Although devices for metering heat energy perform one function, they differ greatly in several aspects. For example, according to the purpose (actually at the place of use) and the principle of calculating the consumed heat.

By design, heat meters are of three categories:

- individual (used in apartments and private houses of all types, where there is centralized heating);

- common buildings (in demand when equipping large buildings - residential high-rise buildings in a complex or separate entrances, blocks);

- industrial (designed for installation at industrial facilities and in apartment buildings).

Their main difference is in the calculated volume, size and range of measurements of the coolant. The smallest are individual or, as they are also called, apartment. The diameter of these devices reaches from 25 to 300 mm, and the throughput is approximately 0.6-2.5 cubic meters per hour.

According to the principle of heat metering, heating meters are divided into four groups:

- mechanical;

- ultrasonic;

- electromagnetic;

- vortex.

Mechanical (tachometric) heat meter

It has a rotor impeller and a recording mechanism that detects the number of rotations performed to calculate the volume of water passing through the pipes. The coolant temperature is recorded by an electronic module built into the device body. Data on the state of water is supplied to it through two probes located at the inlet and outlet of the stream. The device is powered from an internal source. That is, it is a simple heat meter that is in demand among private homeowners and apartment owners.

Pros: a profitable and inexpensive device, quickly pays for itself, compact, small, with proper operation and regular maintenance, it has a high resource of action.

Minuses: requires replaceable filters and constant monitoring, is sensitive to water quality and often clogs in the presence of foreign impurities (scale, scale, rust).

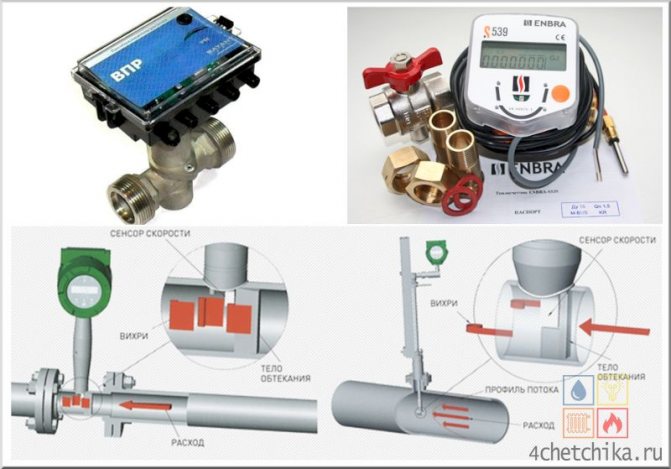

Ultrasonic Thermal Energy Meter

This option does not contain moving mechanisms, therefore, it is more durable and reliable. To obtain information, he uses the principle of propagation of ultrasonic vibrations - along and against the flow. Because of this, its design includes two component parts placed opposite each other (receiver and emitter). The interval between signal waves depends on the speed of fluid movement through the pipeline. The heating medium flow is calculated based on the time obtained.

Pros: allows you to customize the individual supply of thermal energy, is reliable, highly accurate, durable, pays off due to increased stability.

Minuses: extremely sensitive to contamination of the working fluid (even with relative purity of water, it can give erroneous readings), in most cases it operates from a battery, which must be changed / recharged in a timely manner.

Thermal flow meter

Previous6Next

Thermal flow meter - a flow meter, in which the effect of heat transfer from a heated body by a moving medium is used to measure the flow rate of a liquid or gas.

Distinguish calorimetric

and

hot-wire

flow meters.

IN calorimetric

In flow meters, the flow is heated or cooled by an external heat source, which creates a temperature difference in the flow, according to which the flow rate is determined.

Fig. How a calorimetric flow meter works

If we neglect the heat losses from the flow through the walls of the pipeline into the environment, then the heat balance equation between the heat generated by the heater and the heat transferred to the flow takes the form:

Where k

- correction factor for the uneven distribution of temperatures over the cross-section of the pipeline;

QM

- mass flow rate;

CP

- specific heat capacity (for gas - at constant pressure);

Dt = T2-T1

- temperature difference between sensors (

T2

and

T1

- flow temperature before and after the heater).

Heat is usually supplied to the flow in calorimetric flow meters by electric heaters, for which

Where I

- current through the heating element;

R

- electrical resistance of the heater.

Based on these equations, the static conversion characteristic, which links the temperature difference across the sensors with the mass flow, takes the form:

Principle of operation thermometric

anemometer is associated with the use of convection heat transfer by a moving medium from a heated surface. The sensing element of such an anemometer is a heated wire or surface, usually of platinum or tungsten. Heating of the element is usually carried out from a constant voltage source through a regulator that keeps the temperature of the heating element constant. To determine the flow rate in the device, the convection heat transfer from the wire is measured, which is a function of the speed of movement of the medium surrounding the element.

Fig Principle of operation of hot-wire flowmeter

1 - flow temperature sensor, 2 - heater, 3 - heater temperature sensor.

Typically, the wire of industrial hot-wire anemometers for measurements in gas flows has a diameter of 4-10 microns and a length of 1 mm. Another design is a surface sensing element lined with heat-resistant glass with a sprayed coating or platinum foil.

The heat balance equation on the heater can be written as:

Where

I

- the strength of the electric current passing through the heating element;

RW

- electrical resistance of the heating element;

h

- coefficient of heat transfer of the heating element;

AW

- the surface area of the heater washed by the moving medium;

Dt

- temperature difference between heater and medium.

Since the resistance RW

the heater depends on the temperature

Where

a - Temperature coefficient of electrical resistance;

RC is the electrical resistance value at the calibration temperature;

- temperature maintained by the regulator;

- calibration temperature.

Heat transfer coefficient h

is a function of the flow rate

V

and can be described by empirical dependence:

Where: a, b, c

- constants determined during sensor calibration (

c = 0.5

). Based on the written equations, it is possible to determine the flow rate, and hence the flow rate:

The advantages of the hot-wire method of measurement include high sensitivity, high speed, and simplicity of design. Disadvantages: reliable operation is possible only in clean streams with constant thermophysical characteristics and the need to clean the element from contamination.

The measurement error of thermal flow meters usually does not exceed 1 - 3% The considered set of thermal flow meters, type RTN-21, is designed to measure toxic and corrosive liquids and gases in the flow range 0 02 - 10 -3 - 0 06 kg / s with a scale range of 1: 10,

Previous6Next

Date Added: 2016-12-09; views: 2244; ORDER WRITING WORK

Similar articles:

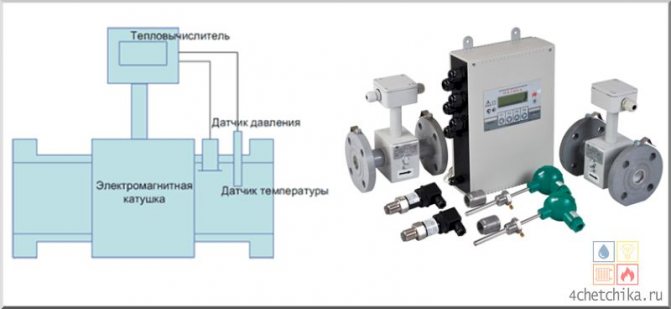

Electromagnetic heating meter

This device is designed for calculating heat in large volumes.It is able to control the circulation of heating energy in large residential, industrial, commercial, office and other facilities. Works on the principle of changing electromagnetic pulses passed through the water column. For this, the heat meter is equipped with an electromagnetic coil that generates the necessary fields: when water flows through the magnetic zone, it generates a current, the strength of which serves as the basis for the measurement.

Pros: reliable and accurate, compact, can track massive flows of coolant without compromising readings, mounts on large diameter pipes.

Minuses: depends on the electrical network (most often), needs regular maintenance, is sensitive to electromagnetic surges from nearby equipment, it acts worse in the presence of iron inclusions in the water.

Vortex heat meter

The operation of this device is based on a natural mechanism - a natural phenomenon, the so-called water funnel. By design, the device consists of a triangular prism (it is installed vertically), a magnet (in the outer part) and an electrode (for monitoring the flow pressure). At a high speed, the vortices form a constant path, and the stall flow of water in the pipeline creates pulsations, which determine the volume of the supplied coolant.

Pros: not subject to the influence of deposits and iron residues (rust, scale), is placed both on vertical and horizontal sections, not picky about the length of straight sections and fine dirt.

Minuses: sensitive to fluctuations in the working fluid, not suitable for use in steam heating systems, malfunctioning with large impurities in the water, dependent on a constantly stable pressure.

Frequently Asked Questions

What kind of flow meters are on sale?

The following products are constantly on sale: Industrial ultrasonic flow meters and heat meters, heat calculators, apartment heat meters, ultrasonic stationary in-line flow meters for liquids, ultrasonic stationary overhead and portable overhead flow meters.

Where can I see the characteristics of the flow meters?

The main and most complete technical characteristics are indicated in the operation manual. See pages 24-27 for the installation conditions and requirements, in particular the lengths of the straight runs. You can find the wiring diagram on page 56.

What liquid does the US 800 ultrasonic flowmeter measure?

Ultrasonic flowmeters US 800 can measure the following liquids:

- cold and hot water, network water, hard water, drinking water, service water,

- sea, salt, river water, silted water

- clarified, demineralized, distilled, condensate

- waste water, polluted water

- stratal, artesian and Cenomanian waters

- water pressure for high pressure, 60 atm (6 MPa), 100 atm (10 MPa), 160 atm (16 MPa), 250 atm (25 MPa)

- pulp, suspensions and emulsions,

- fuel oil, heating oil, diesel fuel, diesel fuel,

- alcohol, acetic acid, electrolytes, solvent

- acids, sulfuric and hydrochloric acid, nitric acid, alkali

- ethylene glycols, propylene glycols and polypropylene glycols

- surfactants surfactants

- oil, industrial oil, transformer oil, hydraulic oil

- motor, synthetic, semi-synthetic and mineral oils

- vegetable, rapeseed and palm oil

- oil

- liquid fertilizers UAN

How many pipelines can be connected to the US 800 ultrasonic flowmeter?

Ultrasonic flowmeter US-800 can serve, depending on the version: Execution 1X, 3X - 1 pipeline; Execution 2X - up to 2 pipelines at the same time; Execution 4X - up to 4 pipelines simultaneously.

Multiple beams are made to order. US 800 flowmeters have two versions of ultrasonic flow transducers: single-beam, double-beam, and multi-beam. Multi-beam designs require fewer straight sections during installation.

Multichannel systems are convenient in metering systems where several pipelines are located in one place and it would be more convenient to collect information from them into one device.

The single-channel version is cheaper and serves one pipeline. The two-channel version is suitable for two pipelines. Two-channel has two channels for flow measurement in one electronic unit.

What is the content of gaseous and solid substances in% by volume?

A prerequisite for the content of gas inclusions in the measured liquid is up to 1%. If this condition is not observed, stable operation of the device is not guaranteed.

The ultrasonic signal is blocked by air and does not pass through it; the device is in a "failure", inoperative state.

The solids content in the standard version is not desirable more than 1-3%, there may be some disturbance in the stable operation of the device.

There are special versions of the US 800 flow meter that can measure even heavily contaminated liquids: river water, silted water, waste water, sewage, slurry, sludge water, water containing sand, mud, solid particles, etc.

The possibility of using the flow meter for measuring non-standard liquids requires mandatory approval.

What is the production time of devices? Whether there are available?

Depending on the type of product required, the season, the average shipment time is from 2 to 15 working days. The production of flow meters goes on without interruption. The production of flow meters is located in Cheboksary at its own production base. Components are usually in stock. Each device comes with an instruction manual and a passport for the device. The manufacturer cares about his customers, and therefore all the detailed necessary information on the installation and installation of the flow meter can be found in the instructions (operation manual) on our website. The flow meter must be connected by a qualified technician or other certified organization.

What types of ultrasonic flow meters is the US 800?

There are several types of ultrasonic flow meters according to the principle of operation: time-pulse, Doppler, correlation, etc.

US 800 relates to time-pulsed ultrasonic flow meters and measures flow by measuring pulses of ultrasonic vibration through a moving fluid.

The difference between the propagation times of ultrasonic pulses in the forward and reverse directions relative to the movement of the liquid is proportional to the speed of its flow.

What are the differences between ultrasonic and electromagnetic devices?

The difference is in the principle of work and some functionality.

Electromagnetic is measured based on the electromagnetic induction that occurs when a fluid moves. Of the main disadvantages - not all liquids are measured, exactingness to the quality of the liquid, high cost for large diameters, inconvenience of repair and verification. The disadvantages of electromagnetic and cheaper (tachometric, vortex, etc.) flow meters are very noticeable. The ultrasonic flowmeter has more advantages than disadvantages.

Ultrasonic is measured by measuring the propagation time of ultrasound in a stream.

Undemanding to liquid quality, measurement of non-standard liquids, oil products, etc., fast response time.

Wide range of applications, any diameters, maintainability, any pipes.

Installation of such flow meters will not be difficult.

Look for ultrasonic flowmeters in the range we offer.

You can see the photos of the devices on our website. Look for detailed and complete photos of flow meters on the corresponding pages of our website.

What is the depth of the archive in US 800?

The US800 ultrasonic flowmeter has a built-in archive. The depth of the archive is 2880 hourly / 120 daily / 190 monthly records.It should be noted that not in all versions the archive is displayed on the indicator: if EB US800-1X, 2X, 3X - the archive is formed in the nonvolatile memory of the device and is displayed via communication lines, it is not displayed on the indicator. if EB US800-4X - the archive can be displayed on the indicator.

The archive is displayed via communication lines via the digital RS485 interface to external devices, for example, a PC, laptop, via a GSM modem to the dispatcher's computer, etc.

What is ModBus?

ModBus is an open communication industrial protocol for data transmission via the digital RS485 interface. The description of the variables can be found under the heading documentation.

What do the letters and numbers mean in the flow meter configuration record: 1. "A" 2. "F" 3. "BF" 4. "42" 5. "without COF" 6. "IP65" 7. "IP68" 8. "P" "- verification

A - archive, it is not present in all executions and not in all executions is displayed on the indicator. Ф - flanged version of the flow transducer. BF is a wafer-type flow transducer. 42 - in some versions, designation of the presence of a 4-20 mA current output. KOF - a set of counter flanges, fasteners, gaskets (for flange versions) Without KOF - accordingly, the set does not include counter flanges, fasteners, gaskets. IP65 - dust and moisture protection IP65 (protection against dust and splashes) IP68 - dust and moisture protection IP68 (protection against dust and water, sealed) P - method of verification by imitation method

Calibration of flow meters is organized on the basis of appropriately accredited enterprises. In addition to the imitation method of verification, some diameters of flow meters, on request, are verified by the pouring method on a pouring installation.

All offered products comply with GOST, TU, OST and other regulatory documents.