Advertising

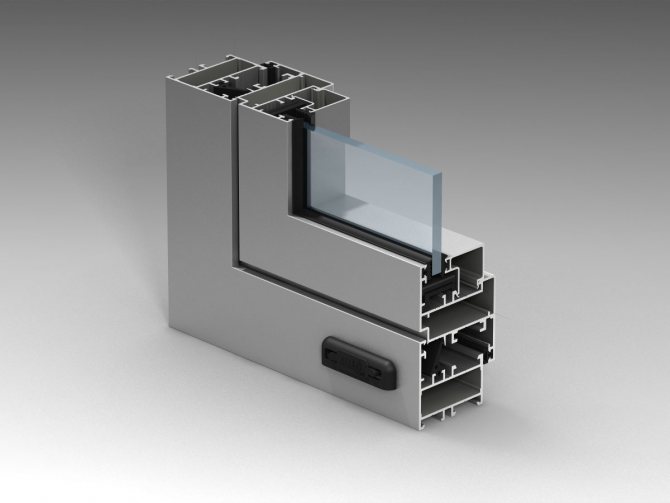

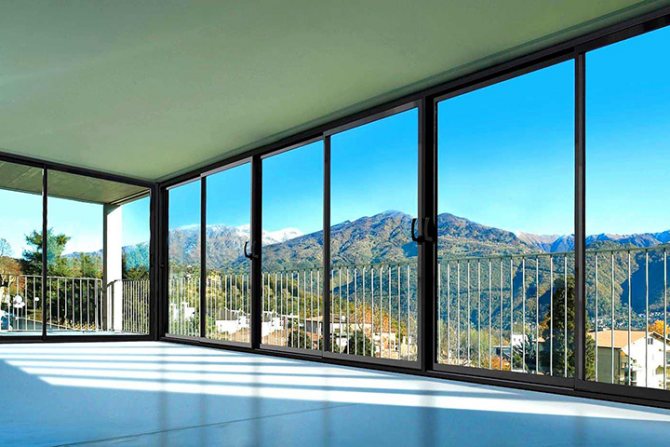

Until recently, the main type of translucent structures used in individual buildings was PVC double-glazed windows, which practically replaced wooden windows. However, with the development of architecture, the use of modern design solutions in construction, buyers increasingly began to look towards windows made of aluminum profiles. Why aluminum, what are its advantages over plastic - let us consider the example of the ALT W62 and ALT W72 window and door systems from the Group.

Previously, windows and doors made of aluminum profiles, as a rule, could be seen in shopping and business centers. Structures made of this material are very reliable, durable, have a stable geometry and make it possible to put into practice a variety of ideas. After all, aluminum is, first of all, a reliable and durable metal, so it becomes the best choice where there is a need for large glazing. At the same time, there is an opinion that aluminum structures do not keep heat, and therefore do not comply with the principles of energy efficiency implemented in modern private houses.

Where is the aluminum profile used?

Aluminum strips are widely used in building construction and interior design. This is facilitated by their increased strength. The material is most often used to compose load-bearing frames that are sheathed:

- plywood;

- siding;

- plastic cassettes;

- drywall;

- glass.

However, stronger steel products are used to assemble the solid structures. Stone slabs and other heavy materials are attached to them.

Facade cladding with aluminum profile

Types of aluminum window openers

Aluminum window constructions are sliding and hinged.

Sliding | Swinging |

| The sliding type of opening is used when glazing balconies and loggias, when creating panoramic glazing in private houses, restaurants and cafes. | The classic hinged type of opening is used for glazing large openings in office and industrial buildings. Windows of this design of standard size are increasingly seen in apartments and private houses. |

Technical characteristics of aluminum profile

Aluminum structures are a more profitable purchase than wooden or PVC profiles. However, according to several indicators, they still lose. Product characteristics can be formulated as follows:

- Durability. The service life of the aluminum structure reaches 60-80 years.

- Environmental friendliness. When the climate changes, the profiles do not change their qualities. For example, under the influence of heat, many materials release toxic substances. This property does not apply to aluminum.

- Ease. The material is very light, but at the same time it is as strong as possible.

- Space for imagination. Aluminum is able to repeat the texture of any other material. In addition, the material can be painted in any color by means of anodizing.

- Resistant to fire. The aluminum structure cannot be set on fire.

The material protects the walls of the building well from dampness if used for facade cladding. In addition, with the help of the design, it is possible to shift the "dew point" to the outside, which additionally protects the room.

Advantages of the aluminum profile in comparison with other materials

Important! Despite the apparent fragility and lightness, aluminum is able to support massive glass units and other cladding materials.

Aluminum structures are very light and durable

Painting the frame

The ability to cover structures in any color should be considered as a huge plus of these products. The coloring composition has excellent adhesion and will last as long as the window itself, in addition, the paint has properties to additionally protect the structure and increase strength.

The staining procedure is rather complicated, special compounds and equipment are used, so it is better to entrust it to professionals. The process takes several days, you can choose a color from the catalog or tint the paint to your liking.

The ability to cover structures in any color should be considered as a huge plus of these products.

There are two methods of coating aluminum profiles for windows with paint: electroplating and paint and varnish. Paints and varnishes are often used. The frame is degreased and cleaned, then covered with paint powder, after which the paint polymerizes at high temperature and results in a bright and elastic coating.

What should be considered when choosing a profile?

Aluminum profiles are the main parts of the supporting mechanisms, so they have to meet a lot of requirements. So, special attention when choosing requires an assessment:

- ultimate strength;

- maximum elasticity;

- the degree of maximum contraction under the influence of temperatures;

- viscosity qualities.

In some cases, corrosion resistance, electrical conductivity and heat resistance also need to be assessed. That is, check if the profile meets the conditions in which it will function.

In order to end up with a high-quality aluminum profile, for its smelting, it is necessary to select the correct alloy, taking into account the level of heat treatment and autofrettage. In addition, an important point is the exact observance of the dimensions when creating the profile.

T-shaped alloy construction

Aluminum profile prices

Aluminum profile

Shape and dimensions

Aluminum gives you the freedom to create windows of various shapes. The profiles can be bent to form an arch and can be combined almost arbitrarily into various architectural ensembles. Modern technologies make it possible to design aluminum windows with various opening methods and in a wide range of shapes, sizes and configurations.

Large lift-and-slide patio doors with appropriate fittings can have a sash weight of up to 400 kg and a maximum size of up to 2700 mm in height and 3235 mm in width. Considering that the movable sash should slide behind the blind sash, it is possible to get a glass surface up to 6500 mm.

Modern manufacturers of aluminum systems are also ready to provide customized solutions tailored specifically to the needs of a particular building.

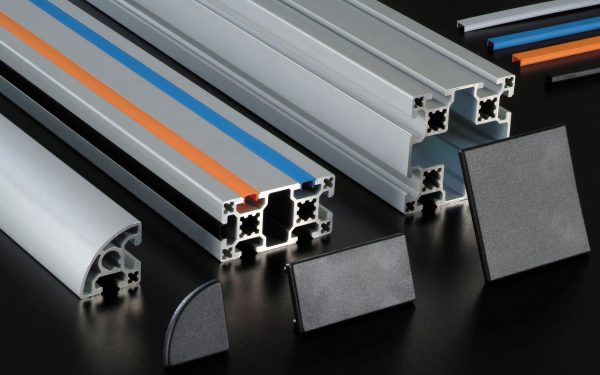

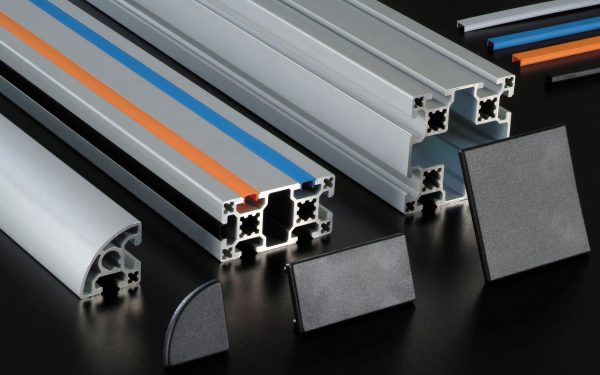

Classification of aluminum profiles

The material from which aluminum structures are created has several classifications. Including in size, production method, exterior and other characteristics. The most significant classifications are presented below.

Classification 1. By internal filling

According to existing regulations, aluminum profiles are divided into several types. These characteristics are provided for by Russian GOST 22233-2001 and GOST 8617-91. The features of this classification are described in the table.

Table 1. Characteristics of aluminum elements by filling level:

| Variety of profiles | Description of the structure |

| Hollow | These are profiles with free space inside. According to the standard, such structures must be equipped with at least one closed side, visible in cross-section. |

| Solid | Continuous structures have no enclosed areas. |

| Open end | Both hollow and solid parts can be supplied with a "free" end. All these varieties are subject to various requirements for the maximum possible inconsistencies in shape. |

| Semi-closed / Semi-free | Hollow structures are also semi-open / semi-closed. They are characterized by an incompletely closed cavity (rectangle or circle), on one side of which there is an entrance. However, not every open-entry cavity makes the part semi-closed. The area of the profile itself should be significantly larger than the entrance area. |

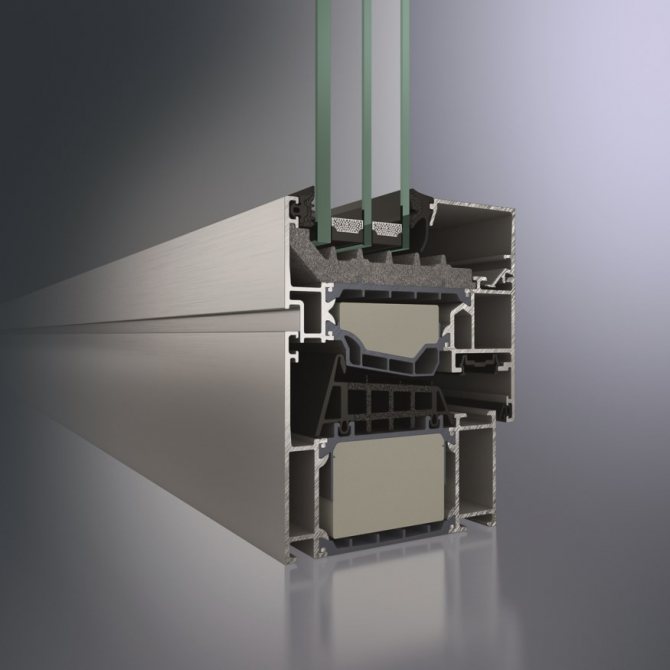

| Hollow dies | Semi-open and hollow profiles are made on the same "hollow" dies, therefore, they are additionally combined into one group. There are three types of free matrices: porthole; cruciform; bridge. Products created on such dies are equipped with one or more longitudinal welds. This is because during the smelting process, liquid metal flows around the bridges to support the bezel. The latter serves to indicate the inner contour of the future profile. |

The aluminum profile is welded under high pressure and high temperature. Solid profiles are created on solid dies - these are metal discs with one or more holes.

Classification 2. By profile shape

Metal structures also differ from each other in their external shape. Each variety has its own purpose of use. For example:

- Frame constructions. Suitable for marking door or balcony openings. They can be used as decorative elements in the interior.

- U-shaped detail. Such structures are used as load-bearing structures when installing massive slabs. They are broader than the frame ones. The narrowest side is most often the bottom or top edge.

- L-shaped element. It is used as a "edging" for decorative items. It can also be used to separate incompatible types of coatings from each other.

U-shaped metal part

The aluminum profile is fixed with clamps or brackets. An excellent frame is obtained from such an assembly. On top of the weightless profile, panels of any nature are attached - glass, plastic, acrylic or vinyl. Any other modern material can be used as cladding. It will look pretty stylish in a matte silver aluminum frame.

Classification 3. By production method

Aluminum profiles are created in one of two ways, each with its own nuances:

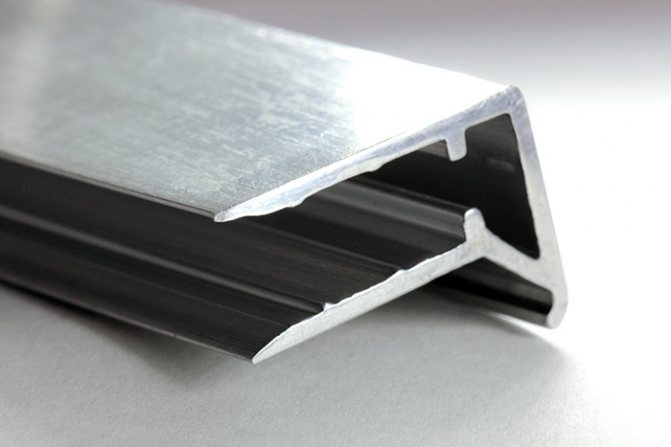

- Cold-formed. The profile is made of thin aluminum strips no thicker than 4 mm. They are bent in the right directions, the metal does not heat up in the process.

- Pressed. It is made on special pressing mechanisms under the influence of pressure and high temperature. The products obtained in this way are hardened and aged. Also, the press can create materials without heat treatment.

Classification 4. By field of application

From the current production, finished profiles are sent to various areas of life. The main purposes of the structures are discussed in the table below.

Table 2. Grouping of aluminum strips by purpose and features of such categories:

| Purpose of the product | Characteristics |

| Construction and architectural | The profiles of this group are directed to the production of doors, shutters, shelves and shelving for shops. Barrier structures are assembled from separate planks. The material is created from an alloy of the AD31-35 brand. |

| Transport | They are used in the production of sea / river vessels, land vehicles, in aircraft construction. Also used in the assembly of elevator structures and railway equipment. Planks are obtained from alloys A1, D5, D6 and others. |

| Universal | This category includes universal elements - channels, corners, brands. They are made from both aluminum and stronger metal alloys. |

| Electrotechnical | This group of profiles is directed to the manufacture of parts for heat exchangers, radiators, air conditioners and other equipment. Basically, equipment is assembled for industrial enterprises. |

First of all, the aluminum profile is appreciated for the fact that it makes it possible to assemble lightweight and reliable structures. Installation is also simplified due to special technical holes, which are required to supply any aluminum strip.

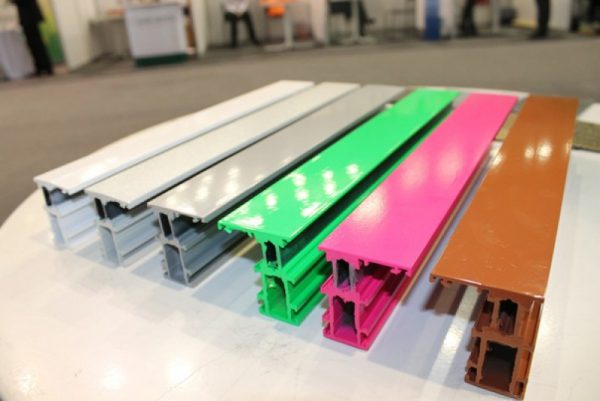

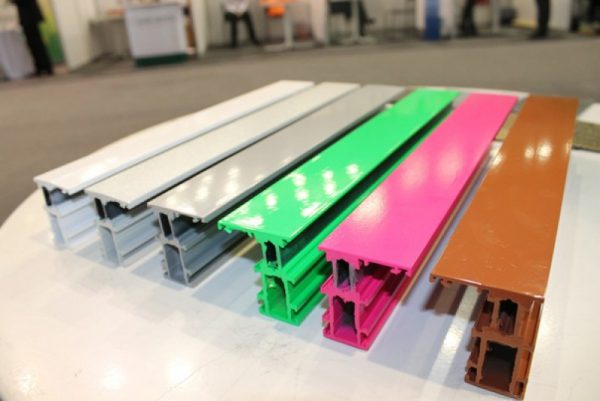

Classification 5. By staining method

Aluminum strips can be painted in one of three ways:

- For the finished material. The profile is powder coated in the desired color.

- Decorating. It is a coating that mimics other textures. For example, wood, marble and others.

- Anodizing. During the dyeing process, a colored oxide film forms on the surface of the alloy.

Despite the variety of colors and staining methods, most buyers opt for a regular unpainted profile.

Powder coating of aluminum systems

Classification 6. By application in installation

With regard to the use in the assembly of structures, an aluminum profile is:

- Connecting for polycarbonate. It is used when installing transparent polycarbonate structures. These can be greenhouses, gazebos, canopies and arches, stops, tents in parking lots and other structures. In this case, polycarbonate sheets no thicker than 2.5 cm are attached to the aluminum strips.

- End. It is used for mounting structures of any shape and size, including non-standard ones. The difference between this profile is that it is protected from the accumulation of liquid in the cavity. For this, there is a drain channel inside and a small steel plate with curved edges.

- Click profile. Frames and light boxes are assembled from such unusual materials. The anodized alloy click profile bar snaps into place and transforms into a luminous frame. Such designs show themselves well in outdoor advertising.

- LED profile. Aluminum LED profile is used for the construction of main or decorative lighting. Such strips are also called LED strips. This is a common metal profile that is painted with anodizing. An LED strip is inserted inside it. The profile is supplied with a white or transparent cover.

LED LED profiles are now very popular and are used everywhere. So, similar designs decorate store shelves, kitchen sets, stairs and railings, bathrooms, roads and sidewalks.

LED profiles, the principle of creating a structure

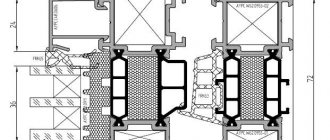

Classification 7. According to the level of thermal insulation

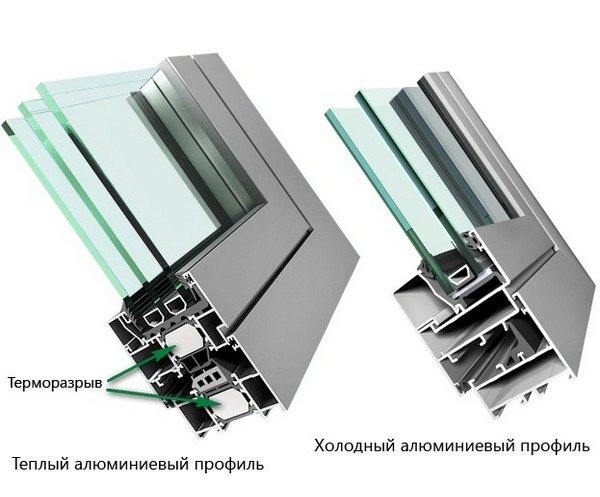

Depending on the conditions in which the aluminum structure will be used, two types of them are distinguished according to their qualitative characteristics. They are described in the table below.

Table 3. Classification of aluminum profiles by quality:

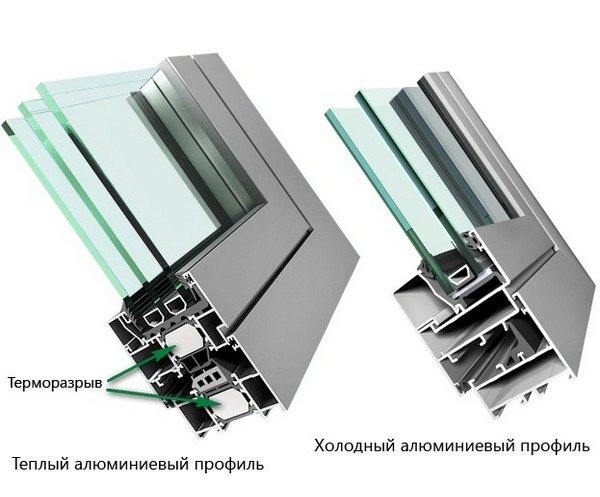

| "Warm" | "Cold" | |

| Description | Such strips are additionally equipped with rubber inserts and thermal pads. Fiberglass reinforced. The thickness of the gaskets is adjustable, due to which the level of thermal insulation can be changed. Due to the good additional layer, such profiles have high-quality sound and heat insulation. | There are no thermal inserts in such designs. It does not keep warm at all. Therefore, it is used in places where it is not required to maintain a comfortable microclimate. There are practically no fittings, so the design is very light. If necessary, glass with a thickness of 4-6 mm is mounted on it. |

| Where is used | The products are used for the installation of partitions and windows in offices, rooms and private houses. These can be industrial premises or subsidiary plots, verandas, loggias, balconies. | The "cold" profile can play the role of an office partition or a stained-glass window. |

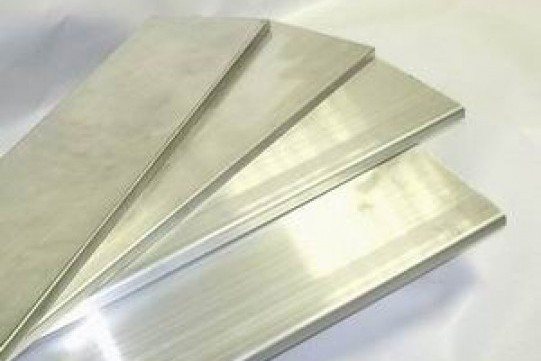

By section shape

Solid aluminum profiles

1. The solid profile has no closed cavities.

2. Hollow profile.This is a profile with at least one closed cavity in a perpendicular section.

A hollow profile is also semi-open (semi-closed) with a partially closed cavity, for example, a rectangle or a circle.

In addition, there is an "open end" profile. This "end" can be either a solid or a hollow profile.

The dimensions of these profiles are specified in the current standards. Read more about what aluminum alloy profiles exist in the article on our website "Making aluminum profiles for every taste!".

Also in these standards are given all existing configurations of aluminum profiles. Read more about the use of profiles of various types in the architectural and construction industry in the article on our website "Aluminum profile in glass structures: where and why is it used?"

Aluminum profiles for loggia glazing

Balcony glazing is a mandatory procedure to protect the premises from dust, wind, precipitation. On the glassed-in balcony almost no noise from the street is heard and the sharp temperature drop from "street" to "home" is not so felt.

You can glaze a balcony using plastic, wood or aluminum structures. In recent years, aluminum has become especially popular as it has several important features.

Glazing of loggias using aluminum structures

Pros and cons of aluminum for balcony glazing

Aluminum structures in balconies have both disadvantages and advantages. There are much more of the latter, because the material is so popular in this area.

Table 4. Advantages and disadvantages of finishing the balcony with aluminum strips:

| Dignity | disadvantages |

| Ease of designs. Glazing with aluminum does not add additional load to the supporting structures. In addition, for the sake of such elements, you will not have to expand and strengthen the fences. Strength. Aluminum alloys are capable of taking on a load 7 times more than natural wood. Long service. The material will last a long time, since it does not change under the influence of temperature and moisture. Mold, corrosion or cracks from drying out cannot appear on aluminum profiles. Convenience of service. Profiles do not require specific maintenance. They do not need to be regularly coated with protective compounds like wood. It is enough to occasionally wipe the surface with a damp cloth and lubricate the moving parts. Low cost. Due to the low cost of the material, it is more profitable to use aluminum for glazing than other materials. | Active thermal conductivity of the aluminum profile. Due to this property, it is impossible to provide a climate on the balcony that would be the same all year round. There are options with thermal inserts, but they also cannot compete with PVC sheets in terms of thermal insulation. Aluminum expands when exposed to high temperatures. This feature must be taken into account during installation, since the frames will change in size. This feature can cause some inconvenience. The cold profile freezes in subzero temperatures. Because of this, the doors that are to be opened are blocked. |

Aluminum is a metal alloy that affects the ability to transmit heat. Without additional elements, it does not delay it at all. cold bridges are formed from the aluminum structure, so the unprotected balcony cools quickly. Inserts help reduce heat loss. And the heat-insulating qualities increase significantly.

Installation of metal battens with insulation

Balcony glazing methods

With the help of an aluminum profile, you can glaze a balcony in two different ways - standard and insulated. The structure of the material itself is the same in both cases:

- Standard. The air temperature on the balcony and outside is only slightly different, but the design will be as light and cheap as possible.This option is used in regions with a mild climate or in garden houses.

- With insulation. It is possible to insulate aluminum profiles using additional profile elements. These can be double-glazed windows, energy-saving glass and other parts with enhanced thermal insulation.

Insulated structures will cost a little more than conventional ones. The future owner will have to pay extra for thermal insulation. But the aluminum profile, even in this state, will be much lighter and more durable than plastic and wooden ones.

Aluminum windows to the balcony - step-by-step installation instructions

Now that you know about all the features, advantages and disadvantages of aluminum windows to the balcony, let's look at how the installation takes place.

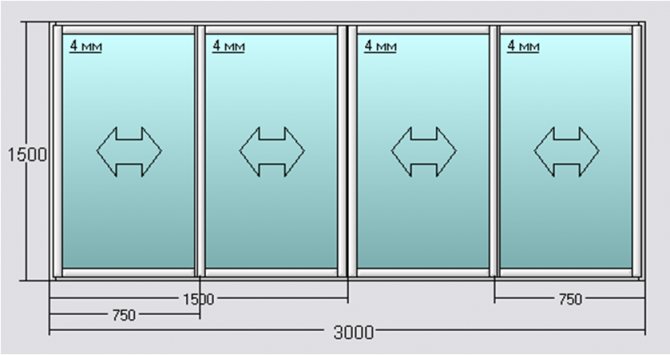

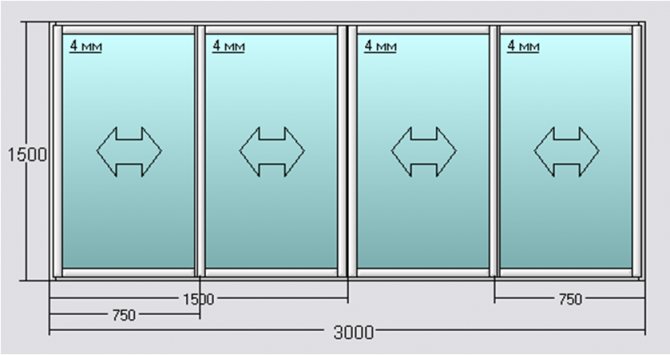

Dimensions of a sliding aluminum glazing frame for a typical loggia of a panel house

List of instruments

But before starting work, any master needs to stock up on a set of tools. You can familiarize yourself with the list of what you need to install aluminum windows on a balcony from the table below.

Mosquito net for aluminum windows

Table. Installation of aluminum windows on the balcony is a necessary tool.

| Tool name | What is it used for |

| Scrap | Dismantling old glazing elements |

| A hammer | Driving fasteners into dowels, fitting, dismantling old sashes and frames |

| Chisel | Dismantling the window sill and ebb |

| Wood saw | Splitting the old frame into several parts for easy dismantling |

| Roulette and level | Measurements and control of evenness vertically and horizontally |

| Screwdriver | Screwing in self-tapping screws and other fasteners used when installing aluminum windows on a balcony |

| Screwdriver | Used to loosen or, conversely, tighten the fastener |

| Drill with a drill for concrete | Making holes in the parapet to secure some parts of the aluminum glazing |

| Hex wrench | Working with some mechanisms of aluminum windows |

| Gun with silicone sealant or polyurethane foam | Processing the joints of various glazing elements and sealing gaps that could remain after the installation of aluminum windows on the balcony |

Prices for popular models of screwdrivers

Screwdrivers

Important! It is advisable that the screwdriver has two batteries - while one is working, the other is being charged. Then they change places. Thus, the continuity of the work process is achieved.

Dismantling old glazing - step by step instructions

Before proceeding with the installation of new aluminum windows on the balcony, it is necessary to get rid of the old glazing.

Step 1. The dismantling of the old glazing begins not with breaking the window frames, but with preliminary measurements. Using a tape measure, the length, height and depth of the opening on the balcony are determined. Without these data, it is impossible to choose an aluminum glazing that is suitable in terms of dimensions.

Preliminary measurements

Step 2. Further, the window sashes on the balcony open and the width of the low tide is measured. Also, the number of sashes in the new aluminum glazing and the width of the window sill, if it is planned to be installed, are determined.

Measuring the width of the ebb

Step 3. The building level is carried out along the upper part of the balcony opening - it is necessary to find out how flat the concrete slab is, whether there are any distortions there. Such defects are characteristic of old houses that are in disrepair, and this must be taken into account when installing aluminum windows on a balcony.

The flatness of the concrete slab is checked

Prices for building levels

Building levels

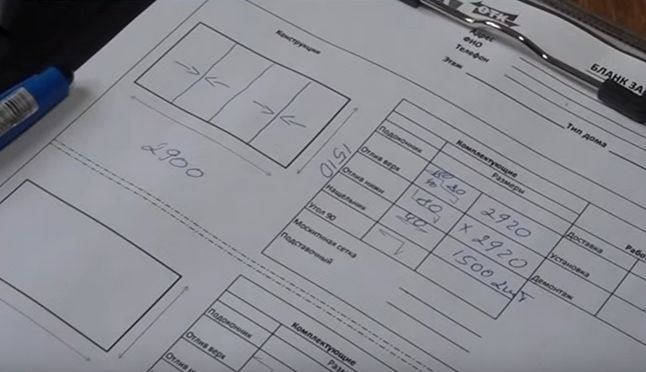

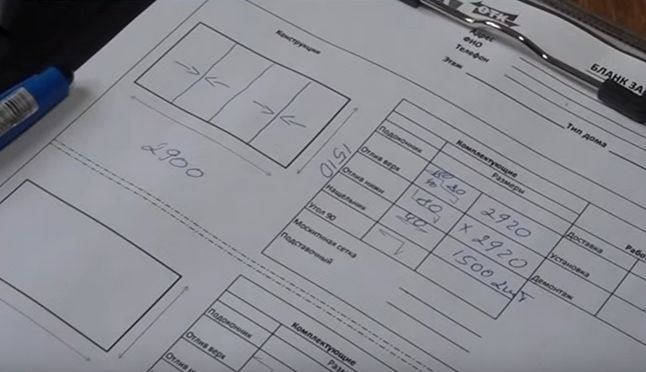

Important! In the process of performing all measurements, it makes sense to record the results of the work. Craftsmen working in firms for glazing windows and balconies use standard forms for these purposes, as in the image below. You can adapt a regular piece of paper for your notes.

Standard form for measurement results

Step 4. Only after all measurements have been completed, you can start dismantling the old glazing. Work begins by removing the leaves from the hinges. If they (sash) are in a satisfactory condition, then the process is done carefully, using a screwdriver. But more often the sashes of the old balcony glazing are removed using scrap. Much faster, more efficient and safer, this work is done in pairs.

When disposing of old window sashes, be careful not to let any parts fall out onto the street. It is also undesirable to break the glasses themselves - there is a risk of getting hurt about them at one time or another.

Step 5. The window sill and ebb tide are pushed on and removed with a crowbar. If they hold too tightly and tightly and do not just dismantle them, then the craftsmen resort to using a hammer and chisel - the latter is driven in between the parapet and the window sill (or ebb) in several places. Then, a scrap is inserted into the cracks formed, the glazing piece is pushed off and removed from the fasteners.

The ebb is removed

Step 6. Then, with a conventional saw, cuts are made at several points on each side of the window frame. This operation greatly facilitates the subsequent process of dismantling the structure, making it possible to remove it in small parts.

Making cuts

Step 7. The sawn-off parts of the balcony glazing frame are removed from their place and removed to the rest of the construction waste. If necessary, resort to the use of scrap.

Removing sawn frame parts

Step 8. After removing all parts of the old glazing, the opening on the balcony is protected from concrete fragments, individual small parts of the frame or from fasteners. Then small irregularities are smoothed out. All construction waste resulting from the dismantling of the old glazing is disposed of.

Cleaning work surfaces

Important! Before installing aluminum windows, serious defects and unevenness of the window opening are eliminated with cement mortar.

Installation of aluminum windows on a balcony - step by step instructions

Now that the balcony opening is free of old and worn-out glazing, new aluminum windows are being installed. As in the previous section, information about this case is presented in the form of step-by-step instructions.

Step 1. In this example, the alignment of the edge of the parapet is done by installing wooden planks. They are fixed on long self-tapping screws screwed into concrete. In this case, the boards are aligned horizontally using the building level.

Drilling a hole

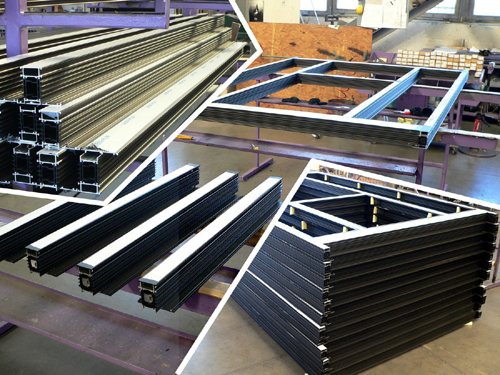

Self-tapping screw

Step 2. The delivered aluminum window parts are unpacked, counted and checked for defects. Then the frames are assembled from the individual elements - with rubber gaskets inserted between them, which are necessary to seal the connection. The parts are connected to each other using self-tapping screws.

Fastening a rubber gasket to the end part of a frame element

Assembling the horizontal and vertical frame members together

Fixing the frame parts in the joint using screwed self-tapping screws

Step 3. All other frames are assembled according to the same principles that were outlined in the previous operation. As for the sashes, they are usually supplied ready-made - assembled and glazed.

Assembly of window frames

Step 4. Anchor plates are installed on the upper part of the frame, with the help of which the structure will be connected to the ceiling on the balcony. The places for installation are not chosen by chance - from the edge of the frame to the anchor plate should be no more than 20 cm, and the interval between the elements should be no more than 40 cm.

Anchor plates are screwed on

Step 5. A window sill is installed on top of the board laid on the parapet. For starters, it is horizontally aligned.

Sill alignment

Step 6. Then the window sill is fixed on the board using self-tapping screws screwed into the part.

Sill mount

Step 7. The laying and fixing of the second window sill is carried out according to the same principle. In this case, both parts should fit tightly with each other, and their edges should lie on the same line.

Installing a second window sill

Step 8. On the outside of the parapet, a metal drip is laid on top of the newly installed window sill. It is fixed with small screws.

A metal ebb is installed

Step 9. Another ebb is laid next to it, while it does not just fit with the previous one, but overlaps with it, as shown in the image below.

Low tides are joined with an overlap

Step 10. The installation of the aluminum window frame begins from one of the edges of the balcony. One of its component parts is inserted into the opening and fixed there from bottom to top. Its vertical position is controlled by the building level.

Window frame installation

Window frame installation process

Step 11. Part of the aluminum frame is attached to the parapet with self-tapping screws. They are inserted into the corresponding holes in the bottom part and screwed in with a screwdriver.

Fastening part of the aluminum frame to the parapet

Step 12. Another part of the frame is installed next to it. It then joins the glazing element installed in the previous operation. Fixation is carried out using self-tapping screws screwed into the side parts of both parts of the aluminum frame.

Installing the second part of the frame

Connecting two structural elements

Step 13. Holes are drilled in the concrete slab on the balcony ceiling for fastening the anchor plates. Then dowels are inserted there and self-tapping screws are hammered. The latter fix these plates, and at the same time the parts of the aluminum frame from the upper side of the opening.

Drilling holes

Prices for popular models of rotary hammers

Perforators

Self-tapping screw

Step 14. Between the ceiling of the balcony and the upper edge of the aluminum frame from the outside, a visor is installed and installed, which is necessary to protect the glass from pollution during rains and other precipitation. The visor is attached with self-tapping screws screwed through the holes in the anchor plates.

The visor starts up

Attaching the visor with self-tapping screws

Step 15. The joints "visor-frame" and "frame-ebb" are treated with silicone sealant - through them not a single drop should penetrate into the balcony, even during the strongest downpour.

Sealing joints with silicone sealant

Aluminum profile windows: types of structures

This unique metal allows for a variety of window configurations. They can be framed or frameless, with sliding or swing doors. The detailed classification is presented in the table below.

Prices for metal-plastic windows

Window

Table 5. Varieties of window structures based on aluminum profiles

| Construction type | Description |

| Frameless | The window has upper and lower guides, left and right - free glass edges. The frame does not exist, so the window opening is covered only by transparent glass. This allows sunlight to enter the room freely. This design looks aesthetically pleasing, but almost does not protect against sounds from the street and temperature differences. |

| Framed | Sliding Framed glazing is more insulated than frameless glazing. The sliding windows are fitted with frame-shaped aluminum strips on all four sides. There are also two guides above and below, between which the window moves on rollers. It is important to mount and position the frame correctly, otherwise it will get stuck between the rails and allow cold air from outside to pass through. Swing These are ordinary window constructions that are installed on balconies. They are not as convenient to open as sliding ones. They swing open inside the room, so there must be free space for manipulation.However, with hinged structures, better thermal insulation and noise protection can be provided. |

| Remote | The frame on the loggia or balcony is moved forward by 30-40 cm. It turns out that the balcony expands outward, which makes the room more spacious. The window sill is very wide. This design is highly functional and attractive. At the same time, it does not create a large load on the structure. Used in both old and new homes. Due to the removal of the structure, its cost increases, since additional reinforcement is required for the removed frames. |

Video - aluminum windows, pros and cons

Types of windows by the number of fittings

Window aluminum profile is a multi-piece system, which includes a lot of auxiliary parts. These are various fasteners, inserts, pads for thermoregulation. In this regard, the profile is classified according to the following parameters:

- the nature of the seal (average or on the porch);

- type of installation of accessories (terminals or screws);

- number of heat chambers (from 3 to 7); thickness (inserts from 2 to 3.5 cm);

- a kind of thermal bridge (the gaps between the frames are filled with dense material or foam).

If a rigid special material is used as filling, the thermal insulation will be lower. Nylon, nylon, propylene and dederon are used as such interlayers.

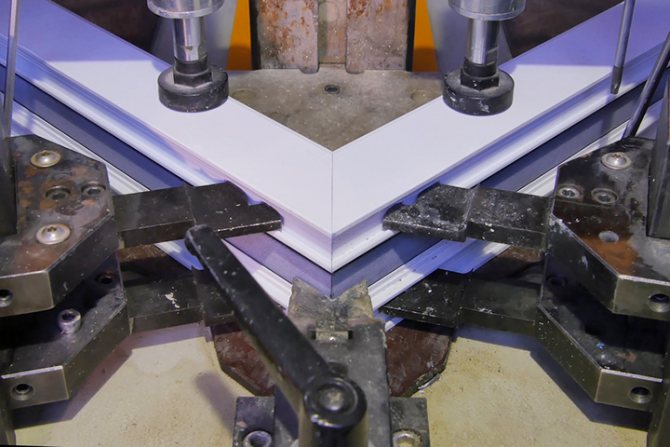

Manufacturing technology

Manufacturing of aluminum windows is costly and takes place with the use of specialized equipment, which partly explains the high cost of finished products.

- First, the profile is cut into pieces of the desired size according to the buyer's order.

- Already cut parts are milled, then the required holes are punched.

- Next, the installation of a rubber seal begins.

- The impost (part that holds the sash in the frame) and frame elements are fixed.

- Installation of fittings and a lock is in progress.

- All parts are connected into a single whole, packages and fillers are inserted into the frame one by one.

This is how the production of aluminum windows takes place. The finished product can be installed in a residential or commercial space. The installation procedure is described below.

Manufacturing of aluminum windows

Aluminum structures in the creation of facades

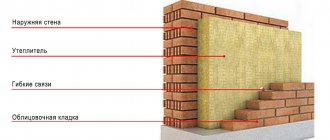

Ideal ventilated facades are obtained from such profiles - lightweight, durable and easy to install. The aluminum construction is robust enough to support the weight of the insulation, cladding and to withstand the effects of rainfall. The ventilated façade subsystem includes several elements.

Video - how the facade system is assembled. Assembling the structure

Bearing profile

This is a bar made of aluminum, in which the shape of the section may differ. It depends on what kind of "role" this element will be used in. The following forms are distinguished:

- T-shaped or Y-shaped. The main element in the assembly of the suspension system for home decoration. It is intended to support insulation and finishing materials, but will not withstand additional weighting.

- U-shaped. Able to take on increased loads. In this regard, it is mounted only on a reinforced bracket. It is also installed on floor slabs.

- L-shaped. Curved plank used to trim window and other openings. It is not designed to take loads, it is used only for closing difficult areas.

- F-shaped and H-shaped. With their use, windows, arched structures, parapets are processed.

The individual structures of the aluminum subsystem are connected with special strips. The latter is attached between the two ends of adjacent parts.

Important! When joining aluminum structures, it is important to consider thermal expansion. For this, a gap of at least 5 mm is left between adjacent strips to control seasonal deformation.

Installation of suspended facade systems

Carrying bracket

A device on one side of which an aluminum profile is attached.The opposite side of the bracket is mounted to the wall. There are 2 types of parts:

- Simple. Suitable for fixing ordinary profiles in the shape of the letter T. It has no additional reinforcement, therefore, it cannot withstand excessive load.

- Reinforced. Profiles with square and U-shaped sections are mounted on it. Equipped with reinforced shelves, so it can handle heavy loads.

Warming and vapor barrier

Insulation is an obligatory element in the installation of aluminum claddings. As a rule, for the purpose of insulation, a layer of mineral wool with a density of up to 120 kg per cubic meter is used. The material well inhibits extraneous noise from the street.

To protect the insulation from the ingress of liquid, a membrane vapor barrier is used. It sends water outside if it accumulates inside, and blocks its flow back. Condensation is deposited between the outer cladding and the wall, after which it is dried by air currents.

Insulation layer

Connecting elements

The brackets are attached to the wall with anchors. To connect the bracket and profile together, self-tapping screws for metal are used. Insulation also requires fastening - it is nailed to the wall using disc dowels.

Repair features

In case of damage to the profile (depressurization, fogging, other difficulties), repair or replacement may be required. Repair work may be required for the following reasons:

- the double-glazed window is damaged;

- the formation of condensation;

- the sash is warped (you have to deal with this due to poor-quality installation).

The glass unit is sometimes replaced with a new one. This can be done in casements, blind windows. First, the damaged element is removed, then the surface is thoroughly cleaned, degreased with a solvent, and a sealant is installed. Last of all, a new double-glazed window is installed, glazing beads are mounted.

The appearance of condensation is due to mistakes made when installing the frame. The level of tightness of the glass unit also plays an important role. To avoid the appearance of steam on the glass, it is enough to timely change cracked and shriveled seals. Condensation can build up if the thermal insulation is insufficient. With significant temperature differences, when outside the window - 30, and inside +25, the window can fog up. This is due to the fact that the glass unit does not sufficiently maintain the temperature difference and the window freezes. Consult with a specialist what kind of double-glazed window to install for yourself.

If, during the opening or closing process, the profile clings to the sash, there is a loose fit of one of the corners to the frame - this indicates that the mentioned element of the system is sagging. It is not difficult to eliminate this flaw, it is enough to pull out the decorative plug, then slightly tighten the adjusting screw located directly in the hinge.

Installing profiles

Aluminum strips are mounted on brackets strictly at right angles vertically or horizontally. The structures are connected with self-tapping screws. The main thing is not to forget about the gap, which is created as a safety net during the seasonal deformation of aluminum.

Bending or trimming of the supporting structure may also be required during installation. Bending aluminum is difficult. To do this, use hand tools or a professional machine. If you need to change several elements at once, it is advisable to order the work from a professional.

Prices for bending machines

Bending machine

Installation of windows and cladding of a loggia

Indeed, after completing the installation work, there will be much less free space. Therefore, it will be more difficult to clad the outer part of the loggia. After finishing the finishing work, you can start glazing the loggia with an aluminum profile, that is, start installing the balcony frames.

However, there are several reasons why glazing with an aluminum profile should not be done on your own.The first reason is that employees of specialized companies have the necessary skills and know all the nuances of the installation. The second reason is that when representatives of a specialized organization perform work, the customer is provided with a written guarantee for the product.

Facade cladding with aluminum

Aluminum can act not only as a structural element. Panels of this material are often sheathed with a ventilated facade.

Aluminum panels: what are they?

Panels come in square, rectangular or more complex geometric shapes. Such finishing will cost the owner of the house quite expensive, but it will be reliable and strong. Each aluminum panel consists of three layers:

- two layers of durable aluminum alloy;

- homogeneous mass as a spacer, which is located between the layers of aluminum.

Thanks to this structure, the panels are fire resistant and have a long service life. Instead of aluminum trim, sheets of porcelain stoneware, various alloys and other materials are also used.

Important! Often, designers use elements whose length is many times greater than the width. Such elements are called linear panels.

Cladding of an administrative building with aluminum panels

Composite panel prices

Composite panels

Methods for installing aluminum trim

Aluminum alloy panels can be installed in two ways:

- Open. The aluminum cassette has raised, slightly serrated edges. Thanks to them, it is fixed over the profile with self-tapping screws.

- Closed. The panel is equipped with a top curved edge only. The lower half has grooves that snap it into the lower cassette. The initial row of finishing cassettes is attached to the façade rail.

The aluminum facade looks very stylish and interesting. It decorates the building and provides it with additional strength and heat loss protection.

Cold or warm

When choosing an aluminum profile as a structural material, you need to know that this metal has a high thermal conductivity.

In winter, aluminum, unlike wood, does not "keep" heat. The temperature on the balcony will be about the same as outside.

Emphasizing this feature, consumers and specialists have given this solution the name "cold glazing".

Moreover, this design has the following positive properties:

- light weight and environmental friendliness;

- strength and durability;

- ease of use.

To this list must be added the cost, which is noticeably lower than that of plastic or wooden products.

Homeowners who wish to have warm glazed balconies should not be upset and refuse to use an aluminum structure.

To implement an all-season project, you need to use a special profile that has thermal inserts.

Thanks to these inserts, the aluminum structure allows a minimum of heat to pass into the street. Plus, energy-saving glass or double-glazed windows are used.

All of the above techniques and methods ensure the creation of comfortable conditions on the balcony at any time of the year. Numerous reviews confirm this.

Aluminum profiles in the interior

Aluminum profiles together with panels are an excellent design solution for creating an “apron” for a modern kitchen. Such a material with a surface that is distinguished by silver is suitable for interiors in the style of:

- techno;

- minimalism;

- loft.

Aluminum structures look good in the interior of the kitchen

Alloy facades are very easy to clean, so it will be easy to clean them of grease and other contaminants. Such a comfortable surface will make life much easier for the hostess, who already has to constantly clean up in a small kitchen. At the same time, aluminum does not change its color if hot steam or boiling water gets on it.

Also, aluminum will be a great ally in bathroom renovation.It is suitable for arranging wardrobes. The H-shaped aluminum strips are ideal for decorating doorways. They impart rigidity and strength to structures.

Aluminum goes well with glass, not only in variations with window openings. Such metal structures look good in the interiors of living rooms, bedrooms and bathrooms.

Sliding glazing of gazebos and verandas

Sliding glazing is relevant not only for a balcony or loggia. Sliding sashes are also often used for glazing verandas and gazebos. In the case of glazing a gazebo or veranda, you can make sashes from floor to ceiling.

This way you get a kind of sliding door. It is very convenient and beautiful. In warm weather and no rain, you can move the doors to the side and enjoy the fresh air, and closed sliding doors will also help you hide from the weather.

Plastic windows, their pros and cons

Windows made of PVC profiles were developed in such a way that these constructions would be available to a wide consumer audience and meet the most important requirements of buyers. Typically, most of the customers' requests are for the interior to be warm, quiet and dry, and also beautiful. That is why these products have the main advantages:

- energy efficiency - PVC profiles keep heat well;

- sound insulation - plastic and air chambers separated by internal partitions do not allow noise to pass through;

- tightness - due to the presence of 2-3 sealing contours, PVC windows do not blow;

- shape stability - the installation of steel liners in the inner chambers minimized the risk of deformation of the profile structures;

- safety - multi-chamber plastic profiles, steel reinforcement, triplex double-glazed windows and reinforced fittings make burglary much more difficult;

- fire safety - PVC does not burn, but melts and charred;

- assortment - profiles are on sale in a huge number of systems from European and domestic manufacturers, which have different colors, mounting depths, number of chambers and shapes.

When choosing plastic windows, their advantages, as in the case of aluminum models, must be considered together with their disadvantages. The disadvantages of products from PVC systems include size restrictions, a large mass of reinforced structures and the difficulty of replacing individual elements of sashes and frames during the repair of products.