The heating system of private houses and country cottages needs regular monitoring of the technical condition and preparation for operation in anticipation of the cold period.

In order for the system to function without interruption, it is necessary to periodically perform pressure testing, which helps to detect defects and identify leaks before the start of the heating season.

- 2 Features of the operation

- 3 Pumps

- 4 Types of equipment

4.1 Electric pump

- 4.2 Mechanical

The essence of crimping

Pressure testing is a special test of the heating system of a building for tightness and strength by means of high pressure, which is created after pumping the pipeline with liquid.

Since the heat carrier in the pipes is under constant pressure, therefore, all components of the circuit are subjected to systematic stress.

Often during the heating season, air masses penetrate into the system, leading to hydraulic shocks. As a result, various leaks appear, which are not always fixed. For example, in certain areas of the system in warm floors.

It is for this reason that the heating system must be pressurized before connecting the heating. In addition to detecting damage, pressure testing helps to clean the pipeline from accumulations of debris, rust, air residues, dirt and other deposits that impede the free movement of fluid.

A defect in the pipeline can lead to pipe rupture, large leaks and the impossibility of shutting off the water flow.

Do-it-yourself crimping of the heating system and why is it needed

Somewhere in late summer or early autumn, many owners of cottages or country houses begin to think about the upcoming heating season and preparations for it.

And in order for the heating complex of the house to work smoothly until spring, a number of measures should be taken before the onset of cold weather. These include self-pressure testing of the heating system, which can be carried out by anyone with special equipment.

What is the crimping process and why is it needed?

Pressure testing is a hydraulic (water) or pneumatic (air) test of a home heating system by pumping air or liquid into the system under high pressure.

For the first time, such a test and flushing of the heating system of a house should be carried out before connecting it to the centralized network, the subsequent ones - at intervals of 5-7 years (depending on the quality of the component parts - pipes, pumps, valves).

Such a procedure is carried out in order to remove any types of pipe contamination from the inside, obtained both during the installation or replacement of elements, and during operation.

The fact is that due to the frequency of use of the heating hydraulic system (half a year - it works, half a year - not), rust, salts and other deposits accumulate on the inner surfaces of parts and assemblies, which impede the free flow of liquid.

Also, when installing heating systems, dirt, small particles of construction and household waste can get inside. All of this must be removed from internals and connections for efficient operation and uninterrupted heat supply.

In addition, such diagnostics allows you to identify problem areas: leaks, rusty pipes or components that require repair or replacement: broken taps, worn connections.The detection of these places during diagnostics allows you to avoid big problems during the heating season - pipeline rupture, battery leakage, inability to cut off the water flow.

Preparatory work

Do-it-yourself crimping of the heating system should begin with preparatory work - inspection of nodes and connections of the entire structure, which includes inspections:

- The boiler itself;

- Connections and pipes connected to it;

- Highways;

- Locking mechanisms (valves);

- Air bleed valves;

- Batteries or radiators.

If damage, malfunction or wear is detected in any part of the heating complex, it is necessary to repair or replace the part with a new one. It is also necessary to seal the connections and renew the worn-out insulation.

The next preparatory step can be chemical flushing of pipelines. Such a procedure is necessarily carried out by an experienced specialist in compliance with all safety standards.

Chemical flushing poses a certain threat to health, as it involves the use of aggressive chemicals. Therefore, it will be much more profitable to carry out hydraulic tests of the structure in two stages.

The process of diagnosing the heating hydraulic system under pressure

Do-it-yourself crimping of the heating system begins with disconnecting the structure from the centralized line and completely removing the working fluid from it.

When conducting a hydraulic test, all actions prescribed in the instructions for a mechanical or automatic unit should be clearly followed, as well as all safety rules should be followed when performing such work.

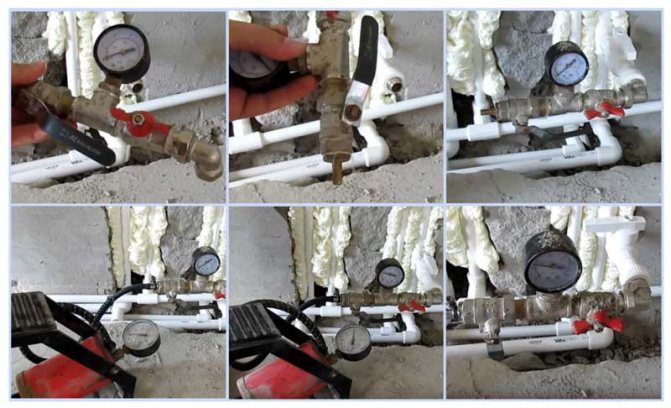

The process of carrying out a hydraulic check consists of the following stages:

- Open all air vents and close the outlet valves;

- Filling the entire pipeline structure with water;

- Connection of a pressure generating device (press);

- Adjustment to create a pressure of 2 atmospheres (necessary to check the heating of a private house);

- Checking the manometer readings for half an hour;

- Checking the nodes of the entire pipeline (from the boiler to the batteries) in the event of a pressure drop for integrity;

- Turn off and disconnect equipment and drain water from the tested structure.

Testing

If the check was successful, and for half an hour the pressure in the pipes, boiler and radiators was stable, then the preparation for the heating season can be completed. If a leak or any other structural malfunction is found, it is imperative to eliminate the malfunction and retest.

The test in two stages consists of:

- Hydraulic flushing of pipelines and radiators, which removes dirt and impurities, as well as rust, scale and sediment formed during operation;

- The test itself, conducted in order to identify defects and clogging of the lines during flushing.

Carrying out such work by specialists is not cheap, so self-diagnostics of heating under pressure can save significant money.

Recommendations for testing

If you decide to carry out a pressure test yourself, there are a few tips and tricks that you should heed:

- Carefully check the condition of assemblies, connections and equipment before starting the test;

- Eliminate all flaws and malfunctions;

- Connect the equipment, strictly observing the correctness and reliability of the connections;

- Before starting, double-check if everything is done correctly;

- Observe the rules of caution when operating the unit;

- Be careful not to leave the equipment unattended;

- Under any force majeure circumstances, immediately turn off the equipment and only then proceed to eliminate them.

Features of the operation

The first time the pressure test should be carried out before connecting the pipeline to the centralized system.

In the future, prophylaxis is performed every 5 years. It depends on the quality of the source material and components (constipation, pipes, pumps).

Steel pipes are connected by welding and threads, polyethylene modifications - with fittings, and propylene ones using low-temperature brazing. Any connector is considered a potential leak point.

To determine the damage, hydraulic pressure is created in the system. Its coefficient must be greater than the maximum possible working pressure in the pipeline. So, if the system can withstand a hydraulic load of 16 atmospheres, then the pipes can also withstand the standard pressure of 8 atmospheres.

In addition, pressure testing is mandatory after repair work or prolonged downtime, as well as after replacing radiators or heating risers. After all, it is better to detect a violation in the system in the off-season than during the first frosts.

Pressure test pump: main purpose

During the operation of the heating system, some parameter changes appear, for example, radiators, pipes, boiler or nozzles at the joints. What is crimping and how does it identify such problems? This question is very interesting for people who connected heating systems.

When a series of work is carried out to install a new heating system or repair an old system, there is a small chance of cracks at the joints of the system. The crimping unit detects such problems before starting the system. The work of such a device is to create a high pressure in the required area or in the entire heating system. Pressure control or visual inspection can show problem connections.

Crimping is necessary in 4 cases:

- After completion of repair or installation work;

- Before the heating season starts;

- After the system has been serviced;

- After replacing some system components.

To carry out this kind of work, pumps are used to create a pressure test in the heating system. These pumps are pneumatic and hydraulic. Experts recommend drawing up a schedule for the pressure testing of the heating system of a house or apartment. But before that, you need to understand the technology of the crimping process and choose a device for it.

Pumps

Pressure testing of the heating system is carried out by means of pressure pumps simulating a situation similar to a water hammer.

A pressure pump is a kind of press that is used for hydraulic testing of plumbing, engineering and communication systems.

This mechanism connects directly to the loop. With its help, the controlled pressure created in the pipes is increased. After connecting the device, the working substance begins to be supplied to the system under a certain pressure, then the readings of the manometer are taken.

The pressure is applied until its level exceeds the operating value by 3 times. The verification procedure takes 2-3 hours. All this time, they monitor the readings of the manometer.

If during the process there is a sharp drop in pressure, then the tightness of the pipeline is broken. In this case, it is necessary to identify the location of the leak, carry out repair work and start a new test. Stable readings indicate the tightness of the heating system.

Diy pressure pump

In order to make a crimping, it is not necessary to purchase a special device. A device such as a crimping pump can be made independently. To do this, you will need to have some parts and elements.

You can use an old jack and cylindrical containers.

Devices of this type have an average capacity of 50 liters and can operate at a pressure of 10 bar. The arrangement of the pump elements with the system elements is carried out by a threaded connection. Holes must be made in the cylinder. Among the holes, there must be one for the fluid supply, the second for the manometer, you will have to buy it. This is a manual version of the pipe crimping pump.

A homemade pressure testing pump is great for pipelines before starting hydraulic tests. The crimper can be not only manual, but also mechanical.

Equipment types

Depending on the technical parameters, all crimping pumps are classified into two groups: electrical and mechanical.

There are several modifications of electro-hydraulic pumps, however, they are used somewhat less often.

Although the principle of operation of the pumps is different, the functional purpose is almost identical: pressure testing of the system, finding leaks, preventive maintenance and commissioning. Before using the equipment, you must read the attached instructions.

If you wish, you can design a homemade pump, especially if you need it for crimping a private house. This will require copper pipes, plugs, a check valve, a pressure gauge and a fitting through which the pipe must pass.

All elements are assembled in a specific sequence using welding. Linen strands are used to seal the joints. The cost of such an installation will be much cheaper than analogues, however, certain skills and knowledge are required for its manufacture.

Electric pump

The device is equipped with a motor and operates from a 220V network. This unit is used for testing heating, plumbing and oil systems.

Electric models are used in professional activities with intense loads.

The main advantages of an electric pressure test pump are:

- Easy to operate and maintain. To connect the mechanism, you just need to press a button on the control unit.

- High level of performance. Thanks to the electric drive, the maximum pressure is generated very quickly.

- Long service life due to high-quality and reliable housing.

- Convenient pressure regulation with a bypass valve.

- The presence of special protection against overheating. With strong heat, it automatically lowers the pressure level, causing the device to cool down.

- Mobility. The device can even be carried in the trunk of a car.

The disadvantages of an electric pressure operator include its high cost, dependence on the electrical network and a solid weight.

Mechanical

The hand crimper consists of a pressure pump handle, indicator, hose and housing.

These devices are often used as clamps or hydraulic lines. They are indispensable for use in places where there is no electricity or water supply.

The mechanism has many advantages:

- compactness, mobility;

- can be used in a limited area, when carrying out small-scale work;

- long service life with careful maintenance, the possibility of repair;

- safety in operation, due to the absence of rapidly rotating elements;

- acceptable cost.

The disadvantages of a mechanical pump are low pressure delivery rates and the need for constant monitoring. In addition, working with the device requires some physical effort.

What is a pressure pump

We already know what crimping is and how to carry it out. Now you need to figure out the types of device used. In order to carry out this work, special installations are used, they differ in configuration, design and technical parameters.

Hand pumps operate on the basis of a piston system in order to generate pressure.

Electric pumps for pressure testing of systems are power pumps and build up pressure with liquid in the system. All such pumps are suction. For a large volume of pressure testing, it is recommended to use only electric pumps, and for a small volume, mechanical ones can also be used.

These 2 types of pumps differ in design according to the following features:

- Membrane constructions;

- Piston structures;

- And plate-rotor.

Almost always, to create pressure testing of heat supply in an apartment building, exclusively piston ones are used, since they have an acceptable cost and they are reliable. If it is planned to pump liquid into the system, then it is better to install a different type of pump. In this situation, the diaphragm type of pumps will be the best choice. With the help of such pumps, you can very quickly and with your own hands make a pressure test of the heating system.

Important instrument parameters

The maximum possible pressure level in the heating system depends on the power of the installation.

Therefore, pressure testing equipment can be systematized into several categories:

- pressure varies within 30 bar;

- pressure reaches 60 bar;

- maximum pressure level 100–120 bar;

- over 150 bar.

The functional component of the unit is of no small importance. It depends on the pump model and determines the volume of fluid that the mechanism can pump. The weight of the pump and the volume of the reservoir for storing the working fluid are important.

Also, when choosing a certain modification, it is worth considering the working environment in which the pump can operate.

Characteristics of crimpers

When choosing a crimper, one should be guided by the following characteristics of the devices, on which the comfort of operation will depend.

- Cost.

- Dimensions.

- Accuracy of readings.

- Weight.

- Performance.

- The pressure generated in the system.

- Dependence / independence from the electrical network.

It should also be remembered that the parameters of pressure operators for heating or water supply may be different depending on the purpose of the work. For large objects, more powerful devices are needed, the cost and dimensions of which will be much higher.

Crimping technology in an apartment building

The crimping procedure is carried out according to a single algorithm, carrying out has some peculiarities in different cases.

Special services are obliged to carry out hydraulic tests before and after the heating season.

Also, this event is carried out after repair or when commissioning the equipment.

The result of the event is documented and an appropriate act is drawn up.

Before crimping, carry out:

- inspection of the supply unit, pipeline and other parts of the system.

- checking the state of the thermal insulation of the main line.

If used for more than 5 years, it is recommended to flush the system before the hydraulic test. For this purpose, a special solution is poured into the pipes freed from the coolant.

After completing these activities, they proceed to crimping. Actions are in the following order.

- Water is poured into the newly installed or flushed system.

- With the help of special pumping equipment, an increased pressure is created, which is controlled by a pressure gauge.

- If the pressure level remains unchanged for 15-30 minutes, then this indicates the tightness of the system and the reliability of the equipment that is included in it.

- If a decrease in pressure is observed, the reason for this is found out.

- Having found out the place where the leak occurs, it is eliminated or the defective element is changed and the procedure is repeated.

- A test is considered successful if the pressure drops not more than 0.1 atm for 30 minutes.

Types of crimpers

A pressure testing pump is a special professional device that is used for technical pressure testing of units, pipelines, systems and assemblies. ROKRAFT offers various types of devices to carry out the corresponding work on site.

Manual. Among their positive qualities, one can note a relatively low price, low weight, ease of transportation and ease of use. As a rule, Rothenberger hand-held pipe crimpers have a working pressure (up to 50 atm) and are often equipped with a tank, high-pressure hoses and a built-in pressure gauge.

Electrical. The indisputable advantages of these heating systems pressure operators are high performance indicators, working pressure and the presence of an electric drive. Due to the latter, the direct participation of the operator in the crimping process is minimized.

Gas. Used to check the tightness of indoor gas equipment systems. The device can also monitor the integrity of a pipeline using liquid propane or other low pressure mixture.

Air pressure testing of open heating systems

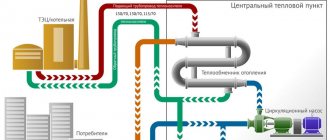

In the open circuit of the heating system of a private house, an expansion tank is used to create pressure, installed in the attic of the building. The pressure in the system is determined by the head of the water column, when its height from the lowest point of the pipeline to the water surface in the expansion tank is about 10 meters, the head in the line will be 1 bar.

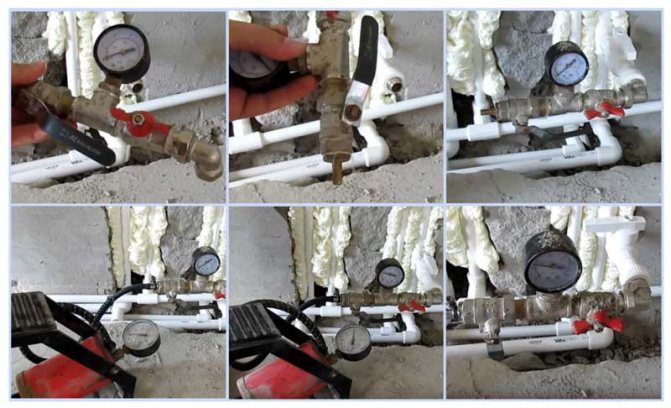

To check the system, 2 times the test pressure of 2 atmospheres is sufficient, such a parameter is quite simple to obtain using pneumatic methods of pressure testing with a compressor or a hand-held car pump. The air pressure test consists of the following operations:

- They completely close all the automatic air vents on the manifolds, hydraulic switches and heated towel rails, tighten Mayevsky's hand taps on the radiators more tightly.

- The coolant is drained from the heating system, after which it is rinsed as described above, then the water is poured out.

- The inlet pipe of the expansion tank in the attic is hermetically closed, a herringbone-shaped pipe is connected through a special adapter to the drain pipe of the lower part of the system, a hose is put on it, to which the compressor or pump is connected, and it is secured with a clamp or wire.

- Air is pumped into the system, monitoring the readings on the pressure gauge, when the pressure of 2 bar is reached, the inlet valve is closed.

- The manometer readings are monitored for 30 minutes, if they do not change, the pressure test is considered complete. When the pressure gauge readings decrease, they try to detect the leak with a soap solution; if the result is positive, the air is released under pressure.

- After repairing the problem unit, the pressure test procedure is repeated, again pumping water with a compressor or a hand pump to the desired pressure.

In a private house, an overpressure check of the heating system is usually carried out after the heating is put into operation and repairs are carried out; it is advisable to carry out this procedure at least once every 5 years to prevent and detect possible leaks.

The process of carrying out the work does not present any particular difficulties for an unprepared homeowner; special expensive equipment can be rented from one of the companies and tested independently within a few hours in accordance with the technical regulations.

Features of the hand crimper

Models of this type are advantageous in that they have practically no restrictions in application when it comes to operating parameters corresponding to technical capabilities. That is, a compact hydraulic device will be convenient for checking a home system, and will allow you to assess the quality of the networks in the communal infrastructure of an apartment building.

An important feature that a manual crimper has is a low level of error. Since injection is done manually, the operator can vary the applied force without affecting the circuit. By the way, manufacturers themselves take care of reducing unwanted risks to the network and hoses. They cover the hose with a special sheath to prevent accidental expansion.

Electrical devices also have protective covers on the hoses, but in some cases of peak loads, automatic injection will not stop, unlike manual crimping.