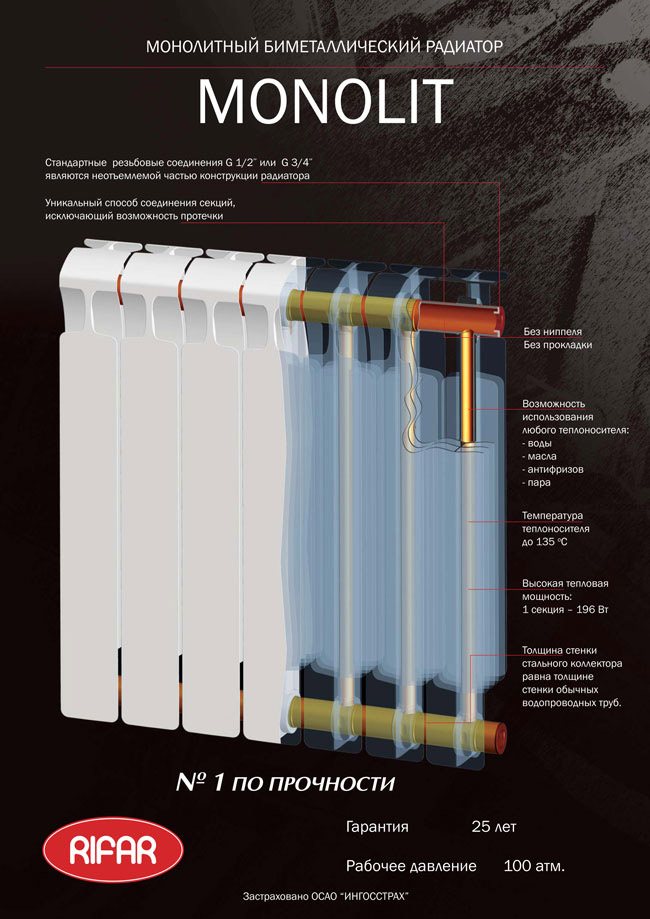

After all, a bimetallic radiator is not afraid of any pressure surges - in its passport, it has declared indicators for this parameter up to 20-50 atmospheres (depending on the model). So even powerful water hammers are not capable of breaking a quality bimetal product. And we will also mention the models with a monolithic steel core - they can easily withstand up to 100 atmospheres. An example of such radiators can be Russian-made radiators Rifar Monolit, you can see its technical features in the photo below.

Ability to hold pressure: Cast iron — | Bimetallic +

What is the Difference Between Cast Iron and Bimetallic Radiators

Comparative characteristics of heating devices will help to determine which option is better:

Design differences:

- Cast iron appliances are assembled from sections. They are supplied with a wide channel for the coolant, they have a reliable structure. Modern designs are lightweight, weighing only 3-4 kg. They produce classic, sleek and artistic designs.

- Bimetallic radiators are composed of 2 types of metal: copper or steel core and aluminum housing. Stainless steel, which is in direct contact with the liquid, protects the device from corrosion. The aluminum body is lightweight and provides high heat dissipation.

Differences in the level of heat transfer:

- cast iron radiators operate within 100-160 W;

- bimetallic devices give off heat with a power of 150-200 watts.

Differences in operating pressure:

- Cast iron elements are capable of withstanding 9-12 atmospheres.

- Bimetallic ones withstand from 25 to 40 atmospheres.

Differences in resistance to coolant:

- Cast iron does not react to the acidity of the liquid. Pebbles that form over time in an alkaline environment weaken the walls of the radiators, but this is a very time-consuming process. If the walls of the sections are thick enough, then the impact can be endless.

- The bimetallic device does not react to the acidity of the coolant. However, if the liquid is drained, corrosion can form.

Differences in temperature:

- cast iron can withstand up to + 110 0С;

- bimetal - up to + 130 0С.

Differences in terms of service life:

- Manufacturers limit cast iron radiators to a service life of up to 50 years. However, there are cases when the service life exceeded 100 years.

- Bimetallic devices are set for 25-30 years of operation.

These differences show that the practical parameters are not too different.

Advice! Experts recommend replacing cast-iron radiators with bimetallic ones in high-rise buildings, since they cope better with high pressure. In private buildings and five-story buildings, replacement is not recommended.

It is convenient to install bimetallic radiators alone. Cast iron are installed together, since they have significant weight.

Resistance to poor quality of the heating medium

Another disadvantage of central heating is the dubious quality of the coolant. The hot water going from the pipes to the radiators is neither clean nor chemically neutral. And it also contains a considerable amount of the smallest grains of sand and pebbles that can affect the inner walls of the battery, like an abrasive.

Cast iron is chemically absolutely "calm", so a high level of alkalis or acids in hot water will not harm it. And in summer, when there is a general drainage of water from the system, it will not rust. But she does not like small abrasive stones - they wear out gradually. However, if the radiator walls are rather thick, this is not so critical.

Bimetal is also resistant to chemically active water during the heating season. However, in summer, when water is drained from the system for repair and maintenance work, air appears in the radiators, the steel core can be attacked by corrosion. So the bimetal is a little less durable than cast iron.

Low-quality heat carrier: Cast iron + | Bimetallic + —

The maximum temperature of the coolant and its fluctuations

And the temperature of the coolant in our heating systems does not shine with stability. Now the pipes are barely warm, then hot, like fire. It is important for us how the radiators will behave in the latter case, whether they can withstand too hot water. For this parameter, the indicators are as follows. For a cast iron radiator, the coolant can be heated up to 110 degrees. Hot water flowing through the pipes of the core of a bimetallic radiator can have a temperature of up to 130 degrees. But in general, both types of radiators tolerate temperature changes well. The only thing is that due to the difference in the expansion of steel and aluminum, with a sharp change in temperature, small crackles can be heard at the bimetallic radiator.

Maximum coolant temperature: Cast iron + | Bimetallic +

Which radiators are easier to install

There is nothing to argue about - naturally, there will be more problems with cast iron during installation and transportation. And it is beyond the power to lift such a battery alone, and special brackets are needed for it - especially strong, and the plasterboard wall will not withstand it.

And one more thing: when purchasing cheap domestic radiators, one must be prepared for the fact that they will additionally need painting and broaching.

But working with bimetallic radiators is, one might say, a pleasure.They are so light and neat that hanging them (and on any surface) is not difficult. And if in the first place you have ease of installation, then the answer to the question of which is better - bimetallic or cast iron radiators, is unambiguous. Of course, bimetal.

Ease of installation: Cast iron — | Bimetallic +

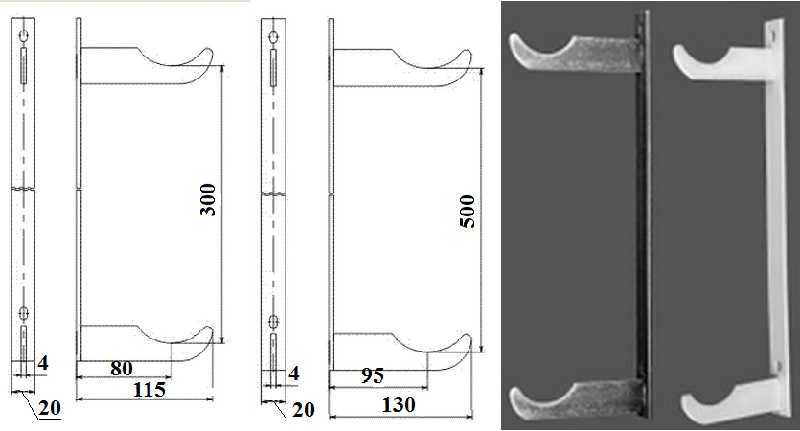

Installation of aluminum radiators

Due to their low weight, aluminum radiators can be installed by one person. You will need: shaped wrenches, adjustable rack and pinion pliers, a drill - screwdriver, a set of fasteners, ancillary equipment included in the radiator kit supplied by the manufacturer.

Demir Dokum Retro 600 (cast iron)

If the radiator is connected to a heating network made of plastic pipes, the process will take one and a half to two hours.

Be careful not to forcefully hit the radiator housing or fall. Deformation, rapid failure of the device is possible. Aluminum is a soft metal.

When installing an aluminum heating battery, you must strictly follow the manufacturer's recommendations, do not forget to mount the required piping.

When placing the radiator on the wall, you need to observe the necessary indents:

- 3 cm from the wall,

- 5 cm from the windowsill,

- 10 cm from the floor.

A heat reflecting shield should be placed between the outer wall and the battery. It will save 5-7% of energy.

Before installing the battery under the window, you need to make sure that there are no cracks at the junction of the window sill and the wall. Otherwise, a significant part of the heat will go outside.

Alpine Air History 600 Retro Cast Iron

Let's talk about the difference in the price of radiators

Pig iron is undoubtedly cheaper, especially domestically produced. So, the cheapest section of the MC model, for example, costs only about 300 rubles. However, only classic models will have such a "tasty" price. But radiators in the "retro" style, made by the method of artistic casting, are several times more expensive. Such models of the Konner brand cost from 2000 rubles (for one section).

Sectional models of bimetallic radiators will be somewhat more expensive than similar cast iron ones. For example, one section of a radiator from the Rifar company (Russia) will cost at least 500 rubles. The price of a section of the same Italian radiator starts from 600-700 rubles.

Price: Cast iron + | Bimetallic —