The dimensions of the profile for PVC windows depend on the opening, the type of construction, the wishes of the buyer, installation work. There are GOSTs that regulate the permissible parameters of the finished system. They are enshrined in law, violation of GOSTs is the reason for contacting government agencies, the society for the protection of consumer rights. Small deviations from GOST are permissible, the vibration amplitude is precisely defined in the positions.

The manufacturer knows exactly what dimensions of the PVC profile for plastic windows are permissible according to GOST. When examining the premises, the master determines which window installation is best suited to the room, satisfies the wishes of the buyer, and will serve for a long time without changing the characteristics.

The best plastic profile for a PVC window in Moscow

When choosing a profile for the production of window structures, pay attention to properties such as:

- The material from which the product is made;

- Its width and thickness.

All of these indicators will affect the quality of "work" and operation of the finished structure, including its ability to absorb and transfer heat, as well as sound vibrations. Of course, other structural parts, including fittings or double-glazed windows, will also be of great importance.

How to choose a quality profile for a window

Quality profile - for a good window

A quality window can only be made from a good profile. The quality and durability of the window primarily depends on the quality of the profile from which it is made. The influence of this component on the durability and technical characteristics of the window is so great that it is the manufacturer of the PVC profile that is indicated as the manufacturer of the window. It is important to understand that the quality cannot be determined by eye: externally, windows from different profiles may look exactly the same. The difference will appear later: for example, when the sashes of a low-quality window sag and stop closing. Therefore, the buyer should study the accompanying documentation.

The document confirming the compliance of the profile with the established quality standards is a certificate. An important nuance: it is not issued to the profile system, but to products manufactured at a specific plant. The products of different factories can vary greatly, so the quality of the output of each plant is certified separately.

Another important document is the international certificate DIN ISO 9001: 2000. It confirms that the company has an effective quality management system. This document is also issued only to a specific production. He guarantees that a system of continuous and comprehensive quality control of products is established at the plant indicated in it. That is, not only each batch of finished products is checked, but also semi-finished products at different stages of production.

The VEKA company is one of the few profile manufacturers with all production certifications. Including two factories located in Russia - in Novosibirsk and in the Moscow region.

This is the width ... What kind of profiles are there?

The first term that a person comes across who wants to install plastic windows in his house is the mounting width of the profile. It is she who is often indicated in advertising. Let's take a closer look at which window properties are affected by the profile width and how to select it.

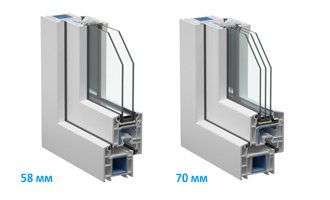

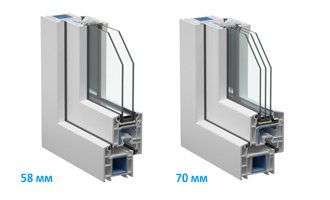

Classic size - 58 mm

The first window profiles, which appeared in the mid-50s in Germany, were 58 mm wide. This was due to the fact that they actually repeated the geometry of wooden frames, where this width, in turn, was due to technology.58-mm systems allow solving most of the problems in the design and production of windows in all climatic zones - if, of course, the manufacturer complies with the technology of assembly and installation of ready-made structures. VEKA produces the 58 mm EUROLINE profile system, the quality and reliability of which is appreciated by consumers all over the world.

70 mm - warmer and safer

Since about the mid-1980s, the production of profiles with an assembly width increased to 70 mm began.

The increase in the mounting width of the profile made it possible to install thicker double-glazed windows in the windows, due to which the thermal performance of the windows significantly improved. The increase in the thickness of the window also had a positive effect on sound insulation: in houses with such windows, it became not only warmer, but also quieter.

The VEKA product line includes three profile systems with a width of 70 mm: SOFTLINE, SWINGLINE and PROLINE. If for some reason the standard windows are not enough for you, choose one of these options.

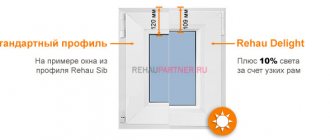

These products are almost identical in terms of heat engineering parameters, but slightly differ in the shape of the profile. The SWINGLINE profile has rounded edges. SOFTLINE and PROLINE are very similar in appearance, but the latter has a lower height. Due to this, the area of the light opening at the window from such a profile is larger and due to this, more light enters the room.

For those who love to the maximum

But 70 mm is not the limit for the profile width. Relatively recently, VEKA has launched on the market a completely new system VEKA SOFTLINE 82. This is an innovative development that allows today to design and manufacture windows that meet the high demands of tomorrow. The width of these profiles is 82 mm. If in 58-mm profiles it is possible to use double-glazed windows with a width of up to 32 mm, in 70 mm - up to 42 mm, then in SOFTLINE 82 double-glazed windows can be installed from 24 to 52 mm. Three sealing circuits reliably protect against noise, cold, moisture and drafts.

A few words about cameras

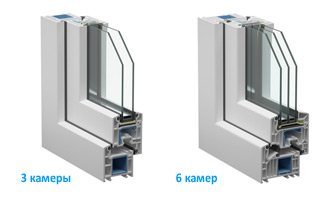

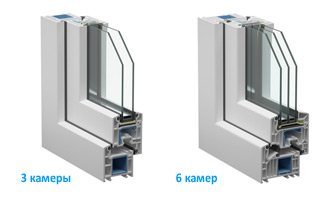

No less than width, window shop sellers love to talk about the number of cameras in a profile. What it is? What are cameras for and how do they affect profile quality? Does the “more cameras, better profile” rule work? These questions arise from the buyer immediately. Let's figure it out.

One two Three…

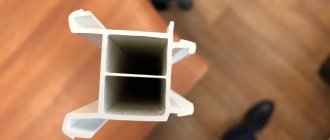

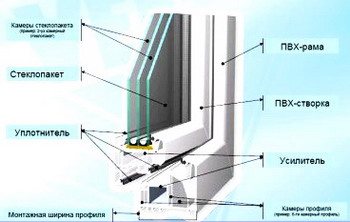

The PVC profile, in contrast to the wooden frame, is hollow inside. The walls visible from the outside are interconnected along the entire length by horizontal and vertical partitions. The spatial structure formed by them turns out to be light and strong at the same time. The cavities between the walls of the profile and the partitions are called chambers.

There are three such cameras in the classic 58 mm profile. The front camera - facing the street - serves to drain rainwater that falls on the window. A steel reinforcing insert is installed in the middle chamber, without which the PVC profile will not have the required rigidity. The third chamber (back, from the side of the room) is used to secure fittings: hinges, handles and locking elements.

How many cameras do you need?

The number of cameras is primarily dictated by the profile width: wider profile means more cameras. There are three chambers in a 58 mm profile, four or five chambers in a 70 mm profile, and six chambers in the VEKA SOFTLINE 82 profile system, whose width is 82 mm.

The hollow window frame has good thermal insulation properties. At the same time, the number of chambers by itself has almost no effect on the thermophysical properties of the window. The main thing is that there are air gaps inside the profile, their size matters. Therefore, when choosing a PVC profile for your future windows, look at the width of the profile, and ignore the number of cameras.

So does size matter?

The short answer to this question is: yes, size matters.

The consumer properties of the window (and its price too) directly depend on the width of the PVC profile used in it.According to the mounting width, the profiles are divided into two large classes: 58–64 mm and 70–75 mm. In addition, profile systems are produced with a larger installation width, for example, 82 mm in the already mentioned VEKA SOFTLINE 82 profile.

The heat-saving and noise-insulating characteristics of profiles belonging to the same class are practically identical. Moreover, in a broader profile, they are better. The main advantage of a wide profile is the ability to use thicker double-glazed windows in the window, which, in turn, to the greatest extent determine the consumer qualities of the entire window.

Real danger, or A and B sat on a pipe

It is very easy to discuss with the buyer the width of the profile, the number of cameras in it and juggle numbers. However, the parameters that are really important for the future window are often left behind the scenes, and it is almost impossible for a simple consumer to check them. We are talking about profile classes depending on the wall thickness. National and international standards establish the division of PVC profiles into three classes, depending on the wall thickness:

| Wall thickness (mm), not less | |||

| Class | BUT | IN | FROM |

| Outer wall | 3,0 | 2,5 | Not standardized |

| Partition | 2,5 | 2,0 | Not standardized |

The cost of manufacturing profiles of classes B and C is lower, but their strength characteristics are much worse:

● the profile deforms more easily and faster under the influence of wind loads and the weight of the glass unit: the window sashes sag and stop opening and closing normally;

● fillet welded joints of the frame may collapse; sometimes this happens already during the installation process;

● a window made of a weak profile is a real luck for an intruder, it is easier to break open.

A cheap class C profile is used for windows in temporary buildings and industrial buildings. It can be used to make inexpensive blind windows that do not open and therefore cannot sag.

Buyers of apartments in new buildings often encounter windows made of class B profiles. The developer, in pursuit of cost reduction, orders a batch of low-cost windows for an apartment building. Some newcomers immediately change the windows to better ones, others - a little later, when the sashes stop closing normally and simple ventilation turns into a problem.

The VEKA company has chosen the simplest and most reliable way: it produces only class A PVC profiles. Therefore, our customers do not need to understand the intricacies of this classification. Choose any profile - it will correspond to class A.

Met by clothes: profile appearance

A high-quality and durable profile is a must. But besides this, I want the window to look beautiful and fit into the interior of the room and into the architectural style of the house.

Most of the windows are made in plain white. This is a tradition, but not a duty. The consumer can choose the color of the window frame to their liking. Such an opportunity is provided by the lamination technology - the application of a decorative film on the surface of the PVC profile, which completely changes the color and texture of the product.

Imitation of wood of different species, painted and brushed metal, matte or glossy colored surface - the discerning consumer is faced with the difficult task of choosing from dozens of possible options. At the same time, you do not have to worry that the surface will fade or tarnish over time: the durability of the laminated coating is comparable to that of the entire window.

Algorithm for choosing a quality profile

To help the consumer choose a high-quality profile for a window, we formulated these recommendations, taking into account all of the above:

1. Start by choosing a trusted profile manufacturer. The quality of its products must meet the requirements of international and Russian standards.It will not be superfluous to make sure that a continuous quality control system has been established at the manufacturer's factories, and its presence is confirmed by appropriate certificates.

2. Determine for yourself what you expect from the window: what properties in terms of heat saving, noise insulation and light transmission it should have. Remember that windows in an apartment on the ground floor or in a country house should additionally protect the home from potential intruders. With all these considerations in mind, choose an insulating glass unit.

3. Knowing what kind of double-glazed window is needed for your windows, select the profile system that is suitable for its installation.

4. At the final stage, select the color and texture of the lamination that matches the architectural style of your home and interior design.

What material for the profile to choose?

Now the most popular in the production of metal-plastic window systems is polyvinyl chloride. It was first used back in the seventies. Since that time, it has significantly ousted its counterparts from the market, primarily wood.

Unlike more fragile and expensive wood, polyvinyl chloride has impeccable performance. It looks good, is lightweight, flexible and easy to work with. From it you can create windows of any type or shape, for example, rectangular, arched and others. PVC is a durable material. Unlike wood, it does not need additional processing or protection, and products made from it will serve you for at least 20 years.

In addition, aluminum structures can now be found. This type of metal is very versatile and is just as suitable for the production of window systems as PVC.

Most common installation depth parameters

Profile manufacturers adhere to generally accepted standards in the manufacture of PVC products. Therefore, the installation depth of systems of different brands on our market is practically the same. The most common sizes are 58, 60, 70 and 82 mm. But the thermal characteristics of profiles with different depths differ significantly - this is perfectly noticeable when studying the comparative table. Since there is practically no difference between the 58 and 60 mm systems, the data common to the 2 types of these profiles are considered.

| Installation depth (mm) | Number of cameras | Maximum thickness of glass unit (mm) | Coefficient of resistance to heat transfer with steel liners in profiles (W / m2 × ° C) |

| 58-60 | 3 | 38 | 0,72 |

| 70 | 3-5 | 58 | 0,86 |

| 82 | 6-7 | 60 | 1,11 |

On the window market, there are systems with a width of more than 90 mm, which can reach 110-130 mm. Such profiles have excellent thermal performance, but they are not in high demand with us due to the cost and installation features. They are mainly used in regions with very harsh climatic conditions.

What is the best thickness to install a profile in Moscow?

For plastic windows, this parameter may differ, so it is better to choose it individually. Most often, of course, there are products with a thickness of about 60 millimeters. But it must be remembered that the thickness of plastic products must be uniform over the entire width of the model. Also consider how massive and heavy the volume of the structure as a whole is. If it is too heavy, then it is better to use a material thinner than usual.

Please note that if you really need the best profile for plastic windows in Moscow, then you can find it on the website. We offer profiles from the most famous manufacturers at the best prices.

Plastic window profile size standards

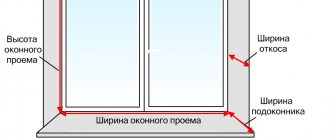

Plastic profile systems are manufactured according to standards. The height and width of the profile of the plastic window are calculated taking into account the structure of the opening. The window installed according to the standards will save you from the appearance of disadvantages: freezing, fogging, leakage. Durability, reliability, strength depend on it.

sells window systems of standard sizes that meet GOST standards:

- with two leaves are 140 cm wide and 130 cm high;

- with three doors: width - 205 cm, height - 140 cm.

The company's specialists will find a window system that suits the size of the structure of the room. When calculating the size of the frame, the window sill, the number of doors, the width, the length of the glass unit, and the thickness of the walls are also taken into account. The workers will make frames of any kind.

Call the measurer for free!