There are several types of plastic pipes for use in the installation of gas communications:

- Polyvinyl chloride (PVC) remains in high demand;

- Polyethylene pipes are somewhat inferior due to the fact that they are able to function only in an isolated form and under certain temperature conditions;

- Much more functional gas metal-polymer pipes;

- polypropylene is also popular. Chemical composition and resistance to aggressive external environment, does not require isolation. Low thermal conductivity prevents the formation of condensation, and therefore does not damage the transported substance.

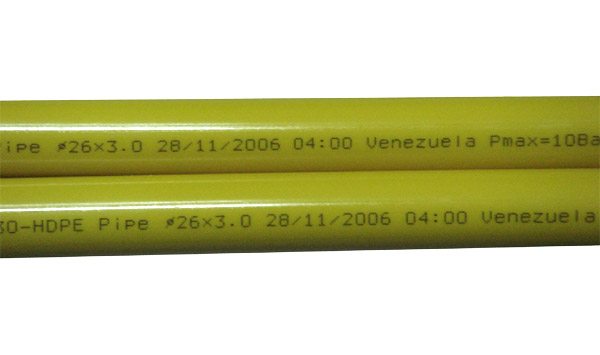

A distinctive feature of gas pipes is a yellow stripe applied to the surface, which does not allow it to be confused with the rest.

For a long time, it is plastic pipes that have occupied the leading place among components for various systems. Gas communication is no exception, which is fully capable of appreciating all the advantages of these pipes:

- longer service life than metal;

- current conductivity and non-contact with the ground;

- light weight, which is very convenient for transportation and installation;

- reasonable price, as a result, favorable cost of communication;

- ease of installation.

Particular attention should be paid to the low pressure of polyethylene gas pipelines, which allows transportation to the most distant points. Underground gas pipelines for combustible gases are also made from these pipes.

The sequence of replacing pipes in the apartment

It is strictly forbidden to work with gas communications on your own, because they belong to the category of increased danger. Seeking help from specialists of the gas service will significantly save not only time, but also become a guarantee of your security.

An experienced gas operator will first of all perform a preliminary inspection of the gas system and determine the degree of wear.

The replacement of gas pipes in the apartment is carried out in strict observance of safety rules.

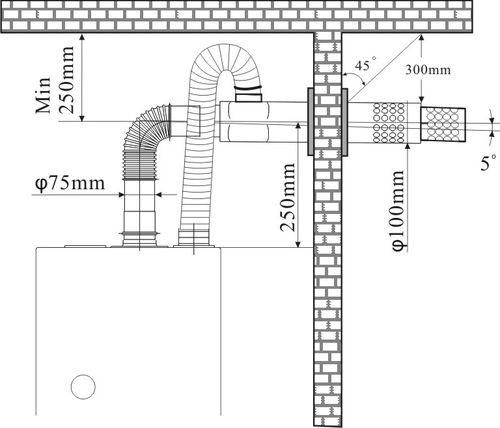

First of all, it is necessary to ensure the presence of additional ventilation in the room, shut off the gas supply and be sure to blow through the pipes. The utmost attention is paid to the presence of an open fire nearby, which is unacceptable and requires intervention.

After completing all the preparatory measures, you can start disassembling the required section of the gas pipeline. No special tools are required for this, it is enough to have an ordinary hacksaw for metal or a grinder in the house.

The gas pipe is tapped using special fittings or overhead heating elements. Installation must be done in such a way that the structure is completely sealed and does not allow gas to enter the room.

There is currently a fairly small selection of pipes available to the buyer on the market. On the one hand, these are steel pipes, which are very strong, but they are afraid of aggressive environments, and on the other hand, plastic pipes that are not afraid of corrosion, but they are much more fragile. But there are also metal-plastic pipes in which the advantages of both materials are combined. In this article we will talk about metal-plastic pipes for gas, their advantages and rules of use.

Output

Many homeowners cannot imagine how they would live without gas. However, his supply is not always able to satisfy all the needs of homeowners.Often there is a desire to change it, for example, when the gas pipe behind the refrigerator does not provide its normal service.

All this can be done, but only on one condition - all work must be carried out by an organization that has the necessary licenses. The video in this article will help you find additional information on this topic.

Did you like the article? Subscribe to our channel Yandex.Zen

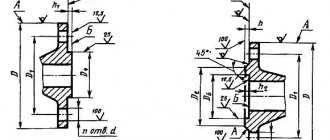

Metal-plastic pipe device

A metal-plastic pipe has an aluminum layer between two layers of polyethylene. Such pipes are joined with a laser or ultrasound, making overlap seams. Thanks to the smooth inner surface, rust and other deposits do not accumulate in the pipes. The quality, strength, flexibility and durability depend on the adhesive with which the pipe layers are glued.

Reinforced plastic is a fairly versatile material, so such pipes can be laid both inside and outside buildings. After the appearance of this material, it became possible to install "warm floor" systems.

Construction of metal-plastic pipes

The following structure of metal-plastic pipes should be distinguished:

- A layer of polyethylene.

- Adhesive composition.

- Aluminum layer.

- Adhesive composition.

- Polyethylene layer

Specifications

The working parameters of reinforced-plastic pipes are as follows:

- working pressure - 1 MPa;

- burst pressure - 4-6 MPa;

- hydrostatic constant pressure - 2.1-2.7 MPa;

- the minimum allowable bending radius is 80-160 mm.

disadvantages

Like any other material, metal-plastic has its own negative sides. Aluminum and plastic have different indicators of thermal conductivity - aluminum is higher. This can lead to the fact that when supplied through the pipeline in short periods of time, for example, first cold and then hot water, a leak can form at the junction of the pipes.

These nuances must be taken into account when laying such pipes. The pipeline should be laid with a margin, and expansion loops should be provided at the bend.

To obtain the correct bend, it is better to use a pipe bender, well, or manually. The bending radius and angle can be adjusted with the tube bender. To bend by hand, the pipe is first filled with sand and a spring is inserted inside. In any case, the spacing of the bends should not be less than 50 mm, in addition, the pipes must not be twisted.

Benefits

Such piping systems are more flexible than plastic or steel. No bends, corners or elbows are needed to get a bend, just bend it. The complete system is simply connected to the central line, without the need for welding.

Due to their versatility, metal-plastic pipes are excellent for use in communication systems, for heating and supplying both cold and hot water, for sewerage and gas supply, and even for laying electrical wiring.

Justification of using metal-plastic for gas supply

It is worthwhile to understand in more detail the question of whether it is possible to use metal-plastic pipes for gas.

Currently, steel and copper pipes are still in high demand in the gas industry. It was only a matter of time before alternatives emerged, as material was required that could be assembled with less effort while still achieving the highest safety and durability.

It is no secret that steel gas pipes are very difficult to install, while they are easily oxidized in corrosive environments, and, moreover, they require high maintenance costs.

Reinforced-plastic gas pipes can provide:

- Long service life - over 50 years, 2nd generation pipes can last over 100 years.

- Ease of installation work and low weight compared to pipes made of other materials.

- Due to the smooth inner surface, a large capacity of plastic pipes for gas in the house is ensured.

- Profitability. For the arrangement of pipelines, a minimum of fittings are required, since the pipes do not deform when bent.

- Versatility.

- A wide range of pipe and fittings cross-sections are available for sale - many varieties of gas equipment can be connected.

- The possibility of laying a hidden pipeline, which makes it possible to connect gas equipment at any point in the room.

Types of pipes

Therefore, today there are several types of pipes, almost equally used in the creation of water supply and fire extinguishing systems for buildings:

- Steel tubesproduced by technological methods of hot forming or electric industrial welding. To give them corrosion resistance in contact with water, they are treated in various ways with a protective layer of zinc, which rather effectively protects against the formation of rust and the growth of silt deposits.

- Galvanized gas pipes are traditionally chosen in the design of stationary fire extinguishing systems with sprinkler, deluge sprinklers, for the distribution of gas fire extinguishing installations.

- Stainless steel pipes are too expensive, so they are usually not used to create AUPT.

- PVC, polyethylene pipes. PVC products, due to some of their shortcomings, primarily the rigidity of products, have become widespread only for waste water drainage systems, sewage of low-voltage communication networks, signaling, and polyethylene pipes, despite a number of advantages, are quite expensive for mass, serial use.

- Polypropylene pipes... Products made of polypropylene - an organic polymer rather quickly squeeze competitors from PVC, polyethylene, for example Aquatherm red pipe, on the market of pipeline products. They are used for laying many types of piping systems in buildings.

More details about this type of pipes and a complete description of the system with the link: https://agpipe.ru/aquatherm-polipropilenovye-truby/aquatherm-firestop

Immunity to corrosion, aggressive chemical environment, which is not uncommon at production facilities of various industries, low weight, reasonable price per running meter of products and connecting components, as well as resistance to shock loads, hydraulic shocks - these are the main advantages of polypropylene pipes.

Due to the high technical parameters, such commercial products began to be considered as a worthy inexpensive replacement for steel pipes, not only in the development of traditional water-based fire extinguishing systems, but also in the installation of water mist fire extinguishing systems.

- Reinforced-plastic pipes are made from both polypropylene and PVC, polyethylene. Unlike conventional one-piece pipes, they are made in multi-layer, and one of the shells is a fine mesh of aluminum, copper wire or a layer of foil made of these metals. Such reinforcement of the pipe makes it more durable, resistant to external influences, internal pressure of the transported medium; while increasing flexibility, which is important during installation, further operation of any pipeline systems.

- Fiberglass pipes - this is an analogue of metal-plastic linear products. In them, shells, fiberglass threads, fire-retardant basalt material, and other fire-resistant fiber fibers act as a reinforcing layer, an internal structure.

Such a composition made of plastic, incl. polypropylene, makes products made of it fire-resistant, which allows them to be used in the development, installation of several types of automatic fire extinguishing installations, without conflicting with the rather stringent fire safety requirements for technical elements in their composition.

Additional material: Polypropylene pipes for fire extinguishing systems

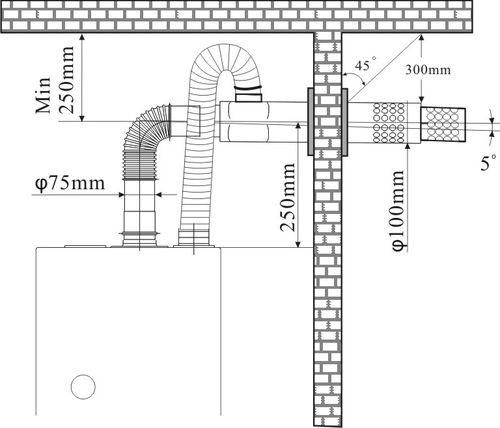

The process of laying metal-plastic pipes for gas

Now we know what pipes can be used to carry gas, water, and that the installation process is quite simple.It is worth noting that you do not need to look for complex equipment for this. These factors make the material quite popular among buyers.

Reinforced-plastic pipes are not subject to oxidation, exposure to chemicals, they do not clog and serve for a very long time without failures. In addition, such products are capable of operating at high temperatures, which makes them the main competitors for PP pipes. Even metal-plastic pipelines perfectly dampen noise, and this greatly increases living comfort.

When laying pipes, it is worth considering their location relative to heating devices, since they should not overheat.

Special scissors are used for cutting pipes. For flaring (making the end part of the pipes rounded), a calibrator is required, after which the fittings can be installed. The communications are fixed to the walls with fastening clips; when pipes of large sections pass through the wall, it will be necessary to install pass-through sleeves.

In this article, we learned why metal-plastic products are better than metal pipes for gas, water supply, or any other system, and how to properly install them.

If you intend to keep up with the times in everything, then it's time to think about modern plumbing.

If it seems to you that your old cast-iron pipes, firstly, “do not interfere” with you, and secondly, are still quite modern, then you are a little mistaken.

In European countries, they moved away from metal pipes for a long time. In our country, the transition to new technologies has not yet been carried out everywhere, but all this is available at an inexpensive price.

Why don't you learn more about the modern approach to gas pipelines? What are plastic pipes, and what are they good for?

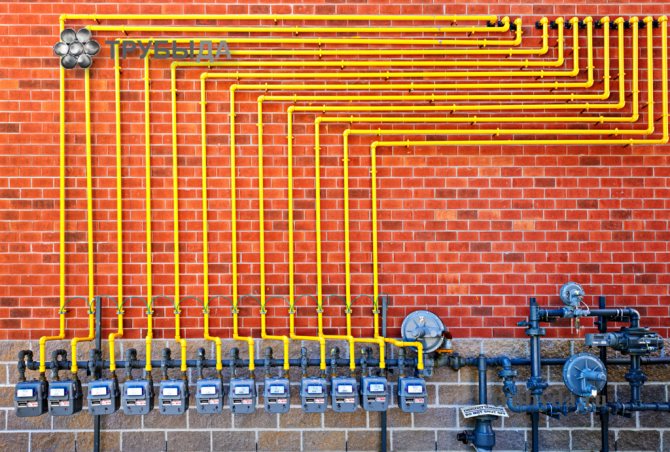

Gas pipes have a yellow stripe

Characteristics

The technical characteristics of the material determine the scope of its application. In the manufacture of a gas pipeline, you can use different types of plastic pipes. Each of them has its own technical characteristics.

Parameters of metal-plastic:

- High chemical resistance.

- The material is not subject to oxidation.

- The maximum temperature of the coolant is up to 95 degrees.

- The maximum allowable pressure is up to 25 bar. If the temperature is high, the allowable pressure is reduced to 10 bar.

- The thickness of the metal layer between the plastic is up to 0.3 mm.

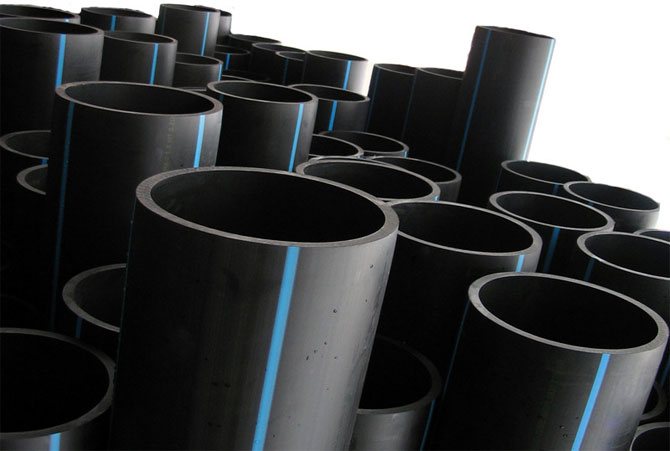

Polyethylene characteristics:

- the outer diameter of the tubes is 10–110 mm;

- the maximum temperature of the coolant is up to 95 degrees;

- at high temperatures, the maximum pressure is up to 10 bar.

Polypropylene parameters:

- the maximum temperature of the coolant is 90 degrees;

- allowable pressure at maximum temperature - up to 10 bar.

Polypropylene pipes can withstand short-term overheating up to 110 degrees.

Diameter of plastic pipes

What are the plastic pipes

- Polyvinyl chloride, or PVC, pipes are the best known. Their distribution on the market is largely due to their affordable price, because they are relatively cheap. However, in the process of use, as a result of chemical decomposition, these products release toxic chloroethylene. For this reason, they are not suitable for use in water supply systems. For sewer devices, these pipes are suitable as a cheap analogue of cast iron. Lightweight and cheap, they will replace their predecessors seamlessly.

- Polyethylene pipes are a more profitable option, especially for those who want to arrange a cold water supply system. The insulated material of these pipes is stable. The temperature of liquids or gases that these products can carry reaches -25 degrees. This is much less than other plastic counterparts. Unfortunately, uninsulated polyethylene pipes lose their strength and, therefore, their effectiveness. Summing up, it should be said that this kind of pipes suitable only when insulated and only for cold transmission conditions.

- Metal-polymer pipes are analogous to the previous ones, however, the polyethylene layer is in solid insulation. The benefit of the purchase lies precisely in the versatility of this type.

- Polypropylene pipes are one of the most advanced options on the plastic pipe market today. The fact is that polypropylene is chemically inactive. Therefore, he does not need isolation. That is, it is highly resistant to external influences, which means it is permissible for use in various conditions.

The low thermal conductivity of polypropylene prevents condensation from forming, which means that the transportation of gases or liquids through such pipes does not damage the transferred substance itself. It is also possible to make pipes of any length and diameter, so they are suitable for operations of all sizes.

Benefits of using in laying a gas pipeline

Connect to device

Plastic pipes have got their place in the construction of gas pipelines, having a lot of advantages:

- Plastic pipes are ready to last much longer than metal pipes.

- They do not interact with the soil and do not conduct current, which allows their cathodic insecurity.

- In terms of their weight, gas pipes, consisting of polyethylene, are several times lighter than metal ones, so the construction of gas pipelines proceeds faster.

- Prices for such pipes are lower, so the construction of gas pipes made of polyethylene is much more profitable.

- The replacement of plastic gas pipes is carried out faster, due to the availability and ease of installation of new ones. And this is another plus, since in case of failure of cast-iron pipes, tens and hundreds of people can remain without gas for weeks.

Gas polyethylene pipes have low pressure (hereinafter referred to as HDPE). They are able to transport water and gas over any distance. HDPE pipes transport natural gas from the mains to your apartment. They are also used for the construction of underground gas pipelines, through which flammable gases flow. This is, on the one hand, the transportation of fuel, and on the other hand, raw materials.

It can be used in both the household and industrial sectors. Nowadays, low-pressure polyethylene pipes occupy about 90 percent of all gas pipeline systems. It should be noted that when gas is supplied through the pipe, the sound is isolated. Plastic pipes for a gas pipeline have an aesthetic appearance.

Installation features

The installation of plastic pipes has its own secrets. Flexibility and high suitability for concealed installation make work easier. However, when installing, it is worth considering their low strength, thermal expansion and sensitivity to ultraviolet radiation.

The range of plastic pipes is wide

The fewer connections your system has, the stronger and cheaper your system will be. Polyethylene gas pipes must be installed in special conditions, in which there are no external influences. To increase the maintenance-free period, a network of gas pipes of the same material should be planned. Otherwise, various cracks and gaps will form at the joints.

In order not to damage the material, the elements should be connected by welding. Pipes that are not resistant to sunlight should be installed in dark places for durability. However, it is possible to determine how long the gas pipes will last at the installation stage, since if any material is made from low-quality raw materials or is already damaged, then problems will begin to arise when assembling the system.

Which pipes are suitable for conducting and supplying gas

The choice for gas pipelines today is not great - either use steel pipes, or plastic or metal-plastic.

Each of these types of pipes has its own advantages and disadvantages.So, metal pipes are subject to corrosion, and plastic pipes are quite fragile. Therefore, the choice is often stopped on - metal-plastic, which has the strength of metal structures, but at the same time is elastic and easy to transport and install.

Which pipes to choose depends on the operating pressure in the gas pipeline. The higher the pressure, the greater the demands placed on the material from which the pipes are made.

Comparison of metal and polyethylene pipes

| Metal pipes | Polyethylene pipes | |

| Weight | The weight of 1 running meter of pipe used in a Category 3 gas pipeline ranges from 1.4 to 4.1 kg, depending on the diameter. | The weight is 3-4 times less than that of a metal product. |

| Transportation | Metal pipes are transported by stacking products on a platform. Due to the large dimensions and weight, special transport is required for the transportation of pipes. | Flexible pipes are produced in coils of several tens of meters, which, due to their low weight, makes it possible to transport a significant footage. |

| Installation | In the installation of metal pipes, a gas welding machine is used, changing the direction of the pipe is possible strictly by 90 °. The large weight of the structure requires the installation of additional supports. | Thanks to the great flexibility of PE pipes, even the most complex projects can be carried out. However, supports or wall fixings are still needed to prevent sagging of the pipes. |

| Resistance to mechanical stress | Resistant. | PE pipes are quite soft, and therefore it is much easier to mechanically damage them than metal pipes. |

| Exposure to temperature | Thermal insulating indicators are minimal, at low temperatures it accelerates the cooling of the transported substances, complete freezing of the pipe is possible. | It has quite good heat-shielding properties, but at temperatures below -25 ° C they lose their strength properties. |

| Chemical interaction level | The metal is quite chemically active, easily reacts with some substances. | Possesses low reactive characteristics. |

| UV resistance | Quite resistant to sunlight. | Low resistance to UV rays, it is better to lay the gas pipeline underground. |

| Corrosion susceptibility | Metal is highly susceptible to corrosion, therefore, without regular cleaning and repair measures, such pipes will quickly lose their properties and begin to leak. | Polyethylene is practically non-corrosive. |

| The possibility of sediment settling | Metal pipes often have irregularities on the surface, on which sediment quickly adheres, forming blockages. | Polyethylene has a smooth structure, there is nothing to catch the sediment. |

| Ultimate pipe pressure | Metal pipes are used in laying gas pipelines of any category, including high pressure pipelines. | PE pipes are mainly used in gas pipelines of category 3 (residential buildings, catering establishments, etc.), with pressures up to 0.005 MPa. |

| Lifetime | 50-70 years old. | 50-100 years old. |

| Price | Quite a high price. | The cost is several times lower than that of metal pipes. |

We recommend that you familiarize yourself with: Sewer pipes, their types and installation rules

However, they are inferior to steel pipes in strength and resistance to ultraviolet radiation, therefore, these features should be taken into account when choosing, especially since there are several types of plastic pipes with different characteristics.

Thus, polyethylene pipes have a number of advantages over metal pipes: they are more durable, have less weight, do not corrode, have better thermal conductivity, and are easier to install.

When choosing pipes for supplying and transporting natural gas, one should take into account not only the financial side, but also how much gas is needed, as well as what type of soil on the site and its condition.

Comparison of plastic and metal-plastic pipes

| Plastic pipes | Reinforced-plastic pipes | |

| Structure | Thick-walled polyethylene gas pipes are used for gas systems in lines of 3, and sometimes even 2 categories. | It is made of aluminum, covered with an outer and inner polyethylene layer, which are connected with a special glue. |

| Where to use | Polyethylene pipes can only be used in underground utilities. Polypropylene - suitable for the installation of internal gas distribution in apartments: they are not afraid of the sun and are easy to install. | It can be used for both internal and external systems, but it is recommended to use a stealth method. |

| Benefits | Polyethylene does not react with gas, and is not afraid of exposure to chemicals from the outside, does not corrode. | These pipes do not form deposits and rust, the possibility of leakage is zero, and the strength of the structure is comparable to that of steel. Metal-plastic pipes can be made of very small diameters. They are universal - they have great flexibility, do not require connecting elements during installation. |

| disadvantages | Not every plastic can be used in gas systems (PVC pipes cannot be used, because reaction and release of toxic substances are possible. It is inferior in strength. Cannot be used at low t, afraid of UV rays. | Thermal conductivity is high enough, therefore it reacts poorly to differences in t. You cannot make a bend at an acute angle, this will lead to leaks. |

We recommend that you familiarize yourself with: Linear expansion when installing pipelines from polypropylene pipes

Types of plastic pipes

When carrying out communications, 4 types of plastic pipes are used: polyvinyl chloride (PVC), metal-polymer, polyethylene and polypropylene. All types are used for gas supply, except for PVC pipes.

- PVC pipes are very common due to their low cost and ease of installation. However, during use, this material emits toxic chloroethylene, so it cannot be used for water supply. For this reason, PVC pipes are mainly used for sewage.

- Polyethylene pipes are suitable for cold water supply and gas supply. They do not emit toxic substances, however, they require additional insulation to maintain their technical characteristics. Nevertheless, for a gas pipeline, PE pipes are an ideal option.

- Metal-polymer pipes are the same polyethylene pipes, only reinforced with steel mesh, aluminum foil and have greater strength. Due to this, the range of use of such pipes expands, but the cost also increases.

- Polypropylene pipes are the most technologically advanced today. They are chemically weakly active, resistant to external influences: corrosion, temperature extremes, sunlight.

In terms of price-quality ratio for gas pipelines of category 3 (for supplying and transporting gas to a residential building), the most optimal is the use of polyethylene pipes. They are not only chemically resistant to natural gas, they are not subject to corrosion and sludge deposits, but they are also very plastic, therefore they are suitable for installation of any complexity.

Brands of polyethylene pipes

There are 2 brands of polyethylene pipes for a gas pipeline: PE-80 and PE-100. Depending on the class (brand), pipes are able to withstand higher pressure, therefore PE-100 can be used in medium pressure distribution lines up to 0.3 MPa. Usually polyethylene pipes are made in black or dark gray, and markings are used for external distinction:

- yellow stripe for PE-80,

- orange - for PE-100,

- also sometimes the PE-80 pipe is completely made in yellow, and the PE-100 - in orange.

Good to know. The diameter of the pipe has nothing to do with the brand, therefore, both PE-80 and PE-100 can be produced in diameters from 20 to 400 millimeters or more.

Polyethylene pipes have an SDR, which is the ratio between the pipe diameter and its wall thickness. The lower the SDR, the thicker the pipe wall and the more pressure it can withstand. Standard SDR values for domestic gas pipelines range from 11 to 18.

Welding: little tricks

Special equipment was invented for. There are three welding methods: electrofusion, butt and socket welding.

- Electrofusion welding uses the method of melting the plastic as a result of the thermal action of the current and the connection with the fitting. Such welding is used on sections of gas pipelines. Socket welding is often used for joints of polyethylene and polypropylene gas pipes.

- Socket welding is used for connections in sewer systems. It is also suitable for repairing pipes with a diameter of 15 to 90 mm in bathrooms.

- Butt welding is used for almost any plastic gas pipe with a diameter range of 5 to 16 cm. Gas pipes eliminate the need for laborious cutting work and in most cases eliminate the need for welding.

When choosing the nature of the installation and the technology by which the system will be installed, it is necessary to study the characteristics of the polymer and the joining conditions favorable for it. For example, polyethylene pipes, regardless of the place of assembly, are connected to each other by attaching fittings. This method is the most durable only for this type of pipe.

You will need different fittings

For polypropylene pipes, an unusual welding method is used, in which the air heats up to about 270 degrees. With this method, the usual solder is absent. PVC pipes are adhered to glue, because all other types of installation are unsuitable for this type of polymer. Do not be bad about such fasteners, since modern glue is able to ensure the operation of pipes for several decades.

Gas pipe classification

Different pipes are used for systems of different classes. State norms for them are as follows:

- for gas pipelines with low or medium pressure, electric-welded longitudinal seam pipes are used for general purposes;

- for systems with high permissible longitudinal electric-welded and seamless hot-rolled.

The choice of material is also influenced by the installation method.

- For underground utilities, both steel and polyethylene products are the norm.

- For overhead, only steel is allowed.

- The house, both private and multi-storey, uses steel and copper pipes. The connection is supposed to be welded. Flanged or threaded is allowed only in the areas of installation of valves and devices. Copper piping allows connection to press fittings.

The photo shows an example.

Dimensional parameters

GOST allows two types of gas pipes in an apartment. The products belong to general-purpose products, since complete gas tightness and mechanical strength are important here, while pressure resistance is insignificant: 0.05 kgf / cm2 is a modest value.

- The parameters of the steel pipeline are as follows.

- The outer diameter of the steel pipe can range from 21.3mm to 42.3mm.

- The nominal bore ranges from 15 to 32 mm.

- The choice is made depending on the scope of delivery: a gas appliance in an apartment or a riser in a house.

- The diameter of the copper pipe is selected in the same way. The advantage of this option is a simpler installation - with press fittings, anti-corrosion material and an attractive appearance. According to the norm, copper products must comply with GOST R 50838-95, other materials are not allowed.

- The diameter of gas pipes for pipelines with a pressure of 3 to 6 kgf / cm2 varies in a much wider range - from 30 to 426 mm.In this case, the wall thickness depends on the diameter: from 3 mm for a small size, up to 12 mm for a diameter over 300 mm.

- When constructing an underground gas pipeline, GOST allows the use of low-pressure polyethylene gas pipes. The material is designed for pressure up to 6 kgf / cm2. The diameter of the plastic pipe ranges from 20 to 225 mm. The photo shows a gas pipeline from HDPE.

The pipeline is laid into the trench only in ready-made sections, so the installation of the pipeline is an expensive and time-consuming job. When cornering, the steel gas ducts are cut and connected through special elements. Polyethylene allow bends: for systems with pressures from 3 to 6 kgf / cm2 up to 25 outer diameters, with a value of up to 0.05 kgf / cm2 - up to 3. Combined with greater ease and high corrosion resistance, this makes the option with a plastic pipeline more and more attractive ...

How to choose the right way

If you decide to start installing plastic pipes, then it is better not to resort to the welding method, since it is demanding on the conditions. This means that it can be of poor quality at home. In this case, it is better to choose metal-plastic pipes.

Pipes such as polyethylene or HDPE for home installation are not suitable, since they have high conditions, which are practically impracticable at home.

Metal-reinforced plastic can be formed into any shape, which makes the work easier for the installer. These pipes bend easily and are secured with crimp or compression fittings. The latter are more expensive, but their reliability is highly appreciated by experts.

The total cost of installation is made up not only of the cost of the material of the pipes used, but also of the quantity and quality of fasteners, the number of connections. It so happens that pipes are more expensive in one store, but fittings and other connecting things are cheaper, in other stores the opposite is true. Also, do not forget about shaped products, which will also have to be spent on.

It is worth remembering that nowadays plastic pipes are supplied to the market in huge quantities, so there is always plenty to choose from.

Where and how are polymers mounted

Although the market for polymer products is quite wide, not every plastic is suitable for use in the gas industry. In addition, plastic is significantly inferior in strength to metal, in this regard, special requirements are imposed on the installation of such structures (see also the article "Steel water and gas pipes - their characteristics and features").

What polymers are allowed

- Polyethylene gas pipes are currently the leader among polymers in the gas supply market, the price for them is affordable. Thick-walled polyethylene pipes for gas can be used in 3, and in some cases even 2 categories.

Polyethylene wiring around the house is also quite acceptable. This material does not react with the transported mixture and is not afraid of the external influence of chemically active substances.

Polyethylene for trunk lines.

- But polyethylene pipes for gas have several significant limitations. In particular, these structures are not recommended for use if there is a possibility of temperature drop below -25 ° C. In addition, this material is afraid of exposure to ultraviolet rays, so such pipes cannot be mounted in the sun.

Important: all HDPE gas pipes and other polymers, in comparison with metal, are characterized by low weight and low mechanical stability. In this connection, the laying of these lines outside buildings is allowed exclusively by underground means.

- Metal-plastic is also approved for installation on gas lines. Due to its multilayer structure, it is more durable and durable than polyethylene, but its mechanical strength also leaves much to be desired. Therefore, it should also be laid in a hidden way.

Polypropylene gas pipes.

Important: PVC polyvinyl chloride products are not recommended for use in the gas industry, since this material is capable of reacting with some mixtures and emitting toxic chloroethylene.

- Polypropylene gas pipes for laying internal wiring in the house are almost ideal. The price of this material is higher, but the technical characteristics are incomparably higher than those of competitors.

Their strength is quite enough for laying in an open way around the apartment, they have the highest resistance to any chemically active substances. Polypropylene pipes for gas are not afraid of sunlight and are easily joined.

Installation tips

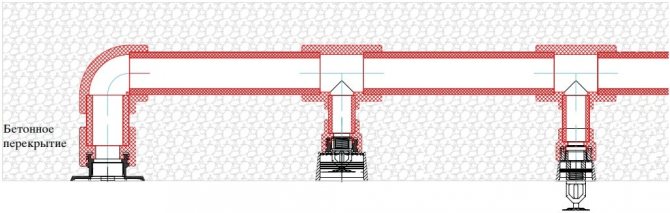

As mentioned earlier, HDPE pipes for gas (HDPE - low pressure polyethylene) are afraid of the sun, are lightweight, highly elastic and have limited temperature conditions. This leads to hidden underground or inside walls installation of structures.

Joining of soft lines.

Moreover, such lines are laid underground, only with insulation, they cannot be placed in concrete boxes or equipped adits, since in the event of a leak, there is a high probability of an explosion. In the case of laying in walls, the coefficient of thermal expansion to which this material is subject should be taken into account. The lines are equipped with soft thermal insulation.

When installing, take into account the fact that the fewer various connecting nodes or transitions in the structure, the more stable the pressure will be, therefore, energy costs for transportation are significantly reduced. HDPE systems can be connected by crimp fittings or butt welded.

Compression fittings are only suitable for transporting liquids, polyethylene gas pipes can only be connected by butt welding, they are marked in yellow.

Connection of polypropylene products.

Polypropylene pipes for gas supply are joined in the traditional way, using a special soldering iron. In accordance with the diameter of the products, nozzles of the appropriate size are selected and installed on the soldering iron.

After that, the pipe and fitting are put on these nozzles from both sides. Within a few seconds, heating occurs, then the parts are connected all the way. Do not forget that after docking, the connection must be kept in a stationary static position for 5 - 7 seconds.

The system can be put into operation in 20 minutes. If the wiring is done in an open way along the wall, then it must be fixed at intervals of at least 50 cm.

Pressure testing of a metal-plastic pipe.

Reinforced-plastic lines are installed only in a closed way. This is very convenient if, for example, you are doing a renovation. Durable, elastic material has a low coefficient of thermal expansion, so it can be safely bricked into walls.

These pipes are also convenient for equipping lines between adjacent buildings in private construction. It is possible to throw a branch from the house into the summer kitchen with the help of a metal-plastic pipe.

As for the connection of metal-plastic lines, the instructions only allow installation with press fittings. At the same time, the pipe is inserted all the way into the crimp sleeve and crimped using a special tool. All such connecting systems are not designed for dismantling, they are permanently mounted.

Soft hoses for gas facilities.

Important: all work on the installation of gas lines must be carried out exclusively by specialists with a special permit. Plus, the route scheme must be registered in advance and approved by the relevant authorities. With your own hands, you can only connect a flexible gas hose from a pipe to a gas stove.

The video in this article shows some points related to plastic pipes.

Are there any disadvantages to plastic pipes?

Now let's talk about the disadvantages of plastic pipes.Unfortunately, plastic pipes are unstable when used in chlorinated water. In those places where water with a high concentration of chlorine is used, they are subjected to various tests for resistance to exposure.

Also, with some heat or light effects, plastic pipes begin to emit more toxic substances. So, for example, PVC as a result of heating emit hydrochloric acid, which, instantly evaporating, causes various severe burns. Also, due to favorable conditions, bacteria form on the inner walls, which can penetrate through pipes into kitchens and other human habitats.

Be careful when buying cheap gas pipes because not all of them can keep your home safe. You should immediately set the maximum value of the temperatures that your pipeline can definitely withstand without various changes in its composition.

The disadvantages of modern plastic pipes limit their scope of application, however, in the gas sector, there are fewer problems with such pipes. This is due to the chemically inactive gases flowing through the pipes and the certain properties of gas pipes, which make it possible to build gas pipelines that are ready to serve for decades.

Gas pipes will serve you for a long time if they are in your house in conditions isolated from light and heat.

When arranging a gas pipeline in apartments and private houses, copper or steel pipes are traditionally used. Until recently, there was no alternative to this product in Ukraine. But now they are increasingly using metal-plastic pipes. In this article, you will learn the main characteristics of this product, its disadvantages and advantages, installation features, and you can also see its photo.

Benefits of using plastic piping

Another advantage of using plastic products for fire extinguishing systems is the service life of the products:

- The manufacturer's declared period for plastic products is 50 years, although, for obvious reasons, there is still no full-fledged operating experience.

- For galvanized water and gas pipes, the design service life is 30 years, but given that water does not circulate in water AUPT, the process of corrosion and formation of deposits goes quickly, shortening this period.

An example of laying polypropylene pipes in a concrete floor

The choice of pipes for fire extinguishing systems is based on many factors:

- Traditional use, habits of specialists of design organizations, their reluctance to contact new materials, to coordinate their use in most cases leads to the use of steel water and gas pipes.

- On the contrary, plastic pipes are much more attractive to customers, which will last at least twice as long, will not rust, requiring regular cleaning and painting.

The advantages and disadvantages of both steel and plastic pipes are not limited to this:

- The strength that products from all these materials fully possess.

- Polypropylene has high resistance to corrosion, aggressive chemical environments, high moisture content in the indoor air of protected objects, and low - in metal.

- Easier installation of polypropylene pipes at facilities due to their small, compared to metal, weight, flexibility of linear products.

- Excellent permeability, non-susceptibility of polypropylene pipes to overgrowing of the passage with rust, scale, silt deposits due to a smoother, not prone to ulceration, cavities during operation, inner surface. Lower head loss in polypropylene pipes due to these factors.

- Frost resistance of polypropylene products filled with water, in contrast to metal ones, unable to expand under the influence of the resulting ice.

- Insignificant noise level in fire extinguishing systems made of polypropylene pipes, when filling, draining water during testing, and operation of installations; compared to traditional AUPT, using metal products.

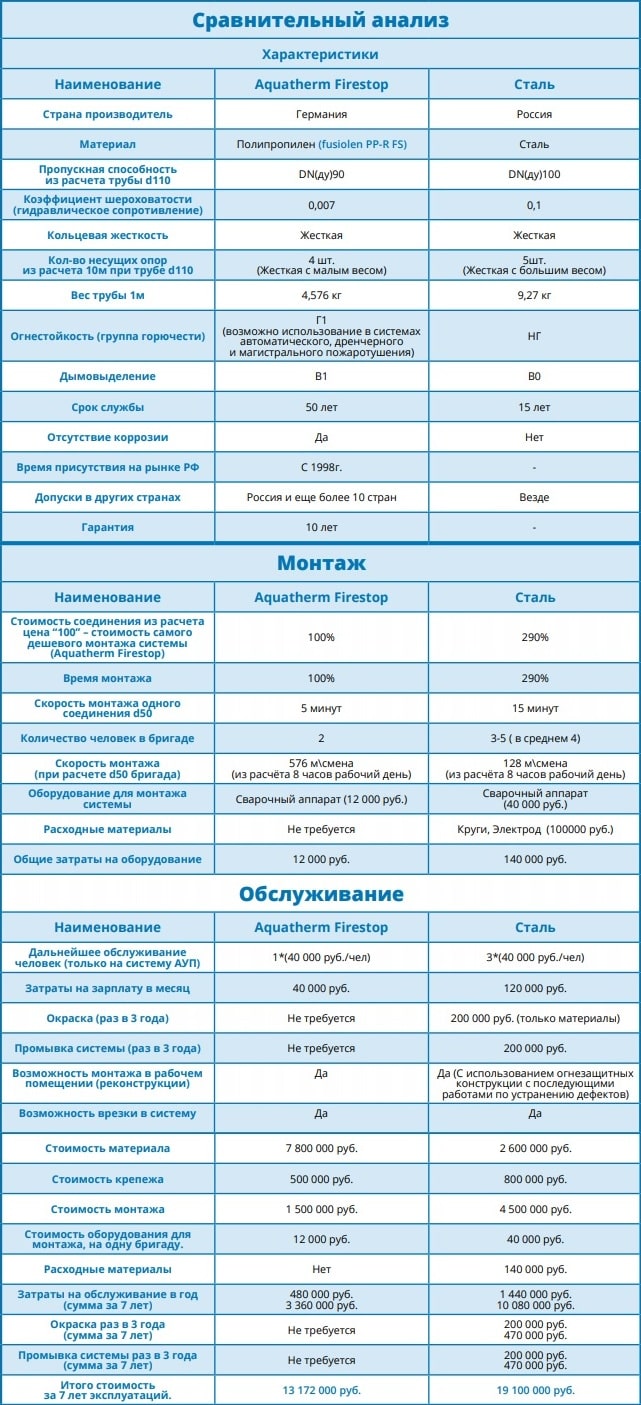

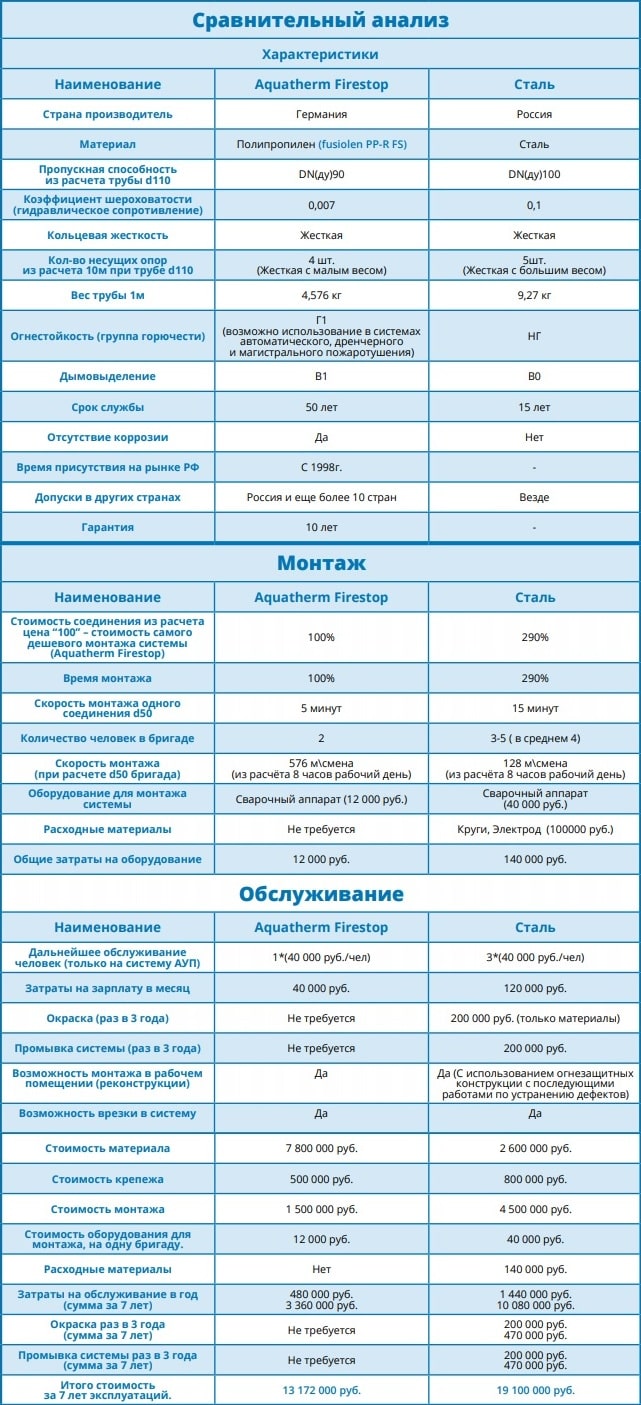

Comparison Chart for Piping Systems in Applications: Automatic Fire Suppression

Comparative analysis of aquatherm firestop plastic system pipes

* the table shows the prices at the time of writing, perhaps they have changed now, check with the manufacturer.

Key advantages over steel systems:

- Service life up to 100 years;

- The ability to mount at an existing facility, without stopping the work of people inside (does not require welding and fire hazardous equipment);

- 100% corrosion resistant;

- Light weight and load on the roof - cheaper fasteners and installation itself;

- Does not require painting after 3 years, like steel;

- Does not require rinsing.

Output: At first glance, a fire extinguishing system is cheaper to install from steel pipes, in contrast to the plastic aquatherm firestop red pipe system. But, if we look at the initial cost of the system and its maintenance for 15 years, then the picture becomes far from rosy and changes for the better to aquatherm firestop plastic pipes.

Please note that certification and testing of the fire extinguishing system by an authorized state organization - this is the key to its applicability.

Today, there are systems that have not passed such tests, so it is important to pay attention to the following documents:

- Technical conditions VNIIPO MES;

- Test report;

- A package of certificates for the system;

- Availability of an insurance policy with a guarantee for fire extinguishing systems and others.

Package of documents for pipes aquatherm firestop red pipe and a list of objects where the fire extinguishing system is already installed, available by the DOWNLOAD button for your reference.

Manufacturing technology

The production of metal-polymer pipe products is strictly regulated by the approved state standard. Subject to technological standards, metal-plastic products receive excellent performance characteristics. They are devoid of the disadvantages that products made of metal have.

The production of metal-polymer pipes takes place in several steps:

- The extruder is used to extrude the inner shell of the products.

- From the outer part of the resulting shell, an aluminum layer is glued, laser-welded with an overlap, or butt-welded.

- An outer shell is applied on top of the foil.

- The resulting sandwich construction is pressed.

The outer polymer layer helps protect the metal from water and air. Aluminum gives the product strength and rigidity. In this case, the inner layer serves as protection against the appearance of condensation and the destructive influence of the pipeline carrier.

Metal polymer V.S. metal

The use of the technology described above makes it possible to impart good physical and mechanical properties to the product. It is thanks to them that metal-plastic pipes are in many ways superior to their metal counterparts.

They are characterized by:

- high throughput;

- resistance to the appearance of internal deposits;

- the ability to maintain its shape after bending;

- easy installation;

- excellent heat resistance;

- resistance to corrosive processes and aggressive environments.

Product labeling

Products made of metal-plastic can be used for laying water supply, sewerage, heating and gas supply systems.

There is an international labeling system for the products in question. It allows the consumer to get the maximum of the necessary information about the product. It is not a problem to understand it. The first thing to pay attention to is the type of polymer used to make the pipe.

The following encoding options are available:

- PP-AL-PP - the product is made of polypropylene;

- PE-AL-PE - material of manufacture: ordinary polyethylene;

- PERT-AL-PERT - the pipe is made of heat-resistant polyethylene;

- PEX-AL-PEX - products are made of cross-linked polyethylene.

Please note that products made of cross-linked polyethylene have additional letters in their marking. They indicate the method of stitching the material. There are the following options: C - electronic, B - silane, A - pyroxide.

The indicator of the diameter of pipes and their thickness is indicated by different manufacturers in different units of measurement. In most cases, this data is written in inches or millimeters.

You also need to pay attention to the nominal pressure that can withstand a particular type of product. If this indicator in the system does not exceed the factory limit, the service life of metal-polymer products reaches fifty years.

Maximum pressure is a parameter that is relevant for pipes used to deliver media with a high temperature reading.

The technical documentation for the product also lists the environments for which it can be applied.

Product marking also contains the batch number and date of manufacture. When installing pipe structures, it is necessary to provide access to the information specified in the encoding. It can be useful in the future when carrying out repair work, if necessary.

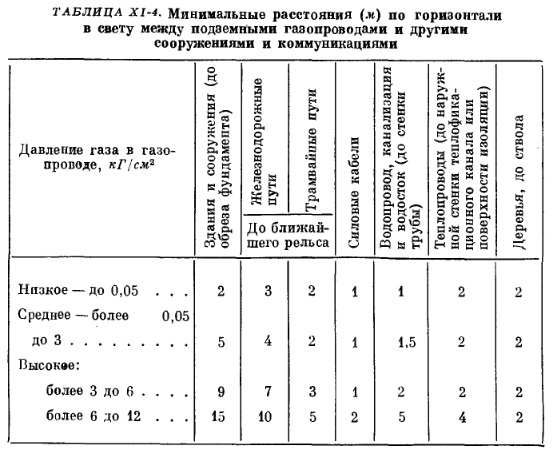

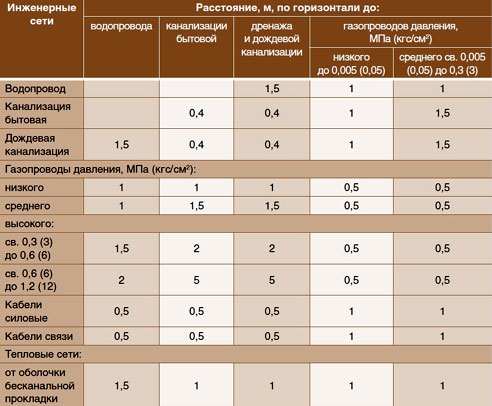

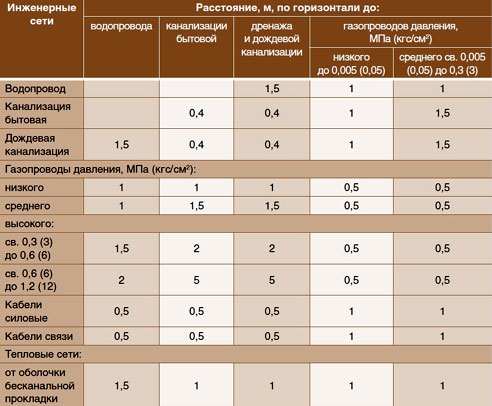

Determination of remoteness: conditions and factors

Since 2010, the norms specified in SNiP and SP have become as binding as those specified in other legislative documents. Like any permitted construction conditions, they are permanently checked by supervisory authorities. Their function is to ensure the safety measures required by the regulations.

Gate valve

Failure to comply with the specified minimum distances from the gas pipe may become a reason for consideration in court or the imposition of administrative penalties if a violation is found.

The use of bottled gas in the house provides for less stringent requirements - only fire safety standards.

Subtleties

Delivery for domestic or industrial needs depends on several factors, which are detailed in the current regulations. In the first case, a gas with a high calorie content is considered optimal. Pipeline transportation is preferred because this method is the safest.

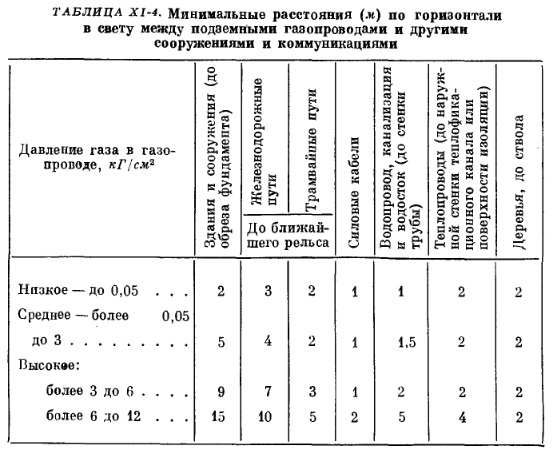

Distance from the gas pipe (underground gas pipeline) to structures and communications in accordance with SNiP standards

However, this method requires laying a network of gas pipes in areas with different reliefs and depends on the operating features existing in each case:

- Around the overhead communications, which, according to the requirements of the joint venture, can be made only of high-quality steel, a two-meter security zone is left. This type of gas transportation does not create any special problems and does not require additional costs. There is no need to dig special trenches either when laying a gas pipe or when repairing it. A two-sided security zone will certainly be left. Aboveground pipeline can run in any area - urban, rural or suburban. In this case, the distance from the intake to the high or low pressure gas pipeline is dictated only by compliance with the security zone, and no special requirements are provided.

- The construction of an underground communications network for transporting fuel is considered safer, but also more expensive. Digging trenches during laying and in case of necessary repairs is a significant inconvenience. However, in modern conditions, you can save on gas pipes made of polymer, which do not require periodic replacement and are not subject to corrosion. Underground installation requires consideration of the flow rate of the supplied gas. For example, low pressure or other stipulated by the norms.The safety of the location is also determined by the diameter of the pipe. Therefore, at what distance a residential building is located from underground utilities is determined by several parameters. From the fence to the main gas pipeline network on the street, there is a sufficient security zone determined by the gas distribution station. But this is only if the fence and the residential building being erected are distanced according to all standards from the passage or the roadway.

- Internal networks that supply economical and productive fuel to various types of buildings can be installed exclusively from high-quality steel or copper. Here, the determining factors are the purpose of the structure and the number of storeys of the house. In the city, it can be industrial, where high-pressure gas pipes are used, or public buildings. The supply of heating boilers or individual projects requires medium pressure. You need to know what distance should be observed from potential objects of ignition - fireplace, heating boiler, chimney.

Distances between communications according to SNiP and SanPiN

How are pipes connected?

When installing metal-polymer pipes, it is necessary to correctly join them together.

For this purpose, special connecting nodes are used, such as:

- Press fittings.

- Threaded fittings.

The latter option is characterized by ease of use. There is no need to use special tools for joining pipes through a threaded fitting with an O-ring. However, this connection method is not suitable for the arrangement of gas pipelines. At the joints of the pipes, the level of tightness decreases over time. Therefore, there is a high probability of gas leakage.

It is best to install the gas pipeline using the knots created by the press fittings. Such connections are distinguished by a high level of reliability. They are one-piece structures. To create them, you need to use a special press toolkit.

GOST metal-polymer products

High-quality pipe products made of metal-plastic must comply with the state. standard 53630-2009. The document contains the key requirements for the products in question.

- The order of packaging products.

- Requirements for raw materials required for the production of products.

- The products are divided into two groups according to the specified working pressure. In the first category, this figure is up to 0.6 MPa, and in the second - 2.5 MPa.

- The maximum temperature of the carrier in a pipeline made of metal-polymer pipes is allowed up to ninety-five degrees for nine thousand hours.

- Product labeling is established (discussed above).

- Depending on the diameter, structures are divided into two categories. The first includes pipes ranging in size from ten to sixty-three millimeters. The second category includes products with a diameter of seventy-five to one hundred and ten millimeters.

- Methods of delivery of products are indicated. Pipes of the first category are delivered in lengths up to twelve and a half meters or in coils. In the latter case, the footage must be a multiple of one hundred. Products of the second category are supplied only in the form of sections of different lengths.

If the structures comply with the specified GOST, they must have a certificate confirming this. Consider this if you decide to buy pipes for arranging a gas pipeline in a private house or apartment.