The need for sealing

Sealing sewer pipes, like sealing all water pipes, is a very essential step in the pipeline installation process. It is especially important to properly seal the joints.

To prevent the pipeline from leaking, since the appearance of unpleasant odors in an apartment or a private house depends on this, it is necessary to choose the right seal for the sewer pipes.

This means knowing which sealant is best for sealing plastic, polypropylene, cast iron, steel, and other products. And you also need to have information on how to seal the threaded connections of the water supply, coupling, flange.

You need to familiarize yourself with other materials necessary for the repair or installation of heating systems, gas supply, repair of sewerage systems intended for draining acids and alkalis, other systems, so that, if necessary, do such work with your own hands.

How to seal any pipe - now in order and in more detail.

Slicing

If the pipes were purchased without a thread, then it must be created. This will require certain tools:

Instruments

Klupp with a set of dies

So how to thread a water pipe? Let's see:

| Tool | Appointment |

| Klupp with a set of cutters of various diameters | External threading |

| Gas wrench | Fixation of pipes during the cutting process |

| Machine oil | Smoothing cutter passage on metal |

| "Bulgarian" | Trimming of tubular products |

Advice: when working with a "grinder", be sure to wear safety glasses, as the accidental hit of scale in the eye can lead to tragic consequences.

Work progress

- We measure the required pipe section and cut it off with a grinder.

Advice: it is advisable to pre-fix the metal product in a vice, this will greatly facilitate the work with it.

Pipe cutting with a grinder

- We cut off the chamfer from the edge of the pipe to facilitate its entry into the die.

- Lubricate the prepared edge with oil.

- We bring the die with a suitable cutter strictly perpendicular and start cutting, holding the cut with a gas wrench.

Threading a threaded connection

- After a few turns, we bring the tool back to free the processed area from sawdust, after which we return to the task.

- Having reached one centimeter, we remove the klupp and wipe the resulting thread from the oil.

Next, we will analyze how to seal the threaded connections of the water supply system during installation directly of the water supply system itself.

Role of sealing

If external defects of the pipes can be easily corrected, then in order to seal the pipe connection during operation, it will be necessary to completely suspend the functioning of the sewer system.

That is, re-sealing cast-iron sewer pipes, or risers with hot water, is the same as starting to re-install the pipeline system. Therefore, the appearance of leaks inside the water supply system should be avoided (for example, so that ground water does not get into the pipeline).

It is equally important that there are no slightest leaks from the inside of the sewer system, since this is fraught with the appearance of not only unpleasant odors, but a possible destructive effect on the walls of wet secretions from the pipe.

Materials. What is the name of the thread for sealing pipes?

3.1.List of materials used

Sealing of pipe joints or sockets is carried out using:

- self-adhesive tape (regular and foil type);

- silicone sealants;

- anaerobic sealants;

- gels, pastes;

- epoxy resin;

- sulfur for technical purposes;

- bituminous mastic;

- winding record;

- fluoroplastic sealing material, etc.

Effective means are rubber seal (especially for standard sewer pipes) and pipe seal with linen (tow with solutions made on the basis of red lead and drying oil or Portland cement). The latter is used to seal large sockets.

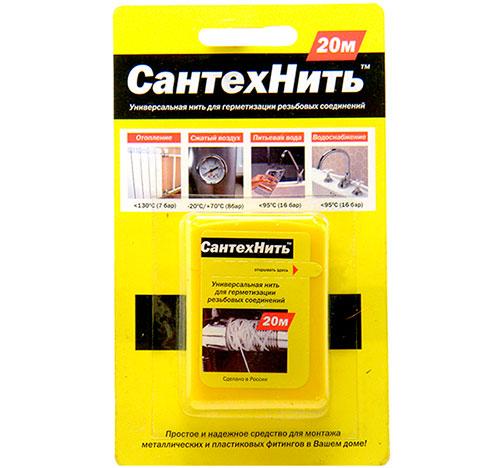

Another very important tool often used by plumbers is plumbing thread (or, as it is also called, thread for sealing pipes).

3.2. Self-adhesive tapes

The agent is one of the newest in the field of use for sealing pipe joints.

It differs:

- good anti-corrosion properties;

- high quality sealing;

- efficiency in use;

- ease of use;

- long service life, since they are made on a high-strength polyethylene base;

- breadth of application.

With the help of self-adhesive tape, you can qualitatively carry out not only the sealing of the sewer pipe, but also apply it when installing plugs, turning corners, bends, couplings, valves, and other elements of pipe fittings.

When carrying out sealing, you should adhere to the following algorithm:

- prepare the surface. To do this, it is necessary to clean it of dirt, wipe it dry well;

- when winding the film on the joint, it is necessary to maintain it in a constant tension, in order to avoid possible folds, irregularities;

- it is necessary to wind the material in a spiral manner with an overlap, approximately half its width in order to ensure that the entire surface necessary for insulation is under two layers of material.

Important! Self-adhesive tape is UV-resistant. In order to ensure a long service life, it is recommended to wind 1-2 more protective layers of another material over the tape.

A primer is used to treat certain types of films. It will exclude the minimum impact on the tape of air, moisture, including precipitation. Such measures contribute to a significant extension of the life of the sealing material.

3.3. Silicone based sealants

Any rubber-based silicone sealant is available. Due to the presence of various substances, a reliable, long-term sealing, good adhesion to the surface is ensured.

It is best if the places of future sealing will be pre-treated with a primer. The hardener determines the type of sealant, cure time.

According to this classification, sealants are:

- neutral;

- acidic, characterized by chemical resistance and a relatively low price.

Silicone sealants can be used to seal both cast iron pipes and plastic risers.

After polymerization, the paste becomes rubbery.

Important! It is best to use a special assembly gun when working with sealants. Thanks to him, the paste is squeezed out smoothly, easily, in the required amount.

3.4. Tow

This material, together with red lead on drying oil, for decades has been and will remain one of the most reliable among many other analog-seals.

Thread with wound tow

With the use of linen strands, in the overwhelming majority of apartments and private houses, gas, heating, and plumbing structures were installed.

Important! The use of red lead makes it possible to prevent the occurrence of corrosive processes, which cannot be said about the iron analogue.

The main advantages of sealing with tow:

- reliability;

- ease of installation. In order to make a high-quality seal, it is necessary to wind tow on the external thread, generously coat the material with red lead and tighten the fitting well. After that, you need to tighten the lock nut. Simple, reliable;

- availability, minimal financial costs;

- ensuring a high level of adhesion;

- the presence of strong fixation of the connections after tightening with a gas (pipe) wrench.

Disadvantages:

- in order to correctly install the connection and the pipe as a whole, you must have a sufficient level of professional knowledge;

- applying too much force when tightening, can cause damage to threads, fittings;

- the complexity of dismantling work, which can lead to heating of individual units, in order to replace them with others, of higher quality;

- the need to monitor the state of the system, since over time, the strands lose their original properties, which can lead to gas leakage.

Pros and cons of materials

Flax and pasta... The advantages of these materials include the durability and tightness of the connection, if done correctly. Flax thread sealing is used when installing plumbing and heating systems, while the maximum allowable temperature of the working environment should not exceed 90 °, otherwise the seal will begin to collapse.

Among the disadvantages is the complexity of the installation work - it takes skill to properly seal the joints with flax fiber. It should also be noted that when tightening and dismantling such a connection, serious physical efforts are required, which can damage the connecting elements.

Flax fiber is not suitable for sealing threaded fittings made of polymer materials - when wet, the natural material expands, as a result of which the plastic element can burst. It is not recommended to use flax seal during the installation of the heating system, if it is planned to use antifreeze liquid as a heat carrier.

FUM tape... Fluoroplastic sealing material (FUM), which is produced in the form of a tape, retains its operational properties at temperatures from -200 ° C to + 240 ° C and pressure up to 30 atm, which allows the material to be used for the installation of plumbing and heating systems without restrictions. The tape seal is suitable for heating systems with antifreeze. The material protects the metal of the thread from corrosion, due to the smoothness of the tape, the connection can be easily mounted and dismantled.

The disadvantage of the material is the same smoothness of the tape - under the influence of vibration and mechanical loads, the joints weaken and may begin to leak. FUM tape is not suitable for positioning mounting, especially when it comes to valves and taps.

Sealing threads... Also, for sealing threaded joints, polyamide and fluoroplastic threads are used, provided with a special lubricant, which simplifies installation and dismantling, and also prevents joints from leaking. The fluoroplastic thread in terms of characteristics and scope coincides with the FUM tape. Thread sealing with polyamide thread is used in pipelines with medium temperatures up to 130 ° C and pressures up to 16 atm.

Plumbing threads have all the advantages of a linen seal, but at the same time they are much easier to install, do not rot, do not collapse from temperature effects, and protect the metal from corrosion. The only drawback of the material is its high cost.

Non-drying pastes - are made on the basis of synthetic resins with oils and fillers. The advantage is ease of use - to seal the joint, it is enough to lubricate the threads of both elements to be connected. Non-drying paste seals the joint and protects the threaded joint from corrosion, makes it easy to dismantle the assembly.

The disadvantages include a narrow scope of application - a non-drying composition is suitable only for non-pressure or low-pressure systems, since it will be squeezed out under pressure. The seal is destroyed by aggressive media, therefore it cannot be used for heating systems with antifreeze.

Drying pastes... Solvent sealants are suitable for use in pressure systems. To seal the threads, the compound is applied to both parts to be connected, and the parts should be connected immediately so that the sealant does not have time to seize. The drying paste effectively seals the threads.

Sealing with this type of paste is only suitable for mounting joints with a small gap, otherwise, when dry, the material will shrink strongly and the threaded joint will leak.

Anaerobic sealant... Practically, the liquid composition is as simple as possible to use - it is applied to the thread and the elements are twisted.

Anaerobic sealants are divided into several types depending on the conditions of use, therefore, when choosing, you should pay attention to the following parameters:

- Operating temperature range;

- thread diameter for which this type of seal is designed;

- the effort required for disassembly;

- polymerization time.

It is important to know that before sealing with an anaerobic sealant, the threaded joint must be degreased and dried. The seal is suitable for plumbing and heating systems, including those with antifreeze liquid.

Anaerobic sealants

Anaerobic sealants play a special role in the installation or repair of piping systems.

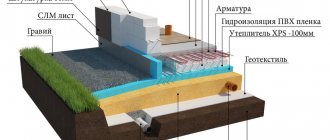

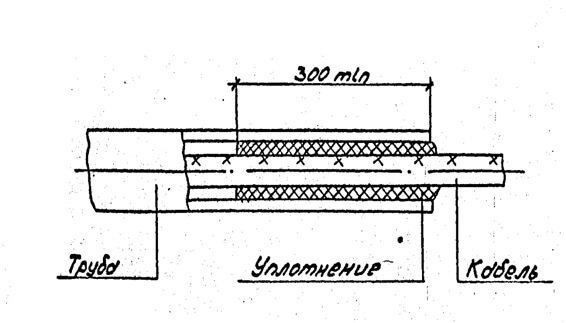

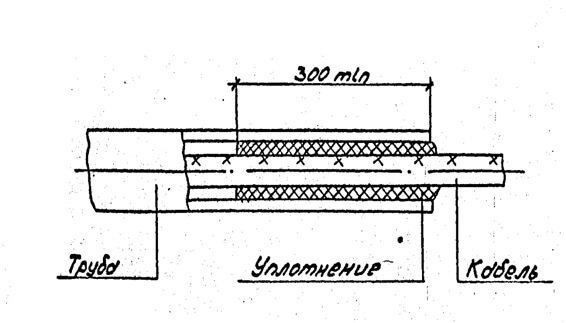

This silicone sealant is used when laying cables in the ground. Namely, if the cable line must pass through aggressive soil, then it is allowed to place the cable in an asbestos-cement pipe.

The end, at the point of exit from the pipe, must be reliably sealed to prevent moisture and soil from entering the structure.

An anaerobic sealant is used as such a sealant. An example of such a cable seal in a pipe can be seen in Fig. 1, which corresponds to sheet a5-92-45 of the Standard Project for laying cables with a voltage of 35 kV in soil.

The price for such work depends on the length and diameter of the pipe part where the sealing process needs to be carried out.

Picture 1

Each type of system is determined by specific regulatory documents, in which the permissible load on the pipeline is strictly regulated. Although the standards are different for different pipe connections, each regulation specifies that threaded and flanged connections must be subject to special tightness.

In this regard, it is necessary to use modern and reliable materials for sealing, which is an anaerobic sealant. It is used for sealing high pressure threaded connections where minimal leakage of the working medium is not allowed.

4.1. Application

Until recently, these pastes were used only in the military industry, aerospace, and the engineering industry. That is, the fact that they found their application where strong, reliable, durable connections were needed.

Today, such material is used in the repair or installation of threaded connections for water supply systems, gas and heat supply systems. They are also called thread clamps.

Anaerobic sealants are successfully used when a conventional gel pad is required. One cannot do without them, both in mass housing construction and in private households.

It can be noted that, due to its significant advantages, anaerobic sealants are becoming more and more popular when working with threaded connections.

Important! Anaerobic pastes are used in extreme pipeline operating conditions.The sealant is ideal for sealing threads with a sealant in an aggressive environment with high temperatures or pressures up to 50 atm.

4.2. Advantages and disadvantages

As with any sealant, anaerobic sealant has its positive and negative sides.

The "pluses" include:

- ease of use. You do not need to have a lot of work experience, serious skills of a plumber to learn how to use the material correctly;

- quick application and twisting, which allows you to complete the work within 20-25 seconds;

- economical consumption of substances. This means that if there is an excess of paste on one threaded connection, they are transferred to another;

- ensuring complete sealing, which allows the joints to be successfully operated in extreme temperature conditions at high pressures;

- the possibility of anti-corrosion effects on a metal surface;

- affordable price, given the incredible properties of the substance.

A negative point can be considered the fact that during repair or installation at low temperatures, the agent must be warmed up.

How to use anaerobic adhesive sealant - instructions for use

The adhesives are sold in flat-necked packages. Additionally, a brush may be included. The glue is squeezed out of the tube and distributed over the surface with it without the use of additional tools.

The procedure for using the tool:

- shake the packaging,

- open the package and apply a dense layer of glue to the thread,

- connect parts,

- Remove any excess glue with a cloth or transfer to another area with a brush.

To obtain a quality result, it is important to apply anaerobic thread sealant

over the entire surface, both inside and outside, and also ensure the distribution of the sealant over the entire area of the joint.

To dry the product, a temperature of about + 15C is required. Under these conditions, the glue will dry in about 15 minutes.

Operating procedure:

- shake the package to mix the contents,

- open the tube and apply the product with the neck (the dense consistency of the glue will not let it spread, the product does not drip by),

- leave to dry for 15-20 minutes (it is not necessary to use a tightening wrench, the glue will polymerize even when wrapped in just a few turns),

- check the connection under a pressure of 10 atmospheres.

If no leaks are found, a second check can be carried out within a day under a working pressure of up to 40 atmospheres. If the room temperature is below + 15C, heating of the joint will be required to speed up the drying process of the glue.

The total curing time depends on the diameter of the joint, as well as the characteristics of the material and the ambient temperature.

In addition, nothing is required to add to the sealant, since anaerobic adhesives are already completely ready for use. The only recommendation is to pre-clean the surface, degrease it, and then apply glue.

If it becomes necessary to disassemble the glued joints, this can be done both immediately after the connection and after it has hardened. This will require a key and a hair dryer (if the gel is very durable).

The procedure for removing glue:

- turn on the construction hairdryer and direct it to the connection,

- wait until the glue begins to crumble, remove it with a regular cloth,

- use the key to disassemble the connection.

It is not necessary to completely remove the remnants of the old adhesive-sealant, a new layer of the product can be applied directly on top of it.

Rating review of anaerobic sealants

Many companies are involved in the production of anaerobic sealants. When choosing an adhesive, it is important to rely on the operating conditions of the future connection, as well as on the following factors:

- thread feature,

- temperature conditions in which the sealant will be used,

- requirements for the level of bond strength,

- the need to disassemble joints,

- materials from which the thread is made.

Consider the popular options for anaerobic sealants on the Russian market

VIDEO ON TOPIC 1.Loctite Anaerobic Sealant

is presented in different model options - in the form of sealing threads, liquid compositions that prevent liquid and gas leaks. The use of adhesives of this brand can significantly increase the strength of pipelines.

In addition to anaerobic adhesives, other materials for sealing joints are also produced under this brand. All products are characterized by durability and reliability. The cost of funds is a difference and depends on the characteristics of the composition and scope. So, the universal glue Loktite 577 with fast polymerization costs about 1,750 rubles per 50 ml package. Loctite 542 with low viscosity, designed for fine threads, is sold at a price of 1,784 rubles per 50 ml.

2. Anaterm sealants have similar properties. They are used for fixing threads during assembly, eliminating small cracks and pores, fixing welded seams, porous casting, instant and durable gluing of parts, repairing steam lines, restoring and repairing mechanisms and assemblies. Prices for Anaterm products start at 2400 rubles per 200 g package.

3. Anaerobic sealant Santekhmaster is another popular domestic product. Releases it. It is an innovative adhesive for sealing flanged and threaded metal connections. Adhesives are resistant to gasoline, alcohol, antifreeze, retain their properties under extreme conditions, at high temperatures and pressures.

Prevents corrosion. The composition is non-toxic, does not have an unpleasant odor, can be applied by hand, but prolonged contact with the skin is still not recommended. The economical consumption of the product makes it profitable for purchase and use. So, a 15 gram package should be enough to process 30 ½ ”fittings. The cost of a 15 gram tube starts at 145 rubles.

The plumbing thread is imperfect. Without a sealant - nothing. But what to choose from the many offers on the market: linen, fum tape, sealing thread or anaerobic sealants? In this article I will tell you what and under what circumstances to use when sealing threads. It so happened that I use 4 types of seals:

- Linen

- Fum tape

- Sealing thread

- Anaerobic sealants

As a professional plumber, I carry all 4 types in my suitcase - it's hard to say what I will have to face in real installation. Any of these seals, when properly installed, are 100% functional. But which of them to apply and in what conditions depends on the circumstances. Let's analyze the circumstances.

In terms of cost, flax and pasta are in the first place. Many believe that this is the last century. Sometimes they even get surprised and poke their eyes on me:

“Are you going to wind my tow on the thread? - they ask. - I have fum and thread, let me teach you how it should be ... "

I have to interrupt the agitated homeowner and tell in what cases, which seal works best. So flax. Previously, it was used with a special lubricant - red lead or oil paint. Now, instead of them, gray-colored sealing pastes are used.

There are water-soluble and insoluble. But this will be discussed in another publication. These are not sealants. These pastes prevent flax from drying out and rotting. Without them, on hot water and heating, the flax will dry out over time, turn into dust and - the connection will flow.

In cold water, the flax will turn into black slush and the compound will also flow.

The sealing paste will prevent these processes. Linen joint together with the paste is absolutely reliable and durable. Moreover, the paste allows you to adjust the connection - adjust for loosening up to 45 °.

And there would be no drawbacks in flax, if not for other seals that pressed the flax connection.

Flax benefits

- Linen is wound to any diameter

- On dirty and wet surfaces

- There is no doubt about the reliability of the connection

Cons of flax

- You still have to hold out the connections with the key.

- When working with flax and pasta, your hands are always dirty. Very dirty. Because of this, during work, for example, white polypropylene pipes get dirty easily.

- With flax, you need to be careful on plastic threads, on fine or tight threads, on thin-walled fittings and during other "jewelry" work.

And, for me personally, flax also does not like the fact that, with constant use, its threads will be everywhere: on the locks of bags and clothes, it will stick to the keys, become magnetically attached to clothes. Linen requires a professional attitude, including when applied - you need to be able to wind it. He also needs supervision and regular revision. Total. Linen is a reliable seal that, if properly installed, will last for many years. But if in doubt, you don't want to bother with the winding, get your hands dirty in the paste, or just this method seems morally obsolete to you - pay attention to other sealing options.

Fum tape

Fum tape could be wound anytime, anywhere:

- hands are always clean

- it is safe to wind on thin-walled fittings,

- on dirty threads, on wet threads,

- on plastic and very small.

Conveniently. But much more expensive than flax and pasta. The price also creates restrictions on the use of the fumlent. I never spend more than an inch of fum tape on threads. I think this is economically unjustified.

Another drawback is that the fum tape does not allow you to adjust the connection. That is, you cannot unscrew it back in order to put a tap or a pressure gauge in the desired position: tightness is lost. Higher labor costs and consumption when sealing with fum tape lead to the fact that I use it little and do not use it with large thread diameters.

Sealing thread

For example, Tangit Unilok widely represented in our market:

professional Loctite:

- Hands are always clean

- It is possible to adjust the connection for loosening up to 180 ° without loss of tightness. Really - I have not tried more than 90 °. It seems dangerous to me.

- You can wind on dirty threads, you can wind in heat and cold, but just like flax and fum, you must always hold out the connection with a key. Significantly more expensive than linen joints and comparable to the cost of fum tape.

Manufacturers claim superior properties of their filaments due to the ability of microfibers to maintain tightness in the face of vibration, temperature extremes and related displacements in the threads.

I myself prefer to use a thread when I need to replace something quickly and reliably, for example, send a dozen pressure gauges for verification:

Pros in working with thread:

versatility of the material, speed of work with it, good quality of the obtained seal.

All of the above three threads served me equally reliably. I did not notice any differences. However, the Record is distinguished by an abundance of impregnation and a price, therefore, it is she who has recently been living in her little case.

Anaerobic sealants

The supply of anaerobic sealants on the market is increasing every day. For today, I would point out the following: Loxeal (Lokseal)

Unitec

and the domestic sealant SantechMasterGel

If a few years ago it was not at all clear what kind of tubes were on the showcase, today a rare master does not know what it is. The professional audience spends many hours debating whether to use anaerobes or not. My practice of working with anaerobic sealants suggests that with proper application (complete filling of the thread gap), there are no leaks. Before applying, I thoroughly prepare the thread, sometimes even degreasing it. Then I estimate the likelihood of dismantling the connection in the future and the ability to crawl with the key. Based on this, I choose the desired composition of the anaerobic.Each manufacturer has a dismantled and difficult to dismantle composition, so I work with one or the other. According to circumstances.

I have been using the anaerobic sealant SantechMasterGel for several years. The advantage of anaerobes is the speed of work. I would attribute to the disadvantages:

- Relatively high price This is the most expensive seal on my list. Although the price here is a relative disadvantage and you will soon see why.

- Applicability only to clean new threads The sealant adhesive may only be applied to clean new threads. Foreign objects and impurities are not allowed.

Can be collected without keys. This is convenient when adjustment is needed and the position of the required element (tap or pressure gauge) is known in advance.

Real life examples

The choice of the seal when installing the collector

Let's look at an example. Suppose we have a cold water collector with 9 outlets:

- washing

- drinking filter

- bath

- sink

- dishwasher

- toilet

- boiler (water heater)

- washer

In front of the collector there is a coarse filter, meter, check valve, pressure reducer, main filter. On hot water the same, but the collector outlets are smaller. For each collector outlet, an American must be screwed, because there is no other material. (A common situation far from megacities).

So for this whole group with a wall hanging and cleaning the thread with flax, I spend almost the whole day, with fumlent or thread, a little less. With an anaerobic sealant, it takes me 2 hours to complete everything.

Linen: All day

Fum or thread: Less

Anaerobe: Two hours

And it turns out that although a tube of sealant initially costs more, it pays off four to five times due to the time gained.

What is the cost of such savings?

It's simple. Flax, tape and thread after winding on the thread must be twisted with keys. It takes time. An anaerobic sealant: smeared it, twisted it with my hands until it stopped or to the desired angle, and that's it - put it to dry. You don't waste time tightening the keys. Wipe off the remnants of the glue with a cloth. But the extra linen or thread must be cut, which also takes time. (Fum tape is easier to remove than linen or thread).

As you can see, the cost of anaerobic sealant is offset by significant time savings. There are two disadvantages of this seal:

- It is not possible to seal old, untreated, non-greased threads. Generally speaking, in fact, anaerobic is intended for new systems and is not suitable for repairing old ones.

- It is difficult, and sometimes impossible, to disassemble the connection without heating. Depends on the type of adhesive sealant.

Otherwise, it is an ideal seal for new systems. Why do I always have all the seals in my tool bag? The fact is that it is impossible to say for sure what exactly will have to be compacted and in what volume at the facility.

Threaded connections used in heating and gas supply must be completely sealed. It is practically impossible to achieve this only due to the quality of the thread itself, without the use of additional materials. There are several methods of sealing, but recently anaerobic thread sealant has gained immense popularity among craftsmen. Why?

Naturally, the main task of such seals is to completely seal the joints. The material used must completely eliminate the leakage of water or gas through the threaded gap. But a high-quality sealant should have other important properties:

- It should not contribute to corrosion of the connected elements. On the contrary, the material applied to seal threaded connections is intended to protect these vulnerabilities from destruction caused by exposure to water or corrosive substances.

- All sealing materials, including sealants, must have good adhesion properties in order to prevent them from being squeezed out of the joints under the pressure of water or gas.

- It must be resistant to temperature changes, withstand vibrational vibrations.

- The materials used to seal the pipes should not significantly hinder assembly or disassembly of the joint. It is very convenient if, after dismantling, the seal can be easily removed and reapplied.

Another important feature to look out for when choosing a sealant or thread sealant is ease of use. Very often, such connections are located in hard-to-reach places where any manipulations are difficult. In such cases, sealants have a distinct advantage, as they do not require such careful and thorough application as sealing strips or linen.

Sealing with other materials

In addition to the aforementioned seals, they are often used for sealing:

- epoxy resin. It is clear that the principle of its action is the same as that of the glue of the same name, produced on its basis. using this substance, they connect the risers of the sewer system;

- Portland cement. With its help, more than one sealing mixture is produced, which, in combination with an asbestos rope, is used to caulk the socket joints of the pipes of the cast-iron sewage system;

- petroleum bitumen or asphalt mastic. These substances are very effective in cases where ceramic or cast iron sockets need to be sealed;

- technical gray. When using this substance, the sealing of cast iron joints and similar sockets is almost ideal.

Important! Before use, the sulfur must be broken into small pieces, heated to a liquid state and filled with cracks. The uncured substance allows the compound to be adjusted.

Sealants are different in purpose, depending on the material of manufacture. Before installing the seal, you need to remember that they are trapezoidal, shaped (P-, H-, T-shaped) and other profiles.

They are installed on pipelines, car windows, house windows. Such products are excellent waterproofers, dock seals. They can also be used as cushioning materials.

For their manufacture, special rubber is used, which is highly resistant to oils, gasoline, water, and high temperatures.

On those pipelines where oil and gasoline products are transported, one can often find the NT 42-75 / 7 seal, which is distinguished by its hardness, high heat resistance, and reliability.

Non-hardening sealants

They are produced in the form of thick and viscous pastes, consisting of polymers and synthetic resins. This consistency allows them to provide high-quality sealing of joints, calmly transfer vibration loads. These sealants are often used in combination with other sealants.

Important! Non-hardening sealants cannot be used in high pressure systems - the compound will simply squeeze out of the threads. They are also poorly tolerated by aggressive materials.

The use of sealing materials in various fields

It often happens that it is necessary to securely fix the bearing surface of the pipe. To do this, use a steel pipe bracket with a rubber seal.

In the event that a leak appears in the riser not at the junction, but directly on the pipe, then rather quickly and, relatively, qualitatively, you can seal the pipe using a pipe clamp with a rubber seal.

Different seals are used in different areas of life. For example, when repairing the valve mechanism of a car, rubber gaskets are used as a seal for the tubes of the rods of the pushers.

Bracket with rubber seal

Car owners often carry out some repairs to their "iron horse" themselves.Replacing the extension arm ("crab"), laying the intake pipe, other relatively not too voluminous, but expensive work, you can do it yourself, which most amateur motorists do.

If, for example, the gasket of the "pants" is burnt out, then very quickly and reliably the assembly can be sealed with the help of high-temperature sealant, which must be applied to the gasket and securely tighten the nuts on the studs. Budget option - but reliable.

In complex technical structures, it is necessary for the seal to serve for a long time and reliably. These include powerful turbine generators, for which it is necessary to ensure a continuous oil supply to the end shaft seal.

The design of such a device, an important part of which is the anti-siphon tube of the hydrogen seal, is quite complex, like the very principle of its operation.

A special place in oil and gas equipment is occupied by a mud pipe with a mechanical seal. Among all device options, JJC products occupy a special place.

Mechanical seal

They differ:

- rational design;

- ease of installation and replacement of seals;

- long-term operation;

- reliability;

- high efficiency;

- safety while drilling oil and gas wells.

Seals are also used in the arms industry. Among fans of pneumatic weapons, air rifles of the Turkish company Hatsan are in special demand. For their successful operation, it is necessary to change the seal of the small Hatsan AT-44 air tube in time, the price of which is about $ 3. for 1 pc.

How to seal threaded connections for heating

7.1. Gaskets

Many people use end gaskets to seal heating pipes. This method is technologically the fastest, but the quality of sealing could be better.

The fact is that during the assembly of the structure, the gasket is strongly pressed by the thread and the joint density may suffer a little, since the part opposite to the external thread has a slight narrowing.

But in order for the joint to be tighter and more reliable, they use a paronite or fluoroplastic part, after the installation of which, it is necessary to securely screw the entire structure. Although it is not always possible to achieve transitions without narrowing with this method.

Considering this, the gasket is often installed when sealing sensors and instruments for measuring pressure or temperature, where the hydraulic resistance is not very high. True, experienced plumbers, for greater confidence and reliability, use an additional seal in the form of, for example, tow with red lead. They explain this by the fact that we are dealing with hot water, which is not always safe.

7.2. FUM tape

Since the coefficient of friction of the fluoroplastic tape is low, it can be used to assemble the whole threaded structure without much effort. The advantages of the material include high chemical resistance and long-term operation.

Like all materials, FUM-tape has some "disadvantages":

FUM tape winding

- during the assembly process, it can be torn into separate pieces, or twisted back;

- cannot be used in joints with possible thermal deformations. The fact is that the tape has poor adhesion to the metal, and if the joint is "playing" - possible squeezing out of the seal;

- can act as a reliable sealant for threaded connections only up to 25 mm in diameter. Therefore, using such a material, it is impossible to completely assemble the heating system.

7.3. Tow

This simple and cheap material has been a reliable sealant for decades. Lead red lead on drying oil or ordinary oil paint is most often used for impregnation.

Despite the emergence of good modern seals, flax strands have been and remain the leader among the most reliable sealants.Due to its positive qualities, the material is often used in the installation or repair of heating systems.

Oakum is different:

- reliability;

- the quality of the seal;

- cheapness;

- ease of use.

The disadvantages include:

- limited service life;

- tendency to dry out;

- the need to have certain skills in winding and wrapping.

Sealing with linen thread

This is the oldest method. This is how the pipe joints were sealed in Soviet apartments. If there are no other sealants in the store, then flax and plumbing paste will certainly be found. But this sealant has a number of significant disadvantages:

- According to the rules, flax is used in combination with drying oil and red lead. Lead prevents corrosion of the compound, while drying oil fills the pores of flax like a polymer. But finding quality ingredients is quite difficult, so red lead is often replaced with iron, which only accelerates the oxidation of metal components. Some craftsmen get out of the situation by using silicone-based car sealants.

- The difficulty of laying linen thread on the thread. Something that is so easy for experienced plumbers to do can cause a lot of difficulties for the layman. It is unlikely that it will be possible to correctly wind flax on the joint the first time, and any error in performing this operation will lead to the fact that the seal will not last long.

- Flax does not tolerate changing working conditions very well. Therefore, in heating systems, its strands will collapse much faster. Also, this type of seal reacts poorly to aggressive environments.

- The high hygroscopicity of the material leads to its swelling, due to which insufficiently strong joints can simply burst. For example, it is not recommended to use flax when sealing aluminum radiators.

A little about the connections of gas risers

Most often, gas is transported by steel pipes. Indoors, plastic gas hoses are also used. Almost always, a gas pipeline consists of several risers, and therefore the problem of their connections arises.

Gas can seep out on fittings, threaded connections. Therefore, perfect sealing of gas pipe joints is the number one task when installing or repairing a gas pipeline.

For such work, special sealants, seals, etc. are used. Let's pay attention to the most demanded of them, which by their quality have won the trust of citizens.