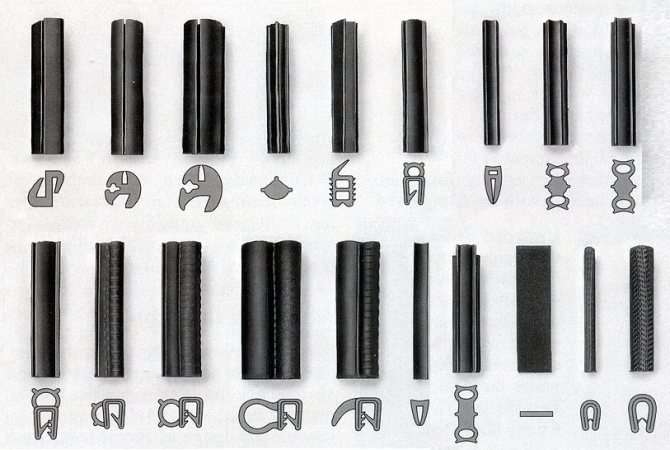

In residential and work premises, plastic windows are not uncommon. In order for them to close tightly and not leak through, the structures are equipped with rubber seals, which can shrink during operation. To prevent this from happening, and they served for a long time, you need to know how to lubricate the rubber bands on plastic windows.

The need to lubricate plastic windows

When cleaning at home, we do not forget about cleaning the double-glazed windows from dust and traces of rain. However, not everyone thinks that window care is not limited to external procedures. Over time, internal mechanisms and accessories begin to work incorrectly, and the reason is the decline in the quality of factory lubricants. Dryness leads to the accumulation of dust from the street and metal particles. Malfunctions can signal themselves with squeaks, grinding, clicking, jamming the door. When buying a new window, the manufacturer gives a 4-5 year warranty. This is the shelf life of the factory grease. Unfortunately, not all sellers notify buyers about the need to carry out preventive work, and therefore situations are brought to critical moments. If you do not respond to the problem in time, then the end can be sad. Lubricant for plastic windows performs the following tasks:

- reduces the level of friction of metal elements, increasing their wear resistance;

- facilitates the closing / opening of the flaps;

- protects against rust by creating a protective layer on the metal;

- the rubber seal retains its elasticity, does not stretch and ensures the necessary tightness of the sash.

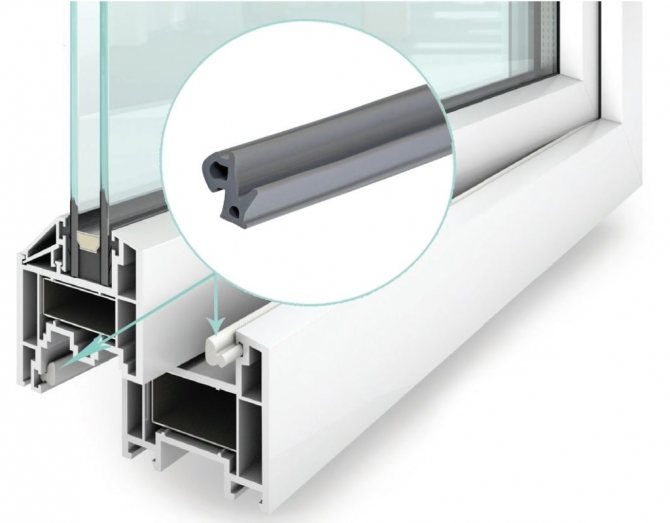

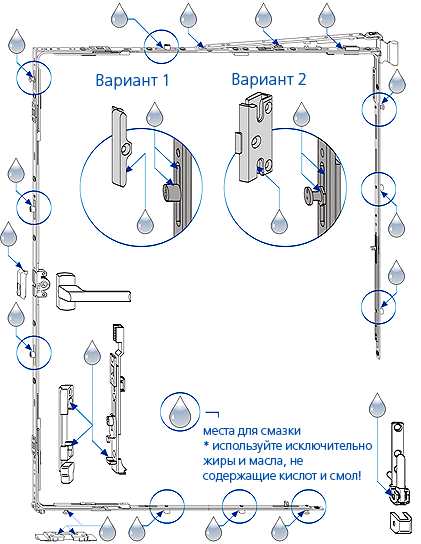

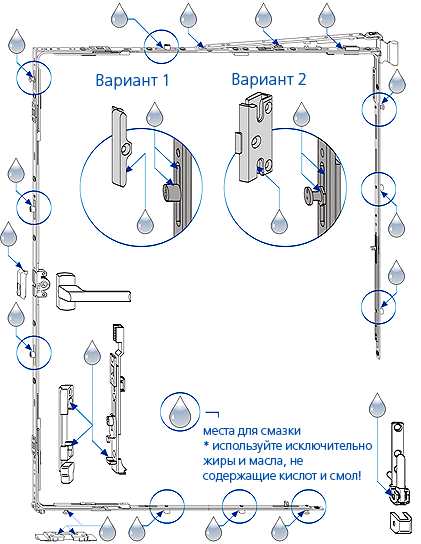

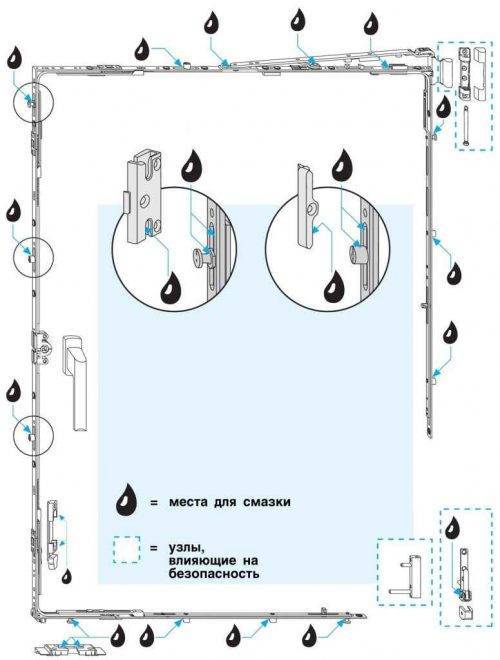

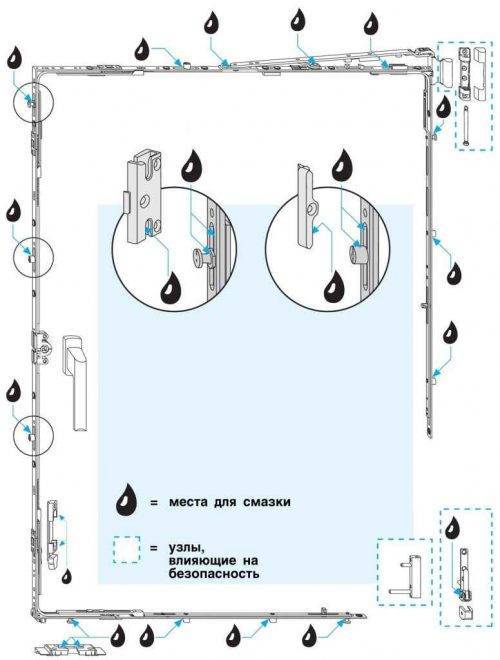

All moving and rubbing elements and seals on the frame and sash are lubricated. On some models of PVC windows, you can see the corresponding marking with an oil can. Thus, manufacturers give a hint as to which elements need lubrication.

Lubrication of plastic windows

The situation is aggravated by the fact that the structures installed with the advent of the first PVC windows have fittings and fasteners, which are difficult to find a replacement for now. Therefore, the wear of one or another element leads to a complete replacement of the internal mechanism or the entire unit.

How to replace an old seal on a metal-plastic window or door

To replace the seal of a metal-plastic window or door, you can use the services of specialists. If you want to save money, you can do it yourself.

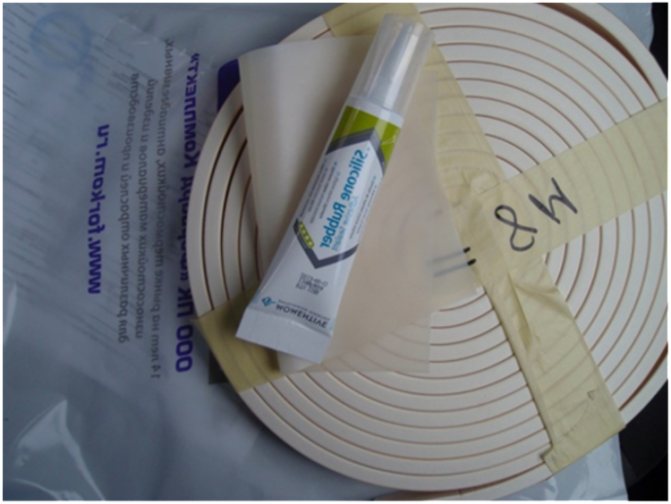

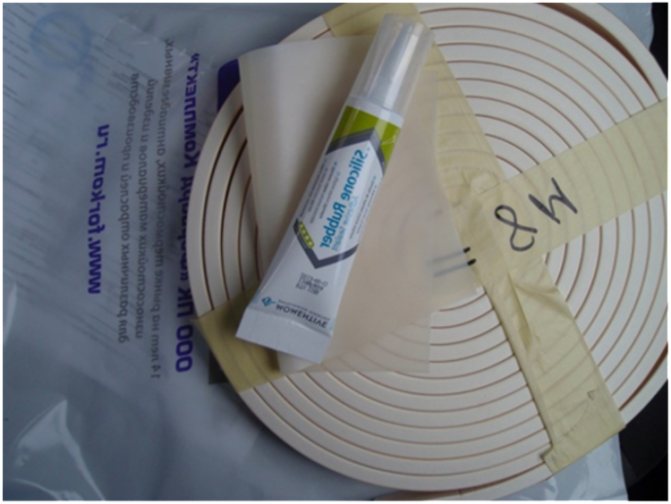

To do this, you need to have: a new seal, silicone glue, a gun holder for it, scissors.

In order for the replacement of the seal to take place without incident, the following rules must be adhered to:

- Using scissors or a screwdriver, it is necessary to pick up the old seal from the opening and remove it completely. This procedure is often not problematic. If the seal is already crumbled, then it is necessary to carefully remove all crumbs of material from the opening.

- The freed grooves for the gasket must be cleaned of dust and dirt so that the new layer of the gasket fits into the grooves as tightly as possible. Cleaning can be done using a damp, soapy sponge. After washing, wipe the grooves dry with a dry cloth and allow the grooves to dry completely.

- Next, using a pistol, you need to apply glue to the grooves of the window or door.

- The sealant must be carefully inserted along the entire perimeter of the window (door) into the grooves.

- Please note that the gasket harness must be guided along the grooves without effort (pressing, stretching, and other deformations).

- The excess part of the seal harness must be cut evenly with scissors.

- The junction of the two ends of the seal must be connected with glue.

For more information on replacing the seal, see the article How to replace the seal on a plastic window.

When replacing the seal, it is necessary to accurately calculate the distance along the perimeter of the window or door. It is unacceptable to use several pieces of harness. There should only be one seal joint.

Any thing in our everyday life in any case requires care, and the window seal is no exception. Perform all the necessary procedures on time, and the metal-plastic products will delight you with high-quality operation and a long service life.

How to lubricate plastic windows, types of products

Not all products are suitable for lubricating windows. On sale you can find ready-made kits for the care of plastic blocks, but their cost is not available to everyone. It is better to purchase everything separately, especially since half of such kits may not be useful.

How to lubricate the mechanism of plastic windows

The following products will be the best choice for lubricating window mechanisms:

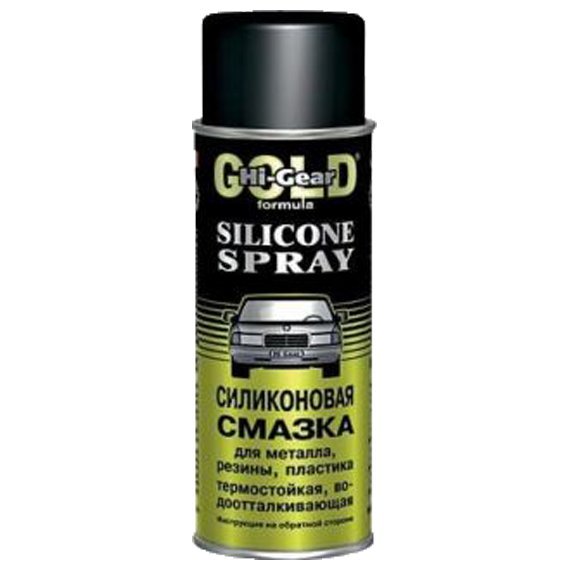

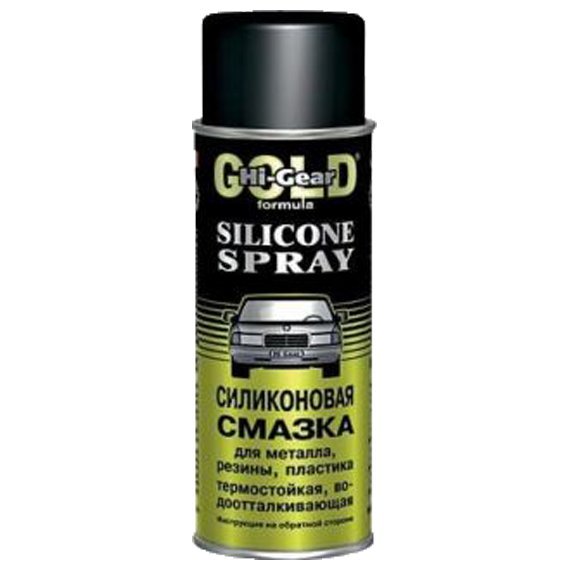

- silicone based products specially made for window mechanisms. When applied to a metal surface, a thin, resistant film is formed. The lubricant is available in tubes or sprays. Both options will work;

- universal grease, which contains the same silicone. It is identical to the special tool, but it can be used not only on windows. The consumption of funds is minimal, so one tube will last for a long time;

- lubricating oil for sewing machines or bicycles. Similar to machine oil, but better cleaning. It is easy to use and stays on the surface for a long time;

- mineral or synthetic lubricants. The main thing is to choose products that do not include acids, aggressive reagents and abrasives.

It is not recommended to use any vegetable fats, petroleum jelly, shoe polish for lubrication. This is due to the fact that vegetable oils leave a film on the mechanisms that dries for a very long time, about two weeks. During this time, a large amount of dust accumulates on it, which complicates the operation of the fittings, accelerating its wear.

Types of products for plastic windows

What can not be used to lubricate the fittings of plastic windows? Products containing acids and chemicals destroy the metal surface, “eat up” the anti-corrosion layer and oxidize the parts. Guns and automotive oils are also not suitable. The former are expensive, and do not perform protective functions in relation to windows. The latter have a low degree of purification.

How to lubricate rubber bands on plastic windows

The seals also need care. You can buy special lubricants, or you can use the tools at hand:

- silicone based lubricants;

- silicone sponges;

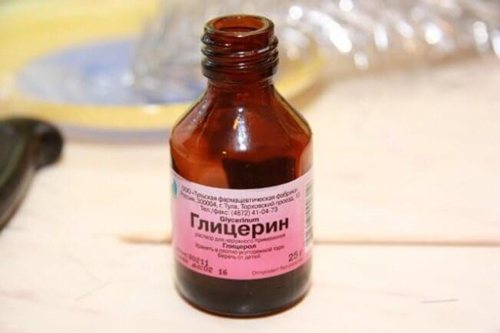

- pharmacy glycerin, but only in pure form, without cosmetic additives.

Do not use petroleum jelly and baby powder. Also, do not choose products containing a solvent, alcohol and alkali. They will destroy the structure of the rubber.

There is a controversial opinion about the use of WD-40. Some argue that the use of an aerosol will create a protective waterproofing film on the surface. Others say that at low temperatures, the agent can thicken and interfere with the operation of window mechanisms. If only this tool is at hand, it can be used to lubricate the seals.

Fittings

What can you do?

As you can see, the answer to the question of whether it is necessary to lubricate the window is obvious - it is necessary. So we just have to choose a composition for the treatment of rubbing surfaces and apply it correctly.Here you need to be careful enough: using the wrong oil will not only not improve the situation, but will also lead to an increase in the level of wear of the hardware parts.

So, let's take a look at how best to lubricate plastic window fittings:

- The ideal option is a lubricant that is focused specifically on working with window mechanisms. It can be purchased as part of a window care kit or purchased separately. As a rule, the basis of such a tool is silicone, which, when applied to the metal surface, forms a thin and sufficiently resistant film. The lubricant is available in tubes or sprays, both options can be used.

Care set for PVC structures: grease for fittings, for a sealant, profile cleaner

- Silicone multipurpose lubricants are almost identical in composition to those included in the "window" kits. A tube or a can with such a composition will definitely not be superfluous on the farm, therefore it is definitely worth buying it. Moreover, the price of the product is quite reasonable, and it is spent so economically that one cylinder will last for several years.

- Lubricant for bicycles or sewing machines. In essence, it is engine oil, only well refined. It is applied simply, adheres well to the metal surfaces of the fittings.

Will do too!

- General purpose mineral or synthetic grease. Slightly worse than the options listed above, but also quite suitable. The main thing is that the composition of the material does not include abrasive particles, acids and other aggressive reagents.

If you use a standard lubricant, then you just need to carry out preventive work a little more often, and monitor the state of rubbing parts a little more carefully, that's all.

What is not allowed?

Now - a few words about what oil cannot be used to treat PVC window fittings:

- Vegetable oils - olive, corn, sunflower. After application, the oil dries up within two to three weeks, having managed to collect a sufficiently large amount of dust during this time. As a result, a dense viscous layer of material with abrasive properties is formed on the surface of the fittings. Naturally, both the resistance during movement and the degree of wear from friction will increase significantly.

Vegetable oil helps for a week, and then leads to disastrous consequences.

- Compositions containing kerosene, solvents, acids and other aggressive components. When it gets on the surface of the fittings, such a lubricant provokes the destruction of the anticorrosive coating, accelerating the oxidation of the metal.

- Automotive lubricants, especially those with poor cleaning performance.

- Weapon oils. Firstly, it is expensive, and secondly, not all of them are suitable for long-term protection of metal from corrosion, so you should not check on fittings!

Gun lubricants are like yoghurts: not all are created equal

How do you need it?

So, we have chosen the oil, now let's see how to properly apply it with our own hands.

The instruction will be quite simple and involves the following sequence of actions:

- Open the window sash by setting it in a pivot position. This will ensure access to all fittings.

- Remove the plastic covers from the upper and lower hinges to protect the mechanism from dust and debris.

- With a brush with a fairly hard bristle (naturally, synthetic, not metal), we clean all parts of the fittings from contamination (dust + old grease).

Scheme of applying the lubricant composition

- We wipe all metal surfaces with an alcohol wipe or clean cloth. The indentations can be cleaned by wrapping a tissue around a toothpick or other long enough thin and long rod.

- First, we apply grease to the hinges: two or three drops per joint.

- Then we drip oil into the holes on the fittings.Some manufacturers mark such holes with special icons in the form of an oiler, but if they are not there, just pour two or three drops into all the grooves. The excess oil will drain and we will wipe it off!

Apply the oil in dosed doses, a few drops at a time.

- Now we need to distribute the oil through the mechanism. To do this, open and close the window several times, turning the hinges in all possible modes (rotary opening, tilting opening, step-by-step ventilation, micro-ventilation). In this case, the internal components of the fittings will be evenly coated with grease.

Selection criteria for window lubricants

You need to take care of window structures with high-quality and proven means. Poor lubricant quality will result in reduced machine life. When buying, be guided by the region of residence, because some products have the property of "tanning" at low temperatures.

Aerosol for lubricating plastic windows

Check with the seller in the store which lubricant is suitable for your plastic window model. Choose products in aerosols. This is the most convenient and economical lubricant. By spraying, you can reach the most inaccessible parts of the mechanism. It is not necessary to buy expensive products. Often they contain components found in inexpensive lubricants, and the principle of operation is the same.

Reasons for replacing the seal

If you have not taken care of the seal of a metal-plastic window or door, say, for 5 years, then it is no longer worth feverishly processing it with all possible means. Seal care sprays and lubricants are capable of maintaining the original structure of the material. However, no means can restore a crumbly, brittle, non-elastic seal.

In this case, only the replacement of the seal will help you. You can use the services of firms dealing with metal-plastic products. You can replace the seal yourself.

The first signs that a seal change is necessary:

- drafts;

- poor sound insulation;

- the passage of cold through the window;

- glaciation of the window in winter;

- the occurrence of condensation;

- dryness and cracks in the material;

- the appearance of fungi and mold on the seal.

Repair of a broken glass unit - causes, remedies, prevention. Read about the choice of soundproof plastic windows in this article.

We take care of the outer surface of the plastic window -.

How to lubricate plastic windows yourself

It is not necessary to be a specialist to carry out preventive maintenance of window fittings. To do this, you need to know the sequence of actions and have the necessary materials on hand. Remember to remove all decorative trims from the hinges and handles.

Cleaning plastic windows

Before starting to lubricate the elements of the window structure, you need to thoroughly clean them of accumulated dirt and dust. The sashes of the window open wide and are well inspected. All brackets, bolts and other moving parts need to be cleaned.

Use a damp soft cloth, sponge or brush for cleaning. The old grease layer is removed along with the dirt. After wet, use a dry cloth and wipe all parts dry. In warm weather, you can leave the window to dry on its own. Remember not to use any detergent. You can use WD-40 for metal elements. The frame is washed with ordinary soapy water. For hardened dirt, use a stiff brush, paying particular attention to the joints between the door and frame.

Fittings lubrication

Before starting the lubrication procedure, you need to understand where to lubricate plastic windows. The lubricant is applied to all elements that move during operation. If the work is done with an aerosol, then the process is greatly simplified. It is enough to spray the product at a distance of 3-5 cm.It is necessary to lubricate with oils by digging them onto the guide rails of the products, all rotary mechanisms and grooves. 2-3 drops will be enough. For convenience, oil grease is drawn into a syringe or small oiler, the tip of which is directed to the mechanism element. For the lubricant to penetrate well between moving parts, the window sash must be closed. It is better to open and close in different modes several times. This will allow the product to quickly disperse in all parts and lubricate them better.

Silicone is often used to lubricate the window. Before the procedure, the can is shaken well several times. The spray hole is directed to the element to be lubricated at a distance of 3-5 cm. Pressing the valve, release the agent for about two seconds. This will be enough for the grease to get inside. Silicone in cylinders is good because, due to its transparency, it does not leave marks on the surface. After lubricating all the fittings, wipe off the lubricant drips with a clean cloth.

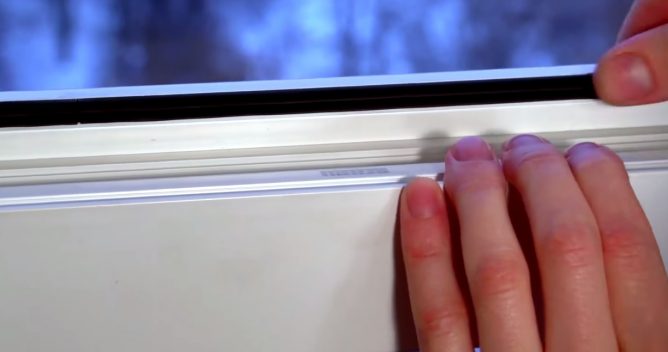

Lubrication of seals

In order for the sealing rubber on the plastic window not to dry out and to ensure a snug fit of the sash, it must be regularly lubricated. The window opens completely before lubrication, allowing access to all rubberized areas. The sealant is thoroughly cleaned with a brush from dust, and also washed with a soapy solution and left to dry completely.

Professional products or those that fit from the home arsenal are selected as a lubricant.

The product is applied to the seals and, using a cotton swab, is evenly distributed over the entire surface. You can choose grease in a container with a roller at the end. It will be more convenient for them to apply the product.

People's experience

Professional tools are, of course, good. However, human experience has shown that a rubber seal can be treated with a more affordable product. Such a remedy is glycerin known to all. Its disadvantages include a low level of water resistance. But in the case of seals, it does not play any role: these elements of the window structure are rarely exposed to prolonged exposure to moisture.

Glycerin is most likely a cosmetic product. Therefore, it may suggest using some kind of cosmetic cream. Don't ever do this! Additives, flavors and additives can be an exceptional punishment for rubber products.

Speaking of glycerin. It should be used even when washing. Tell your spouse about this!

The frequency of the procedure for lubricating plastic windows

The frequency of lubrication of PVC windows depends on the frequency of their use. Living conditions also matter. For example, those windows that face the road will get dirty more and faster. Accordingly, care for them should be performed more often, about once a year. It is better to lubricate plastic windows in early autumn or late spring at above-zero temperatures. If you notice extraneous sounds emanating from the flaps between lubrication periods, then do not wait for the right time. Tightening with the procedure can negatively affect the quality of fittings and sealing elements.

Fittings lubrication

Since these fittings are so capricious, why should they be lubricated so that they “behave well”? In fact, the procedure can be carried out with ordinary machine oil.

Moreover, no matter what: synthetic or mineral. Consider only the fact that mineral oil can become more viscous at low temperatures.

However, this is most likely important when the oil is used in some kind of car mechanism.

Do-it-yourself lubrication of plastic windows can be done using the usual silicone oil

... A mixture of the type of solid oil - CIATIM is quite suitable.

Important! In no case should the plastic window mechanism be lubricated with vegetable or other organic oils. The effect of this will be negative.

How can the fittings not be lubricated and why?

Some ignorant owners of plastic windows strive to lubricate window fittings with what should not be processed under any circumstances.

The main thing to remember is that vegetable oil is not a window lubricant. When the oil dries, a sticky film forms on the metal surface of the window fittings, to which small particles of stones, sand and dirt immediately begin to adhere. As a result, you create sandpaper with your own hands right inside the mechanism. The wear and tear of window fittings will reach a new ultra-fast level.

Also, you do not need to lubricate window fittings with butter, margarine, shoe gel, cream or natural petroleum jelly. Such substances will also significantly shorten the life of your windows.

Lubrication of the seal of plastic windows

The gum should be treated as often as the window hardware. Silicone oil can be used for these purposes. It does not damage rubber, it impregnates it well, giving elasticity. You can also resort to using regular technical silicone. If all this does not suit you, then there is a special lubricant for window seals.

Traditional methods used for seals

There are other substances that can be used to lubricate sealing gum in plastic windows., for example glycerin. It is often used by professional craftsmen. However, this substance is not able to adequately protect against moisture and over time it is washed off from the seal either when washing windows or when it rains.

Advice: you can use glycerin in its pure form, but you cannot use creams containing it or other substances, since the hand cream contains, in addition to glycerin, other substances that will be harmful to rubber.

Conclusion: when deciding how to lubricate the seals of plastic windows, you will proceed from the price, but it is worth remembering that the substances offered by window manufacturers are superior in quality to cheap counterparts. You should not save on trifles, since replacing rubber bands in a PVC window is impossible, and you will have to spend a lot of money and time to replace the seals.

Correct operation of PVC window structures depends on regular and proper maintenance of them. After prolonged use, the mechanisms require lubrication. How to lubricate plastic windows to extend their service life and ensure comfortable operation.

Caring for rubber seals

Despite the fact that modern plastic windows are made of high quality materials and provide adequate comfort, they are not insured against damage, wear and tear. This applies to all elements of the product, including rubber seals. An inconspicuous element protects the house from drafts, prevents moisture, dust, and reduces street noise. But seasonal temperature drops, humidity, dirt destroy rubber components. How and with what to process the seal of plastic windows so that it lasts longer? There are special solutions for this.

Why is it necessary to lubricate the window rubber seal

Window seals are installed in order to eliminate drafts and minimize entry into the house:

- water suspension formed during precipitation;

- street dust;

- external noise.

High quality rubber is used for the manufacture of window seals. However, over time, it also begins to lose its properties and wear out.

The reasons for the wear of the seals are as follows:

- susceptibility to temperature differences (external and internal);

- periodic exposure to dry heat in summer and wet frost in winter;

- exposure to direct sunlight and city dust.

Since windows are constantly being opened and closed, the seals in them are also subject to physical wear and tear.

That is why window rubber seals need restorative care, which mainly consists in lubricating them.

Do you want to choose the right PVC windows and install them yourself? Read this article of ours, and you will successfully cope with this task!

How often and with what do the sealing gum be lubricated?

Most often, after installation, the master lubricates all the gum on his own, but this does not always happen. The installer may forget to do this, and if you installed windows yourself, you could have missed this moment unknowingly. It is best to lubricate the seals immediately, sometimes the manufacturer does this, but not always. It will not be superfluous to repeat the procedure after 6-12 months: this will help protect the structural elements from external influences. The fact is that the protective substance is washed off over time by rain and detergents.

Why do you need to lubricate the seals?

Elastic bands on the windows serve not only to keep the glass unit tighter, but also protect the room from drafts, the structure itself - from moisture, dust, and other debris. In the production of windows, special rubber is used, which is of high quality and durability, but any material requires proper care.

Seals can lose quality due to external influences. For example, they are exposed to ultraviolet radiation, high and low temperatures with frequent changes. Dryness in hot weather is harmful for rubber, moisture in frost negatively affects. In order to protect the material, a lubricant is applied. The physical effect on the material is also destructive. This includes pressing the frame against the sash. The rubber rests only if the window is completely open, which does not happen very often. Most often, the seal is in a tightly compressed state.

Even if they did not forget to process the seals from the factory, know how to lubricate the sealing gum on plastic windows, necessary, since the lubricant needs to be periodically renewed.

What is used to lubricate rubber bands?

Many window manufacturing companies offer special materials that can be used to lubricate rubber bands on plastic windows at home.. Such lubricants can be found from the manufacturers of plastic windows Fenosol, KBE Edel Weiss and others. But most often it is impossible to buy the material separately, and you have to purchase a set for the care of plastic windows. It comes out quite expensive.

Silicone grease is versatile. Most often, it does not cost more than $ 5, you can buy it at any car dealership.

When buying, be sure to pay attention to the fact that the lubricant has a note that it is applicable specifically for rubber products. Similar materials are sold for plastic and are not suitable for rubber. The fact is that they contain chemical elements that can destroy rubber, make it more fragile and damage the seal.

Correct handling of rubber elements

Buying the right product is not enough - it is important to know the key aspects of caring for rubber seals. The user should follow the advice below:

- it is necessary to take care of the elements of PVC windows made of rubber twice a year - before winter and summer;

- first, the seal is cleaned - wiped with a damp cloth, sponge, then with a dry cloth;

- if the seal has petals, they are lubricated first, then the rubber outside;

- when using viscous products, use brushes of different thicknesses;

- having lubricated the sealant, it must be allowed to dry for about an hour, after which the window sashes can be closed.

There is no easier way to extend the life of PVC windows than to regularly lubricate rubber seals with high-quality alcohol-free solutions.The user, spending only 20 minutes annually on the maintenance of elastic elements, will increase the durability of the plastic structure several times.

What happens if you don't lubricate?

Any grease dries out over time, which leads to mechanical overload of the metal moving parts of the fittings. The additional load itself significantly reduces the service life of the mechanisms, not to mention the fact that unlubricated elements are subjected to this load. In the grooves of the frame and sashes, various kinds of particles accumulate, including sand and metal dust (appears during prolonged operation of the fittings). These materials are abrasives and do not have the best effect on the performance of mechanisms and the window as a whole.

The service life of rubber seals is about seven years. In hot, dry climates, rubber and polymeric materials lose their necessary elasticity even earlier. Without treatment, the rubber quickly coarsens and cracks, the tightness of the flaps in the closed position becomes insufficient, as well as the energy-saving characteristics of the window unit.

In residential and work premises, plastic windows are not uncommon. In order for them to close tightly and not leak through, the structures are equipped with rubber seals, which can shrink during operation. To prevent this from happening, and they served for a long time, you need to know how to lubricate the rubber bands on plastic windows.

Household seal care products

If it is not possible to purchase imported funds, you can get by with what you probably have in everyday life. Among them stand out:

Colorless, odorless viscous liquid. It is used in cosmetology as a by-product of fat saponification. From the point of view of chemistry, glycerin belongs to alcohols, however, experience of use says that it is safe for PVC windows. It is available - in the pharmacy you can buy 25 ml of the substance for 10 rubles. The bad thing is that it weakly protects the rubber from the effects of precipitation, quickly washing off.

It softens rubber well, covers it with a dense, colorless layer. It is insoluble in water, therefore it is good as a waterproofing agent. Vaseline has two drawbacks:

- It has low frost resistance (-25 degrees).

- Melts at a temperature of +27 degrees.

This substance will not last long, but petroleum jelly is a good alternative to products that contain alcohol. You can buy it at the pharmacy; 75 ml will cost 30 rubles.

Why care for seals?

Rubber elements of PVC windows are elastic and are located along the perimeter of the skylight. Due to the tight contact of the sashes with the frame, they are subjected to cyclic compression loads on a daily basis.

No matter how good the element is, over time it will wear out and lose its functions. In production, to delay an unpleasant moment, a lubricant for rubber seals is used, enveloping them with a thin film.

After a couple of years of operation, the protective layer comes off completely, and the user has to solve the problem himself. For this purpose, he needs to purchase some kind of solution for the care of rubber objects.

Correct execution of the lubrication process

Some window manufacturers indicate the lubrication points directly on their products or on sales documents. In the absence of this information, below is a lubrication diagram for the most common window structures.

Maintenance of a plastic window begins with cleaning its elements from dust, dirt and remnants of old lubricant. To do this, you need to open the doors, wipe them with a rag and rinse with warm water. After that, thoroughly wipe all components and surfaces with a dry napkin or cloth. Dry the moisture completely by airing and only then start applying the lubricant.

It is recommended to treat dry plastic surfaces with an antistatic compound. This will significantly reduce the amount of deposited dust and ensure long-term retention of the lubricant in working condition.

Lubrication of locking mechanisms and fittings

When preparing a window for lubrication of metal elements, it is not recommended to use active detergents and solvents. Work is best done in calm, warm weather, as the wind can bring in dust, soot and other pollutants.

The most convenient way to apply the lubricant is with a syringe. From a tube or bottle to lubricate one point, it is enough to take 2-3 drops of material. The use of aerosol cans leads to a clear over-consumption of lubricant and its ingress into adjacent areas. All nodes are processed in one go.

After applying the lubricant, the window sashes must be opened and closed several times by moving them in each work plane. As a result, the lubricant is evenly distributed over the entire surface of metal parts and assemblies.

Rubber seals

Use warm soapy water, a sponge, or a soft cloth to clean the surface of the rubber seals. After washing, the rubber must be wiped dry and air-dried. With double-leaf rubber profiles, the inner surface is initially lubricated and only then the outer surface.

To apply bulk lubricants, a cotton or gauze swab is used, aerosol products are simply sprayed on, thick substances can be spread with a finger or a brush.

Proper care of rubber seals requires treatment at least twice a year.

What can not be used when lubricating window seals

First of all, you should know that the rubber seal will not withstand if it is treated with solvents or substances containing alkalis or alcohol. Knowing the mistakes often made by users, we separately want to warn you against the use of the following substances:

- edible oils - it is absolutely impossible to process seals with them;

- petroleum jelly, which is not glycerin at all. Its application can cause the gum to crack (real men know this very well!);

- baby powder can dry out the seals.

So, remember that the PVC window seal rubber needs maintenance. Only in this way is he able to serve long enough, effectively coping with the task assigned to him. To care for it, you should always use those substances that are compatible with rubber products.